Article Contents

Industry Insight: Dmx Led Tape

The commercial and industrial lighting landscape is undergoing a significant transformation, driven by the demand for dynamic, energy-efficient, and highly controllable illumination solutions. DMX512-controlled LED tape has emerged as a pivotal technology within this shift, moving far beyond basic accent lighting to become a core component for sophisticated architectural integrations, retail environments, hospitality venues, and even specialized industrial applications requiring precise light management. Its ability to deliver pixel-level control over color, intensity, and effects enables the creation of immersive brand experiences, adaptable workspaces, and functional lighting schemes that respond to occupancy or operational needs. Crucially, for any specification in these high-stakes environments, compliance with rigorous safety and performance standards is non-negotiable. Products must consistently carry recognized certifications such as ETL (verifying adherence to North American safety standards) and CE (demonstrating conformity with essential health, safety, and environmental requirements for the European market) to ensure reliability, mitigate liability, and meet code requirements. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution. Leveraging over two decades of specialized expertise in advanced LED lighting systems, we design and manufacture DMX LED tape solutions engineered specifically for the demanding performance, durability, and compliance expectations of the commercial and industrial sectors, providing integrators and specifiers with the tools to realize truly intelligent and impactful lighting designs.

Technical Specs & Certifications

DMX LED tape is a high-performance, digitally addressable lighting solution designed for architectural, entertainment, and decorative applications where precise control of color and brightness is essential. At Beauty (STC) Manufacturing Co., Ltd., our DMX LED tapes are engineered to deliver superior optical performance, durability, and consistency, meeting the demanding standards of professional lighting installations.

