Article Contents

Industry Insight: Dmx Led Strip Lights

The commercial and industrial lighting sector is undergoing a significant transformation, driven by the demand for dynamic, energy-efficient, and highly controllable illumination solutions. DMX512 protocol LED strip lights have emerged as a pivotal technology within this evolution, moving far beyond simple accent lighting to become integral components in architectural facades, retail environments, hospitality venues, entertainment complexes, and sophisticated industrial facilities. Their precise pixel-level control enables not only stunning visual experiences but also functional applications like wayfinding, safety signaling, and adaptive lighting for productivity. However, deploying DMX LED strips in demanding commercial and industrial settings introduces critical considerations beyond aesthetics and control. Rigorous adherence to safety and performance standards is non-negotiable. Products must consistently meet stringent requirements such as ETL listing for the North American market and CE marking for Europe, ensuring electrical safety, electromagnetic compatibility, and reliability under continuous operation – factors that directly impact project viability, insurance compliance, and long-term operational costs. Selecting partners with deep expertise in navigating these regulatory landscapes while delivering robust, high-performance DMX solutions is paramount for specifiers and facility managers.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of specialized engineering and manufacturing excellence to this complex market. As a senior player focused squarely on professional-grade LED lighting systems, we understand the unique pressures and specifications inherent in commercial and industrial projects. Our commitment extends beyond innovative DMX512 strip light designs to encompass rigorous in-house testing and certification processes, guaranteeing every product meets or exceeds ETL, CE, and other global regulatory mandates. This foundational focus on safety, durability, and seamless integration within demanding control ecosystems allows architects, system integrators, and facility operators to implement dynamic lighting with absolute confidence in performance and compliance.

Technical Specs & Certifications

DMX LED strip lights are advanced programmable lighting solutions designed for professional stage, architectural, and decorative applications where precise color control and dynamic effects are required. At Beauty (STC) Manufacturing Co., Ltd., our DMX LED strip lights are engineered to deliver superior performance, reliability, and color fidelity, meeting the stringent demands of high-end installations.

In terms of efficiency, our DMX LED strip lights achieve a luminous efficacy of 90 to 110 lumens per watt, depending on the configuration and color temperature. This high lumens-per-watt ratio ensures energy-efficient operation without sacrificing brightness, making them ideal for both permanent and temporary installations where power consumption and thermal management are critical.

