Article Contents

Industry Insight: Led Tape Light Transformer

The commercial and industrial LED tape lighting segment continues its robust expansion, driven by demands for energy efficiency, design flexibility, and long-term operational savings in environments ranging from retail displays and hospitality venues to warehouses and manufacturing facilities. At the heart of any reliable, high-performance installation lies a critical yet often underappreciated component: the LED tape light transformer, or power supply. These units are far more than simple converters; they are the essential guardians of system stability, longevity, and safety. In professional settings where uptime is paramount and electrical compliance is strictly enforced, the transformer must deliver consistent, clean power while adhering to rigorous international safety and electromagnetic compatibility standards. Certifications such as ETL (indicating compliance with North American safety standards) and CE (demonstrating adherence to European health, safety, and environmental requirements) are not optional extras but fundamental, non-negotiable requirements for market access and end-user confidence. Beauty STC, established in 1998, has dedicated over a quarter century to mastering this critical infrastructure. We engineer and manufacture precision LED power solutions specifically designed to meet the demanding performance, reliability, and certification needs of commercial and industrial lighting professionals worldwide, ensuring installations operate safely and optimally for their intended lifespan.

Technical Specs & Certifications

The LED tape light transformer, also known as an LED driver, plays a critical role in delivering stable and efficient power to LED tape lighting systems. At Beauty (STC) Manufacturing Co., Ltd., our transformers are engineered to match high-performance LED tapes, ensuring optimal brightness, color accuracy, and longevity. When paired with our premium LED tape lights, the system achieves exceptional efficiency, typically delivering 110 to 130 lumens per watt depending on the specific configuration and input voltage. This high lumens-per-watt ratio reflects our focus on energy efficiency without compromising light output.

A key feature of our recommended system is the integration with LED tapes that maintain a Color Rendering Index (CRI) greater than 90. High CRI ensures that colors appear natural and vibrant under the light, which is essential for retail, hospitality, residential, and architectural applications. Beauty STC’s LED tapes utilize high-quality phosphor coatings and bin-selected LEDs to achieve consistent color fidelity across installations, and our compatible drivers are designed to preserve this performance by minimizing current fluctuations that can affect color stability.

Regarding environmental protection, Beauty STC offers LED tape and driver solutions across multiple IP (Ingress Protection) ratings to suit diverse installation environments. For indoor dry locations, IP20-rated drivers are suitable. For damp or outdoor applications, we provide fully potted, encapsulated drivers with IP65, IP67, and even IP68 ratings. These transformers are resistant to moisture, dust, and corrosion, enabling reliable performance in bathrooms, cove lighting, outdoor signage, and landscape installations. All enclosures are constructed with durable aluminum or high-grade polycarbonate housings that dissipate heat efficiently and withstand harsh conditions.

Beauty STC is committed to superior build quality and long-term reliability. Our transformers undergo rigorous testing for surge protection, thermal management, and electrical safety, complying with international standards including UL, CE, and CCC. We utilize premium components such as high-efficiency IC controllers, low-EMI circuitry, and flame-retardant materials to ensure safe, flicker-free operation. With over two decades of expertise in LED lighting systems, Beauty STC delivers drivers that not only meet but exceed industry benchmarks for performance, durability, and compatibility with high-CRI, energy-efficient LED tape lights.

