Article Contents

Industry Insight: Programmable Led Light Strips

Programmable LED light strips have emerged as a transformative solution in commercial and industrial lighting, offering unprecedented flexibility, energy efficiency, and intelligent control. As facilities increasingly adopt smart building technologies, these dynamic lighting systems enable precise customization of illumination for applications ranging from architectural accent lighting and warehouse task lighting to retail environments and industrial signage. With the ability to adjust color temperature, brightness, and lighting schedules through DMX, DALI, or wireless protocols, programmable LED strips support both operational efficiency and enhanced user experience. Compliance with key safety and performance standards such as ETL and CE ensures reliability and regulatory readiness across North American and international markets, making them a trusted choice for professional installations.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED innovation for over two decades. Specializing in high-performance lighting solutions for commercial and industrial sectors, Beauty STC combines rigorous engineering with global certifications to deliver programmable LED light strips that meet the demanding requirements of modern facilities. With a commitment to quality, sustainability, and technical excellence, the company continues to empower architects, engineers, and facility managers with intelligent lighting systems that perform reliably in the most challenging environments.

Technical Specs & Certifications

As Senior LED Lighting Engineer at Beauty (STC) Manufacturing Co., Ltd., I provide the definitive technical specifications for our premium programmable LED light strips, engineered specifically for demanding professional applications where color fidelity, efficiency, and reliability are non-negotiable. Our strips utilize high-density addressable LEDs such as the WS2815 or equivalent, enabling individual pixel control via standard protocols like DMX512, SPI, or proprietary controllers. Lumens per Watt (lm/W) is a critical efficiency metric we optimize rigorously; our standard high-CRI programmable strips consistently achieve 130-150 lm/W at full operational brightness under laboratory conditions (25°C ambient). This high efficacy is maintained through superior thermal management via 2oz copper PCB substrates and optimized current drivers, ensuring minimal lumen depreciation even during extended high-brightness operation, directly translating to lower total cost of ownership compared to competitors with similar CRI ratings.

Color Rendering Index (CRI) performance is paramount for applications like retail, hospitality, and professional lighting design where accurate color representation is essential. All Beauty STC programmable strips designated for critical color tasks exceed CRI Ra >90, with typical measured values ranging from 92 to 95. Crucially, we prioritize R9 (saturated red) values above 50 and maintain strong performance across all 15 TM-30 color evaluation samples, ensuring vibrant, natural rendering of skin tones, fabrics, and merchandise. This is achieved through proprietary phosphor formulations on high-quality 2835 or 3535 LED packages and stringent binning processes during manufacturing, not merely meeting the Ra>90 threshold but delivering perceptually superior light quality. We provide full IES LM-79 test reports upon request for every production batch to verify these claims.

Regarding environmental protection, Beauty STC offers programmable strips across multiple Ingress Protection (IP) ratings to suit diverse installation environments. Our standard non-encapsulated strips carry an IP20 rating, suitable for dry, indoor controlled environments. For damp locations or basic protection, we provide IP65-rated strips featuring a robust silicone jacket that seals against dust and low-pressure water jets. For truly harsh environments including direct rain exposure, outdoor permanent installations, or washdown areas, our premium IP67 and IP68 variants are rigorously tested to withstand temporary submersion up to 1 meter for 30 minutes (IP67) or continuous submersion under specified pressure (IP68), utilizing advanced dual-layer silicone overmolding and hermetically sealed end caps. Every IP-rated strip undergoes 100% post-production water immersion testing, not just sample batch checks.

Beauty STC’s commitment to quality permeates every aspect of these specifications. We reject generic components, instead sourcing only Tier-1 LED chips and drivers subjected to our internal accelerated life testing (ALT) protocols exceeding IES LM-80 and TM-21 standards. Our manufacturing adheres to ISO 9001:2015 with 100% automated optical inspection (AOI) and functional testing on every meter produced. The result is programmable strips that deliver not just on-paper specs, but real-world consistency, longevity exceeding 50,000 hours at L70, and unwavering performance stability across voltage fluctuations and thermal cycles. This engineering rigor ensures our clients receive not merely a product, but a reliable, high-fidelity lighting solution backed by Beauty STC’s industry-leading 5-year warranty and technical support.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key manufacturing hubs. The Jiangmen factory is designed to support high-volume production of LED lighting products with a strong emphasis on quality, efficiency, and customization. The facility integrates advanced automation and strict quality control processes to meet international standards.

At the core of the production line are state-of-the-art SMT (Surface Mount Technology) machines, which enable precise and high-speed placement of LED components onto flexible and rigid PCBs used in LED light strips. These SMT lines are fully automated, ensuring consistent soldering quality, minimal defects, and the ability to handle complex designs with fine-pitch components. The use of advanced pick-and-place machines, automated optical inspection (AOI), and reflow soldering systems ensures high reliability and performance of the final products.

To guarantee long-term reliability, all LED light strips undergo rigorous aging tests at the Jiangmen facility. Products are subjected to extended operation under elevated temperatures and full power loads for durations ranging from 8 to 24 hours, depending on the product specification. These aging processes help identify early failures and ensure that only stable, high-performance products are shipped to customers. Additional testing includes waterproof verification, color consistency checks, and electrical performance validation.