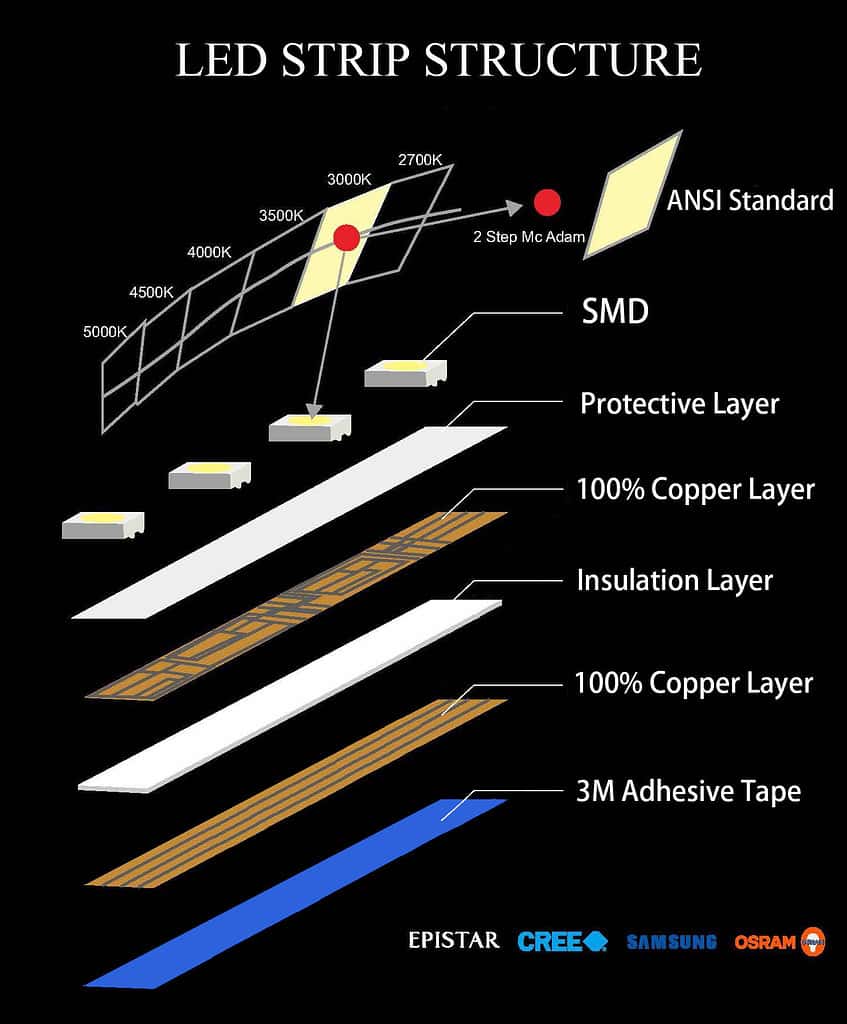

In terms of efficiency, our DMX LED tapes achieve a luminous efficacy of up to 18 to 22 lumens per watt, depending on the configuration, color temperature, and drive current. While this is slightly lower than standard non-addressable LED tapes due to the integrated control circuitry and data components, the trade-off is fully justified by the granular control each LED node provides. The use of high-quality 5050 or 3535 SMD LEDs ensures optimal light output while maintaining thermal stability across extended runs.

Color Rendering Index (CRI) is a critical factor in premium lighting applications, and Beauty STC’s DMX LED tapes are specifically designed with CRI values exceeding 90—typically ranging from 92 to 95—using carefully selected phosphor blends and binning processes. This high CRI ensures accurate and vibrant color representation, making our tapes ideal for retail, hospitality, and media environments where color fidelity is paramount. Options are available in multiple CCTs (Correlated Color Temperatures), including 2700K, 3000K, 4000K, and 6000K, all maintaining consistent high CRI performance.

Regarding environmental protection, our DMX LED tapes are available in multiple IP rating configurations to suit diverse installation requirements. Standard non-protected flexible PCB versions are suitable for indoor dry locations (IP20). For damp or outdoor environments, we offer fully encapsulated versions rated at IP65, IP67, and even IP68. These are achieved through silicone overmolding or conformal coating processes that protect the LEDs, ICs, and copper traces from moisture, dust, and mechanical stress without compromising signal integrity or heat dissipation.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout the production process. Our DMX LED tapes utilize top-tier components, including internationally recognized driver ICs such as the APA102, SK9822, or WS2815, ensuring stable data transmission and minimal signal degradation over long runs. Each batch undergoes strict testing for color consistency, forward voltage, and waterproof integrity. Our manufacturing complies with ISO9001 standards, and all products are RoHS compliant.

In summary, Beauty STC’s DMX LED tapes combine high luminous efficacy, exceptional color rendering (CRI >90), and robust environmental protection (up to IP68), all backed by our commitment to engineering excellence and product reliability. These features make our tapes a preferred choice for integrators and designers who demand precision, quality, and long-term performance in dynamic lighting applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as our primary production hub for advanced LED lighting solutions. This state-of-the-art factory spans over 20,000 square meters and operates under strict ISO 9001 and ISO 14001 certified quality management systems. The facility features climate-controlled SMT production lines, dedicated R&D laboratories, comprehensive aging and reliability testing chambers, and specialized assembly areas for both standard and custom LED products.

Our SMT production lines are equipped with high-precision Yamaha YSM20 and YSM10 modular placement machines capable of handling components down to 0201 package size. These machines achieve placement accuracy of ±25μm at speeds exceeding 100,000 components per hour, ensuring consistent soldering quality for complex LED tape assemblies. The lines integrate automated optical inspection (AOI) systems after reflow soldering to detect micro-soldering defects, coupled with real-time statistical process control monitoring to maintain yield rates above 99.5%. For DMX LED tape production, these machines precisely mount specialized ICs like the UCS5963 and SM16716 alongside high-density LED packages on flexible PCBs.

Aging and reliability testing constitute a critical phase in our quality assurance process. We operate 48 dedicated thermal aging chambers with a combined daily capacity of 20,000 meters of LED tape. All DMX LED tape undergoes a rigorous 72-hour burn-in test at 50°C ambient temperature under full operational load, with continuous monitoring of voltage, current, and thermal performance. Post-aging, samples undergo lumen maintenance testing using integrating spheres, chromaticity shift analysis via spectroradiometers, and accelerated life testing per IES LM-80 standards. Failed units trigger root cause analysis through our in-house failure analysis lab, which includes X-ray inspection and cross-sectioning capabilities.

