Article Contents

Industry Insight: Strip Led Dimmer

In the evolving landscape of commercial and industrial lighting, energy efficiency, control flexibility, and regulatory compliance are paramount. The strip LED dimmer has emerged as a critical component in modern lighting systems, enabling precise luminance control, reduced energy consumption, and enhanced ambiance in environments ranging from warehouses and manufacturing facilities to retail spaces and office buildings. As businesses increasingly adopt LED technology for its longevity and low operational costs, the demand for reliable, code-compliant dimming solutions has grown significantly. Leading the charge in this space are industry standards such as ETL and CE certifications, which ensure that dimming products meet rigorous safety, performance, and electromagnetic compatibility requirements essential for commercial deployment.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED control solutions since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established a strong reputation for delivering high-quality, certified dimming technologies designed specifically for the demands of commercial and industrial applications. Their strip LED dimmers combine advanced circuitry, robust construction, and full compliance with ETL and CE standards, offering system integrators and facility managers a dependable choice for scalable, efficient lighting control. As the industry moves toward smarter, more sustainable infrastructure, Beauty STC continues to set benchmarks in performance and reliability.

Technical Specs & Certifications

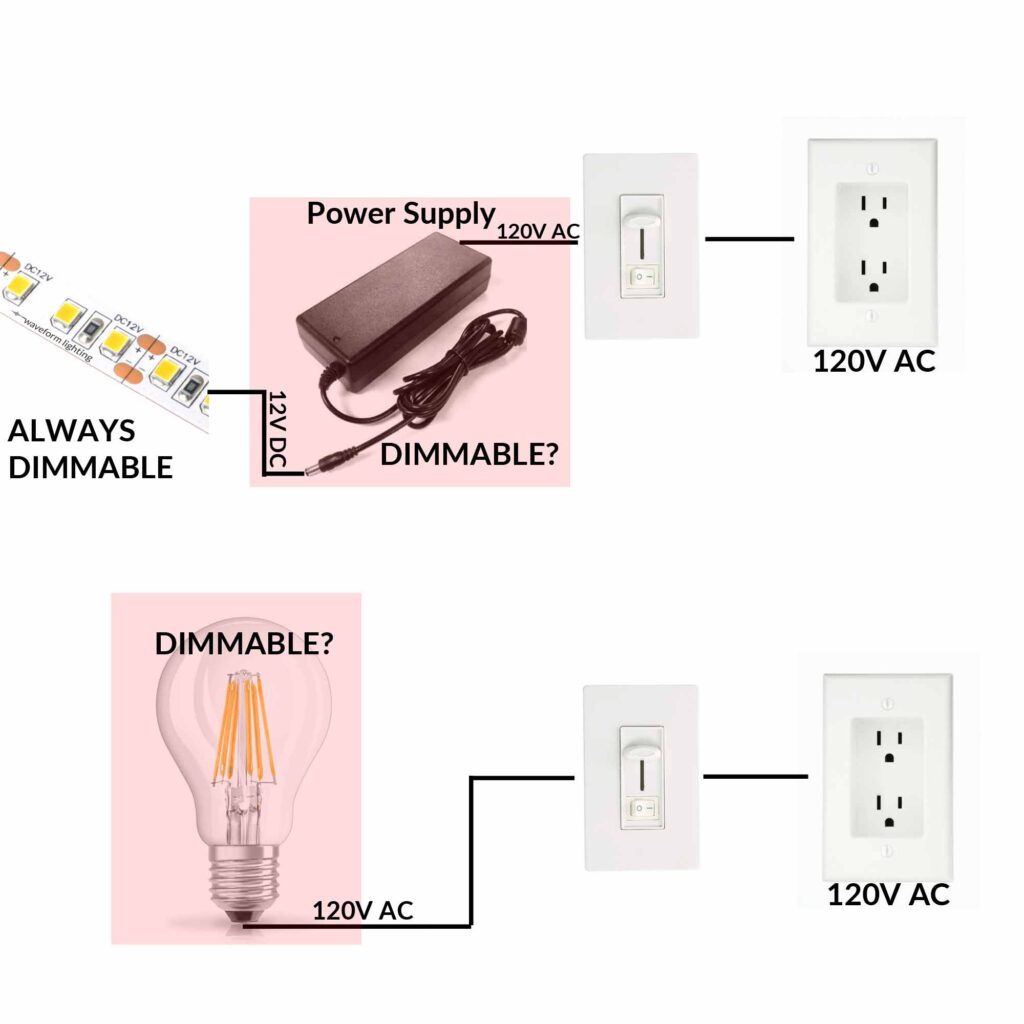

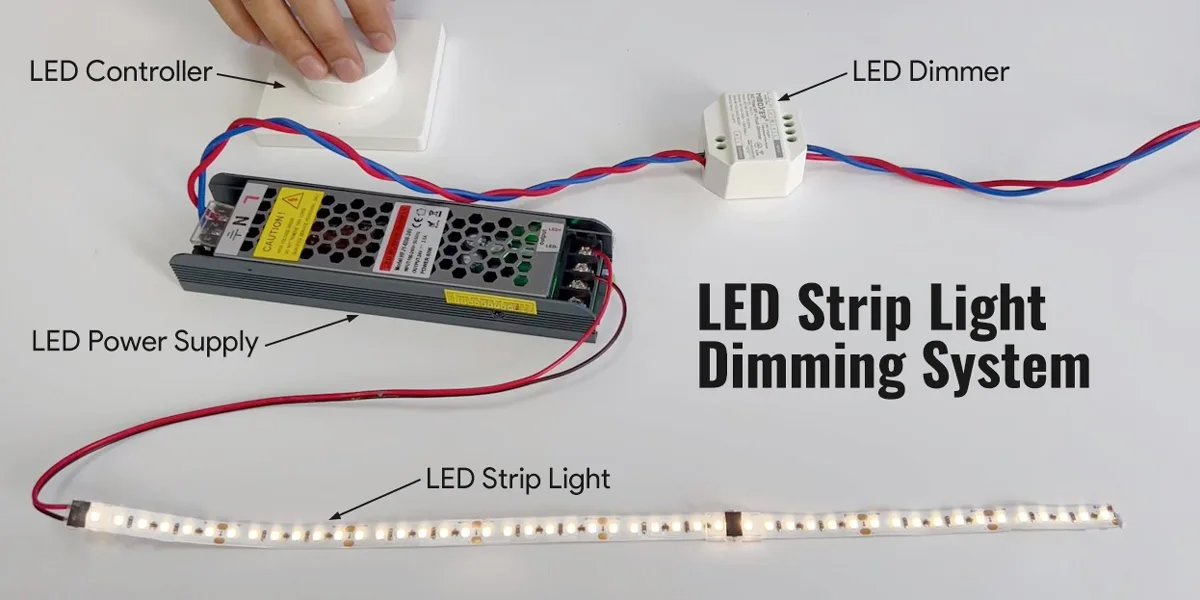

Beauty STC Manufacturing Co., Ltd. provides precision-engineered LED strip lighting systems where the dimmer is a critical control component, though it is essential to clarify that lumens per watt, CRI, and IP ratings are inherent specifications of the LED strip itself, not the dimmer. The dimmer’s role is to enable smooth, flicker-free adjustment of the strip’s output while maintaining these key photometric properties. Our dimmers are rigorously validated for compatibility with high-performance strips meeting stringent efficiency, color quality, and environmental protection standards.

