Article Contents

Industry Insight: Type A Vs Type B Led Tube

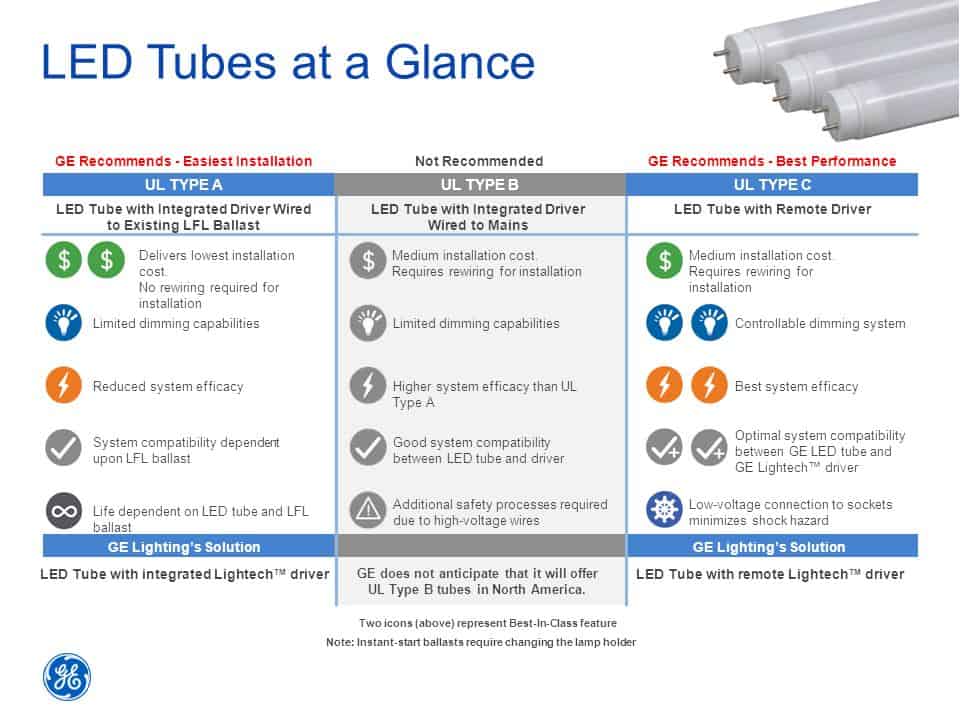

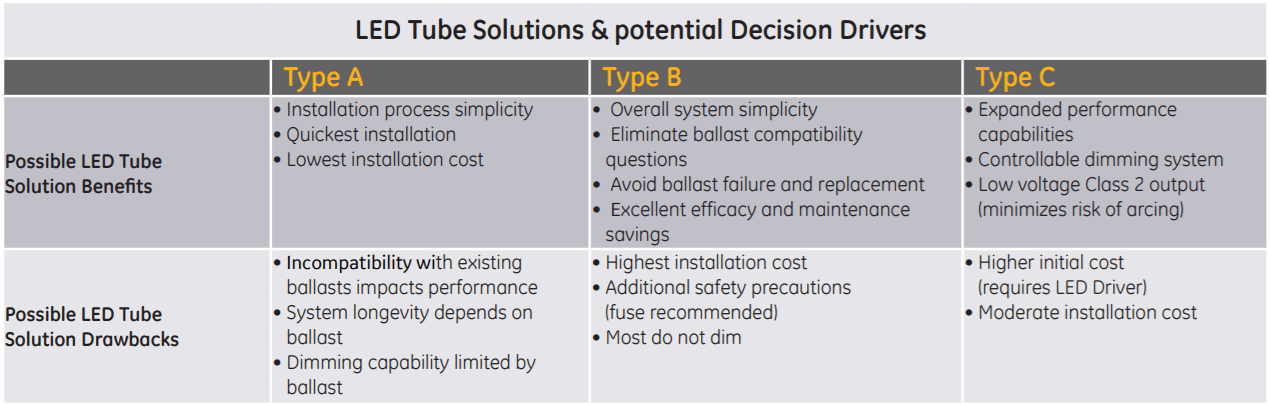

In the evolving landscape of commercial and industrial lighting, the transition from traditional fluorescent tubes to LED technology has become a cornerstone of energy efficiency and operational cost savings. Among the most critical considerations in this shift is the distinction between Type A and Type B LED tube lights—two primary wiring configurations that dictate compatibility, installation requirements, and long-term reliability. Type A tubes operate with existing fluorescent ballasts, offering a plug-and-play upgrade path, while Type B tubes require ballast bypass and direct line-voltage wiring, delivering greater energy savings and longer lifespan by eliminating ballast dependency. As facility managers and electrical contractors navigate these options, compliance with safety and performance standards such as ETL and CE becomes paramount to ensure code adherence and product reliability in demanding environments.

