Article Contents

Industry Insight: Led Bendable

The commercial and industrial lighting sector is undergoing a significant transformation driven by the demand for adaptable, energy-efficient solutions that meet increasingly complex architectural and functional requirements. Within this evolution, bendable LED technology has emerged as a critical enabler, moving far beyond simple decorative applications. Modern flexible LED strips and tape lights offer unprecedented design freedom for cove lighting, under-cabinet task illumination, architectural contouring, signage, and even specialized industrial task lighting where rigid fixtures cannot conform to structural nuances. This flexibility directly translates to reduced installation labor, minimized material waste, and the ability to create seamless, continuous lines of light that enhance both aesthetics and productivity in demanding environments like warehouses, retail spaces, offices, and manufacturing facilities. Crucially, for any specification in professional settings, compliance with stringent safety and performance standards is non-negotiable. Products must consistently bear recognized certifications such as ETL (indicating compliance with North American safety standards) and CE (demonstrating adherence to European health, safety, and environmental requirements) to ensure reliability, longevity, and legal installation within commercial and industrial projects. These certifications are fundamental markers of quality and safety that responsible engineers and specifiers prioritize.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this LED innovation for over 25 years. As a dedicated manufacturer specializing in advanced LED lighting solutions, we have consistently focused on developing high-performance, reliable products engineered specifically for the rigorous demands of commercial and industrial applications. Our deep expertise in thermal management, optical control, and robust construction ensures that our bendable LED offerings not only provide the desired design versatility but also deliver the sustained lumen maintenance, color consistency, and durability required in professional environments. Understanding the critical importance of compliance, every Beauty STC bendable LED product undergoes rigorous testing to achieve and maintain essential certifications including ETL and CE, providing specifiers and end-users with the confidence that our solutions meet the highest global safety and performance benchmarks. Our longevity in the market reflects a steadfast commitment to quality engineering and meeting the evolving needs of the professional lighting industry.

Technical Specs & Certifications

The LED bendable light strips offered by Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance and reliability in a wide range of residential, commercial, and architectural lighting applications. These flexible LED strips are designed to deliver consistent illumination while maintaining excellent energy efficiency and color quality.

In terms of efficiency, Beauty STC’s LED bendable strips achieve a luminous efficacy of 110 to 130 lumens per watt, depending on the specific configuration and color temperature. This high lumen-to-watt ratio ensures optimal energy savings without compromising brightness, making them ideal for both accent and functional lighting installations.

Color rendering is a critical factor in premium lighting solutions, and Beauty STC’s bendable LED strips exceed industry standards with a Color Rendering Index (CRI) greater than 90. This high CRI ensures that colors appear natural and vibrant under the light, which is particularly important in retail displays, hospitality environments, and high-end residential interiors. Some series even offer CRI values above 95, catering to applications where accurate color representation is essential.

Regarding environmental protection, these LED strips are available in multiple IP (Ingress Protection) ratings to suit various installation conditions. The standard versions are offered with IP20 for dry indoor environments, while conformal-coated variants provide IP65 protection, making them resistant to dust and low-pressure water jets—ideal for kitchens, bathrooms, or outdoor signage. Fully encapsulated silicone-jacketed models achieve IP67 or IP68 ratings, offering complete dust tightness and protection against temporary or prolonged water immersion, suitable for demanding outdoor or submerged applications such as landscape lighting or pool perimeters.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout the production process. Components are sourced from trusted suppliers, and each batch undergoes thorough testing for electrical performance, thermal management, and long-term reliability. The use of high-quality phosphor coatings, precision binning of LEDs, and robust circuit design ensures consistent color temperature and extended lifespan—typically rated at 50,000 hours under proper operating conditions. With compliance to international standards including CE, RoHS, and UL, Beauty STC’s LED bendable strips reflect a commitment to safety, durability, and superior optical performance.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility represents a significant strategic asset within our Pearl River Delta operations. Spanning approximately 30,000 square meters, this purpose-built factory leverages Jiangmen’s advantageous location within Guangdong Province for efficient access to the region’s extensive electronics supply chain and skilled labor pool. The facility operates under stringent ISO 9001 and IATF 16949 quality management systems, with dedicated cleanroom environments for critical production stages to ensure particulate control during sensitive assembly processes. All manufacturing adheres strictly to international safety and performance standards including IEC/EN 60598, UL 8750, and relevant RoHS/REACH compliance protocols.

Our Surface Mount Technology (SMT) production lines form the technological backbone for precision component placement. The facility houses multiple high-speed Yamaha YS24 and YSM20 modular SMT platforms, capable of handling components down to the 0201 metric package size essential for modern high-density LED arrays. These machines achieve placement accuracy of ±25 microns at throughput rates exceeding 15,000 components per hour per line. Comprehensive inline automated optical inspection (AOI) and automated X-ray inspection (AXI) systems are integrated post-reflow to validate solder joint integrity, component alignment, and polarity across every circuit board. This capability is particularly critical for the flexible printed circuit boards (FPCs) used in bendable LED products where thermal management and mechanical stress during assembly require exceptional process control.

