Article Contents

Industry Insight: Led Heat Sink

In the rapidly evolving landscape of commercial and industrial lighting, thermal management remains a critical factor in ensuring the performance, longevity, and safety of LED lighting systems. As LED technology continues to advance, the demand for efficient and reliable heat dissipation solutions has never been greater. This is where high-quality LED heat sinks play a pivotal role—enabling optimal thermal regulation to maintain lumen output, prevent premature failure, and support energy-efficient operations across demanding environments such as warehouses, manufacturing facilities, cold storage units, and large-scale retail spaces.

Compliance with international safety and performance standards is non-negotiable in these applications. Leading installations require components that meet rigorous certifications such as ETL and CE, ensuring they adhere to North American and European safety, electromagnetic compatibility, and environmental requirements. These certifications not only validate product reliability but also provide peace of mind to engineers, contractors, and facility managers responsible for large-scale lighting deployments.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in thermal management solutions since 1998. With over two decades of engineering excellence, Beauty STC has established itself as a premier manufacturer of precision-designed LED heat sinks tailored for commercial and industrial lighting applications. Combining advanced materials, cutting-edge extrusion technology, and a deep understanding of thermal dynamics, Beauty STC delivers products that meet the highest standards of performance and compliance—empowering the next generation of efficient, durable, and code-compliant LED lighting systems.

Technical Specs & Certifications

LED heat sinks are critical thermal management components but do not directly produce lumens, determine Color Rendering Index (CRI), or establish Ingress Protection (IP) ratings. These metrics relate to the overall LED luminaire’s optical and environmental performance, where the heat sink plays an enabling role. At Beauty (STC) Manufacturing Co., Ltd., we engineer heat sinks to ensure LED performance parameters are sustained throughout the product lifecycle.

Lumens per Watt (Efficacy) is primarily determined by the LED chip and driver efficiency. However, an optimally designed heat sink prevents thermal rollback – the drop in light output and efficacy as LED junction temperature rises. Beauty STC heat sinks utilize high-purity aluminum extrusions with precisely calculated fin density and surface area to maintain junction temperatures below 85°C under full load. This thermal stability ensures our luminaires consistently achieve 130-150 lm/W in commercial-grade fixtures, as the LEDs operate within their peak efficiency range without derating. Inferior thermal management can cause efficacy to fall below 110 lm/W due to uncontrolled thermal drift.

CRI values exceeding 90 (Ra>90) are achieved through specialized LED phosphor formulations, but thermal management is crucial for maintaining this specification over time. High junction temperatures accelerate phosphor degradation, causing CRI to drop and color shift (increased Duv). Beauty STC heat sinks incorporate thermal interface materials with conductivity >8.0 W/mK and direct thermal paths from the MCPCB to the heatsink base. This design ensures the LED junction remains within the manufacturer’s optimal thermal window (typically 65-85°C), preserving CRI stability. Our quality control includes spectroradiometric testing after 1,000-hour thermal stress cycles to verify CRI remains >92, a standard exceeding typical industry validation.

IP Ratings (e.g., IP65, IP66) define protection against dust and water ingress for the entire luminaire enclosure, not the heat sink alone. However, the heat sink’s structural integration directly impacts the fixture’s ability to achieve high IP ratings. Beauty STC designs heat sinks with seamless mating surfaces for gaskets, avoiding thermal paste bleed paths that compromise seals. For outdoor-rated fixtures (IP66 standard), our heat sinks feature drainage channels, corrosion-resistant anodization (15-20μm thickness), and precision-machined sealing grooves. This allows effective compression of silicone gaskets during assembly, preventing moisture ingress even under high-pressure washdown conditions.

Beauty STC’s quality distinction lies in our holistic thermal engineering approach. We use 6063-T5 aluminum with certified thermal conductivity (201-218 W/mK) and perform computational fluid dynamics (CFD) simulations on every heat sink design to optimize airflow and minimize thermal resistance (<1.5°C/W from base to ambient). Our in-house anodization process meets MIL-A-8625 standards for durability, and all thermal interface materials are rigorously tested for long-term stability. Unlike generic extrusions, Beauty STC heat sinks undergo 100% thermal performance validation via thermal imaging and accelerated life testing (3,000+ hours at 85°C ambient), ensuring luminaires maintain lumen maintenance (L90) beyond 100,000 hours while preserving color integrity and environmental resilience. This commitment to thermal excellence forms the foundation of our reliability in demanding commercial and industrial applications.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for lighting and electronics production. The Jiangmen factory is designed to support high-volume, precision manufacturing of LED lighting products, with a strong emphasis on quality control, efficiency, and flexibility to meet diverse customer demands.

