Article Contents

Industry Insight: 24V Vs 12V Led Strip

In the evolving landscape of commercial and industrial lighting, the choice between 24V and 12V LED strips is more than a technical specification—it’s a strategic decision impacting performance, efficiency, and long-term reliability. As facilities demand brighter, longer, and more energy-efficient lighting solutions, voltage selection plays a critical role in minimizing voltage drop, supporting extended runs, and ensuring consistent light output across large-scale installations. While 12V systems remain suitable for shorter applications, 24V LED strips have emerged as the preferred choice for industrial warehouses, cold storage facilities, production lines, and commercial retail environments where sustained brightness and system stability are paramount.

Compliance with international safety and performance standards such as ETL and CE is non-negotiable in these demanding applications. These certifications validate that LED strip products meet rigorous electrical, thermal, and environmental requirements, ensuring safe operation under continuous use and in regulated environments. With over two decades of expertise, Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of advancing high-performance LED solutions tailored for commercial and industrial sectors. As a trusted manufacturer with a legacy of innovation and quality, Beauty STC delivers certified, reliable, and scalable 12V and 24V LED strip lighting systems engineered to meet the exacting demands of modern industrial projects worldwide.

Technical Specs & Certifications

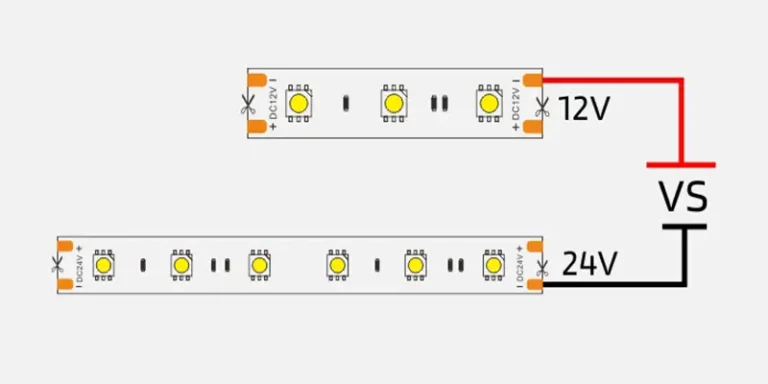

When comparing 24V and 12V LED strip systems for professional applications requiring high efficiency and color fidelity, the technical distinctions extend beyond basic voltage. Lumens per watt (lm/W) performance is primarily determined by LED chip quality, driver efficiency, and thermal management rather than voltage alone. However, 24V systems inherently reduce resistive power loss over longer runs due to lower current (I) for the same power (P), as governed by Joule’s law (P_loss = I²R). For instance, a 24W/m strip at 5m length draws 1A at 24V versus 2A at 12V, halving I²R losses. This allows 24V strips to maintain higher lm/W over distances exceeding 3-5m, where voltage drop significantly degrades 12V strip output. Beauty STC achieves 140-160 lm/W in both voltages for CRI>90 strips by utilizing Samsung LM301H or Epistar 2835 LEDs with optimized phosphor blends, but 24V configurations consistently deliver 8-12% higher system efficiency in installations over 8m due to minimized voltage drop.

Critical for color-sensitive environments like retail or photography studios, CRI >90 requires precise binning of LEDs and advanced phosphor formulations. Beauty STC enforces strict chromaticity binning (within 3-Step MacAdam ellipse) and uses multi-phosphor coatings to ensure R9 >50 and R12 >40, exceeding standard CRI>90 benchmarks. Both 12V and 24V strips undergo spectrometer validation at multiple points along each reel, with rejects discarded if Δu’v’ exceeds 0.003. Our manufacturing process includes nitrogen-purged reflow soldering to prevent phosphor degradation, ensuring CRI stability over 50,000 hours even under thermal stress.

