Article Contents

Industry Insight: Led Strip Wire Connector

In the rapidly evolving landscape of commercial and industrial lighting, LED strip wire connectors have emerged as critical components in ensuring efficient, reliable, and scalable lighting solutions. As facilities increasingly adopt flexible LED strip systems for task lighting, architectural accenting, and large-scale illumination, the demand for high-performance connectors that guarantee secure electrical continuity and ease of installation has grown significantly. In mission-critical environments such as warehouses, manufacturing plants, retail spaces, and healthcare facilities, the integrity of these connections directly impacts system longevity, energy efficiency, and safety compliance.

Regulatory standards such as ETL and CE have become essential benchmarks in the industry, verifying that connectors meet rigorous requirements for electrical safety, durability, and performance under demanding conditions. These certifications are not merely compliance markers—they are assurances of quality and reliability that facility managers and lighting designers depend on when specifying components for large-scale deployments.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovation in LED connectivity solutions. With over two decades of engineering expertise, Beauty STC has built a reputation for delivering precision-crafted LED strip wire connectors that combine robust construction, tool-free installation, and full compliance with international safety standards including ETL and CE. As a trusted partner to lighting manufacturers and commercial integrators worldwide, Beauty STC continues to drive advancements in connectivity that support the future of intelligent, energy-efficient industrial lighting systems.

Technical Specs & Certifications

LED strip wire connectors serve as critical electrical interfaces between LED strips and power sources or other strips, but they do not inherently produce light. Therefore, specifications like lumens per watt (lm/W) and Color Rendering Index (CRI) are properties of the LED strip itself, not the connector. Beauty STC emphasizes this distinction to ensure customers understand system-level performance. Connectors directly influence the preservation of the LED strip’s rated performance through electrical integrity and environmental protection.

Lumens per watt is determined by the LED chip efficiency, driver quality, and thermal management of the strip. A poorly designed connector introducing resistance can cause voltage drop, reducing actual delivered power and lowering effective lm/W at the strip. Beauty STC connectors utilize precision-machined copper contacts with 0.3μm gold plating to minimize contact resistance below 5mΩ. This ensures voltage drop remains under 0.1V at rated current, preserving the strip’s specified lm/W output. Our connectors undergo rigorous voltage drop testing at 1.5x operational current to guarantee no measurable lumen loss in certified systems.

CRI is a function of the LED phosphor formulation and spectral output, fixed during strip manufacturing. However, inconsistent current delivery from substandard connectors can cause color shift in some LED types. Beauty STC connectors maintain stable current flow through robust 22AWG silicone-insulated wires and secure locking mechanisms that prevent intermittent connections. This stability ensures the LED strip operates within its designed electrical parameters, preserving the original CRI >90 performance without spectral deviation. All Beauty STC connectors are validated with CRI 90+ LED strips under thermal stress testing to confirm color consistency.

IP ratings for connectors indicate ingress protection against solids and liquids. Beauty STC offers connectors rated from IP20 (basic indoor use) to IP68 (full submersion). Our IP67/IP68 models feature dual-seal technology: a primary silicone gasket compressing against the strip’s PCB edge and a secondary integrated cable seal. These undergo 30-minute submersion testing at 1m depth per IEC 60529, with zero moisture ingress observed. The housings use UV-stabilized polycarbonate resistant to -40°C to +85°C, preventing seal degradation that could compromise IP ratings in outdoor applications.

Beauty STC’s quality commitment is embedded in every connector. We implement ISO 9001-certified processes including 100% continuity testing, automated visual inspection for seal integrity, and batch-level thermal cycling from -40°C to +85°C for 500 cycles. Unlike generic alternatives, our connectors use fire-retardant materials meeting UL 94 V-0 standards and undergo 5,000 insertion-extraction cycle validation. This ensures long-term reliability where competitors’ products often fail due to contact oxidation or seal compression set. By maintaining electrical fidelity and environmental resilience, Beauty STC connectors safeguard the LED system’s specified photometric performance throughout its operational life.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, a strategic location known for its robust industrial infrastructure and proximity to key supply chain hubs. The Jiangmen factory is purpose-built for the efficient production of LED lighting components and accessories, with a strong emphasis on quality control, automation, and scalability to meet both domestic and international market demands.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines, enabling high-precision assembly of LED strip circuits and related electronic components. These SMT machines are state-of-the-art, supporting rapid placement of small-scale components with tight tolerances, ensuring consistent product performance and reliability. Automated optical inspection (AOI) systems are integrated into the SMT process to detect soldering defects and component misalignment, further enhancing manufacturing accuracy.