Lumens per watt (lm/W) is a measure of the LED strip’s efficacy, indicating how efficiently electrical power is converted to visible light. Beauty STC’s premium LED strips, designed for seamless integration with our dimmers, achieve industry-leading efficacies of 130-140 lm/W at 24V DC under standard operating conditions (25°C ambient). This high efficiency is realized through the use of advanced 2835 or 5050 SMD LEDs mounted on high-thermal-conductivity aluminum PCBs, optimized driver ICs, and proprietary phosphor formulations. These strips maintain stable efficacy across the dimming range when paired with our constant-current reduction (CCR) or pulse-width modulation (PWM) dimmers operating at frequencies >2000Hz, preventing efficiency droop at lower light levels. We ensure that efficacy claims are verified under LM-79 testing protocols at independent laboratories.

Color Rendering Index (CRI) values exceeding 90, specifically Ra >95 with R9 >90, are standard for Beauty STC’s architectural and retail-grade LED strips. Our strips utilize multi-phosphor blends and stringent binning processes to achieve exceptional color fidelity, critical for applications demanding accurate color representation such as retail displays, museums, and high-end residential spaces. When dimmed using our compatible controllers, these strips maintain consistent color temperature (with minimal shift <100K across 10%-100% dimming) and preserve high CRI values down to the lowest dimming levels. This stability is achieved through our dimmers’ precise current regulation and compatibility with strips featuring tight chromaticity binning (within 3-step MacAdam ellipse). We validate CRI using spectroradiometer measurements per ANSI C78.377 and provide full TM-30-15 reports upon request.

