Article Contents

Industry Insight: Addressable Led Strips

Addressable LED strips have emerged as a transformative solution in commercial and industrial lighting, offering unprecedented control, flexibility, and energy efficiency. Unlike traditional static lighting systems, addressable strips allow individual control of each LED or segment, enabling dynamic color tuning, precise lighting effects, and seamless integration with smart building management systems. This level of customization is particularly valuable in environments such as retail spaces, warehouses, manufacturing facilities, and architectural installations, where lighting must adapt to operational needs, enhance visibility, or create immersive brand experiences. With growing demand for energy-efficient and future-ready lighting infrastructure, addressable LED technology is setting new standards in performance and scalability.

Compliance with international safety and performance standards is critical in commercial and industrial applications. Reputable addressable LED strips are rigorously tested and certified to meet ETL and CE requirements, ensuring they adhere to North American and European safety, electromagnetic compatibility, and environmental regulations. These certifications not only validate product reliability but also provide assurance to facility managers, contractors, and end users that the lighting systems will perform safely and consistently in demanding environments.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED innovation for over two decades. Specializing in high-performance lighting solutions for commercial and industrial sectors, Beauty STC combines advanced engineering with stringent quality control to deliver addressable LED strips that meet the highest global standards. With a strong commitment to R&D, sustainable manufacturing, and customer-driven design, the company continues to empower modern facilities with intelligent, durable, and code-compliant lighting technology.

Technical Specs & Certifications

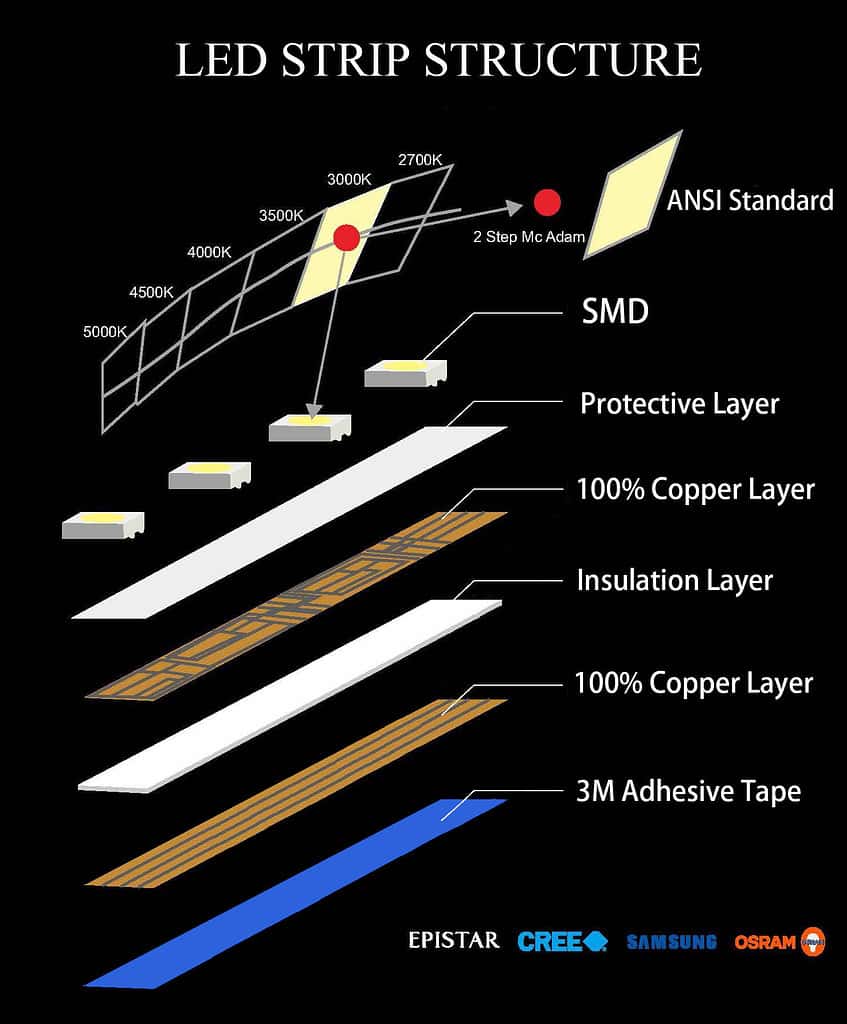

Addressable LED strips represent a sophisticated category of programmable lighting where individual LEDs or small segments can be controlled independently for dynamic color and intensity effects. At Beauty STC Manufacturing Co., Ltd., our engineering focus prioritizes performance, reliability, and color fidelity for professional applications. Regarding lumens per watt (lm/W), our high-end addressable strips utilizing Samsung LM301B or similar premium diodes achieve 140-160 lm/W under standard operating conditions at 24V DC. This efficiency stems from low forward voltage drop characteristics of modern diodes, optimized driver ICs like the SM15026 or WS2815 that minimize power loss in data transmission, and 2-ounce copper PCBs ensuring effective thermal management. It is critical to note that actual lm/W varies with drive current, ambient temperature, and the specific chipset; our 24V strips inherently outperform 5V variants in efficiency due to reduced resistive losses over longer runs.