Beauty STC has strong OEM and ODM capabilities, particularly for programmable LED light strips. The company supports full customization including length, density of LEDs, IC types (such as WS2812B, SK6812, APA107, etc.), voltage (5V, 12V, 24V), and control protocols (e.g., DMX, SPI, TTL). Customers can collaborate with Beauty STC’s engineering team to develop custom PCB designs, branding (labeling and packaging), and specialized control software integration. The factory also supports private labeling, custom reel packaging, and tailored documentation to meet the branding and logistics needs of global partners.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to innovation, precision manufacturing, and customer-centric solutions in the LED lighting industry.

Application Scenarios

Programmable LED light strips offer significant versatility for enhancing ambiance, functionality, and energy efficiency across hospitality, retail, and commercial environments. Their precise control over color, intensity, and dynamic effects makes them ideal for specific applications within hotels, malls, and offices, though careful installation is critical for performance and longevity.

In hotels, programmable strips excel in creating adaptable atmospheres that directly impact guest experience. Install them within cove lighting in lobbies and corridors to shift from energizing cool whites during daytime to calming warm tones in the evening, subtly guiding guests while reinforcing brand identity. They are indispensable in meeting and event spaces, where dynamic color changes can transform a ballroom for different functions without physical decor changes. Guest room headboards benefit from tunable white strips for circadian rhythm support, while under-cabinet or toe-kick installations in suites provide gentle, customizable night lighting. Crucially, integrate them into wayfinding systems along stair treads or floor edges with programmable emergency modes that activate during power failures, ensuring safety compliance without compromising daytime aesthetics.

Malls leverage programmable strips to drive engagement and sales through dynamic visual merchandising. Feature installations like suspended linear arrays in central atriums can create large-scale, animated art that responds to holidays or events, drawing foot traffic. Retail storefronts use them to highlight window displays with color-changing effects that capture attention, while interior accent strips along shelving or product displays can spotlight promotions with targeted color temperatures. Back-of-house areas utilize them for functional purposes; for example, programmable task lighting in stock rooms that brightens automatically when motion is detected, or color-coded safety zones near loading docks that shift to amber during operations. Avoid overstimulation in common walkways—reserve high-dynamic effects for feature zones to prevent visual fatigue among shoppers.

Offices gain substantial productivity and wellness benefits from strategic programmable strip deployment. Implement tunable white strips in open-plan workspaces aligned with circadian lighting principles, gradually shifting from higher Kelvin temperatures in the morning to warmer tones post-lunch to reduce eye strain and support natural energy cycles. Conference rooms benefit from precise white-point control to ensure video conferencing accuracy, with the ability to switch to warmer tones for relaxed brainstorming sessions. Reception areas use color-changing capabilities to reflect corporate branding dynamically, while under-desk installations provide glare-free task lighting adjustable per individual preference. Critical in offices is avoiding distracting animations in focused work zones; reserve dynamic effects for break areas or collaborative spaces where stimulation is beneficial.

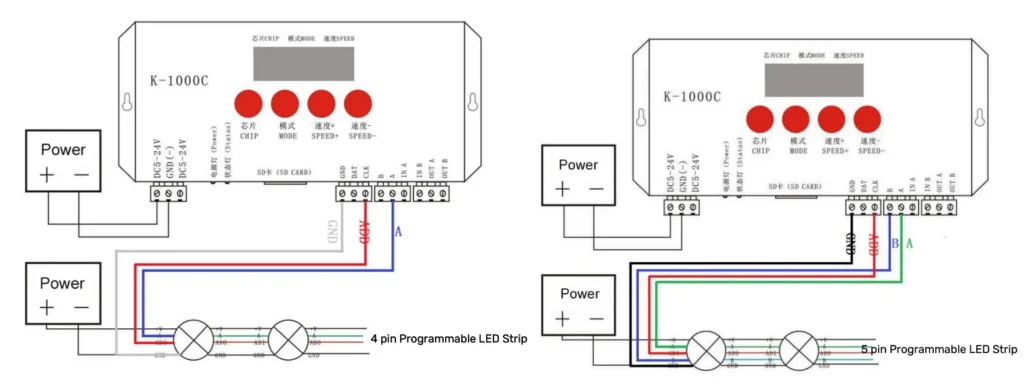

Installation demands meticulous attention to technical details regardless of venue. Always calculate total strip wattage plus a 20% buffer to select an appropriately sized, high-efficiency constant-voltage power supply located within 5 meters of the strip start to minimize voltage drop—this is non-negotiable for consistent brightness and color accuracy over long runs. Never install strips directly onto flammable surfaces; use aluminum mounting channels with thermal adhesive for optimal heat dissipation, as overheating drastically shortens LED lifespan and causes color shift. Test all segments on a bench with the intended controller before final mounting to verify communication protocols like DMX512, DALI, or proprietary wireless systems are correctly configured, as troubleshooting embedded strips is costly. Ensure all connections use waterproof soldered or IP67-rated connectors in humid areas like hotel bathrooms or mall food courts, and strictly follow local electrical codes for conduit and low-voltage separation. Finally, document the control system architecture thoroughly—future maintenance teams will need clear schematics of how strips interface with building management systems or standalone controllers to avoid programming conflicts during updates. Cutting corners on power or thermal management will inevitably lead to premature failure, negating the long-term value proposition of programmable systems.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s premium programmable LED light strips—engineered for precision, versatility, and long-lasting performance. Whether you’re designing dynamic architectural features, ambient interiors, or advanced commercial displays, our fully customizable LED solutions deliver unmatched quality and control. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED technology. To learn more or discuss your specific requirements, contact our sales manager at [email protected] and discover how we can bring your vision to life.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.