IP ratings define the strip’s ingress protection against dust and moisture, a critical factor for durability in challenging environments. Beauty STC offers LED strips with IP65, IP67, and IP68 ratings, all fully compatible with our corresponding IP-rated dimmers and power supplies. IP65 strips feature a flexible silicone overmold for protection against low-pressure water jets and dust, suitable for outdoor eaves or indoor wet locations. IP67 strips include a robust dual-layer silicone encapsulation, surviving temporary submersion up to 1 meter for 30 minutes. Our premium IP68 strips utilize marine-grade silicone and undergo extended submersion testing beyond 1 meter for 60 minutes, making them ideal for permanent underwater or harsh industrial use. All conformal coatings and encapsulants are UV-stable and thermally robust, maintaining integrity across -40°C to +70°C operational ranges. Crucially, our dimmers for outdoor/wet locations are housed in IP67-rated die-cast aluminum or polycarbonate enclosures with corrosion-resistant seals.

Beauty STC’s commitment to quality is embedded in every component. Our LED strips undergo 100% aging at 60°C for 24 hours prior to shipment, with strict binning for color consistency (SDCM <3). We utilize only UL-listed or equivalent safety-certified components, with drivers featuring 50,000-hour L70 lifetime ratings at 45°C ambient. Our dimmers incorporate over-temperature, over-current, and short-circuit protection, validated through 1,000+ cycle life testing. All products comply with IEC 60598, IEC 61347, and relevant regional safety standards. Backed by a 5-year limited warranty and manufactured under ISO 9001-certified processes with rigorous in-line optical and electrical testing, Beauty STC delivers systems where photometric performance, longevity, and reliability are non-negotiable. This engineering discipline ensures that high CRI, optimal efficacy, and robust environmental protection are maintained throughout the product lifecycle when integrated with our dimming solutions.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The factory is designed to support high-volume, precision LED lighting production with a strong emphasis on quality control, efficiency, and flexibility to meet diverse customer demands.

The production line is anchored by advanced SMT (Surface Mount Technology) machines that ensure precise placement of electronic components on PCBs used in LED lighting products. These high-speed SMT systems are capable of handling a wide range of component sizes and types, enabling consistent and reliable assembly of complex circuitry required for LED strips and associated control units such as dimmers. The automation of the SMT process reduces human error, increases throughput, and supports consistent product quality across batches.

To ensure long-term reliability and performance, Beauty STC implements rigorous aging tests as part of its quality assurance protocol. Finished LED strips and dimmer units undergo extended operational testing under controlled thermal and electrical conditions. This aging process typically runs for 8 to 24 hours, during which products are monitored for light output consistency, thermal behavior, and electrical stability. Any units exhibiting performance deviations are identified and removed, ensuring only fully compliant products reach customers.