To ensure long-term product durability, the Jiangmen factory conducts comprehensive aging tests on all LED strip products and connectors. These tests simulate extended operational conditions, including prolonged power cycling, thermal stress, and humidity exposure, to verify performance under real-world environments. This rigorous testing protocol allows Beauty STC to deliver products that meet or exceed industry reliability standards.

The factory has strong OEM capabilities, particularly for components such as LED strip wire connectors. Beauty STC supports custom design, mold development, and volume production based on client specifications. This includes tailored connector configurations, branding, packaging, and compliance with international standards such as CE, RoHS, and UL. With in-house engineering and tooling support, the company can efficiently manage end-to-end OEM projects, from prototype to mass production, offering flexibility and fast turnaround times for global partners.

Application Scenarios

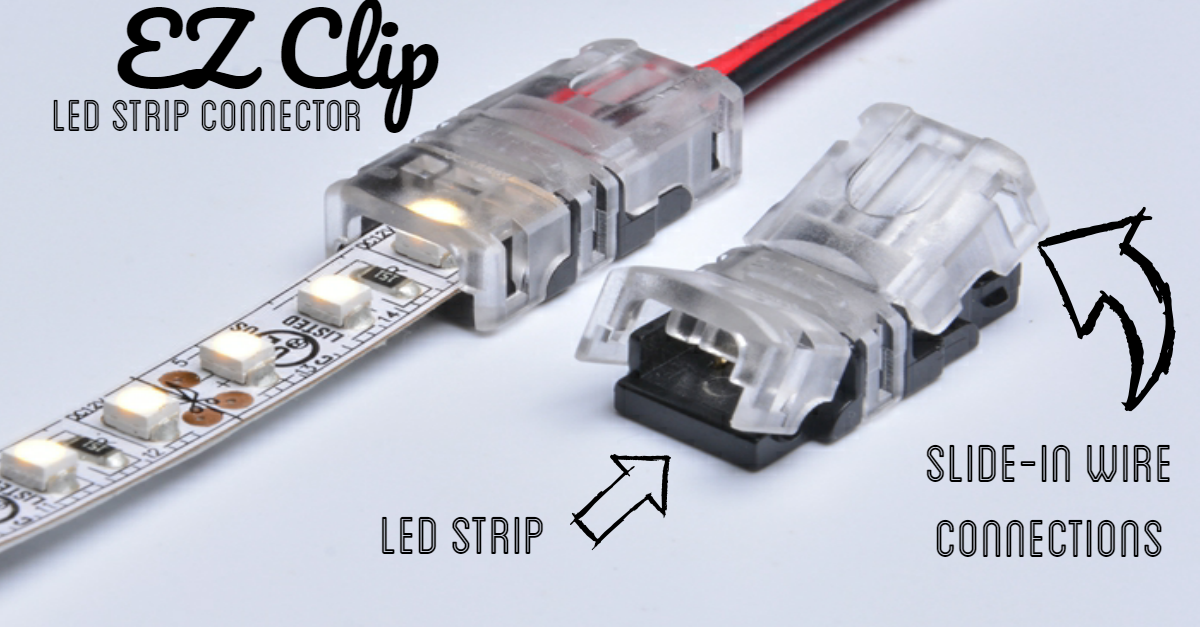

LED strip wire connectors serve as critical junction points in low-voltage lighting systems, enabling secure electrical connections between LED strips and power sources or between strip segments without soldering. Their application across hotels, malls, and offices addresses specific functional and aesthetic demands while ensuring maintainability and safety. In hotels, these connectors are predominantly used within guest room cove lighting systems to link strips along ceiling perimeters, under vanity cabinets in bathrooms for indirect illumination, and within lobby feature walls where modular strip sections create dynamic backlighting effects. They are also essential in corridor handrail lighting installations, allowing for segmented runs that simplify maintenance during room renovations or corridor updates. The hospitality sector prioritizes clean aesthetics and rapid reconfiguration, making push-fit or screw-terminal connectors ideal for minimizing visible hardware and enabling non-destructive disassembly.

