Article Contents

Industry Insight: Led Crown Moulding

In the evolving landscape of commercial and industrial lighting, LED crown moulding has emerged as a versatile and energy-efficient solution for architectural accent and functional illumination. Once primarily associated with residential trim lighting, LED crown moulding has gained significant traction in commercial spaces—including retail environments, hospitality venues, office lobbies, and healthcare facilities—where aesthetic appeal meets performance-driven design. These low-profile lighting systems combine sleek integration with high lumen output, enabling designers and facility managers to achieve ambient lighting effects without sacrificing energy efficiency or maintenance schedules.

A critical factor in the adoption of LED crown moulding in commercial applications is compliance with stringent safety and performance standards. Products bearing ETL and CE certifications ensure adherence to North American and international electrical safety requirements, offering peace of mind in large-scale installations where reliability and code compliance are paramount. These certifications validate not only electrical safety but also thermal management and long-term durability—key considerations in demanding industrial environments.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovative LED lighting solutions for over two decades. Specializing in high-performance linear lighting systems, Beauty STC combines precision engineering with rigorous quality control to deliver products that meet the exacting demands of commercial and industrial clients worldwide. With a strong focus on research, compliance, and sustainable design, the company continues to set benchmarks in the LED crown moulding segment, offering reliable, code-compliant lighting that blends form, function, and lasting value.

Technical Specs & Certifications

LED crown moulding lighting refers specifically to flexible or rigid LED strip systems engineered for seamless integration into crown moulding profiles, coves, and architectural detailing in residential and commercial interiors. At Beauty STC Manufacturing Co., Ltd., we prioritize precision optics and reliability for this application. Our standard technical specifications for high-quality LED crown moulding strips are rigorously defined to meet demanding aesthetic and performance requirements. Lumens per watt efficiency is a core metric; our current generation strips consistently achieve 120-130 lumens per watt at 2700K to 3000K color temperatures under standard operating conditions. This efficiency is realized through the strategic selection of high-efficacy mid-power LEDs combined with optimized driver circuitry and thermal management substrates, ensuring minimal energy waste while delivering ample illumination for indirect lighting schemes.

Critical to the visual quality in architectural applications is the Color Rendering Index. Beauty STC mandates a minimum CRI of Ra95 across all standard crown moulding LED strip offerings, significantly exceeding the requested Ra90 threshold. This exceptional color fidelity is achieved using precisely tuned tri-phosphor or multi-phosphor LED packages with strong spectral output across the visible spectrum, particularly in the deep red (R9) region which is essential for rendering warm tones accurately in wood finishes, fabrics, and skin tones commonly found in living spaces. We implement strict binning protocols during manufacturing to guarantee consistent high-CRI performance across all production batches, avoiding the color shifts that plague lower-tier products.

Regarding Ingress Protection ratings, standard indoor crown moulding installations typically require only IP20 classification, as the strips are fully enclosed within the moulding profile and shielded from physical contact and dust ingress according to IEC 60529 standards. Beauty STC’s standard crown moulding strips are manufactured to IP20, featuring conformal coating on the PCB for basic protection against non-hazardous dust accumulation during installation and operation. We do not recommend or produce IP65 or higher rated strips for standard crown moulding use, as the necessary silicone encapsulation would compromise the critical optical clarity, narrow beam control, and thermal dissipation required for optimal performance in these tight, concealed spaces. For exceptionally rare applications where moisture exposure might occur within the cavity, such as certain high-humidity commercial spaces, we offer a specialized IP65-rated rigid profile variant with a precisely engineered optical lens, though this is not the norm for residential crown lighting.

Beauty STC’s commitment to quality is embedded throughout the product lifecycle for our LED crown moulding systems. We utilize only Tier-1 LED components from global leaders, subjected to our stringent incoming inspection protocols including spectral analysis and flux verification. Every strip undergoes 100% functional testing and a minimum 48-hour aging process on our production line to identify early failures, far exceeding industry norms. Our proprietary thermal management substrates, utilizing high-conductivity aluminum core PCBs, ensure junction temperatures remain well below critical thresholds even during continuous operation, directly contributing to the sustained lumen maintenance and color stability that our customers expect. This rigorous approach to material selection, process control, and validation testing results in LED crown moulding solutions that deliver not only the specified lumens per watt and exceptional CRI but also the long-term reliability and consistent optical performance that define Beauty STC’s reputation in the architectural lighting market.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial and manufacturing hubs. The Jiangmen factory is purpose-built for the production of high-quality LED lighting products, with a strong emphasis on precision, consistency, and scalability. The facility incorporates advanced automation and strict quality control systems to meet international standards.

At the core of the production line are state-of-the-art SMT (Surface Mount Technology) machines, which enable the accurate and efficient placement of LED components onto printed circuit boards. These SMT lines are fully automated, supporting high-speed assembly with minimal error rates, ensuring uniformity and reliability across large production batches. The use of advanced pick-and-place machines, reflow soldering systems, and automated optical inspection (AOI) ensures that each PCB assembly meets rigorous performance and durability standards.

To guarantee long-term reliability, Beauty STC conducts comprehensive aging tests on all LED products, including led crown molding profiles. These aging tests simulate extended operational periods under controlled conditions, such as elevated temperatures and continuous power cycling. This process helps identify early failure points, validates thermal management performance, and confirms the stability of light output and color consistency over time. The aging test protocols are aligned with international quality benchmarks, contributing to the product’s longevity and customer satisfaction.