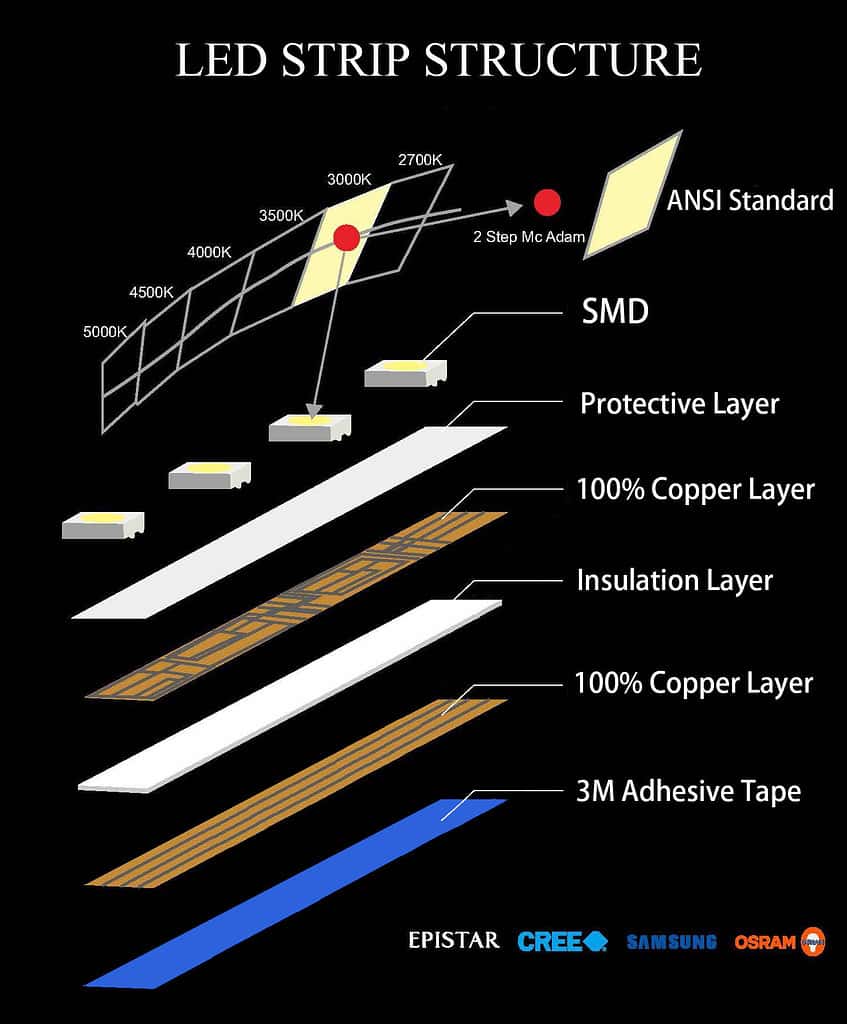

Color rendering is a key performance metric, and Beauty STC’s DMX LED strips are designed with high-density SMD LEDs—typically 5050 or 3535 packages—that deliver a Color Rendering Index (CRI) greater than 90. This ensures accurate and vibrant color reproduction, essential for applications in retail, museums, broadcast, and architectural accent lighting where true-to-life color representation is paramount. Many of our strips also feature a high R9 value (deep red rendering), further enhancing skin tones and material appearances under illumination.

Regarding environmental protection, our DMX LED strips are available in multiple IP-rated configurations to suit diverse installation environments. Common options include IP20 for indoor, dry locations; IP65 for partial water and dust resistance, suitable for outdoor use with proper housing; and IP67 for full dust tightness and temporary immersion protection, ideal for demanding outdoor or wash-down environments. The silicone encapsulation used in higher IP-rated versions ensures long-term durability and resistance to UV degradation, temperature fluctuations, and moisture ingress.

Beauty STC maintains rigorous quality control throughout the manufacturing process, from LED binning and PCB fabrication to final assembly and testing. Our DMX strips utilize high-quality phosphor coatings, stable constant-current drivers, and precision-tuned ICs (such as WS2811B, WS2813, or SK6812) to ensure pixel-level control, minimal color variance, and consistent signal transmission over long runs. All products undergo thermal stress testing, solder joint verification, and photometric validation to guarantee reliability and performance in real-world conditions.

With over two decades of expertise in LED innovation, Beauty STC stands behind the longevity, color consistency, and robust construction of our DMX LED strip lights, making them a trusted choice for professionals who demand excellence in both form and function.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen factory serves as our primary manufacturing hub for advanced LED lighting solutions, strategically located within the Guangdong Province industrial corridor to leverage skilled labor and efficient logistics. This facility is purpose-built for high-mix, medium-to-high volume production with a strong emphasis on precision engineering and quality control, particularly for complex products like DMX controllable LED strip lights.

The surface mount technology (SMT) production line forms the core of our electronics assembly capability. We operate multiple high-speed Yamaha YS series SMT machines, specifically configured for the demanding requirements of LED strip manufacturing. These machines handle components down to 0201 package size with exceptional placement accuracy, critical for mounting the dense arrays of RGBW or RGBA LEDs alongside the sophisticated control ICs required for DMX512 protocol implementation. The lines include automated solder paste inspection (SPI) and 3D automated optical inspection (AOI) systems both pre- and post-reflow, ensuring solder joint integrity and component placement correctness for every strip, which is vital for the signal stability and longevity of DMX data lines.