For Color Rendering Index (CRI), Beauty STC mandates Ra >90 across our professional addressable product lines, with R9 (saturated red) consistently exceeding 50 to ensure vibrant, accurate color reproduction essential for retail, hospitality, and architectural lighting. This is achieved through rigorous LED binning processes using high-CRI phosphor-converted diodes, spectral optimization to fill gaps in the visible spectrum, and factory calibration of white channels. We avoid cost-cutting measures like skipping R9 testing or using low-CRI diodes, as our strips undergo spectrophotometer validation per ANSI C78.377 standards. The result is consistent, museum-grade color accuracy even during dynamic color-changing sequences, critical for applications where visual integrity cannot be compromised.

IP ratings for addressable strips require careful differentiation between the strip itself and connector points. Beauty STC offers IP20 for indoor dry locations, IP65 for protected outdoor use with silicone coating over components, and fully potted IP67 variants where the entire assembly—including solder joints and ICs—is encapsulated in flexible silicone. Our IP67 strips withstand temporary submersion (1 meter for 30 minutes) and resist dust ingress per IEC 60529, achieved through precision injection molding of silicone jackets and hermetic sealing of end caps. Importantly, we engineer connector systems separately rated to IP67 to prevent common failure points; many competitors overstate IP ratings by testing only the strip body while neglecting vulnerable connection interfaces. All IP-rated products undergo 72-hour salt spray testing and thermal cycling validation.

Beauty STC’s quality assurance is embedded in every manufacturing phase. We implement automated optical inspection (AOI) for solder joint integrity, 100% functional testing of data protocols, and accelerated life testing validating 50,000 hours at 70°C per IES LM-80. Our strips feature 10mm-wide PCBs with double-layer copper for thermal stability, preventing lumen depreciation below L70 during lifespan. Unlike generic suppliers, we enforce strict tolerance controls: color consistency within a 3-step MacAdam ellipse, forward voltage variance under ±0.1V, and data signal integrity over 10-meter runs without amplification. All products comply with IEC 60598-1 safety standards and bear CE, RoHS, and REACH certifications. This commitment ensures that when project specifications demand reliability in demanding environments—from humid retail displays to exterior architectural facades—Beauty STC strips deliver sustained photometric performance without field failures. For critical projects, we provide LM-79 test reports and spectral power distribution data upon request to validate all technical claims.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key manufacturing hubs. The Jiangmen factory is designed to support high-volume production of LED lighting products with a strong emphasis on quality control, automation, and customization capabilities.

At the core of the production process are advanced SMT (Surface Mount Technology) lines, which utilize state-of-the-art SMT machines for precise and efficient placement of components onto PCBs. These machines ensure high-density mounting of LEDs, resistors, ICs, and other surface-mount devices on flexible and rigid strips, particularly critical for addressable LED strip manufacturing. The SMT lines are fully automated, featuring pick-and-place machines with high-speed placement accuracy, reflow soldering ovens with temperature profiling, and automated optical inspection (AOI) systems to detect soldering and component placement defects early in the process.

The factory incorporates comprehensive aging and reliability testing procedures to ensure product durability and performance consistency. After assembly, addressable LED strips undergo rigorous aging tests, typically running at full power for 24 to 72 hours under controlled temperature and humidity conditions. This process helps identify early failures and ensures that only stable, high-performing products reach customers. In addition to aging, the facility conducts electrical performance testing, waterproof testing (for applicable models), and color consistency verification using integrating spheres and spectrometers.

Beauty STC has strong OEM and ODM capabilities tailored specifically for addressable LED strips. The company supports custom designs including various PCB widths, LED densities (such as 30, 60, or 144 LEDs per meter), IC types (e.g., WS2812B, WS2815, SK6812), voltage configurations (5V, 12V, or 24V), and waterproofing options (from bare strips to IP65/IP67/IP68 ratings). Clients can provide their own specifications for branding, packaging, reel lengths, and even firmware programming for unique control protocols. The factory’s engineering team works closely with customers to develop prototypes, validate designs, and scale to mass production efficiently.

Overall, the Jiangmen factory combines automation, stringent quality assurance, and flexible customization to serve global clients seeking reliable and innovative addressable LED strip solutions under OEM arrangements.