Factory Tour: Manufacturing Excellence

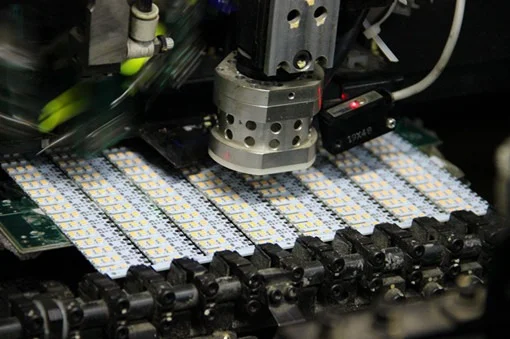

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a modern LED lighting production hub designed to meet international quality and efficiency standards. The factory leverages Jiangmen’s strategic location within Guangdong’s robust electronics supply chain ecosystem, enabling streamlined access to components and logistics infrastructure while maintaining cost-effective operations. Central to the facility’s production capability is its advanced Surface Mount Technology (SMT) line, which utilizes multiple high-speed Yamaha YS series SMT machines. These machines operate with precision placement accuracy of ±25μm and handle components as small as 0201 package sizes, critical for the compact circuitry of LED drivers and transformers. The SMT process includes fully automated solder paste printing, component placement at rates exceeding 80,000 components per hour per line, and integrated Automated Optical Inspection (AOI) systems that verify solder joint integrity and component alignment in real-time. This setup ensures consistent assembly quality for complex power supply units like LED tape light transformers, minimizing defects through closed-loop process control.

Aging and reliability testing form a rigorous cornerstone of the factory’s quality assurance protocol, particularly for power conversion products. All LED tape light transformers undergo mandatory aging procedures in controlled environmental chambers where units operate continuously at 110% of rated load for a minimum of 8 hours under elevated temperatures of 50°C. The aging racks incorporate automated monitoring systems that log output voltage stability, thermal performance, and efficiency metrics throughout the test cycle, with any unit exhibiting parameter drift beyond ±5% tolerance automatically flagged for failure analysis. This extended burn-in process effectively identifies infant mortality failures before shipment, while thermal imaging cameras document hotspot development to refine thermal management designs. The facility’s aging capacity supports concurrent testing of thousands of units weekly, aligning with production volumes while adhering to IEC 61347-2-13 safety standards for LED power supplies.

The factory demonstrates comprehensive OEM capability specifically tailored for LED tape light transformers, accommodating custom specifications from global clients. Engineering teams collaborate on transformer design modifications including input voltage ranges (90-305V AC), output configurations (12V/24V DC), power ratings (20W to 300W), and dimming compatibility (TRIAC, 0-10V, DALI). Clients receive full support from prototype development through mass production, with in-house capabilities covering magnetic component design, PCB layout optimization, and thermal simulation. Beauty STC maintains UL, CE, TÜV, and CCC certifications for standard transformer models and facilitates client-specific compliance testing through partnerships with accredited laboratories. The OEM process includes custom labeling, packaging configurations, and dedicated production lines for confidential projects, with minimum order quantities starting at 500 units to support both large-scale deployments and niche market requirements. This end-to-end manufacturing flexibility ensures transformers meet exact electrical performance criteria while integrating seamlessly with diverse LED tape systems worldwide.

