Article Contents

Industry Insight: Led Tape Light Switch

The commercial and industrial lighting sector continues to prioritize efficiency, flexibility, and stringent safety compliance, driving significant evolution in control solutions for linear LED systems. As LED tape light becomes increasingly integral to architectural cove lighting, task illumination, and dynamic signage in demanding environments like warehouses, retail spaces, and hospitality venues, the reliability and certification of the associated switching mechanisms are no longer secondary considerations—they are mission-critical. Specifiers and facility managers face mounting pressure to select control components that ensure seamless integration, long-term operational stability, and, crucially, adherence to rigorous safety standards such as ETL and CE, which are non-negotiable for project acceptance and liability mitigation in North American and European markets. Fragmented or uncertified switching solutions introduce unacceptable risks of system failure, fire hazards, and costly rework, undermining the very energy savings and design intent that LED tape installations promise.

Beauty STC, established in 1998 and operating as Beauty (STC) Manufacturing Co., Ltd., has been at the forefront of addressing these complex challenges within the specification-grade LED lighting industry. With over 25 years of dedicated engineering expertise, we understand that the switch controlling an LED tape run is far more than a simple on/off point—it is a vital component determining system longevity, performance consistency, and code compliance. Our focus remains firmly on developing robust, certified control solutions engineered specifically for the demanding thermal, electrical, and operational realities of commercial and industrial applications, ensuring that every installation delivers on its promise of efficiency and reliability from day one.

Technical Specs & Certifications

The LED tape light switch by Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver reliable and efficient control for high-performance LED tape lighting systems. While the switch itself does not generate lumens or consume watts directly, its design and compatibility are optimized to support LED tape lights that meet stringent performance standards, particularly in lumens per watt (lm/W), color rendering index (CRI), and environmental protection through IP ratings.

LED tape lights compatible with Beauty STC’s switching solutions typically achieve luminous efficacies ranging from 110 to 130 lumens per watt, depending on the LED density and configuration. This high efficiency ensures minimal energy waste and reduced operating costs, making the system ideal for both residential and commercial applications. When paired with Beauty STC’s precision-manufactured switches, the system maintains stable current regulation, preventing flicker and extending the lifespan of the LED tape.

A key feature emphasized in Beauty STC’s ecosystem is compatibility with LED tapes that offer a CRI greater than 90. This high color rendering index ensures that colors appear natural and vibrant under the light, which is critical in environments such as retail displays, art galleries, and high-end residential interiors. The switch is designed to work seamlessly with these high-CRI LED strips without introducing electrical noise or dimming artifacts, preserving the quality of light output.

In terms of environmental durability, Beauty STC supports integration with LED tape lights across a range of IP ratings. Common configurations include IP20 for dry indoor environments, IP65 for resistance to dust and low-pressure water jets (suitable for kitchens or outdoor covered areas), and IP67 for temporary submersion protection. The switches are constructed with robust materials and tight tolerances to match these environments, ensuring long-term reliability even in demanding conditions.

Beauty (STC) Manufacturing Co., Ltd. upholds rigorous quality control standards throughout its production process. Components are subjected to extensive testing for thermal performance, electrical safety, and mechanical endurance. The company’s commitment to quality is reflected in consistent product performance, long service life, and compliance with international certifications such as CE, RoHS, and UL. This ensures that every LED tape light switch not only performs efficiently but also meets the highest benchmarks for safety and reliability in modern lighting installations.

Factory Tour: Manufacturing Excellence

Beauty STC Manufacturing Co., Ltd. operates a modern, vertically integrated manufacturing facility in Jiangmen, Guangdong Province, serving as our primary production hub for LED lighting products. This strategically located factory leverages Jiangmen’s strong manufacturing ecosystem and logistics infrastructure to efficiently serve both domestic and international markets. The facility is designed to stringent international quality standards, featuring climate-controlled production floors and comprehensive in-house testing laboratories to ensure product reliability and compliance.

