Article Contents

Industry Insight: Led Strip Plug

The commercial and industrial lighting landscape continues to evolve with a growing demand for flexible, energy-efficient, and code-compliant solutions. Among the most transformative innovations in this space is the LED strip plug—a compact yet powerful component that enables quick, safe, and scalable deployment of linear LED lighting systems. Designed for applications ranging from warehouse task lighting to retail accent displays and industrial facility upgrades, plug-and-play LED strip systems offer significant advantages in installation speed, maintenance efficiency, and design adaptability. As regulatory standards become more stringent, certifications such as ETL and CE have become essential markers of safety, performance, and market compliance—ensuring these lighting solutions meet rigorous North American and international requirements.

At the forefront of this advancement is Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting technology since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established a strong reputation for delivering high-quality, code-compliant LED components designed specifically for commercial and industrial environments. The company’s commitment to innovation, durability, and global standards positions its LED strip plug solutions as reliable choices for contractors, facility managers, and lighting designers seeking performance-driven results in demanding applications.

Technical Specs & Certifications

LED strip systems require precise technical specifications to ensure performance and reliability, particularly when demanding high efficiency and color accuracy. It is critical to clarify that the term “LED strip plug” typically refers to the connector or power adapter used with LED strip lights, not the light-emitting component itself. The requested specifications—lumens per watt, CRI, and IP ratings—apply to the LED strip assembly, not the plug or connector. Beauty STC designs and manufactures LED strips meeting rigorous performance standards, with the plug/connector serving as a supporting component rated for safety and environmental protection.

Lumens per watt (lm/W) efficiency for Beauty STC’s high-CRI LED strips ranges from 110 to 130 lm/W under standard operating conditions at 25°C ambient temperature. This efficiency is achieved using 2835 or 5050 SMD LEDs driven at 18–24V DC, with thermal management integrated into the strip’s flexible PCB design. Efficiency varies based on color temperature and drive current; for instance, 2700K strips at 30mA typically achieve 115–120 lm/W, while 4000K strips reach 120–125 lm/W. Sustained output requires adherence to maximum run lengths and adequate heat dissipation, as thermal derating occurs above 45°C ambient. Beauty STC validates lm/W through LM-79 testing, ensuring real-world performance aligns with datasheet values.

Color Rendering Index (CRI) consistently exceeds Ra 90 across Beauty STC’s premium strips, with extended spectrum models achieving Ra 95+ and strong R9 (saturated red) values above 90. This is accomplished through proprietary phosphor formulations and strict LED binning processes that maintain chromaticity within a 3-step MacAdam ellipse. High CRI is non-negotiable for applications like retail lighting or art galleries where color fidelity is critical. We avoid efficiency compromises by optimizing the blue pump wavelength and phosphor ratios, ensuring lm/W remains competitive even at Ra 95. Each production batch undergoes spectrophotometer verification to guarantee CRI compliance before shipment.

IP ratings apply to the LED strip and its connectors as a complete system. Beauty STC offers IP20 for indoor dry locations, IP65 for damp environments with silicone coating, and IP67 for temporary submersion using fully potted end caps and connectors. Crucially, the IP rating is invalidated if connectors are improperly installed; our IP65/67 kits include pre-molded waterproof plugs and detailed installation guides. The strip’s rating depends on the silicone encapsulation thickness (1.2–1.5mm for IP65) and connector sealing integrity. Beauty STC conducts IP validation per IEC 60529 with third-party lab reports available, ensuring no moisture ingress during 30-minute IP67 submersion tests at 1m depth.

Beauty STC’s quality differentiation lies in systemic engineering controls. We implement 100% automated optical inspection for LED placement, 48-hour burn-in testing at 1.2x rated current, and humidity resistance validation per IEC 60068-2-78. Our strips use 2oz copper PCBs for thermal stability, reducing lumen depreciation to <3% at 1,000 hours. Unlike competitors, we provide full TM-30-15 reports showing Rf and Rg values for advanced color fidelity analysis. All components are UL 8750 certified, and our manufacturing adheres to ISO 9001 with traceability to individual reel lots. This end-to-end rigor ensures that when customers specify CRI >90 or IP67, they receive verified performance without field failures.