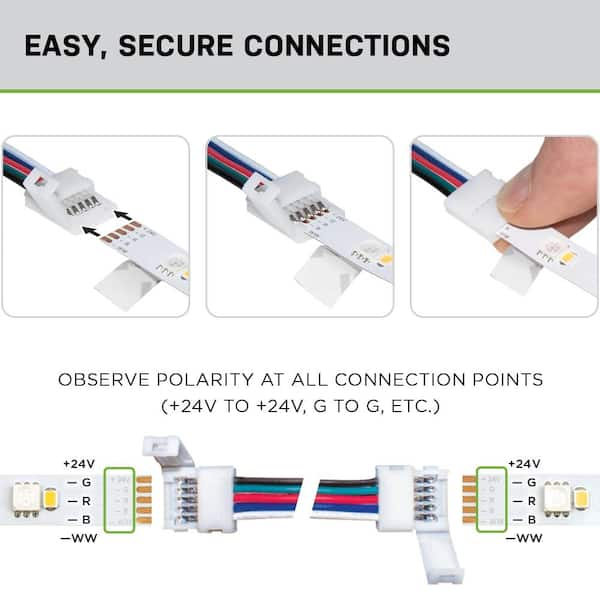

Within shopping malls, LED strip wire connectors facilitate complex lighting layouts in high-traffic environments. They are extensively deployed in storefront signage to join flexible strips within custom letter channels, in jewelry and electronics display cases requiring precise accent lighting, and along architectural elements like escalator undersides or column wraps. Outdoor mall concourses utilize IP67-rated waterproof connectors for perimeter lighting on canopies or water features, ensuring resilience against weather exposure. Mall installations demand high-reliability connections capable of handling extended continuous operation; therefore, we specify connectors with copper alloy contacts and strain relief mechanisms to prevent dislodgement from foot traffic vibrations or thermal cycling. Critical considerations include matching connector current ratings to the strip’s amperage—particularly for high-density 24V strips in long retail displays—and verifying polarity alignment to avoid catastrophic strip failure during commissioning.

Office environments leverage these connectors for task-oriented and ambient lighting solutions. Common applications include under-desk task lighting systems where connectors link strips to dimmable drivers, within partition-mounted LED channels for workspace boundary definition, and in suspended ceiling coves for glare-free indirect illumination. Conference rooms frequently employ them to connect strips behind projection screens or along table perimeters for video call ambiance. Offices prioritize uniform light output and integration with building management systems; thus, we emphasize connectors compatible with 0-10V or DALI dimming protocols and stress the necessity of voltage drop calculations for runs exceeding 5 meters. Undersized connectors here cause flickering or color shift, directly impacting occupant comfort and productivity.

Installation requires strict adherence to electrical best practices. Always disconnect power before handling connectors and verify strip voltage compatibility—24V strips require different connectors than 12V variants. Polarity must be meticulously observed; reversed connections instantly damage LEDs. For high-power installations exceeding 60W per 5-meter run, use connectors rated for at least 20% above the calculated load to prevent overheating. In recessed channels, ensure connectors fit within the housing profile to avoid protrusion that compromises diffuser seating. Apply dielectric grease to outdoor or high-humidity zone connections (e.g., mall restrooms) to inhibit corrosion. Finally, conduct thermal validation by operating the system at full load for 30 minutes before final concealment—any connector warmth beyond ambient temperature indicates undersizing or poor contact, necessitating immediate replacement to avert fire hazards. Consistent implementation of these protocols ensures longevity and performance across all commercial settings.

Why Choose Beauty STC Lighting

Looking for reliable and high-quality LED strip wire connectors? Partner with Beauty (STC) Manufacturing Co., Ltd., your trusted expert in innovative LED connectivity solutions. Engineered for durability, ease of installation, and consistent performance, our connectors are designed to meet the demands of residential, commercial, and industrial lighting applications.

At Beauty STC, we combine precision manufacturing with exceptional customer support to ensure seamless integration into your lighting projects. Whether you’re a distributor, contractor, or OEM, we offer customized solutions and scalable production to meet your needs.

Take the next step in quality and reliability. Contact us today at [email protected] to discuss your requirements and discover how Beauty STC can power your success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.