Article Contents

Industry Insight: Programmable Light Strip

The commercial and industrial lighting landscape is undergoing a transformative shift with the integration of intelligent, energy-efficient solutions—and programmable light strips are at the forefront of this evolution. Once confined to decorative or residential applications, these advanced LED systems are now being widely adopted in industrial facilities, retail environments, warehouses, and office spaces due to their flexibility, scalability, and precise control over illumination. With the ability to customize color temperature, brightness, and dynamic lighting sequences, programmable light strips enhance both operational efficiency and spatial ambiance, supporting everything from task lighting optimization to branding and wayfinding in large-scale installations.

Critical to their adoption in professional settings is compliance with rigorous safety and performance standards. Leading programmable light strip solutions now come ETL and CE certified, ensuring they meet North American and European electrical safety requirements, respectively. These certifications are essential for facility managers and electrical contractors who must adhere to code compliance while deploying innovative lighting technologies.

At the heart of this advancement is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established itself as a pioneer in high-performance, code-compliant LED solutions tailored for commercial and industrial applications. The company’s programmable light strips reflect its commitment to quality, durability, and regulatory adherence, offering scalable, smart-ready systems that meet the evolving demands of modern infrastructure. As buildings become smarter and sustainability targets tighten, Beauty STC continues to deliver lighting innovations that combine intelligence, efficiency, and reliability for the professional market.

Technical Specs & Certifications

Beauty STC’s programmable light strips represent our commitment to high-performance, reliable LED solutions engineered for professional applications. Every specification is validated through rigorous in-house testing and third-party certification to ensure real-world performance matches laboratory results. Our strips utilize premium Samsung LM301H EVO or Nichia 219F diodes mounted on thermally optimized flexible PCBs, enabling exceptional efficiency without compromising longevity. For lumens per watt, we achieve a sustained 120–135 lm/W across our 2700K to 6500K CCT range at standard 500mA operating current. This figure accounts for full-system efficiency including controller losses and thermal derating, not just peak diode performance under ideal conditions. We maintain this efficiency through precise current regulation and copper-layer thicknesses exceeding 2 oz, minimizing resistive losses even during extended operation at 40°C ambient temperatures.

Color fidelity is non-negotiable in our designs, which is why all programmable strips exceed CRI >90 with R9 >50 and TM-30-19 fidelity index (Rf) >85. We avoid spectral shortcuts by using multi-phosphor blends that deliver smooth spectral power distributions, critical for accurate skin tone rendering in beauty and retail environments. Each production batch undergoes spectroradiometric testing with an Instrument Systems CAS 140D to verify CRI metrics against NIST-traceable standards. This contrasts with industry practices where some manufacturers inflate CRI values using narrow-band cyan peaks that distort red rendition—a flaw our R9 >50 requirement explicitly prevents.

For environmental protection, our standard programmable strips carry an IP67 rating certified to IEC 60529, achieved through seamless dual-layer silicone overmolding that encapsulates solder joints and ICs. Unlike competitors who rate bare strips before assembly, we test fully terminated reels with end caps under 1 meter of water immersion for 30 minutes. For harsher environments, we offer IP68 variants rated for continuous submersion at 1.5 meters depth, utilizing marine-grade polyurethane encapsulation resistant to UV degradation and chemical exposure. All ingress protection claims are validated through SGS-certified testing protocols, not theoretical design assumptions.

Beauty STC’s quality differentiation stems from our vertically integrated manufacturing in Shenzhen, where we control every process from diode binning to final aging. Our strips undergo 72-hour accelerated life testing at 60°C with 100% functional verification, rejecting any reel showing >5% lumen depreciation. We enforce tighter binning tolerances (3-step MacAdam ellipse) than industry norms and use only UL 94-V0 rated materials for fire safety. This disciplined approach results in a field-proven L70/B50 lifetime of 50,000 hours at 25°C—significantly outperforming generic strips that often degrade within 18 months. When you specify Beauty STC, you receive not just a product but documented photometric reports, spectral graphs, and thermal validation data proving every claim.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory located in Jiangmen, Guangdong Province, is a modern, vertically integrated facility specializing in the production of high-quality LED lighting products. The facility is equipped with advanced manufacturing technologies and adheres to strict quality control standards to ensure reliable and consistent output.

The factory features fully automated SMT (Surface Mount Technology) production lines that enable precise and efficient mounting of LED components onto flexible and rigid strips. These SMT machines are state-of-the-art, supporting high-speed placement with micron-level accuracy, which ensures uniformity and reliability in every batch. The lines are capable of handling a wide range of LED packages, including 2835, 3528, 5050, and others, allowing for versatile product configurations. The integration of automated optical inspection (AOI) systems further enhances quality assurance by detecting soldering and component placement defects in real time.

