Article Contents

Industry Insight: Individually Addressable Led Strip

The commercial and industrial lighting landscape is undergoing a profound transformation, driven by the demand for intelligent, adaptable, and value-driven illumination solutions. At the forefront of this evolution is individually addressable LED strip technology, which moves far beyond simple ambient lighting to become a dynamic architectural and functional element. Unlike traditional static or zone-controlled systems, these advanced strips empower designers and facility managers to precisely control the color, intensity, and animation of each individual LED node along the length of the strip. This granular control unlocks unprecedented creative potential for retail environments seeking immersive brand experiences, hospitality venues crafting mood-specific atmospheres, industrial facilities implementing intuitive wayfinding or machine status indication, and architectural facades delivering captivating visual displays. The technology’s inherent flexibility allows for responsive lighting that adapts to occupancy, time of day, or specific operational needs, directly contributing to enhanced user experience, improved safety, and optimized energy consumption in professional settings.

Critical to the successful deployment of individually addressable LED strips in demanding commercial and industrial applications is unwavering reliability and strict adherence to global safety standards. Products lacking essential certifications like ETL (North America) and CE (Europe) pose significant risks, including electrical hazards, premature failure, and non-compliance with building codes, potentially leading to costly project delays, liability issues, and operational disruptions. Professional installations require components engineered for continuous operation, robust thermal management, and resilience against environmental factors common in workplaces and public spaces. Specifying strips with verified ETL and CE marks is not merely a regulatory checkbox; it is a fundamental requirement ensuring the safety, longevity, and predictable performance necessary for mission-critical lighting infrastructure where downtime is unacceptable and safety is paramount.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been a dedicated innovator and trusted partner in the professional LED lighting industry for over 25 years. We understand the unique challenges and stringent requirements of commercial and industrial projects. Our expertise is deeply rooted in developing high-performance, certified lighting solutions, including advanced individually addressable LED strip systems designed specifically for professional integration. We prioritize engineering excellence, rigorous quality control, and full compliance with international safety standards like ETL and CE, ensuring our products deliver the reliability, efficiency, and creative versatility demanded by architects, lighting designers, and facility managers worldwide. Beauty STC remains committed to pushing the boundaries of LED technology to provide intelligent lighting that enhances environments, supports operations, and delivers lasting value.

Technical Specs & Certifications

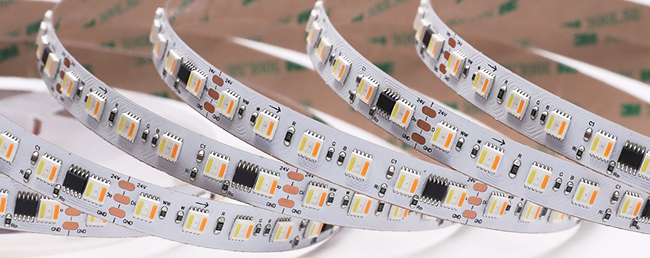

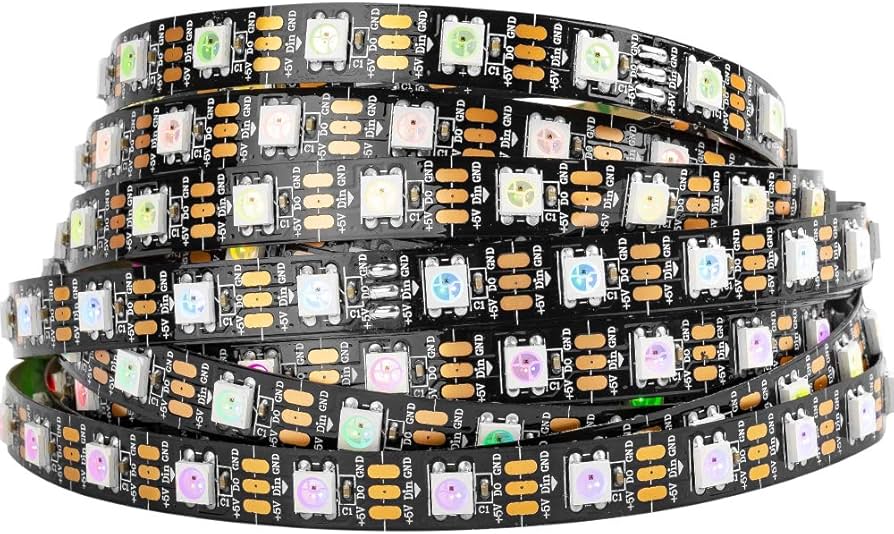

Individually addressable LED strips from Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance and precision lighting control, making them ideal for architectural accents, stage lighting, retail displays, and high-end residential applications. These strips utilize advanced chip-on-board (COB) or surface-mounted device (SMD) technologies such as SMD5050 or SMD3535 with integrated control ICs like the WS2812B, WS2815, or SK6812, enabling each LED to be controlled independently for dynamic color and brightness adjustments.