Factory Tour: Manufacturing Excellence

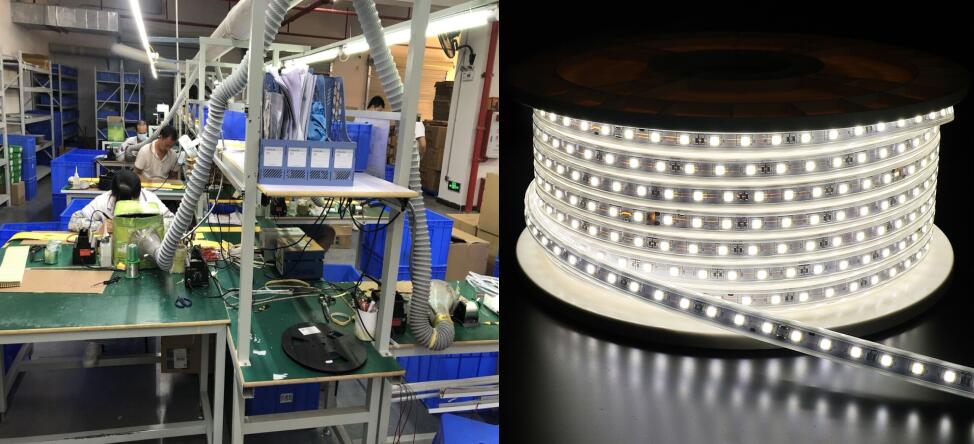

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory is equipped with advanced surface mount technology (SMT) production lines that ensure high-precision assembly of LED components. These SMT machines are automated and feature high-speed placement systems capable of handling a wide range of component sizes and densities, which allows for consistent and reliable production of LED strips and related lighting products. The SMT process is closely monitored with automated optical inspection (AOI) systems to ensure soldering quality and component alignment, minimizing defects and maximizing output efficiency.

In addition to precision manufacturing, the Jiangmen factory places strong emphasis on product reliability through comprehensive aging and burn-in testing procedures. Completed LED strip products undergo rigorous aging tests, typically running at elevated temperatures and full operating voltage for durations ranging from 24 to 72 hours. This process helps identify early-life failures and ensures that only stable, durable products reach customers. Environmental testing chambers are also used to simulate long-term performance under varying humidity and thermal conditions, further validating product lifespan and performance consistency.

The factory has robust OEM (Original Equipment Manufacturer) capabilities, particularly for products such as LED strip plugs and integrated LED lighting solutions. Beauty STC can customize LED strip designs to include specific plug types, voltages, connectors, and packaging based on client requirements. This includes developing proprietary configurations for international markets, meeting various safety and compliance standards such as UL, CE, RoHS, and CCC. The company supports full turnkey solutions—from PCB design and component sourcing to final assembly, labeling, and packaging—enabling clients to bring branded products to market efficiently. With experienced engineering and R&D support, Beauty STC’s Jiangmen facility is well-equipped to deliver high-quality, customized LED lighting products at scale.

