Article Contents

Industry Insight: Double Sided Tape For Led Lights

In the rapidly evolving landscape of commercial and industrial lighting, reliability, efficiency, and ease of installation are paramount. One often-overlooked yet critical component enabling seamless integration of LED lighting systems is double-sided tape specifically engineered for demanding environments. As building operators and lighting designers seek faster, cleaner mounting solutions without compromising safety or performance, high-performance adhesive tapes have become indispensable across applications ranging from office ceilings and retail displays to high-bay warehouses and industrial facilities.

These specialized tapes must meet rigorous standards to ensure long-term durability under continuous operation, temperature fluctuations, and exposure to various substrates. Compliance with ETL and CE certifications is essential, verifying that the tape and the overall lighting assembly adhere to North American and international safety and electromagnetic compatibility requirements. This ensures not only regulatory acceptance but also peace of mind for contractors, facility managers, and end-users.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovation in LED lighting components and accessories. With over two decades of experience serving global commercial and industrial markets, Beauty STC combines advanced materials science with stringent quality control to deliver double-sided tapes that offer superior adhesion, thermal resistance, and UV stability. Trusted by OEMs and lighting integrators worldwide, Beauty STC continues to set industry benchmarks for performance and reliability in the most challenging lighting environments.

Technical Specs & Certifications

Double-sided tape for LED lighting applications serves a critical mounting function but does not possess inherent optical or electrical properties such as lumens per watt, Color Rendering Index (CRI), or Ingress Protection (IP) ratings. These specifications pertain exclusively to the LED light source itself, not the adhesive component used for installation. Confusion often arises between the tape’s mechanical role and the photometric performance of the LED product it secures.

Lumens per watt (lm/W) measures the efficacy of the LED light engine, indicating how efficiently electrical power is converted to visible light. At Beauty STC, our high-efficiency LED strips and modules achieve industry-leading efficacy, typically ranging from 110 to 130 lm/W for standard products, with advanced designs exceeding 140 lm/W under optimized thermal and drive conditions. This performance is attained through proprietary chip-on-board (COB) technology, precision optical design, and thermally conductive substrates—not the mounting tape.

CRI (Color Rendering Index) quantifies light quality, specifically how accurately a light source reveals object colors relative to natural light. Beauty STC rigorously ensures CRI values exceeding 90 (Ra >90) across our premium product lines, utilizing multi-phosphor LED chips and spectral tuning. This guarantees exceptional color fidelity for retail, hospitality, and architectural applications. The adhesive tape plays no role in CRI; it is a function of the LED semiconductor and phosphor composition.

IP ratings define resistance to dust and moisture ingress, critical for outdoor or wet-location installations. Beauty STC achieves IP65, IP67, and IP68 ratings through holistic fixture design—including sealed housings, gaskets, and conformal coatings—not the double-sided tape alone. While high-performance tapes (e.g., UV-resistant acrylic foam tapes) contribute to mechanical stability in harsh environments, they do not independently confer IP certification. The tape must complement the fixture’s sealing strategy; our engineering team validates tape compatibility during IP testing to prevent delamination or moisture wicking at joints.