Beauty STC also offers robust OEM (Original Equipment Manufacturing) capabilities, particularly for specialized products like LED crown molding. The company supports custom design, engineering, and production services tailored to client specifications. This includes custom profiles, dimming options, color temperatures, lengths, and packaging. With in-house mold development, R&D support, and flexible production scheduling, Beauty STC can efficiently accommodate both small-batch prototyping and large-scale OEM orders. Their expertise in extrusion, SMT integration, and final assembly allows them to deliver fully customized LED crown molding solutions that meet exact aesthetic and functional requirements.

Overall, the Jiangmen factory combines advanced manufacturing technology with flexible customization options, making Beauty STC a reliable partner for high-performance, branded, and private-label LED lighting solutions.

Application Scenarios

LED crown moulding serves as a sophisticated architectural lighting solution primarily for creating ambient, indirect illumination in commercial spaces. Its strategic placement enhances aesthetics while providing functional benefits across hospitality, retail, and corporate environments. Within hotels, this application is most effective in lobbies to establish a welcoming atmosphere with soft upward glow that accentuates ceiling height and architectural details. Ballrooms and high-end restaurants utilize it to create layered lighting schemes that support both grand events and intimate dining through dimmable systems. Guest room corridors benefit from its subtle guidance lighting, reducing harsh shadows while maintaining a premium feel. Executive suites and premium guest rooms often incorporate it above door frames or along ceiling perimeters to elevate perceived space quality without direct glare.

For malls and mixed-use developments, LED crown moulding excels in high-traffic entryways and atriums where first impressions matter, using warm white temperatures to soften expansive spaces. Luxury retail storefronts and flagship boutiques integrate it within ceiling coves to highlight merchandise displays through reflected light, avoiding direct fixture visibility. Food court perimeters and upscale dining areas employ it to define zones with comfortable illumination that encourages lingering. Convention centers use it in registration halls and lounge areas to manage crowd flow through differentiated lighting zones while maintaining visual continuity.

In office environments, its optimal use is confined to executive offices, boardrooms, and high-end conference facilities where it creates a refined backdrop for video conferencing and client meetings. Reception areas leverage it to project professionalism through layered lighting that minimizes harsh contrasts. Collaborative lounge spaces and premium breakout areas benefit from its ability to provide ambient light without the visual fatigue associated with exposed fixtures. However, it is generally unsuitable for open-plan workstations due to potential indirect glare on computer screens and insufficient task illumination levels required for productivity.

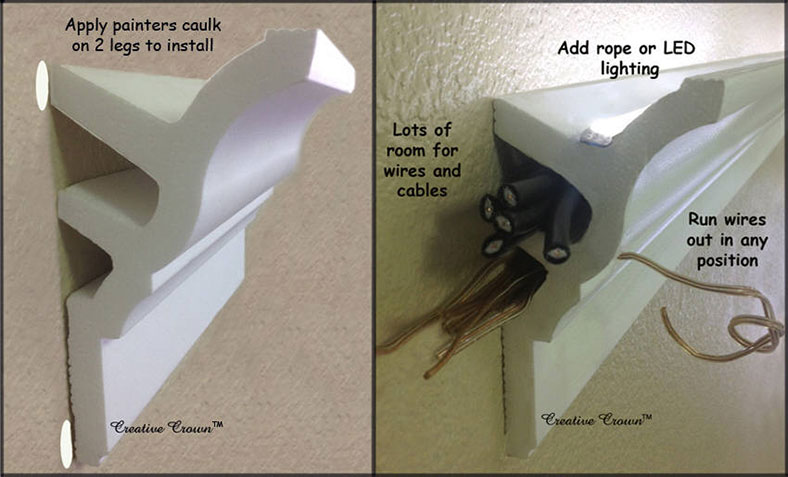

Installation requires meticulous attention to structural and electrical considerations. Ensure the mounting surface is perfectly level and securely anchored to wall studs or ceiling joists, as standard drywall alone cannot support continuous molding weight. Maintain a minimum 15mm gap between the molding’s top edge and ceiling surface to accommodate LED strips and diffusion while preventing thermal throttling. For runs exceeding 10 meters, implement parallel wiring from multiple junction boxes to avoid voltage drop that causes color shift and reduced output at distal ends. Always use silicone-based diffusers with minimum 3mm thickness to eliminate dotting effects, and verify compatibility between LED color temperature and the molding’s interior finish—light-colored surfaces reflect 30% more usable light than dark stains. Integrate thermal management by selecting aluminum-backed LED strips and ensuring airflow within the cove, especially in enclosed molding profiles. Critical for commercial compliance, all components must carry UL/ETL certification for damp locations if installed in lobbies with exterior exposure, and wiring must adhere to NEC Article 410 with accessible junction points every 3 meters. Always conduct a full-scale mockup before full installation to evaluate light distribution against actual wall textures and adjacent finishes.

Why Choose Beauty STC Lighting

Discover the perfect blend of elegance and innovation with our LED crown moulding solutions. Partner with Beauty STC, a trusted leader in premium LED lighting manufacturing, to bring high-quality, energy-efficient designs to your projects. Whether you’re working on residential, commercial, or hospitality spaces, our LED crown moulding delivers superior performance and aesthetic appeal.

To learn more or discuss a custom solution for your needs, contact us today at [email protected]. Let Beauty STC be your go-to partner for advanced lighting innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.