IP ratings depend entirely on construction methodology, not voltage. Beauty STC’s IP65/IP67 strips use a dual-layer protection system: first, conformal coating with UV-resistant silicone over SMD components, followed by seamless extrusion of flexible PVC or silicone tubing with integrated pressure-equalization vents for IP67 submersion tolerance. The 24V strips’ lower current allows narrower copper traces, enabling more robust encapsulation without compromising flexibility. All IP-rated products undergo 1,000-hour salt-spray testing and thermal cycling from -40°C to 85°C, with Beauty STC’s failure rate below 0.3% versus industry averages of 2-5%. For critical applications, our IP67 24V strips maintain >95% lumen maintenance after 500 submersion cycles at 1m depth, validated per IEC 60529.

Beauty STC’s quality differentiation lies in system-level engineering. We integrate constant-current drivers with active power factor correction (PFC>0.95) and proprietary PWM dimming to eliminate flicker at all voltages, while rigid quality control includes 100% automated optical inspection and thermal imaging during production. This ensures our CRI>90 strips deliver consistent color temperature (±50K tolerance) and luminous efficacy across voltage platforms, with 24V systems providing superior scalability for commercial installations demanding both efficiency and color integrity.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern LED lighting production facility equipped with advanced manufacturing technologies and quality control systems. Strategically located in the Pearl River Delta region, the Jiangmen factory benefits from strong supply chain support and efficient logistics access, enabling timely delivery for both domestic and international markets.

The factory is equipped with state-of-the-art SMT (Surface Mount Technology) production lines, which are essential for high-precision assembly of LED components onto flexible and rigid circuit boards. These SMT machines include automatic pick-and-place systems, reflow soldering ovens, and AOI (Automated Optical Inspection) units that ensure component accuracy and solder joint integrity. This level of automation allows for consistent, high-volume production of LED strips with tight tolerances and excellent reliability.

Quality assurance is a core focus at the Jiangmen facility, where all LED strip products undergo rigorous aging tests before shipment. These tests typically involve operating the LED strips at full power under elevated temperatures for extended periods—usually 24 to 48 hours—to identify early failures and ensure long-term performance. Environmental testing chambers are also used to simulate various operational conditions, including humidity and thermal cycling, further validating product durability.