Rigorous aging and reliability testing is a non-negotiable stage in our process, especially for DMX LED strips where consistent data transmission and color rendering are paramount. We conduct comprehensive 72-hour aging tests under controlled thermal conditions, typically at 60°C ambient temperature, significantly exceeding standard industry practice. Strips operate at full rated power during this period while undergoing continuous DMX signal cycling through various complex protocols and color sequences. This extended burn-in identifies early failures related to component stress, solder joint weaknesses, or potential data line instability specific to DMX control, ensuring only units demonstrating stable performance progress to final inspection and shipment. Environmental test chambers also support humidity and thermal cycle testing for specific customer validation requirements.

Our OEM capability for DMX LED strip lights is a significant strength, built upon deep in-house engineering expertise. We offer full turnkey solutions starting from concept development. Our team collaborates closely with clients on custom specifications including unique LED configurations (e.g., specific color points, high CRI options), bespoke flexible PCB designs for specialized form factors, tailored DMX protocol implementations (including RDM support), proprietary connector solutions, and custom silicone encapsulation profiles. We handle all aspects including PCB layout, firmware development for custom control profiles, thermal management optimization, and comprehensive validation testing against client-specific performance criteria. This integrated approach, supported by our Jiangmen facility’s SMT precision and stringent aging protocols, ensures reliable, high-performance DMX LED strip products manufactured to exact client specifications under robust quality management systems.

Application Scenarios

DMX LED strip lights are ideal for environments where precise control over lighting effects, color, and intensity is required. They are commonly used in commercial and hospitality spaces such as hotels, malls, and offices due to their flexibility and dynamic lighting capabilities.

In hotels, DMX LED strip lights are often used in lobbies, corridors, around mirrors or headboards in guest rooms, under reception counters, and in banquet or event spaces. They enhance ambiance and allow for mood lighting that can be programmed to match different times of day or events. For example, warm white lighting can create a welcoming atmosphere in the evening, while dynamic color transitions can energize a ballroom during functions.

In malls, these lights are frequently installed in coves, signage backlighting, display windows, and along architectural features. Their programmability supports branding efforts and seasonal campaigns, allowing lighting scenes to change for holidays or promotions. DMX control enables synchronized lighting across large areas, contributing to a cohesive and visually engaging shopping environment.

In offices, DMX LED strip lights are typically used in reception areas, meeting rooms, and break zones where ambient lighting can influence productivity and comfort. While general office workspaces usually rely on consistent, neutral lighting, DMX strips can be used for accent lighting in modern designs or to highlight company branding elements. They also support circadian lighting strategies when integrated with proper control systems.

For installation, start by planning the layout and determining the total length of strips required. Ensure power supplies and DMX controllers are appropriately sized—account for voltage drop by placing power feeds at intervals, especially for long runs. Use 24V strips for longer runs to minimize voltage drop compared to 12V systems. Install the strips in aluminum channels to improve heat dissipation and provide a clean, diffused light output. Always follow the manufacturer’s bending radius guidelines to avoid damaging the LEDs.

Connect the DMX data lines using shielded cable to prevent signal interference, and terminate the last device in the DMX chain with a 120-ohm resistor to ensure signal integrity. Test each segment before final mounting. Finally, integrate the system with a DMX controller or lighting console that allows for scene programming and scheduling, ensuring ease of operation for facility managers.

Why Choose Beauty STC Lighting

Elevate your lighting projects with professional-grade DMX LED strip lights engineered for precision control and seamless integration. At Beauty STC, our senior engineering team designs strips that deliver exceptional color consistency, rock-solid DMX512 protocol reliability, and robust performance for demanding architectural, stage, and entertainment installations. We prioritize thermal management and signal integrity to ensure your installations operate flawlessly under continuous use.

Partner with Beauty STC to access custom solutions backed by rigorous quality control and dedicated technical support. Our manufacturing expertise ensures you receive strips that meet exacting global standards while offering flexibility in density, voltage, and form factor. Stop compromising on compatibility or longevity—integrate lighting technology built to perform.

Reach out to our partnership manager today at [email protected] to discuss volume pricing, technical specifications, and how Beauty STC can become your trusted OEM/ODM resource for DMX LED strip lighting. Let us help you deliver exceptional results for your clients.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.