Application Scenarios

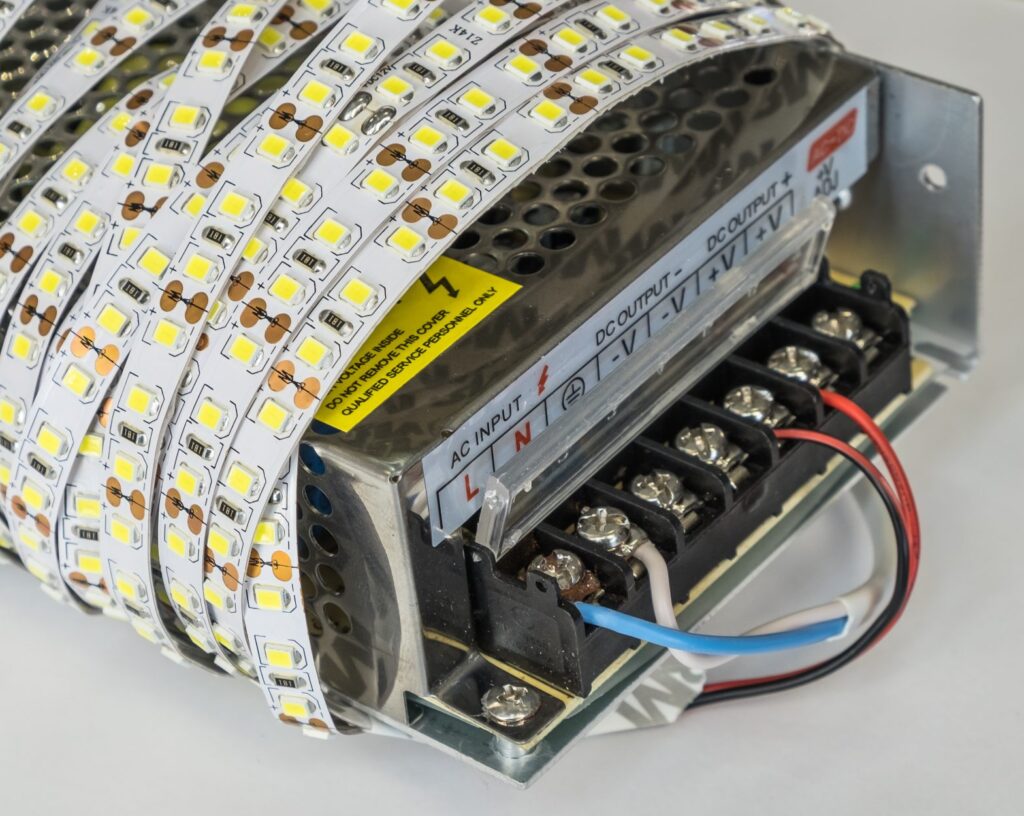

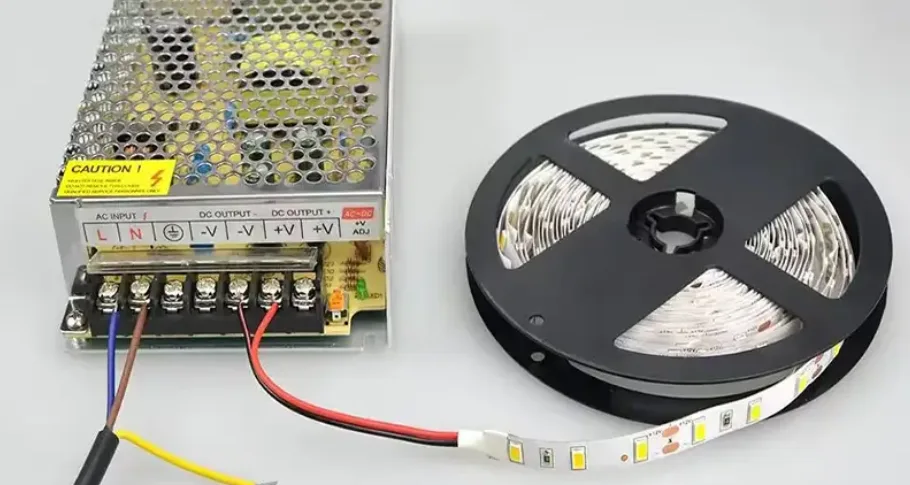

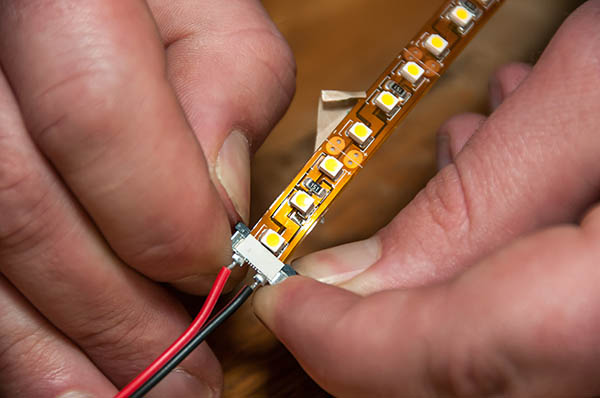

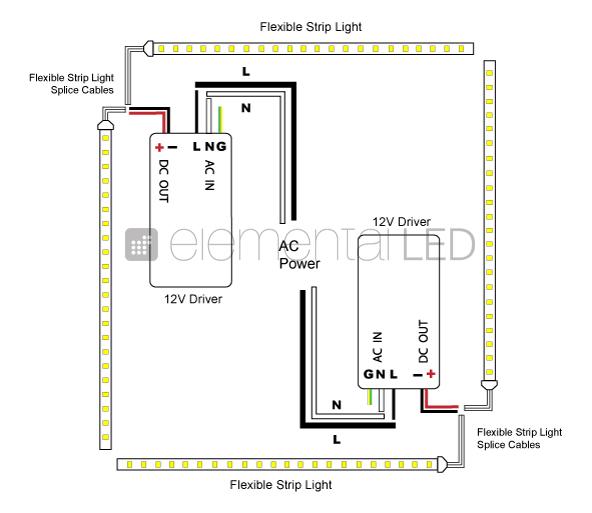

LED tape light transformers are essential components when installing LED tape or strip lights, as they convert the standard mains voltage (typically 110V or 230V AC) to the low voltage (usually 12V or 24V DC) required by most LED tapes. These transformers ensure safe and efficient operation of the lighting system. Their use is common across various commercial and hospitality environments due to the flexibility and aesthetic appeal of LED tape lighting.

In hotels, LED tape light transformers are frequently used to illuminate cove lighting in lobbies and guest rooms, under-bed or headboard lighting, wardrobe interiors, bathroom mirrors, and accent lighting in corridors or staircases. The soft, even glow enhances ambiance and supports energy-efficient design. Transformers are typically installed in accessible ceiling voids or service areas near the lighting runs to minimize voltage drop and simplify maintenance.

In shopping malls, LED tape lighting with transformers is used for cove lighting in common areas, decorative lighting in feature walls, signage backlighting, and display case illumination. The transformers should be installed in centralized electrical closets or above suspended ceilings where ventilation is adequate and access for inspection is easy. It’s important to account for longer tape runs in large spaces, which may require multiple transformers or power injection points to maintain consistent brightness.

In office environments, LED tape light transformers are used for under-cabinet lighting, task lighting in reception desks, ceiling coves for indirect lighting, and architectural feature highlighting. Offices benefit from clean, modern lighting with minimal glare. Transformers should be discreetly located in ceiling plenums or within modular partition systems, ensuring they are not exposed to dust or moisture and remain within safe operating temperatures.