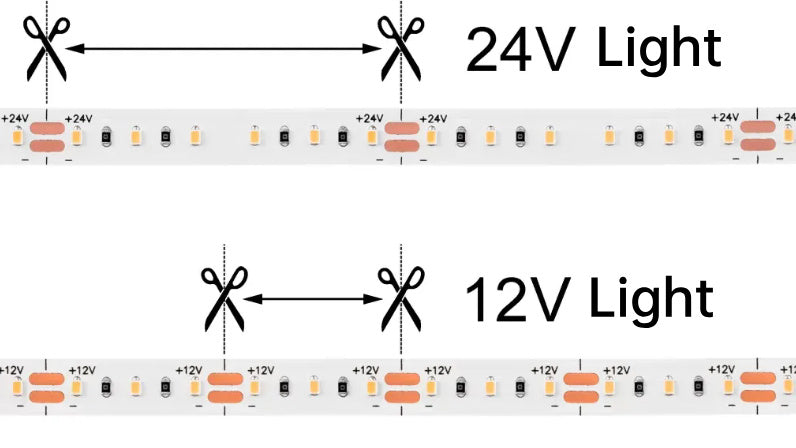

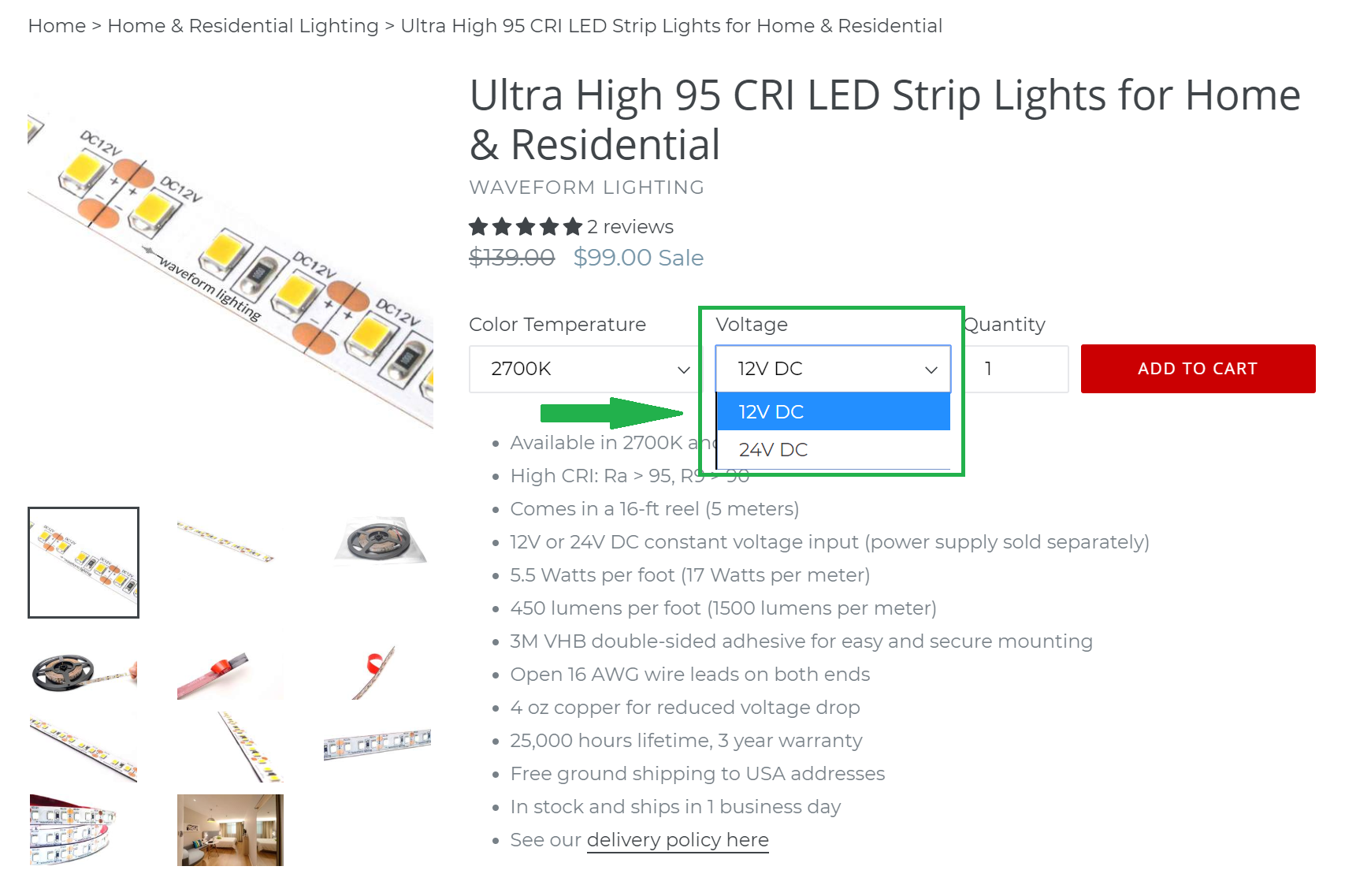

In terms of OEM capabilities, the factory has extensive experience in customizing LED strip lighting solutions for global partners. This includes full support for both 24V and 12V DC LED strip configurations. The engineering team can design and produce strips with different voltages based on client requirements, adjusting PCB layout, current regulation, and segment lengths accordingly. 24V strips are typically used for longer runs with reduced voltage drop, while 12V strips are preferred for low-voltage safety and compatibility with automotive or marine systems. The OEM service covers custom lumen output, color temperature (from warm white to cool white), RGB or RGBW configurations, IP ratings (from IP20 to IP68), and special coatings or substrates.