In terms of efficiency, Beauty STC’s individually addressable LED strips deliver a luminous efficacy ranging from 18 to 26 lumens per watt, depending on color temperature and drive current. While not the highest in efficiency compared to static white LED strips, this range is competitive within the RGB and RGBW addressable segment, where power is distributed across multiple diodes and control circuitry per pixel. The company optimizes driver matching and thermal management to ensure consistent output and longevity.

Color fidelity is a key strength of Beauty STC’s LED strips. Select high-CRI models are available with a Color Rendering Index (CRI) greater than 90, achieved through the use of premium phosphor coatings and tightly binned LEDs. These high-CRI variants are especially suited for applications where accurate color representation is critical, such as in photography studios, retail environments, and high-end interior design. The combination of high CRI and individually controllable LEDs allows for vibrant, natural-looking illumination with minimal color deviation.

Regarding environmental protection, Beauty STC offers individually addressable LED strips in multiple IP ratings to suit diverse installation conditions. IP20 versions are available for indoor, dry locations where protection is minimal. For damp or outdoor applications, the strips are available in IP65-rated configurations, featuring a silicone coating that protects against dust and low-pressure water jets. Fully encapsulated IP67 and IP68 variants are also offered, providing complete dust tightness and resistance to temporary or prolonged submersion in water, respectively. These higher IP-rated strips utilize double or triple-layer silicone encapsulation to maintain signal integrity and prevent moisture ingress without compromising flexibility.

Beauty STC upholds rigorous quality control standards in manufacturing, ensuring consistent soldering, reliable IC performance, and long-term durability. Their addressable strips undergo extensive thermal cycling, humidity, and electrical stress testing during production. Coupled with UL, CE, and RoHS certifications, Beauty STC’s commitment to quality ensures that their LED strips perform reliably in both commercial and demanding environments. With precision engineering, strong color performance, and robust protection ratings, Beauty STC’s individually addressable LED strips represent a premium solution for professional lighting applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant operational hub within the company’s production network. Strategically located within the Pearl River Delta, the Jiangmen factory leverages the region’s deep manufacturing ecosystem, robust supply chain infrastructure, and access to skilled technical labor. This location facilitates efficient logistics for both raw material sourcing and global shipment of finished goods. The facility is designed to support high-volume, precision manufacturing with a strong emphasis on quality control processes essential for modern LED lighting products.

The factory employs advanced Surface Mount Technology (SMT) production lines as the cornerstone of its LED strip assembly capability. These lines feature high-speed, high-precision placement machines from leading manufacturers, capable of handling the minute components required for individually addressable LED strips, including complex integrated circuit drivers like WS2812B, SK6812, or APA102. The SMT process utilizes multi-zone reflow soldering ovens with precise thermal profiling, often incorporating nitrogen environments to minimize oxidation and ensure superior solder joint integrity. Automated optical inspection (AOI) systems are integrated directly into the SMT lines, performing real-time verification of component placement accuracy, solder paste volume, and potential defects immediately after reflow. This level of precision is non-negotiable for addressable strips where consistent electrical connections across densely packed control ICs are critical for reliable pixel-level performance.

Rigorous aging and reliability testing form a fundamental part of the quality assurance protocol at the Jiangmen facility, particularly for individually addressable LED products. Completed strips undergo structured multi-stage aging procedures. Initial burn-in typically involves operating the strips at elevated temperatures, often between 60°C to 85°C, for extended periods ranging from 24 to 48 hours, significantly exceeding standard operational conditions. This process accelerates the identification of early-life failures in LEDs, control ICs, or solder joints. Concurrently, functional testing during aging verifies the stable operation of each individually addressable pixel across the entire strip length under various programmed sequences and brightness levels. Environmental stress testing may also be applied, including humidity exposure cycles. Post-aging, automated systems conduct final functional verification and visual inspection to ensure only units meeting stringent performance criteria proceed to packaging.

