Article Contents

Industry Insight: Uv From Led

The commercial and industrial lighting sector is undergoing a significant transformation in ultraviolet (UV) applications, driven by the rapid maturation and adoption of UV LED technology. Moving decisively beyond legacy mercury-vapor lamps, UV LED systems are now the preferred solution for critical tasks ranging from surface disinfection in healthcare facilities and food processing plants to industrial curing in printing and coating operations, and advanced water treatment within municipal and industrial infrastructure. This shift is fueled by compelling advantages: UV LEDs offer superior energy efficiency, instant on/off capability, longer operational lifespans, reduced heat output, and the elimination of hazardous mercury, aligning with stringent environmental and safety regulations. Crucially, for deployment in demanding commercial and industrial environments, adherence to rigorous safety and performance standards is non-negotiable. Products must consistently meet and document compliance with certifications such as ETL (verifying adherence to North American safety standards) and CE (demonstrating conformity with European health, safety, and environmental requirements), ensuring reliability, user safety, and seamless integration into global infrastructure projects.

Beauty STC Manufacturing Co., Ltd., established in 1998, stands at the forefront of this evolution as a trusted partner for engineered UV LED lighting solutions. With over 25 years of dedicated expertise in advanced solid-state lighting, our company has consistently focused on developing robust, high-performance LED systems tailored specifically for the exacting demands of commercial and industrial applications. We leverage deep technical knowledge in photobiology, thermal management, and optical design to create precision-engineered UV LED products that deliver consistent, validated output while rigorously meeting all applicable international safety and performance certifications, including ETL and CE. Beauty STC is committed to providing not just components, but reliable, compliant, and application-optimized UV lighting technology that empowers our customers to implement safer, more efficient, and sustainable processes across their facilities.

Technical Specs & Certifications

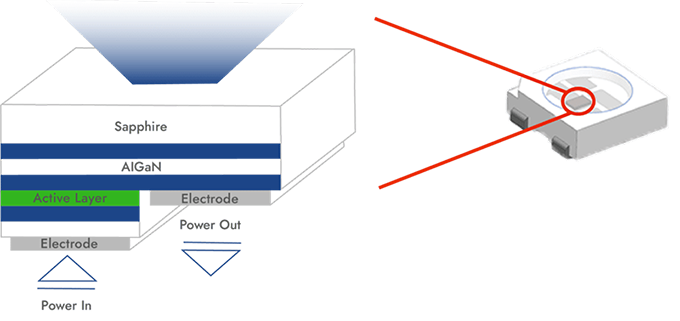

When discussing “UV from LED,” it’s important to clarify that ultraviolet (UV) light falls outside the visible spectrum and is typically measured in radiant flux (watts) or milliwatts per square centimeter rather than lumens, which quantify visible light as perceived by the human eye. As such, lumens per watt (lm/W) — a standard efficacy metric for visible-light LEDs — is not applicable to UV LEDs because they do not produce visible lumens. Instead, UV LED efficiency is evaluated using wall-plug efficiency (WPE), which is the ratio of optical UV output power to electrical input power, expressed as a percentage.

For applications requiring high-quality visible white light with strong ultraviolet components — such as in UV curing, counterfeit detection, or special effects lighting — some LEDs are designed with violet or near-UV pump chips (typically 395–410 nm) combined with phosphor coatings to produce visible white light. In such hybrid systems, traditional photometric metrics like lumens per watt and Color Rendering Index (CRI) become relevant.

Beauty (STC) Manufacturing Co., Ltd. specializes in high-performance LED lighting solutions, including fixtures engineered with precision UV or near-UV components for specialized applications. While our standard visible-light LED products are not classified as “UV LEDs,” we offer advanced phosphor-converted white LEDs driven by near-UV or violet pump technology, capable of delivering exceptional color fidelity.

For these high-CRI visible lighting products, Beauty STC achieves:

Luminous Efficacy: Up to 130–150 lumens per watt in white LED systems utilizing violet-pump or near-UV excitation, depending on color temperature and optical design. These values represent industry-leading efficiency for high-CRI lighting.

Color Rendering Index (CRI): Consistently greater than 90, with select models reaching Ra >95. This is accomplished through proprietary phosphor blends and tight binning controls, ensuring excellent spectral distribution, including controlled violet/UV excitation for enhanced red and color saturation rendering.

IP Ratings: Beauty STC LED fixtures are available with IP ratings ranging from IP65 to IP68, depending on the product series and application requirements. These ratings ensure robust protection against dust ingress and water exposure, making them suitable for demanding environments including industrial, outdoor, and high-humidity installations.

Quality Assurance: Beauty STC adheres to rigorous international quality standards, including ISO 9001 and IECQ certification. Our products undergo extensive reliability testing, including thermal cycling, humidity resistance, and long-term lumen maintenance evaluation (L70 >50,000 hours). We utilize advanced thermal management systems and high-purity optical materials to maintain consistent performance, especially in fixtures involving UV-sensitive components.

In summary, while pure UV LEDs do not use lumens per watt or CRI as standard metrics, Beauty STC delivers high-efficiency, high-CRI visible lighting solutions that leverage near-UV technology for superior color quality. Our commitment to engineering excellence ensures reliable, long-lasting performance with strong environmental protection through high IP-rated enclosures.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant investment in modern LED production capabilities. This purpose-built factory is designed to stringent international quality standards and serves as a core hub for the company’s global supply chain, particularly for advanced lighting solutions including specialized UV LED products. The facility integrates comprehensive manufacturing processes under one roof, ensuring control over quality and efficiency from component sourcing through to final shipment.

