Article Contents

Industry Insight: Led Strip And Transformer

The commercial and industrial lighting sector continues its decisive shift towards LED technology, driven by relentless demands for energy efficiency, operational cost reduction, and enhanced illumination quality across demanding environments. Within this critical transition, LED strips and their corresponding transformers have evolved from simple accent lighting solutions into fundamental components for architectural, task, and high-bay applications. Their flexibility enables precise light placement in retail displays, warehouse aisles, manufacturing facilities, and office interiors, but their successful deployment hinges on robust performance, thermal management, and seamless integration with building control systems. Crucially, for any project targeting professional viability and safety compliance, adherence to stringent regulatory standards is non-negotiable. ETL listing for the North American market and CE marking for Europe are essential benchmarks, verifying that both the LED strips and their power supplies meet rigorous electrical safety, electromagnetic compatibility, and performance criteria. Failure to utilize certified components risks project rejection, liability exposure, and compromised system longevity in environments where lighting is mission-critical.

Beauty STC Manufacturing Co., Ltd., established in 1998, operates at the forefront of this specialized segment. With over two decades of dedicated engineering and manufacturing expertise, we understand the unique pressures and specifications inherent in commercial and industrial projects. Our core focus has always been on developing high-reliability LED strip systems and precision-engineered transformers designed specifically for the rigors of professional installation and continuous operation. We prioritize not only meeting but exceeding ETL and CE requirements, embedding safety and performance validation into the very foundation of our product development process. This long-standing commitment ensures that Beauty STC solutions deliver the consistent output, thermal stability, and regulatory confidence demanded by architects, electrical contractors, and facility managers entrusted with creating efficient, safe, and visually effective illuminated spaces.

Technical Specs & Certifications

Beauty (STC) Manufacturing Co., Ltd. delivers high-performance LED strip and transformer solutions engineered for efficiency, color accuracy, and durability. Our products are designed to meet the demanding requirements of commercial, residential, and architectural lighting applications.

Our LED strips achieve luminous efficacies ranging from 110 to 140 lumens per watt, depending on the color temperature and density configuration. This high lumens-per-watt ratio ensures energy-efficient operation without compromising brightness, making our strips ideal for long-term use in both indoor and outdoor environments. High-efficiency drivers and optimized SMD chip technology—typically using 2835, 3014, or 5050 SMD LEDs—contribute to consistent light output and thermal management.

Color Rendering Index (CRI) is a critical performance metric, and Beauty STC ensures all premium LED strips maintain a CRI greater than 90. This high CRI enables accurate and natural color representation, which is essential in retail displays, hospitality settings, and art galleries where true color perception is vital. We achieve this through the use of high-quality phosphor coatings and binning processes that tightly control chromaticity.

Environmental protection is addressed through rigorous IP (Ingress Protection) rating standards. Our LED strips are available in multiple configurations to suit various conditions. IP20-rated strips are suitable for dry, indoor environments, while IP65-rated versions offer protection against dust and low-pressure water jets, making them appropriate for damp areas such as kitchens or outdoor signage. For fully exposed outdoor or landscape applications, we offer IP67 and IP68-rated waterproof strips that withstand temporary submersion and harsh weather conditions. These higher IP ratings are achieved through silicone encapsulation and robust housing designs.

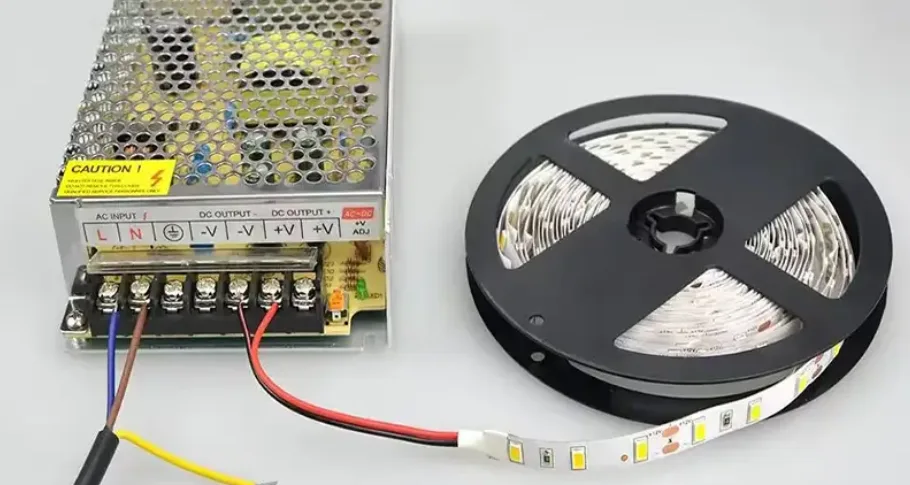

The accompanying transformers, or LED drivers, are designed to match the electrical requirements of our strips with high efficiency (up to 92%), stable constant voltage (12V or 24V DC output), and built-in protections against overvoltage, overcurrent, and overheating. Our drivers comply with international safety standards including UL, CE, and RoHS, ensuring reliability and longevity.