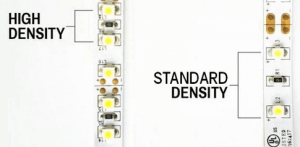

Beauty STC possesses substantial OEM capability specifically tailored for individually addressable LED strips, leveraging the Jiangmen factory’s infrastructure. This capability encompasses comprehensive customization options starting from the core product design. Clients can specify exact IC types, LED densities (e.g., 30, 60, 144 LEDs per meter), flexible PCB widths, and copper weights to meet thermal and electrical requirements. The factory supports custom lengths, cut points, connector types, and various waterproofing solutions including silicone coating or PVC jacketing. Crucially, Beauty STC offers firmware and protocol customization for the control ICs, allowing integration with specific control systems or proprietary protocols. The SMT lines are readily reconfigurable for different client specifications, and the aging/test protocols are adapted to each unique product variant’s requirements. This end-to-end OEM service extends to custom labeling, packaging configurations, and documentation, enabling clients to bring fully branded, application-specific addressable LED solutions to market efficiently. The integration of high-precision SMT, exhaustive aging validation, and deep customization expertise within a single facility ensures reliable, high-performance products meeting diverse client specifications for the demanding individually addressable LED strip market.

Application Scenarios

Individually addressable LED strips are ideal for applications where dynamic lighting effects, precise control, and customization are required. These strips allow each LED or group of LEDs to be controlled independently, enabling complex lighting patterns, color changes, animations, and integration with control systems. In commercial environments such as hotels, malls, and offices, they offer both functional and aesthetic advantages when used strategically.

In hotels, individually addressable LED strips are best used in guest room ambient lighting, such as under cabinets, behind headboards, or along cove ceilings to create customizable mood lighting. They are also effective in lobbies, bars, and event spaces where dynamic color schemes can enhance the guest experience. For example, color transitions during evening hours or synchronized lighting with music in lounge areas add a premium touch.

In malls, these LED strips are highly effective for accent lighting in signage, display windows, and architectural features like columns or staircases. They can be programmed to attract attention during promotions or holidays, with animated sequences or color shifts that draw customer focus. Integration with building management or retail automation systems allows for scheduled or responsive lighting based on foot traffic or time of day.

In offices, individually addressable LEDs are suitable for modern reception areas, meeting room accents, or under-cabinet task lighting in collaborative zones. While general office lighting typically favors uniform illumination, addressable strips can add brand-aligned color accents or support circadian lighting strategies when tuned to mimic natural daylight patterns. They should be used subtly to avoid distraction in workspaces.

When installing individually addressable LED strips, ensure a stable power supply, as inconsistent voltage can cause flickering or data errors—especially over long runs. Use a power injection strategy for runs exceeding 5 meters, connecting additional power at multiple points along the strip. Always follow the manufacturer’s polarity and data direction markings; reversing data flow or power connections can damage the LEDs.

Use high-quality data cables and consider signal boosters for installations longer than 10 meters to prevent data degradation. Protect connections with waterproof enclosures if installed in areas exposed to dust or moisture. For control, pair the strips with compatible controllers—such as DMX, DALI, or proprietary systems—and ensure firmware is up to date for smooth operation.

Finally, plan the layout carefully during the design phase, considering bend radius, mounting surfaces, and accessibility for maintenance. Use aluminum channels to diffuse light evenly and improve heat dissipation, which extends LED lifespan. Test the system thoroughly before final concealment or finishing work to verify addressability and color consistency across all segments.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I emphasize that our individually addressable LED strips deliver unparalleled precision for dynamic lighting applications. These strips enable pixel-level control for intricate animations, architectural detailing, and immersive environments—critical for high-end commercial and residential projects where standard solutions fall short. Partnering with Beauty STC means accessing rigorously tested, industry-leading technology engineered for reliability, color consistency, and seamless integration with major control systems.

Our manufacturing expertise ensures superior thermal management and longevity, reducing field failures and maintenance costs for your clients. We provide full technical support, including custom configuration and prototyping, to meet your project’s exact specifications. Elevate your lighting designs with hardware built to perform under demanding conditions.

Contact our partnership team today to discuss how Beauty STC’s individually addressable LED strips can differentiate your offerings. Reach Manager directly at [email protected] to initiate a technical consultation or request samples. Let us engineer the future of light together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.