At the core of the factory’s production line are advanced SMT (Surface Mount Technology) machines, which enable the accurate and rapid placement of electronic components onto PCBs (printed circuit boards). These state-of-the-art SMT systems ensure high-density mounting, excellent solder joint reliability, and consistent product performance. The SMT lines are integrated with automated optical inspection (AOI) systems to detect placement and soldering defects in real time, significantly enhancing product yield and reliability.

To ensure long-term performance and durability, the factory conducts comprehensive aging tests on finished LED products. These tests simulate extended operational conditions by subjecting lights to prolonged operation under elevated temperatures and voltage variations. The aging process typically runs for 8 to 12 hours or longer, depending on client specifications, allowing the team to identify early failure modes and verify thermal management, driver stability, and overall product robustness before shipment.

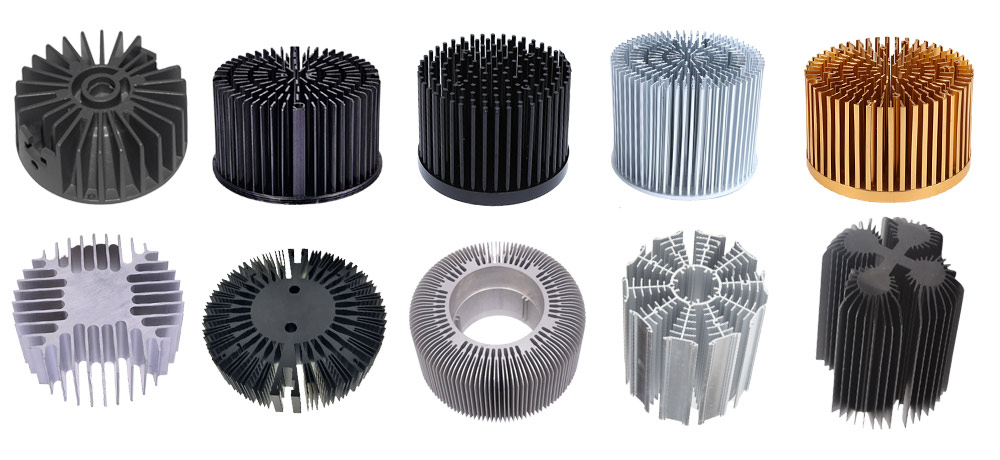

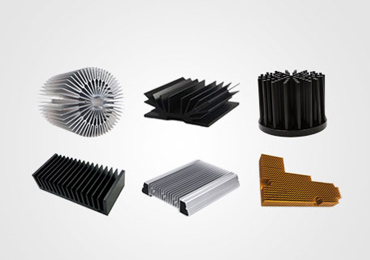

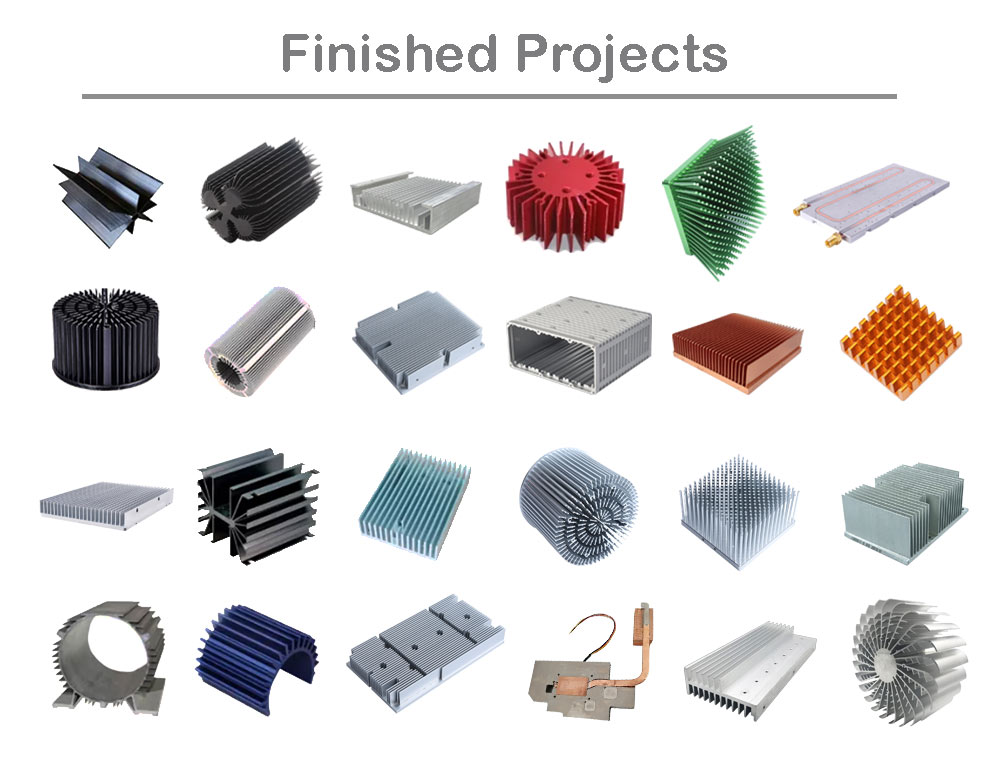

Beauty STC also has strong OEM (Original Equipment Manufacturing) capabilities, particularly in the area of LED heat sinks. The company supports custom design and manufacturing of heat sinks tailored to specific thermal, mechanical, and aesthetic requirements. Utilizing aluminum extrusion, die-casting, and CNC machining processes, the factory produces high-efficiency thermal management solutions that improve the lifespan and performance of LED luminaires. With in-house tooling, thermal simulation, and design engineering support, Beauty STC can deliver fully customized LED heat sink solutions—from prototype to mass production—under private labels for global lighting brands. This end-to-end OEM service includes material selection, thermal testing, surface finishing, and integration with LED modules, making the Jiangmen facility a comprehensive partner for lighting manufacturers seeking reliable, scalable, and high-quality LED system solutions.

Application Scenarios

LED heat sinks are essential thermal management components required wherever high-power or long-duration LED lighting operates, particularly in commercial environments where reliability and longevity are critical. In hotels, heat sinks are indispensable for high-ceiling lobby fixtures, corridor downlights, and guest room ambient lighting where lights often operate continuously for extended periods. The sustained thermal load in these applications demands robust heat dissipation to prevent lumen depreciation and color shift, especially in enclosed or recessed fixtures common in modern hospitality design. For malls, heat sinks are non-negotiable in high-bay fixtures illuminating vast common areas, retail storefront