Beauty STC is committed to quality control throughout the manufacturing process. Our LED strips and transformers undergo rigorous testing for lumen maintenance, thermal performance, and lifespan—rated up to 50,000 hours under normal operating conditions. With strict adherence to ISO 9001 standards and in-house R&D capabilities, Beauty STC provides lighting solutions that combine superior photometric performance with long-term durability and safety.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen is strategically situated within the Jiangmen National High-Tech Industrial Development Zone, leveraging the region’s robust industrial infrastructure and skilled labor pool. The factory occupies a dedicated space of approximately 20,000 square meters, designed specifically for efficient, high-volume LED lighting production with a strong emphasis on quality control and process automation. This facility serves as a primary hub for our global OEM and ODM operations, particularly focused on flexible LED strip lights and associated power solutions.

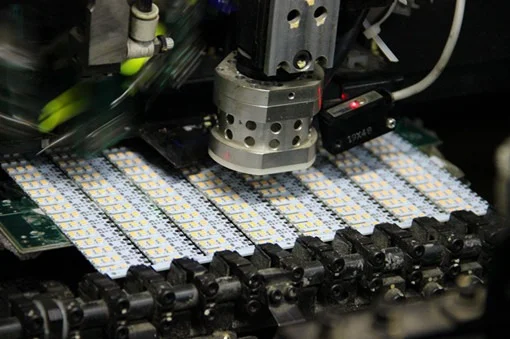

The Surface Mount Technology (SMT) production line represents the core of our manufacturing capability for LED strips. We operate multiple state-of-the-art Yamaha YSM20 and YSM10 high-speed placement machines. These systems feature advanced multi-vision alignment, enabling precise placement of components down to the 01005 package size with an accuracy of ±25μm. The lines are configured for dual-lane operation, significantly boosting throughput for standard and custom strip orders. Integrated automated optical inspection (AOI) stations are positioned immediately post-reflow to detect and correct soldering defects in real-time. Material handling is further optimized through automated guided vehicles (AGVs) feeding reels to the SMT lines, minimizing manual intervention and ensuring consistent component supply. This high-precision SMT capability is essential for producing reliable, high-density LED strips with uniform light output and long operational life.

Rigorous aging and reliability testing are fundamental to our quality assurance process at the Jiangmen plant. We maintain a dedicated aging test area equipped with multiple large-scale environmental chambers capable of simultaneously subjecting over 500 LED strip and transformer units to controlled stress conditions. Our standard aging protocol involves a continuous 72-hour burn-in test at an elevated temperature of 50°C, simulating extended operational life under demanding conditions. Each test chamber is outfitted with comprehensive monitoring systems that track voltage, current, luminous flux, and color temperature in real-time, logging data for every batch. Any unit exhibiting performance drift beyond strict tolerances or failure during this period is automatically flagged for root cause analysis. This analysis utilizes thermal imaging cameras and electrical parametric testers to identify potential weaknesses in components, solder joints, or design before products reach customers, ensuring only units meeting our stringent reliability standards are shipped.

Beauty STC possesses extensive OEM capabilities specifically tailored for LED strip lights and transformers, fully supported by the Jiangmen factory’s integrated processes. For LED strips, we offer complete customization covering flexible PCB width, LED density (ranging from 30 LEDs/m to 120 LEDs/m), color temperature options (2700K to 6500K), CRI values (80+ to 95+), input voltage (12V, 24V, 110V, 220V), and various IP ratings (IP20, IP65, IP67). Clients can specify unique cutting lengths, connector types, reel packaging, and branding. Our transformer OEM service includes custom design and manufacturing of both constant voltage (for standard strips) and constant current drivers, supporting power ranges from 15W to 300W. We accommodate specific requirements for efficiency levels (meeting DOE VI, ERP, etc.), dimming protocols (TRIAC, 0-10V, DALI, PWM), enclosure materials, and safety certifications (UL, CE, SAA, PSE). The Jiangmen facility enables true end-to-end OEM management, from initial technical consultation and prototyping through volume production, stringent aging validation, and final kitting/packaging under the client’s brand, all while adhering to global compliance standards.