Since 1998, Beauty (STC) Manufacturing Co., Ltd. has been at the forefront of LED lighting innovation, engineering high-performance solutions tailored for commercial and industrial applications. With a steadfast commitment to quality, safety, and sustainability, Beauty STC delivers LED tube lighting that meets rigorous North American and international standards, including ETL and CE certifications. Our expertise in both Type A and Type B LED tube technologies enables businesses to make informed, future-ready lighting decisions that enhance illumination, reduce maintenance, and lower total cost of ownership across warehouses, manufacturing plants, office buildings, and retail spaces.

Technical Specs & Certifications

Type A and Type B LED tubes represent fundamentally different approaches to retrofitting fluorescent fixtures, with significant implications for efficiency, performance, and reliability. Understanding these distinctions is critical for specifying high-quality lighting solutions, particularly where metrics like lumens per watt, high CRI, and environmental protection are prioritized. At Beauty STC, we engineer both types to exceed industry benchmarks while ensuring robustness and longevity.

Type A LED tubes, also known as plug-and-play or ballast-compatible tubes, operate by utilizing the existing fluorescent ballast in the fixture. This introduces inherent inefficiencies as energy is lost within the ballast itself, typically reducing overall system efficacy by 10-15% compared to direct AC operation. Consequently, Type A tubes generally achieve 120-140 lumens per watt in practical installations, even when the LED component alone might suggest higher potential. Achieving CRI >90 is feasible with premium phosphor blends, but thermal management within the tube can be challenging due to space constraints from ballast compatibility requirements, potentially affecting color consistency over time. Most Type A tubes are rated IP20, as they rely on the fixture housing for environmental protection and are not designed for direct exposure to dust or moisture. A critical vulnerability is ballast dependency; incompatible, aging, or failing ballasts cause flicker, reduced output, or complete failure, negating the expected energy savings and lifespan.

Type B LED tubes, or direct-wire/ballast-bypass tubes, eliminate the ballast entirely by connecting line voltage directly to the LED driver integrated within the tube. This removal of ballast losses is the primary reason Type B tubes consistently deliver superior efficacy, typically ranging from 140-160 lumens per watt in high-performance implementations. At Beauty STC, our Type B tubes achieve 145-155 lm/W while maintaining CRI values of 95-98 across 3000K to 4000K color temperatures, utilizing advanced multi-phosphor technology to ensure exceptional color fidelity with R9 values >90. The elimination of the ballast allows for optimized thermal design within the tube, often incorporating aluminum PCBs and strategic heat sinking, which stabilizes lumen maintenance and CRI performance over the rated life. While standard Type B tubes are also typically IP20 for enclosed fixtures, the direct-wire design inherently reduces potential ingress points. For demanding environments, Beauty STC offers specialized Type B variants with enhanced sealing, achieving IP65 ratings suitable for damp locations like parking garages or industrial washdown areas, though this requires careful gasketing and driver encapsulation not found in basic retrofit tubes.

Beauty STC distinguishes itself through rigorous quality control and engineering focus. Our LED tubes undergo extended burn-in testing and thermal stress validation to ensure consistent lm/W output and CRI stability well beyond 50,000 hours. We utilize premium 6063 aluminum heat sinks, high-efficiency constant-current drivers with 0-10V dimming capability, and strict binning for color consistency. Unlike generic alternatives, Beauty STC tubes feature robust surge protection (10kV+) and are fully compliant with UL 1598C and IEC 63002, ensuring safety and reliability in critical applications. Our commitment to high CRI without sacrificing efficiency stems from proprietary optical designs that minimize photon loss in the phosphor conversion process. Crucially, all Beauty STC tubes are engineered for minimal lumen depreciation, maintaining over 90% of initial output at 25,000 hours, directly supporting the lm/W claims throughout the product lifecycle. This holistic approach to quality ensures that the specified technical performance—whether for Type A in simple retrofits or Type B in high-efficiency, high-CRI applications—is reliably achieved in real-world installations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and well-equipped facility specializing in the production of high-quality LED lighting products. Strategically located in the Guangdong province, the Jiangmen factory benefits from strong industrial infrastructure and proximity to key supply chain networks, enabling efficient manufacturing and export operations.

The factory is equipped with advanced Surface Mount Technology (SMT) production lines, which are essential for the precise and reliable assembly of LED components onto printed circuit boards. These SMT machines ensure high-speed placement of small LED chips, drivers, and other electronic elements with excellent accuracy and consistency. The use of automated optical inspection (AOI) systems further enhances quality control by detecting soldering defects or component misalignments in real time, ensuring that only defect-free boards proceed to the next stage of production.

A critical part of the manufacturing process at the Jiangmen facility is the aging test procedure. Completed LED tube lights undergo rigorous aging tests, typically lasting 24 to 72 hours under controlled conditions. During this period, the lights operate continuously at rated voltage and temperature to identify early failures or performance inconsistencies. This process significantly improves product reliability and longevity, ensuring that only stable and durable LED tubes are shipped to customers.