Installation Tips:

Always select a transformer with sufficient power capacity—calculate the total wattage of the LED tape and add a 20% safety margin to avoid overloading. Ensure compatibility between the transformer output (12V or 24V DC) and the LED tape specifications. Use enclosed, IP-rated transformers in humid or exposed areas such as bathrooms or outdoor sections of malls. Route low-voltage wiring separately from high-voltage lines to prevent interference. Secure connections with proper connectors or soldering, and use wire nuts or terminal blocks where necessary. Provide adequate ventilation around the transformer to prevent overheating, especially in enclosed spaces. Label all transformers clearly for future maintenance. For longer tape runs, consider using a constant-voltage system with power injection or multiple transformers to avoid voltage drop and dimming at the far end. Always follow local electrical codes and use certified components suitable for the environment.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co. Ltd., I recommend partnering with us for your LED tape light transformer requirements to ensure optimal system performance and reliability. Our engineered solutions deliver precise voltage regulation, thermal management, and dimming compatibility essential for high-end architectural and commercial lighting installations.

Beauty STC provides certified, energy-efficient transformers designed specifically for seamless integration with flexible LED tape systems, minimizing flicker and extending product lifespan. We prioritize rigorous quality control and custom engineering support to meet your project specifications and regional compliance standards.

Reach out to our technical sales team today to discuss your transformer needs and discover how our partnership can enhance your lighting solutions. Contact Manager directly at [email protected] for dedicated support and technical consultation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.