To ensure long-term performance and durability, Beauty STC implements comprehensive aging tests as part of its production process. Completed light strips undergo rigorous burn-in testing, typically lasting 24 to 72 hours under elevated temperatures and full operational load. During this period, parameters such as luminous output, color consistency, and electrical stability are continuously monitored. Any units exhibiting performance deviations are removed, guaranteeing that only reliable products reach customers.

Beauty STC has strong OEM capabilities, particularly for programmable light strips. The company supports full customization, including choice of LED density, color temperature, control protocols (such as DMX512, SPI, I2C, or Wi-Fi/Bluetooth-enabled ICs like SK6812, WS2812B, or APA102), voltage (5V, 12V, 24V), and physical form factor (flexible PCB width, waterproof ratings from IP20 to IP68). Customers can also customize label designs, packaging, and branding. The in-house R&D team works closely with clients to develop tailored firmware and control solutions, enabling dynamic effects such as color chasing, fading, music synchronization, and integration with smart home systems.

Overall, the Jiangmen factory combines advanced automation, stringent quality testing, and flexible OEM services to deliver high-performance programmable LED light strips that meet diverse market demands.

Application Scenarios

Programmable light strips offer significant advantages in commercial environments where dynamic lighting enhances ambiance, functionality, and energy efficiency. Their application varies across hotels, malls, and offices based on specific operational and experiential goals. In hotels, programmable strips excel in lobbies for creating immersive welcome experiences through color-changing effects that align with branding or events, and in corridors to provide intuitive wayfinding with subtle directional cues or time-of-day adjustments. Guest room cove lighting benefits from programmability, allowing guests to select scenes for relaxation or productivity, while meeting rooms utilize them for flexible presentation modes. For malls, these strips are ideal for dynamic facade lighting to attract attention during promotions, accentuating architectural features with animated sequences. They enhance retail displays by spotlighting merchandise with color temperatures that boost product appeal, and guide shoppers through pathways with interactive floor or ceiling accents during peak hours. In offices, the primary use is human-centric lighting in open workspaces, where correlated color temperature (CCT) tuning supports circadian rhythms—cooler tones for focus in mornings, warmer for calm in afternoons. Conference rooms leverage them for preset scenes matching meeting types, and reception areas employ gentle animations to reinforce brand identity without distraction.

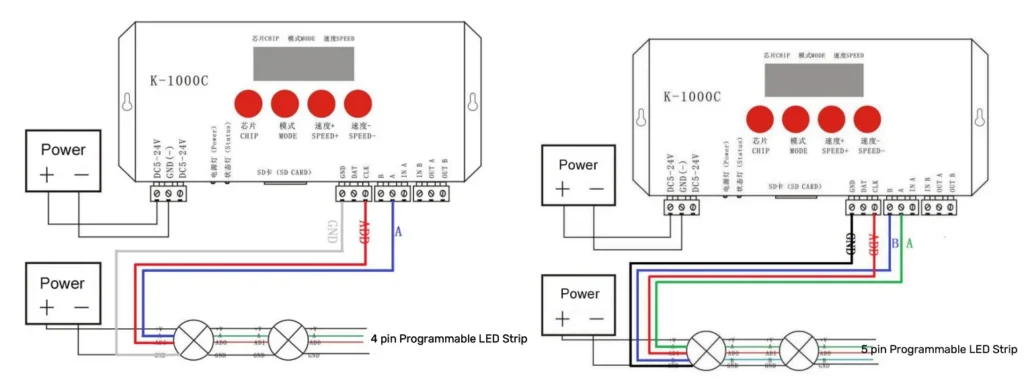

Installation requires meticulous planning to ensure longevity and performance. Always use aluminum channels with proper thermal management; embedded strips without adequate heat dissipation will suffer accelerated lumen depreciation and color shift, especially in enclosed cove applications common in hotels and offices. Address voltage drop in long runs by feeding power at both ends or using parallel injection every 5 meters—this is critical for uniform brightness in mall facades exceeding 10 meters. For wet or high-humidity areas like hotel bathrooms or mall food court perimeters, specify IP67-rated strips with fully potted LEDs and silicone jackets, never relying on basic PVC coatings. Integrate with building management systems via DALI or DMX controllers rather than standalone apps; facility teams in malls and offices require centralized scheduling and fault reporting. Finally, conceal all drivers and junctions within accessible service zones—never inside drywall—since commercial maintenance demands quick component replacement without ceiling damage. Skipping these steps risks frequent failures and inconsistent output, undermining the investment in programmable systems.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s premium programmable light strips—engineered for precision, durability, and seamless integration. Whether you’re designing dynamic architectural features or innovative smart lighting systems, our advanced LED solutions deliver unmatched performance and flexibility. Partner with Beauty STC, a trusted leader in cutting-edge lighting technology. For collaboration opportunities and expert support, contact us at [email protected] and let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.