Application Scenarios

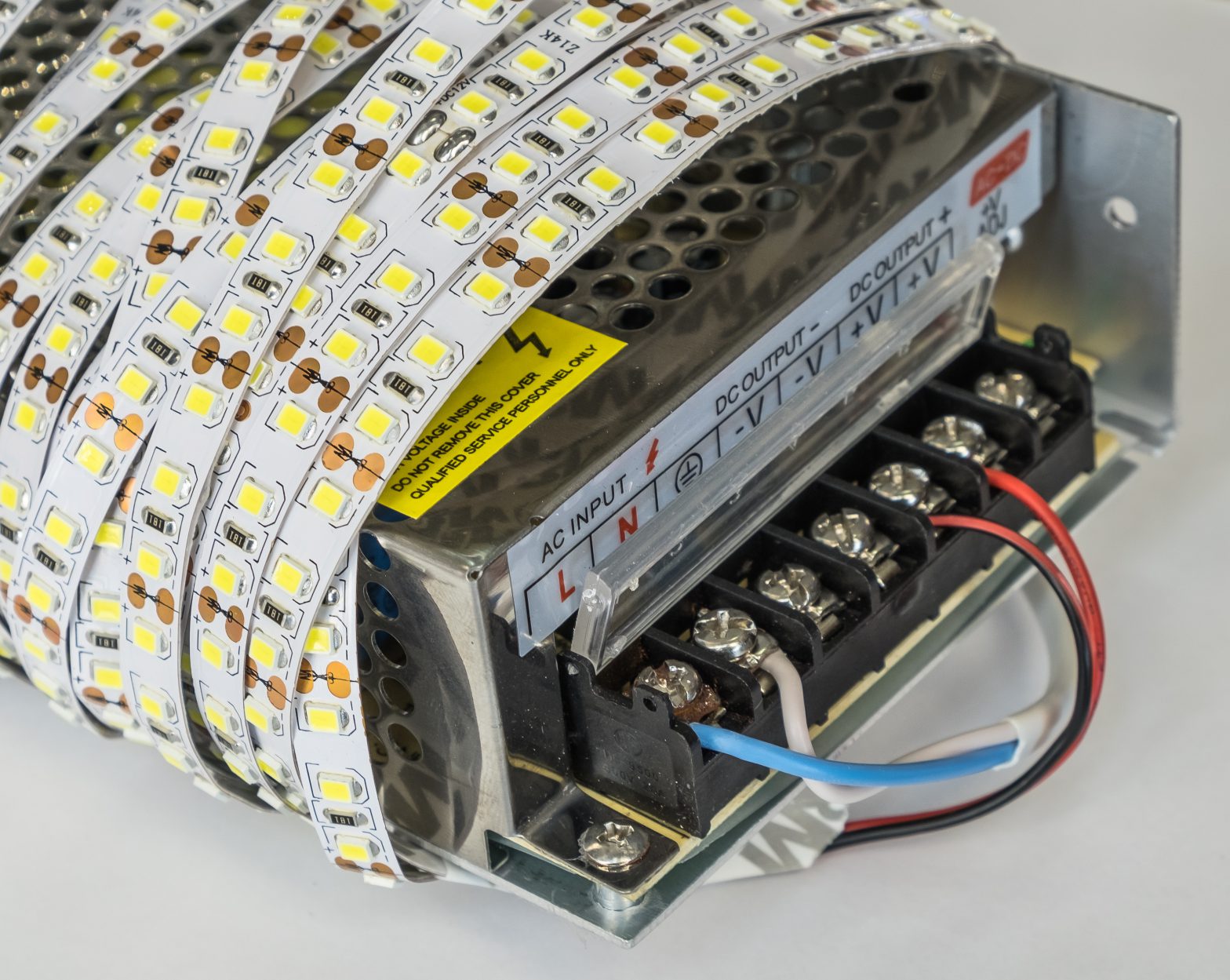

LED strip plugs refer to power supply units or plug-and-play kits designed specifically for LED strip lighting systems, not physical plugs attached directly to the strip itself. These components convert standard line voltage to the low voltage DC required by LED strips and provide a safe, convenient connection point. Their use is widespread across commercial environments due to the flexibility and aesthetic benefits of LED strip lighting.

In hotels, LED strip plug systems are extensively used for ambient and accent lighting. Key applications include under-cabinet lighting in minibars and vanity areas within guest rooms, creating a soft glow that enhances perceived luxury without harsh glare. Cove lighting in lobbies and hallways utilizes these systems to wash walls with light, defining architectural features and guiding guest movement. Under-bed lighting provides subtle night-time illumination for safety, while step lighting in stairwells and pool areas significantly improves safety compliance. The ease of installation with plug-and-play kits is particularly valuable during hotel renovations where minimizing electrical disruption is critical.

Malls leverage LED strip plug solutions primarily for retail presentation and architectural enhancement. Display case lighting within individual stores relies on these systems to highlight merchandise with precise, shadow-free illumination that enhances color rendering. Feature walls and column wraps throughout common areas use integrated strips powered by these plugs to create dynamic branding or seasonal displays. Coving in food courts provides indirect lighting that improves the dining atmosphere, while under-rail lighting in escalators and moving walkways serves both safety and aesthetic purposes. The ability to quickly replace or adjust sections of lighting without rewiring is a major operational advantage in the fast-paced mall environment.

Offices implement LED strip plug systems for both functional task lighting and wellness-focused ambient solutions. Under-desk lighting reduces eye strain during focused work, while cabinet and shelf lighting in reception areas creates a professional impression. Perimeter cove lighting in conference rooms offers glare-free illumination suitable for video calls, and stair tread lighting meets stringent safety codes. Increasingly, circadian lighting systems that adjust color temperature throughout the day utilize these plug-in power supplies for their modular wiring. The low heat output and energy efficiency directly support corporate sustainability goals and reduce HVAC load in climate-controlled office spaces.

Installation requires strict adherence to electrical codes and manufacturer specifications. Always verify the power supply’s output voltage matches the LED strip’s requirement exactly, typically 12V or 24V DC, and ensure its wattage capacity exceeds the total strip load by at least 20% to prevent overheating. Never daisy-chain multiple power supplies to a single AC outlet circuit beyond its amperage rating; each high-wattage supply should have its own dedicated circuit where possible. Maintain proper ventilation around power supplies, especially when enclosed in cabinets or coves, as overheating is the primary cause of premature failure. Use only UL-listed or CE-marked components meeting local safety standards, with IP65 or higher ratings for any damp locations like hotel bathrooms or mall food courts. For long strip runs exceeding 5 meters, inject power at multiple points to avoid voltage drop causing dimming at the far end. Secure all connections with soldered joints or high-quality waterproof connectors rated for the environment, never relying solely on clip-in connectors for permanent commercial installations. Always disconnect power at the circuit breaker before installation and confirm no voltage is present using a multimeter. Consult a licensed electrician for installations involving hardwiring to building circuits, as plug-and-play kits still require proper grounding and overcurrent protection per NEC or local codes.

Why Choose Beauty STC Lighting

Discover the perfect lighting solution with Beauty STC’s premium LED strip plugs—designed for seamless integration, durability, and ease of use. Whether you’re working on residential, commercial, or industrial projects, our high-quality connectors ensure reliable performance and energy efficiency.

Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED solutions. Our team is ready to support your business with customized products, competitive pricing, and global delivery.

For inquiries or to start a collaboration, contact us today at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.