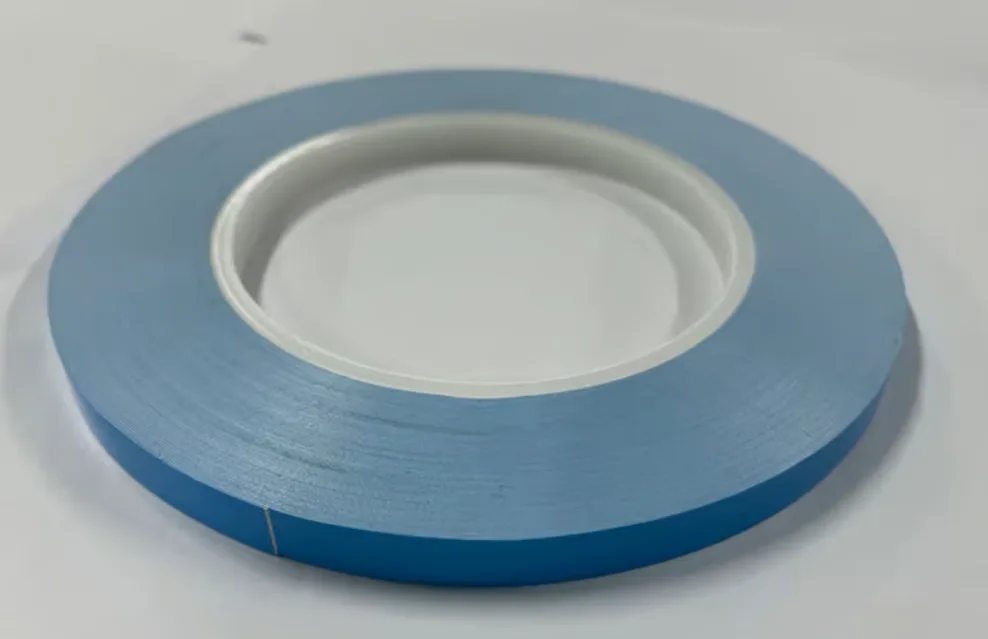

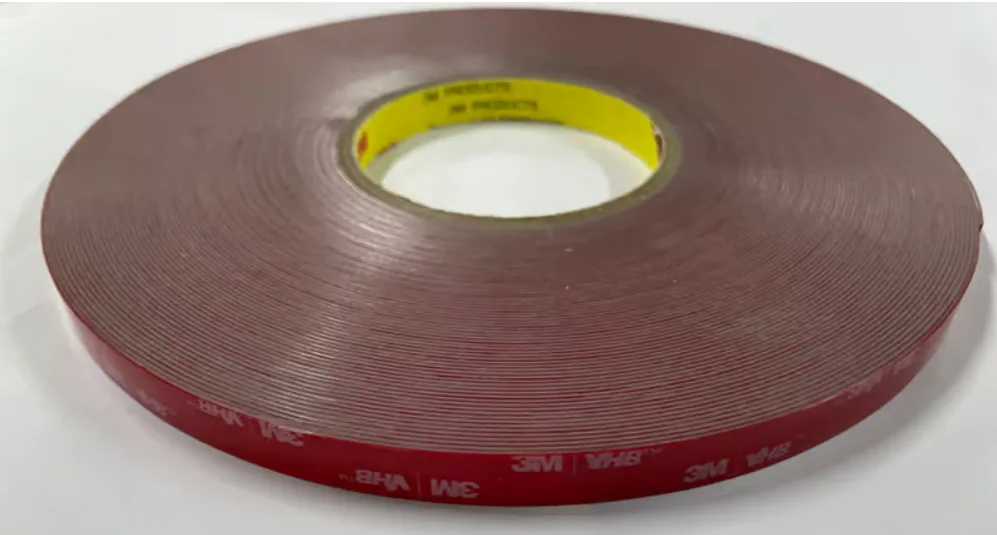

Regarding double-sided tape specifications relevant to LED applications: Beauty STC selects only industrial-grade tapes with minimum 1.0 mm thickness, 15–25 N/25mm tensile adhesion strength, and thermal stability from -40°C to +120°C. Tapes feature acrylic or silicone carriers for UV resistance and long-term bonding to diverse substrates (aluminum, plastics, glass). Crucially, our quality control mandates zero outgassing or yellowing under thermal stress, ensuring no degradation to adjacent optical components. This stringent tape selection—coupled with our LED modules’ 50,000+ hour L70 lifetime—exemplifies Beauty STC’s commitment to system reliability. The tape is an enabler, but our engineering excellence in light source performance and environmental resilience defines the end product’s value.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory is equipped with advanced Surface Mount Technology (SMT) production lines that ensure high precision and efficiency in assembling LED lighting components. These SMT machines are fully automated and capable of handling a wide range of component sizes and densities, enabling the production of compact and high-performance LED strips and modules. The facility maintains strict quality control throughout the SMT process, including automatic optical inspection (AOI) systems to detect soldering and component placement defects in real time.