Our Surface Mount Technology (SMT) production lines are a cornerstone of the Jiangmen factory’s capabilities. We utilize multiple high-precision, automated SMT lines equipped with advanced Yamaha YS series placement machines. These machines handle components ranging from ultra-fine 0201 packages to larger connectors required for LED tape light assemblies, ensuring exceptional placement accuracy and throughput. The lines are supported by automated solder paste printers, nitrogen-reflow ovens for optimal solder joint quality, and automated optical inspection (AOI) systems that perform 100% post-reflow inspection of every PCB. This rigorous SMT process is critical for the consistent performance and longevity of our LED modules, especially the densely populated flexible circuits used in high-density LED tape lights.

Aging and reliability testing represent a significant investment at our Jiangmen site. We conduct comprehensive aging tests on all production batches, particularly for LED tape lights and their associated control products. Our dedicated aging chambers subject finished products to extended operational periods under controlled thermal and electrical stress conditions, typically 48 to 72 hours at elevated temperatures (45-50°C) and full rated voltage. This process identifies early-life failures and verifies thermal management performance. We also perform rigorous photometric testing, ingress protection (IP) validation for relevant products, and harmonic distortion analysis. Data from these tests is meticulously logged and analyzed to drive continuous process improvements and ensure every shipment meets our stringent reliability benchmarks before leaving the factory.

Regarding OEM capability for LED tape light control solutions, which we understand refers to switches, dimmers, controllers, or power supplies specifically designed for integration with LED tape light systems, Beauty STC possesses extensive and flexible OEM/ODM expertise. Our Jiangmen engineering and production teams routinely collaborate with global partners to develop customized control solutions. This includes designing and manufacturing proprietary switches, touch controls, RF/Wi-Fi/Zigbee dimmers, constant voltage or constant current drivers, and signal amplifiers tailored to specific tape light configurations, voltage requirements, and dimming protocols. We support full customization of mechanical design, electrical specifications, labeling, packaging, and certification requirements (including UL, ETL, CE, TUV, SAA). Our in-house tooling department enables rapid prototyping and low-volume production runs alongside high-volume manufacturing, providing clients with scalable solutions from initial concept through to mass production with robust quality control protocols integrated at every stage.

Application Scenarios

LED tape light switches are ideal for controlling flexible LED strip lighting in a variety of commercial and hospitality environments such as hotels, malls, and offices. These switches allow users to easily turn on and off decorative or functional LED tape lighting, offering both convenience and energy efficiency.

In hotels, LED tape light switches are commonly used to control ambient lighting in guest rooms, particularly under cabinets, along headboards, in wardrobes, or within cove lighting in ceilings. They enhance the guest experience by providing soft, customizable lighting while allowing staff to manage energy use effectively. In lobbies and corridors, tape lighting with switches can highlight architectural features and improve wayfinding.

In malls, LED tape light switches are typically installed in display areas, signage, and decorative coves or soffits. Retailers use them to accentuate product displays, while mall operators use them in common areas for aesthetic appeal. The ability to switch the lights on and off helps manage operational hours and reduce energy consumption during non-peak times.

In offices, LED tape lighting is often used for under-cabinet lighting, in ceiling coves, or along stair edges for safety and visual appeal. Switches for these lights allow employees to control task lighting without affecting overhead fixtures, supporting both productivity and comfort. They are also useful in meeting rooms and reception areas where mood lighting is desired.