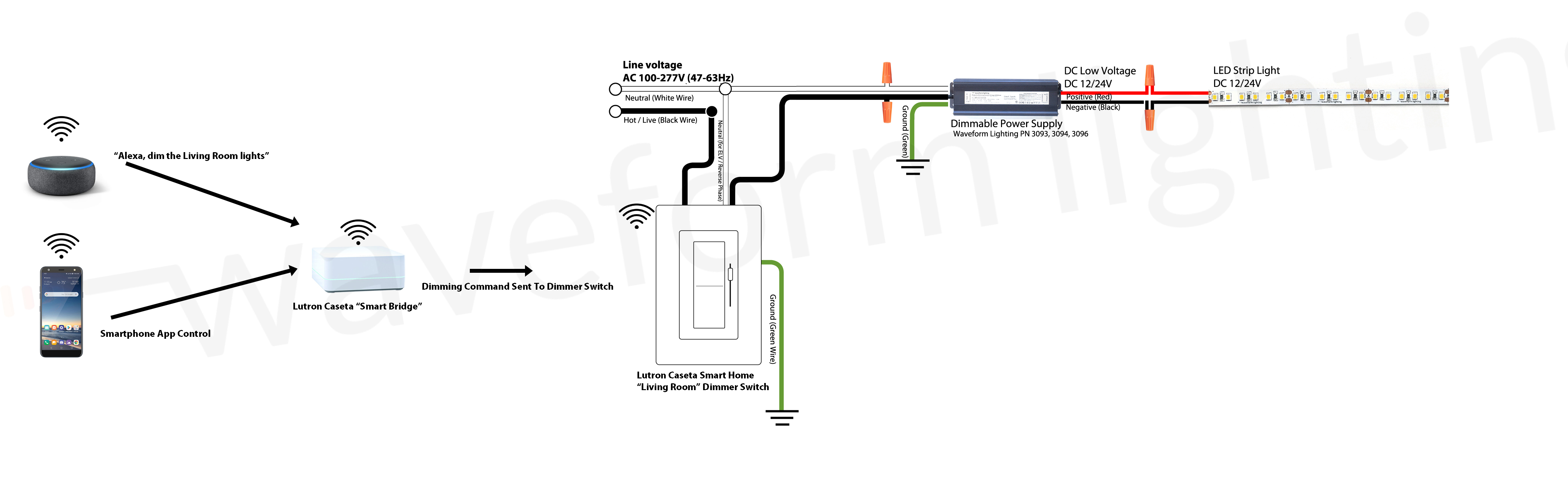

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities, particularly for integrated solutions such as ‘LED strip dimmers’. The company supports full customization, including circuit design, firmware development, enclosure branding, and packaging. Clients can provide specifications for dimming protocols (such as PWM, 0-10V, DALI, or wireless RF/Bluetooth/Zigbee), and the engineering team will develop compatible driver and control solutions. The factory can produce private-label dimmers that are seamlessly compatible with various LED strip formats, supporting both AC and DC configurations. With in-house R&D, tooling, and molding resources, Beauty STC can deliver end-to-end OEM services from prototype to mass production with short lead times and strict adherence to international standards including CE, RoHS, and UL.

Application Scenarios

Strip LED dimmers serve distinct functional and experiential purposes across commercial environments, requiring tailored application strategies. In hotels, their primary deployment occurs within guest rooms to enable personalized ambiance control over cove lighting, under-cabinet strips in minibars, and headboard accents, directly enhancing guest satisfaction through adjustable comfort lighting. Corridor and stairwell applications utilize dimmers for nighttime safety lighting, reducing illumination to 10-20% during off-peak hours to conserve energy while maintaining code-compliant visibility. High-end lobbies and banquet halls employ dimmable linear strips for architectural highlighting, allowing seamless transitions from bright event setups to subdued evening atmospheres without manual intervention.

Malls strategically implement strip LED dimmers within retail storefronts for dynamic merchandise presentation, where spotlighting key displays at full intensity during promotions then dimming peripheral areas directs customer attention and reduces visual fatigue. Common areas like food courts use dimmable perimeter cove lighting to modulate brightness according to natural daylight levels or time of day, maintaining consistent visual comfort. Elevator lobbies and transitional zones benefit from dimmers to create subtle environmental shifts between public circulation spaces and tenant-specific brand experiences, supporting wayfinding through graduated light levels.

Office environments leverage strip LED dimmers most effectively in collaborative zones and private workspaces. Under-desk task lighting strips dim to minimize screen glare during video conferences, while perimeter cove systems integrate with daylight harvesting sensors to maintain uniform illuminance on work surfaces. Executive suites utilize dimmable linear fixtures above credenzas for adjustable accent lighting during presentations. Critical installation considerations begin with verifying driver-dimmer compatibility—Beauty (STC) strongly recommends matching constant current reduction (CCR) drivers with trailing-edge dimmers for flicker-free performance below 10% output. Always calculate total load at 80% of the dimmer’s rated capacity to prevent thermal shutdown, especially with multiple parallel strips. For runs exceeding 5 meters, install dimmers at the strip’s midpoint rather than endpoints to mitigate voltage drop, using Beauty (STC)’s low-voltage amplifiers where necessary. Never daisy-chain dimmers beyond manufacturer specifications; instead, use distributed power injection with individually fused circuits. Crucially, mount dimmers in ventilated electrical boxes away from insulation to dissipate heat, and conduct a 24-hour burn-in test at minimum dimming level to identify early component failures before final commissioning. Always confirm compatibility with building management systems through dry-contact or 0-10V interfaces prior to installation.

Why Choose Beauty STC Lighting

Discover the perfect solution for your lighting needs with Beauty STC’s high-performance strip LED dimmer. Engineered for precision, reliability, and seamless integration, our dimmer offers smooth brightness control and consistent performance for residential, commercial, and industrial applications.

Partner with Beauty STC, a trusted leader in innovative LED solutions. Our team is ready to support your business with customized products, competitive pricing, and expert technical guidance.

To learn more or to start a collaboration, contact us today at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.