Aging and reliability validation constitute a non-negotiable phase in our quality assurance protocol. Every production batch undergoes rigorous thermal aging tests within our environmental simulation chambers. For standard LED modules, this involves continuous operation at 50°C ambient temperature for a minimum of 72 hours with real-time photometric and electrical parameter monitoring. Our dedicated aging bays feature precisely controlled thermal chambers maintaining ±1°C stability, capable of simultaneously testing thousands of units under elevated temperature and operational stress conditions. Data logging systems capture lumen maintenance, chromaticity shift, and driver performance metrics, with failure analysis feeding directly into our continuous improvement processes. This intensive aging regimen is especially vital for bendable LED products where thermal cycling and mechanical flexing can accelerate potential failure modes.

Regarding OEM capabilities for ‘LED bendable’ products, Beauty STC possesses extensive expertise in developing and manufacturing custom flexible lighting solutions. We support full turnkey OEM services from initial concept through to mass production. Our engineering team specializes in designing and producing both silicone-encapsulated flexible strips and ultra-thin rigid-flex hybrid solutions with bend radii as tight as 15mm. We routinely handle custom requirements including unique form factors, specialized diffusers, bespoke connector systems, and integrated smart control protocols (DALI, 0-10V, Bluetooth Mesh). The Jiangmen factory maintains dedicated tooling resources for rapid prototyping of custom bending jigs and formers, along with in-house silicone molding capabilities for encapsulation. Material options span from standard IP20-rated flexible PCBs to IP67-rated silicone extrusions, all subject to our stringent aging and mechanical flex testing protocols to ensure reliability under repeated bending cycles. Clients benefit from our ability to scale from low-volume pilot runs to high-volume production while maintaining consistent quality through our integrated SMT and aging infrastructure.

Application Scenarios

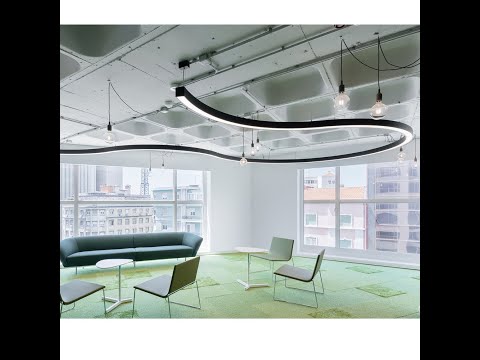

LED bendable strips are highly versatile and widely used across various commercial and hospitality environments due to their flexibility, energy efficiency, and aesthetic appeal. In hotels, they are ideal for accent lighting in guest rooms, particularly along headboards, under cabinets, or within cove lighting in corridors and lobbies. Their ability to curve around architectural features allows for creative lighting designs that enhance ambiance and guest experience. In malls, LED bendable strips are commonly installed in display windows, signage, and along curved ceilings or columns to highlight architectural elements and guide customer flow. They are also effective in illuminating escalator handrails and stair edges for both safety and visual impact. In offices, these strips are used for under-cabinet lighting, within partition walls, or along ceiling perimeters to create a modern, well-lit workspace without glare, contributing to a productive and comfortable environment.

When installing LED bendable strips, ensure the surface is clean, dry, and free of dust to maximize adhesive bonding. For long-term durability, especially in high-traffic or high-humidity areas, consider using mounting clips or aluminum channels to secure the strips and improve heat dissipation. Always plan the layout in advance, taking note of power source locations and voltage drop over long runs—use appropriate power feeds at intervals to maintain consistent brightness. Cut the strips only at designated cut points to avoid damaging the circuitry. For optimal performance, pair the strips with a compatible dimmer and power supply, and protect any outdoor or moisture-prone installations with waterproof-rated (IP65 or higher) versions. Finally, test the installation before finalizing the placement to ensure even lighting and proper functionality.

Why Choose Beauty STC Lighting

Transform your lighting designs with Beauty STC’s precision-engineered LED bendable solutions. Our flexible linear lighting systems offer unmatched adaptability for curved surfaces, custom installations, and dynamic architectural applications without compromising on brightness or color consistency. Experience seamless integration into retail displays, hospitality environments, and high-end residential projects where traditional rigid fixtures fall short. Partner with Beauty STC to access OEM/ODM capabilities, rigorous quality control from our ISO-certified manufacturing facility, and engineering support tailored to your project specifications. Elevate your offerings with bendable LED technology trusted by global lighting professionals for reliable performance and innovative design freedom. Contact our partnership team directly at [email protected] to discuss custom solutions and volume collaboration opportunities.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.