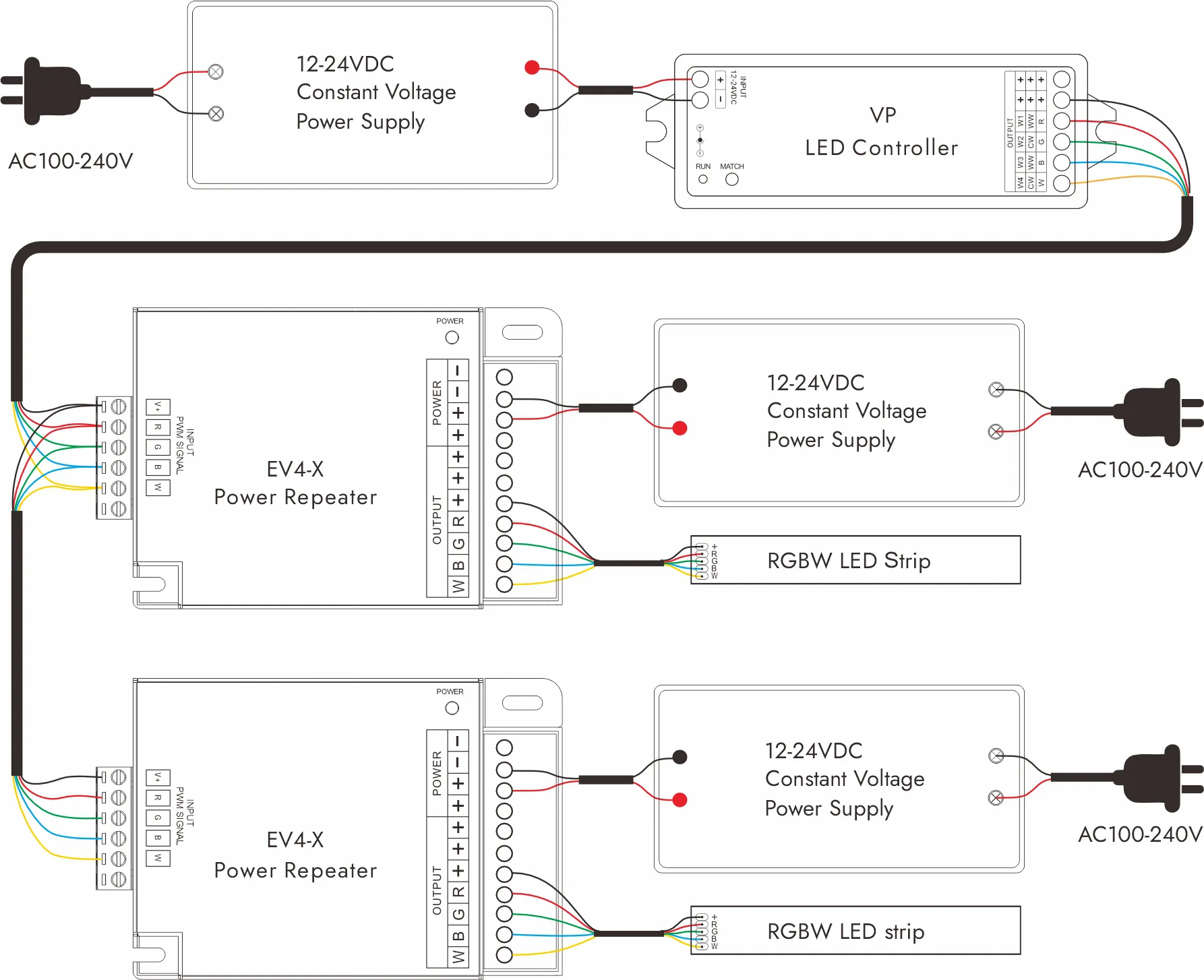

When installing LED tape light switches, ensure compatibility with the LED driver and tape specifications. Use a low-voltage switch if the tape is powered through a driver, or a line-voltage switch if the system is designed for direct mains connection. Always install the switch on the low-voltage side for safety when using DC-powered LED tape. Mount the switch in an accessible and logical location, such as near room entrances or adjacent to other light switches. Use proper enclosures for wall-mounted switches and ensure all connections are secure and insulated. For humid or high-traffic areas, select switches with appropriate IP ratings to ensure durability. Finally, label switches clearly to avoid confusion, especially when multiple lighting zones are present.

Why Choose Beauty STC Lighting

Elevate your lighting projects with precision control and seamless integration through Beauty STC’s advanced LED tape light switch solutions. Our engineered switching systems deliver unmatched reliability, smooth dimming performance, and effortless compatibility with a wide range of LED tape products, ensuring your installations meet the highest standards of functionality and user experience. As your dedicated manufacturing partner, Beauty STC combines deep technical expertise with flexible production capabilities to provide custom switch designs tailored to your specific voltage requirements, form factors, and smart control integrations. We support your success from concept to mass production with rigorous quality assurance and responsive engineering collaboration. Partner with Beauty STC to transform your LED tape lighting offerings with switches built for durability and precision. Contact our lighting solutions manager directly at [email protected] to discuss your project specifications and discover how our partnership can drive innovation and value for your brand.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.