Application Scenarios

LED strips and transformers are widely used across various commercial and hospitality environments including hotels, malls, and offices due to their flexibility, energy efficiency, and aesthetic appeal. In hotels, LED strips are commonly installed in guest rooms to highlight headboards, under cabinets, or along cove ceilings to create ambient lighting. They are also used in corridors, lobbies, and restrooms to provide soft, welcoming illumination. In malls, LED strips enhance architectural features, accentuate signage, and illuminate display windows or walkways, contributing to visual appeal and safety. Offices utilize LED strips for task lighting under shelves, in reception areas, or along staircases and hallways to improve visibility while maintaining a modern, professional look.

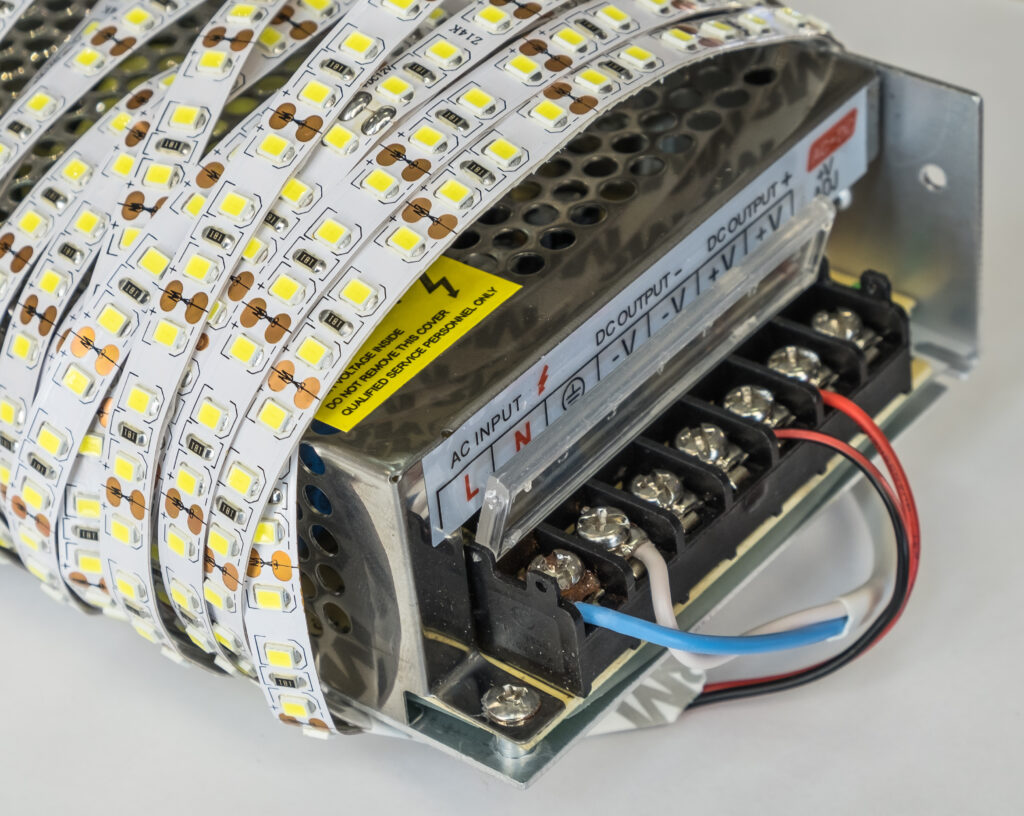

When installing LED strips and transformers, proper planning is essential. First, determine the total power consumption of the LED strip by calculating the wattage per meter multiplied by the total length. Select a transformer—also known as an LED driver—with a capacity that exceeds the total load by at least 20% to ensure reliable performance and longevity. Always use a constant voltage transformer (typically 12V or 24V DC) that matches the voltage requirement of the LED strip. Install the transformer in a well-ventilated, accessible location to prevent overheating and allow for maintenance. Ensure all electrical connections are secure and insulated, and use connectors or soldering for reliable joints. For long runs, consider feeding power from both ends to avoid voltage drop, which can cause dimming at the far end. In humid or outdoor areas, use IP65 or higher-rated waterproof LED strips with appropriately rated enclosures for the transformer. Finally, follow local electrical codes and safety standards, and when in doubt, consult a licensed electrician for installation.

Why Choose Beauty STC Lighting

Beauty STC delivers engineered LED strip and transformer solutions designed for reliability and performance in demanding applications. Our integrated systems ensure optimal voltage stability, eliminate flicker, and maximize the lifespan of your lighting installations. As your manufacturing partner, we provide custom engineering support, rigorous quality control, and scalable production to meet your specific project requirements.

Partner with Beauty STC to access dependable, high-efficiency lighting components backed by our technical expertise. We streamline your supply chain with consistent quality and responsive collaboration from prototype to full-scale production.

Email [email protected] today to discuss your LED strip and transformer needs. Our engineering team is ready to support your project with tailored solutions and dedicated partnership.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.