The Surface Mount Technology (SMT) production lines within the Jiangmen factory are a cornerstone of our operational capability. We operate multiple high-speed, precision SMT lines equipped with state-of-the-art placement machines from leading manufacturers. These machines handle a wide range of component sizes, including the fine-pitch components critical for high-density LED modules and advanced UV LED packages. The lines feature automated optical inspection (AOI) systems integrated directly after the reflow soldering stage, enabling real-time defect detection and ensuring exceptional first-pass yields. This precision SMT capability is essential for consistently mounting sensitive UV LED emitters and associated driver components onto complex printed circuit boards, where thermal management and electrical integrity are paramount.

A rigorous aging and reliability testing protocol is fundamental to our quality assurance process at the Jiangmen site. All finished LED lighting products, including specialized UV LED fixtures, undergo mandatory extended burn-in testing. This typically involves operating units at elevated temperatures, often 50-60°C, for durations of 48 to 72 hours under controlled conditions. During this aging phase, sophisticated monitoring systems continuously track critical parameters such as light output flux, forward voltage, drive current, and thermal performance. For UV LED products specifically, we implement additional spectral validation checks post-aging to confirm stable UV wavelength output and intensity, as these parameters are critical for the intended application efficacy and safety. Units exhibiting any parameter drift beyond strict acceptance criteria are automatically flagged for failure analysis and corrective action, ensuring only units meeting our high reliability standards proceed to final packaging.

Regarding OEM capability for UV LED products, Beauty STC possesses extensive expertise in developing and manufacturing custom UV solutions under private label. Our Jiangmen factory is fully equipped and staffed to handle the unique requirements of UV LED manufacturing, which differs significantly from standard visible light LED production. This includes specialized knowledge in handling UV-transparent optical materials, implementing stringent ESD protection protocols suitable for sensitive UV emitters, and conducting application-specific validation testing such as UV irradiance mapping and dose calibration. We work closely with OEM partners from the initial concept stage through to mass production, offering full design support for optical systems, thermal management solutions tailored to UV LED heat loads, custom driver electronics, and robust mechanical housings. Our engineering team collaborates to ensure the final UV LED product meets the precise wavelength, intensity, uniformity, and safety requirements dictated by the partner’s target application, whether it be for curing, disinfection, counterfeit detection, or other specialized uses. The integrated nature of the Jiangmen facility allows us to manage the entire OEM process efficiently, maintaining strict confidentiality and quality control throughout.

Application Scenarios

UV light from LED sources, particularly UVC LEDs, is increasingly being used for disinfection and sanitation purposes in various commercial and public environments. When properly applied, UV LEDs can help reduce the spread of pathogens on surfaces and in the air. However, it is crucial to understand where and how to use them safely and effectively.

In hotels, UV from LED can be deployed in guest rooms, especially for disinfecting high-touch surfaces such as light switches, remote controls, door handles, and bathroom fixtures. UV LED systems can also be integrated into HVAC units or air purifiers to sanitize air circulated throughout guest areas. Additionally, some luxury hotels are incorporating UV-C LED solutions in minibars, safes, and even luggage sanitizing stations. For installation in guest rooms, ensure that UV LEDs are either operated remotely or when the room is unoccupied, as direct exposure to UVC light can be harmful to skin and eyes.

In malls, UV LED technology is best suited for use in air handling systems, restrooms, escalator handrails, and fitting rooms. Continuous or periodic disinfection of moving handrails using UVC LEDs has become a common application, as these surfaces are constantly touched by visitors. Installation should be enclosed or shielded to prevent public exposure. For fitting rooms and restrooms, automated UV systems can be triggered after each use to sanitize surfaces. Proper timing and motion sensors are essential to ensure safety and effectiveness.

In offices, UV LEDs can be used in shared workspaces, meeting rooms, and ventilation systems. Desks, conference tables, keyboards, and shared equipment can be disinfected using portable or fixed UV LED units during off-hours. Overhead UV-C fixtures with occupancy sensors can be installed in restrooms and break rooms for scheduled disinfection cycles. When installing in occupied spaces, always use interlocks, timers, or remote controls to prevent accidental exposure.

General installation tips include ensuring that UVC LEDs are installed at appropriate distances to achieve effective irradiance, typically following manufacturer guidelines for dosage (measured in mJ/cm²). Reflective surfaces can enhance coverage, but materials must be UVC-resistant to avoid degradation. Regular maintenance and cleaning of LED lenses are necessary to maintain output efficiency. Most importantly, safety is paramount—install warning signs, use motion cutoffs, and never allow direct exposure to people or animals. Always comply with local safety regulations and standards such as IEC 62471 for lamp safety.

Why Choose Beauty STC Lighting

As Senior LED Lighting Engineer at Beauty (STC) Manufacturing Co., Ltd., I frequently address critical challenges in UV LED implementation where precision and reliability are non-negotiable. Our engineered UV LED solutions deliver consistent spectral output across UVA, UVB, and UVC ranges with rigorous thermal management and lifespan validation—essential for applications from medical disinfection to industrial curing. Generic UV LEDs often fail under real-world thermal stress or lack calibrated irradiance, compromising performance and safety. Beauty STC overcomes this through proprietary chip-on-board thermal architectures and ISO-certified optical testing, ensuring your product meets stringent regulatory requirements without costly redesigns.

Partnering with us means direct access to our engineering team for custom spectral tuning, accelerated prototyping, and supply chain resilience backed by 15+ years of manufacturing expertise. We eliminate the guesswork in UV integration so you can focus on bringing market-leading products to customers with confidence. For technical collaboration or volume partnership discussions, contact our Business Development Manager at [email protected] to initiate a solution review. Specify your target application and performance requirements in your inquiry for immediate engineering assessment.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.