Our OEM capabilities for DMX LED tape are comprehensive and tailored to client specifications. We support full customization of electrical parameters including 5V, 12V, or 24V DC operation with pixel densities ranging from 30 to 144 LEDs per meter. Clients can specify DMX protocol variants (DMX512-A standard), pixel mapping configurations, and control protocols including compatibility with Art-Net or sACN systems. We handle all aspects from PCB layout modification and IC programming to custom silicone encapsulation profiles and connector types. The process begins with NDA-protected design collaboration, followed by prototyping with our in-house stencil and PCB fabrication support, and culminates in volume production with dedicated line setup. Every OEM project includes custom firmware development for unique addressing schemes and effect programming, backed by our proprietary thermal management solutions to ensure longevity in demanding applications. All custom DMX tape reels feature serialized traceability through our ERP system, enabling full production history tracking from component lot to final shipment.

Application Scenarios

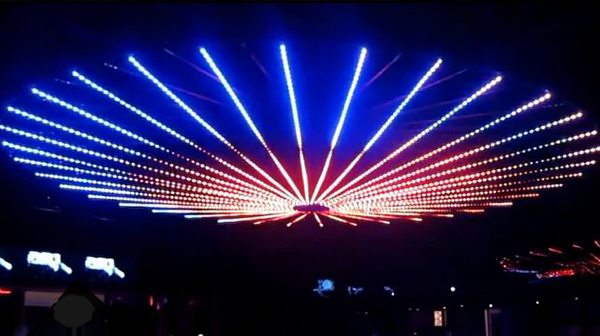

DMX LED tape is a digitally addressable lighting solution that allows for precise control of individual LEDs or segments along the tape, making it ideal for dynamic lighting effects, color changing, and synchronized lighting displays. It is commonly used in environments where lighting design plays a key role in ambiance, branding, or visual impact. Below are typical applications in hotels, malls, and offices, followed by essential installation tips.

In hotels, DMX LED tape is often used in lobbies, corridors, feature walls, and around mirrors or headboards in guest rooms to create a luxurious and customizable atmosphere. It is especially effective in bars, lounges, and event spaces where color-changing effects and lighting scenes enhance the guest experience. Under-bar counter lighting, cove lighting in ballrooms, and accent lighting along staircases or architectural features benefit greatly from DMX control, allowing for mood transitions throughout the day or for special events.

Malls utilize DMX LED tape in signage, display windows, ceiling coves, and feature installations to attract attention and guide customer flow. The ability to program animated effects, color fades, or synchronized light shows makes it ideal for holiday displays or promotional campaigns. It is also used in food courts and common areas to create vibrant, engaging environments that enhance the overall shopping experience.

In offices, DMX LED tape is more selectively applied, typically in reception areas, executive lounges, or conference rooms where architectural lighting adds a modern, high-end feel. While general office spaces prioritize functional lighting, DMX tape can support branding through color-themed lighting or ambient backlighting in feature walls and ceilings. It is also used in wellness areas or break zones to support circadian lighting strategies when integrated with appropriate control systems.

For successful installation, begin by planning the layout and mapping out DMX address assignments to ensure each segment is properly configured. Use high-quality power supplies and ensure adequate power injection points—especially for long runs—to avoid voltage drop and color inconsistency. Always follow the manufacturer’s guidelines for maximum run lengths and consider using a DMX splitter or amplifier for large installations to maintain signal integrity.

Mount the LED tape on clean, dry surfaces using compatible mounting clips or adhesive backing, ensuring proper thermal management by avoiding tight bends or enclosed spaces without ventilation. Protect the tape in high-traffic or exposed areas with aluminum profiles or diffusers to enhance durability and light distribution. Seal end caps and connectors properly, especially in humid environments, to prevent moisture ingress.

Finally, integrate the DMX system with a compatible controller and software platform to enable scene programming, scheduling, and synchronization with other building systems. Label all DMX lines and test each segment before finalizing the installation to streamline troubleshooting and maintenance.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium DMX LED tape solutions designed for professional reliability and creative flexibility. Our advanced tapes deliver seamless control, pixel-perfect precision, and consistent color rendering across installations from architectural highlights to dynamic stage productions. Partner with Beauty STC to access cutting-edge technology engineered for demanding applications including 16-bit color depth, robust waterproofing options, and industry-leading thermal management. We provide comprehensive technical support, custom reel lengths, and rigorous quality assurance to ensure your projects meet the highest standards of performance and durability. Contact our dedicated engineering team today at [email protected] to discuss your specifications, request samples, or explore tailored solutions for your next venture. Trust Beauty STC for innovation you can build upon and results that exceed expectations.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.