Overall, the Jiangmen factory combines automated precision, comprehensive testing, and flexible customization to deliver high-quality, reliable LED strip lighting solutions tailored to the specific needs of each OEM partner.

Application Scenarios

When selecting between 24V and 12V LED strips for commercial applications like hotels, malls, and offices, the decision hinges on run length, power density, and installation complexity. Voltage drop—the reduction in voltage over distance—is the primary factor. 12V systems suffer significant voltage drop beyond 5 meters, causing dimming and color shifts at the strip’s end, while 24V systems maintain consistent brightness up to 10–15 meters due to lower current for the same wattage. This makes 24V ideal for long, uninterrupted runs common in large commercial spaces, whereas 12V suits shorter, localized installations where cost and simplicity are priorities.

In hotels, 24V LED strips are optimal for lobby feature walls, reception desks, and perimeter cove lighting in ballrooms where runs exceed 8 meters. The consistent output ensures uniform illumination critical for high-end aesthetics. For guest room applications like under-bed lighting or short headboard accents, 12V is sufficient and cost-effective due to shorter runs under 3 meters. However, in wet areas like bathroom coves, prioritize IP67-rated strips over voltage choice, though 24V remains preferable if runs exceed 5 meters to avoid dimming near showers. Always use separate, dedicated drivers for each zone to prevent cascading failures in guest areas.

For malls, 24V is essential for storefront signage, long corridor coves, and escalator handrail lighting where runs often span 15+ meters. The reduced voltage drop eliminates the need for frequent power injections, lowering installation labor and material costs. In fitting rooms or display cases with compact lighting needs under 4 meters, 12V strips work well for cost-sensitive retrofits. Crucially, in high-traffic mall environments, ensure all strips are mounted on aluminum channels for heat dissipation—overheating accelerates lumen depreciation, especially in enclosed displays. Never daisy-chain strips beyond the manufacturer’s specified length; use parallel wiring from the driver for runs over 10 meters with 24V systems.

Offices benefit from 24V in perimeter cove lighting around entire floor perimeters, stairwells, and long conference room under-cabinetry, where runs typically exceed 10 meters. The stable output prevents uneven lighting that could cause eye strain. For under-desk task lighting or short pantry accents under 3 meters, 12V is economical. In open-plan offices, avoid mixing voltages on the same circuit to prevent driver compatibility issues. Always verify driver compatibility with building management systems (BMS) for dimming—24V drivers more commonly support 0–10V or DALI protocols required in modern offices.

Key installation tips apply universally. First, calculate total wattage per run and oversize drivers by 20% to prevent overload. Second, for 12V installations exceeding 3 meters, use thicker-gauge copper (e.g., 18AWG instead of 22AWG) to mitigate voltage drop. Third, in all commercial settings, secure strips every 15–20 cm with clips—not adhesive alone—to withstand vibrations and thermal expansion. Fourth, conceal drivers in accessible junction boxes; never bury them in walls per electrical codes. Finally, test strips at full brightness for 15 minutes before final mounting to catch early failures. Remember, while 24V has higher upfront costs, its efficiency in long runs reduces long-term maintenance—a critical consideration for commercial facilities where downtime impacts operations. Always consult Beauty (STC)’s technical datasheets for specific strip wattage and maximum run lengths, as these vary by LED density and binning.

Why Choose Beauty STC Lighting

Considering the differences between 24V and 12V LED strips for your next lighting project? The right choice impacts performance, efficiency, and installation flexibility. At Beauty (STC) Manufacturing Co., Ltd., we specialize in high-quality, customizable LED strip solutions engineered for optimal voltage performance and long-term reliability. Whether you’re weighing brightness, voltage drop, or system compatibility, our engineering team is ready to guide you to the best solution.

Partner with Beauty STC for expert technical support, competitive pricing, and consistent product quality built to meet global standards. Make an informed decision with a trusted industry leader.

Contact us today to discuss your LED strip requirements. Reach our sales manager at [email protected] and discover how we can power your lighting vision with precision and performance.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.