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities, allowing customization according to client specifications. This includes producing LED tubes to meet different technical and design requirements, such as the distinction between Type A and Type B LED tubes. For Type A LED tubes, the factory manufactures plug-and-play solutions that work with existing fluorescent ballasts, integrating internal drivers compatible with the ballast system. These are ideal for customers seeking easy retrofit installations. For Type B LED tubes, Beauty STC produces ballast-bypass or direct-wire LED tubes that require rewiring the fixture but offer higher efficiency and longer lifespan. The factory supports customization in voltage, color temperature, lumen output, and mechanical dimensions to meet diverse market needs.

Overall, the Jiangmen factory combines advanced automation, stringent quality assurance, and flexible OEM services to deliver reliable and tailored LED lighting solutions, positioning Beauty STC as a trusted partner for global lighting brands and distributors.

Application Scenarios

Understanding the distinction between Type A and Type B LED tubes is critical for optimal performance, safety, and longevity in commercial lighting retrofits. Type A tubes operate directly with the existing fluorescent ballast, functioning as a direct replacement. Type B tubes require the ballast to be completely bypassed, wiring line voltage directly to the tube sockets. The choice significantly impacts installation complexity, energy savings, and maintenance requirements across different environments.

For hotels, prioritize Type B LED tubes in high-traffic, hard-to-access areas like lobbies, hallways, and parking garages. The permanent ballast removal eliminates a common failure point, reducing maintenance calls significantly—a major advantage where guest satisfaction hinges on uninterrupted lighting and minimizing disruptive repairs. Use Type A tubes cautiously only in guest room closets or low-usage storage areas where ballast failure is less critical, but recognize that the ballast continues to consume 5-10% extra energy and remains a potential fire risk if aged. Never install Type A tubes in guest rooms themselves; ballast hum or flicker would directly impact guest experience.

In malls and retail environments, Type B is overwhelmingly the superior choice for all general lighting applications including main corridors, food courts, and high-bay ceiling fixtures. The substantial energy savings from eliminating ballast losses (typically 15-20% per fixture) directly improve operational costs in these large, always-on spaces. The reliability of Type B is essential under constant use and high ambient temperatures common in retail settings. Type A tubes should be strictly limited to temporary storefront displays or vendor kiosks where fixtures are frequently changed by non-electrician staff, leveraging their plug-and-play simplicity. Avoid Type A in any mall common area due to the unacceptably high risk of ballast failures causing frequent, costly maintenance disruptions.

Offices present the clearest case for Type B dominance. Install Type B tubes universally in open-plan workspaces, private offices, conference rooms, and server rooms. The consistent light quality without ballast-induced flicker reduces eye strain and supports productivity, while the elimination of ballast energy waste delivers rapid ROI on the slightly higher initial installation labor cost. Type A tubes have virtually no place in modern office retrofits; even in break rooms or janitorial closets, the long-term reliability and energy savings of Type B outweigh the minor installation speed benefit of Type A.

Regarding installation, critical tips differ fundamentally by type. For Type A installations, always verify ballast compatibility with the specific LED tube model—many fail prematurely with older or incompatible ballasts. Physically inspect ballasts for swelling, leaks, or burn marks; replace any suspect unit before installing Type A tubes. Never mix LED and fluorescent tubes in the same multi-lamp fixture as it stresses the ballast. For Type B installations, absolute adherence to safety protocols is non-negotiable: confirm power is OFF at the circuit breaker using a multimeter, not just the wall switch. Completely remove the ballast and starter (if present), then rewire sockets to direct line voltage following the tube manufacturer’s diagram precisely—reversing line and neutral at the sockets is a common, dangerous error. Use only shunted tombstone sockets rated for line voltage on both pins; non-shunted sockets will cause immediate tube failure. Always install new, UL-listed sockets during Type B retrofits as old fluorescent sockets degrade. Crucially, label the fixture internally “NO BALLAST” and “LED TUBE ONLY” to prevent future incorrect tube installation. STC strongly recommends Type B retrofits performed by licensed electricians; the minor cost difference versus potential fire hazards or voided insurance makes this essential for commercial liability. Remember that Type B tubes offer superior lumen maintenance and longer rated life (50,000+ hours) compared to Type A, making the professional installation a sound long-term investment.

Why Choose Beauty STC Lighting

Discover the key differences between Type A and Type B LED tubes to make an informed lighting upgrade decision. At Beauty (STC) Manufacturing Co., Ltd., we specialize in high-performance, energy-efficient LED lighting solutions tailored to your needs. Whether you’re retrofitting fluorescent fixtures or designing a new lighting system, our expert team is here to guide you. Partner with Beauty STC for reliable, code-compliant, and cost-effective LED tube lighting. For technical support or product inquiries, contact us at [email protected] and let us help you illuminate smarter.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.