A critical part of the manufacturing process at the Jiangmen factory is the aging test procedure. Every batch of LED products undergoes rigorous aging tests under controlled conditions to ensure long-term reliability and performance stability. Products are typically operated at elevated temperatures and full power for extended periods—often 24 to 72 hours—allowing early detection of potential failures or performance degradation. This comprehensive testing helps maintain consistent product quality and supports Beauty STC’s commitment to delivering durable LED lighting solutions.

The factory also has strong OEM (Original Equipment Manufacturer) capabilities, particularly for specialized accessories such as double-sided tape for LED lights. Beauty STC offers customized solutions including adhesive type selection (e.g., 3M, TESA, or high-temperature resistant variants), tape width, thickness, and backing material, tailored to customer requirements. The company supports private labeling, custom packaging, and technical collaboration to meet specific application needs—whether for indoor, outdoor, high-heat, or high-humidity environments. With in-house R&D and material testing support, Beauty STC ensures that the double-sided tapes provided are optimized for adhesion strength, durability, and compatibility with various substrates and LED strip designs. This end-to-end OEM service makes the Jiangmen facility a reliable partner for brands seeking high-quality, customized LED lighting components.

Application Scenarios

Double-sided tape for LED lighting serves specific purposes in commercial settings but requires careful application due to inherent limitations in load capacity, thermal stability, and environmental resilience. Its use is strictly limited to lightweight, low-heat, and non-critical installations where mechanical fasteners are impractical. In hotels, malls, and offices, prioritize tape only for temporary or secondary decorative applications under strict conditions.

In hotels, double-sided tape may be considered for mounting very lightweight LED tape in dry, low-traffic areas such as under vanity cabinets in guest room bathrooms (ensuring the tape is explicitly rated for humid environments) or within shallow architectural coves in lobbies where vibration is minimal. Avoid using tape for primary illumination in guest rooms, corridors, or near high-heat sources like recessed downlights. The constant humidity fluctuations in bathrooms and potential for guest tampering make tape unreliable here; mechanical clips or aluminum channels are always preferable for safety and longevity.

For malls, double-sided tape has extremely limited applicability due to high ceilings, heavy foot traffic, thermal stress from HVAC systems, and stringent fire codes. Never use tape for installations above walkways, in escalator soffits, or on structural elements where failure could cause injury. It might only be acceptable for temporary holiday displays on non-structural, smooth surfaces like glass partitions in kiosks, provided the display is lightweight and removed promptly. Mall environments demand robust mounting like extruded aluminum profiles with screw fasteners—tape risks costly failures and safety hazards under mall conditions.

In offices, tape could theoretically secure ultra-thin LED strips under desk edges for ambient task lighting, but only if the fixture weighs under 100g per meter and the surface is perfectly clean, dry, and non-porous. Avoid tape for under-cabinet lighting in shared kitchens or near windows where solar heating occurs, as thermal cycling degrades adhesive bonds rapidly. Office installations typically endure decades of use; tape will fail long before the LED’s rated lifespan, leading to sagging strips and maintenance headaches. Always opt for channel-mounted systems in offices for professional results.

Critical installation tips begin with verifying the tape’s specifications: it must be high-temperature acrylic foam tape (e.g., 3M VHB) rated for continuous use above 60°C, not basic office tape. Surface preparation is non-negotiable—clean with isopropyl alcohol, remove all dust/oil, and ensure the substrate is completely dry. Apply tape only to smooth, rigid surfaces like painted drywall, metal, or glass; never on textured walls, drywall seams, or flexible materials. Press firmly along the entire length for 30 seconds per meter to activate adhesion, and allow 72 hours for full bond strength before powering on. Crucially, never use tape as the sole mounting method for any fixture exceeding 150g/m, in areas with temperature swings above 10°C hourly, or where safety risks exist. For all permanent commercial installations in these sectors, engineered mechanical fastening systems are the only professionally acceptable solution—tape is a temporary compromise with significant liability risks.

Why Choose Beauty STC Lighting

Looking for reliable double sided tape for LED lights? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions. Our high-quality adhesive products are designed for durability, strong bonding, and seamless installation in a variety of lighting applications. Ensure your projects are built to last with performance you can count on.

Take the next step in enhancing your product line. Contact us today at [email protected] to discuss how Beauty STC can support your business with premium double sided tape solutions tailored to your needs.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.