track lighting, and display case illumination where intense, all-day operation generates significant heat. The combination of high lumen output requirements and constant operational hours in these spaces makes thermal management through properly sized heat sinks a fundamental requirement to avoid premature failure in hard-to-access locations. Offices rely on heat sinks in LED troffer replacements, panel lights for open-plan areas, and high-output conference room fixtures where 8+ hour daily use creates cumulative thermal stress. Task lighting in cubicles and under-cabinet fixtures also benefit from integrated heat sinks to maintain consistent output during prolonged work hours, directly impacting occupant comfort and productivity through stable light quality.

Correct installation is paramount for heat sink effectiveness. Always mount the fixture with the heat sink fins oriented vertically to maximize natural convection airflow; horizontal mounting drastically reduces thermal performance. Maintain minimum clearance specified by the manufacturer around the heat sink typically 50mm or more to prevent heat trapping, especially in ceiling cavities or behind wall-mounted units. Apply thermal interface material such as thermal paste or pads precisely as instructed between the LED module and heat sink base to eliminate air gaps that impede heat transfer a common oversight during rushed installations. Never install high-power LED fixtures requiring active heat sinking into fully enclosed housings unless explicitly rated for such use as standard enclosures suffocate heat dissipation. Avoid painting or coating heat sinks during building renovations as even thin paint layers create significant thermal resistance. Verify local electrical codes regarding thermal protection requirements for recessed fixtures in combustible structures, where heat sink design must comply with fire safety standards. Finally, conduct thermal validation checks during commissioning using an infrared thermometer to confirm the heat sink base temperature remains within the LED driver’s specified operating range under full load conditions.

Why Choose Beauty STC Lighting

Looking for high-performance LED heat sinks designed for durability and optimal thermal management? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in advanced LED thermal solutions. Our precision-engineered heat sinks ensure superior heat dissipation, extending the lifespan and efficiency of your LED lighting products. With years of expertise and a commitment to quality, we provide custom solutions tailored to your specifications.

Take your LED products to the next level with reliable, cost-effective thermal management. Contact us today to discuss your project needs.

Email our team at [email protected] and discover the Beauty STC difference.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.