Application Scenarios

Addressable LED strips offer unique advantages in commercial environments due to their individual pixel control, enabling dynamic color changing, precise animations, and zoning without physical segmentation. In hotels, they excel in lobbies for creating immersive welcome experiences with flowing color transitions across feature walls or reception desks, enhancing architectural elements like curved ceilings or water features. Corridor cove lighting benefits significantly by using gentle, programmable wayfinding cues—such as soft directional pulses guiding guests toward elevators or exits—that avoid harsh static lighting while maintaining safety compliance. Guest room applications include under-bed or headboard accents for customizable ambiance, though care must be taken to ensure controls are intuitive for guests and low-glare during nighttime use. High-end suites may utilize them for synchronized lighting scenes matching entertainment systems, but avoid overuse in primary workspaces to prevent visual fatigue.

Malls leverage addressable strips for high-impact visual storytelling in entrance atriums, where large-scale video-mapped installations on staircases or central sculptures create social media-worthy focal points that drive foot traffic. Escalator handrails with embedded strips can pulse directionally during promotions or emergencies, while retail storefronts use them for dynamic signage integration—highlighting sale items with chasing effects or color shifts that refresh without physical banner changes. Feature walls in food courts benefit from subtle, slow-moving gradients that enhance the dining atmosphere without overwhelming patrons, though brightness must be carefully tuned to avoid interfering with meal presentation. Critical consideration includes robust power and data management; large mall installations often require multiple synchronized controllers with Ethernet backbone networks to prevent signal latency across expansive areas.

Offices primarily deploy addressable strips in non-work zones to boost well-being without disrupting productivity. Reception areas use them for branded color schemes that shift subtly throughout the day—cooler tones in morning, warmer in afternoon—to signal time passage and reinforce corporate identity. Break rooms or collaboration zones incorporate gentle, circadian-rhythm-aligned transitions to aid mental resets, while executive boardrooms might feature discreet under-table accents for video conference backdrop enhancement. Avoid direct sightlines in open-plan workspaces; if used in suspended ceiling coves, limit animations to very slow, low-saturation changes to prevent distraction. Conference room perimeter lighting can provide unobtrusive occupancy indicators (e.g., soft glow when booked), but static white operation should remain the default for meeting functionality.

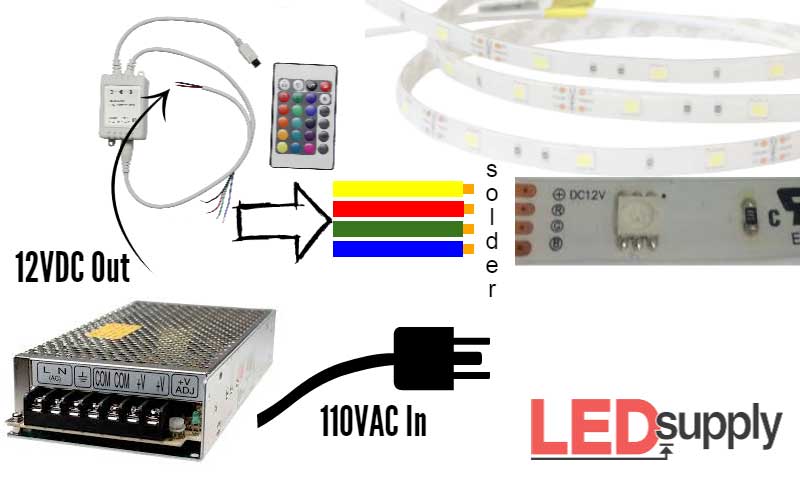

Installation requires meticulous planning to ensure reliability in commercial settings. Always calculate power injection points rigorously—5V strips typically need injection every 5 meters for dense installations, while 12V versions allow up to 10 meters but suffer more pronounced voltage drop at strip ends. Use dedicated constant-voltage power supplies rated at 20% above calculated load, with separate circuits for data controllers to prevent electrical noise interference. Data lines must be shielded twisted-pair cable (e.g., DMX512 cable) run parallel to but not bundled with power wiring, with ferrite cores at both ends to suppress RF interference common in malls with heavy Wi-Fi traffic. For thermal management, never install strips directly against flammable surfaces; use aluminum channels with ventilation slots even in concealed coves, as continuous high-brightness operation in hotels can exceed 60°C ambient. Finally, implement robust grounding—commercial buildings require single-point grounding of all controller chassis and power supply grounds to building steel to avoid ground loops causing flicker, especially critical in steel-framed offices. Test all segments with a dedicated signal generator before final concealment to isolate data errors early.

Why Choose Beauty STC Lighting

Discover the future of dynamic lighting with addressable LED strips from Beauty STC. As a trusted leader in innovative LED solutions, we offer high-quality, customizable addressable strips designed for seamless integration in architectural, commercial, and creative applications. Partner with Beauty STC to access advanced technology, reliable performance, and expert technical support.

To learn more or request a sample, contact us today at [email protected]. Let’s illuminate your next project together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.