Article Contents

Industry Insight: Covers For Led Strip Lights

In the rapidly evolving landscape of commercial and industrial lighting, LED strip lights have become a cornerstone of energy-efficient, flexible illumination solutions. As demand grows for sleek, durable, and code-compliant lighting systems, the importance of high-quality covers for LED strip lights has risen significantly. These protective and diffusive elements not only enhance light distribution and visual comfort but also ensure compliance with rigorous safety and performance standards such as ETL and CE—critical benchmarks for deployment in regulated environments including manufacturing facilities, warehouses, retail spaces, and institutional buildings.

Since 1998, Beauty (STC) Manufacturing Co., Ltd. has stood at the forefront of innovative LED lighting components, delivering engineered solutions that meet the exacting demands of professional environments. With a deep commitment to quality, durability, and regulatory compliance, Beauty STC has built a trusted reputation for producing covers that protect, optimize, and elevate the performance of LED strip lighting across a broad spectrum of industrial and commercial applications.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. provides high-performance protective covers and housings for LED strip lights, designed to maintain the optical integrity and environmental resilience of the underlying LED system. It is critical to clarify that lumens per watt (lm/W) and Color Rendering Index (CRI) are inherent specifications of the LED strip itself, not the cover. The cover’s role is to protect the strip while minimizing negative impact on these key performance metrics. Beauty STC covers are engineered specifically to preserve the high efficiency and color quality of premium LED strips.

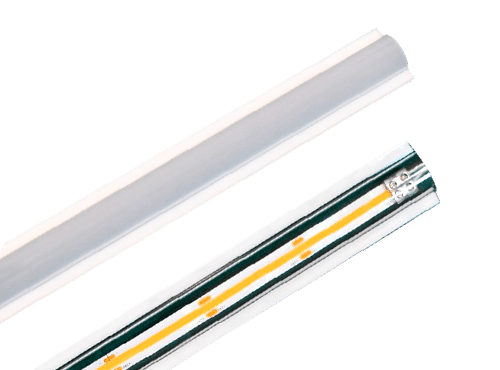

Lumens per watt is a measure of the LED emitter and driver efficiency. Beauty STC covers utilize advanced optical-grade polycarbonate or acrylic diffusers with high transmittance properties, typically exceeding 90-92%. This minimizes light loss, ensuring the final delivered lumens remain close to the strip’s rated output. Poor quality covers can cause significant lumen depreciation (10-20% or more), but Beauty STC’s precision-engineered diffusers maintain system efficiency, supporting overall lm/W values of the integrated solution by limiting optical losses to less than 5% under standard conditions. This allows the high-efficiency LED strips (often 120-150+ lm/W) to perform optimally within the protected assembly.

Regarding CRI, values exceeding 90 are achieved solely by the LED chip technology and phosphor formulation within the strip. Beauty STC covers play a vital role in preserving this high CRI by utilizing diffuser materials with neutral spectral transmission. Our covers avoid yellowing or color shift over time, which can degrade CRI in inferior housings. The optical clarity and stability of our polycarbonate formulations ensure the light exiting the cover maintains the strip’s original color fidelity and Ra value above 90, critical for applications like retail, hospitality, and residential settings where accurate color representation is non-negotiable. Beauty STC rigorously tests diffuser materials for long-term color neutrality to uphold this standard.

IP ratings are a direct function of the cover design, sealing, and installation. Beauty STC specializes in robust extruded aluminum or polycarbonate profiles with integrated silicone gaskets. We offer covers rated IP65 for dust-tight and low-pressure water jet resistance, suitable for indoor damp locations and some outdoor eaves. For full outdoor exposure or washdown environments, our IP67-rated covers provide protection against temporary immersion up to 1 meter. Key to achieving these ratings are the precision extrusion tolerances, UV-stabilized materials, and high-quality compression-molded silicone seals that maintain integrity across wide temperature ranges (-40°C to +80°C). Beauty STC subjects all IP-rated covers to stringent in-house testing per IEC 60529 standards, including prolonged water ingress and dust chamber validation, ensuring consistent field performance.

Beauty STC’s quality is distinguished by our commitment to material science and precision manufacturing. We use only virgin-grade polycarbonate with UV inhibitors to prevent yellowing and brittleness, and marine-grade aluminum alloys for structural profiles. Every cover undergoes optical transmittance verification, dimensional inspection, and seal integrity testing. Our diffusers are optimized for uniform light distribution without hotspots, directly supporting the high CRI and lm/W performance of the LED strips they protect. This focus on preserving the core LED performance metrics, combined with superior environmental protection, makes Beauty STC covers the trusted choice for demanding architectural and commercial lighting installations where reliability and optical quality are paramount.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and well-equipped facility specializing in the production of LED lighting products and related components. Strategically located in the Jiangmen high-tech industrial zone, the factory benefits from streamlined logistics and access to a skilled manufacturing workforce, supporting both domestic and international markets.

The factory is outfitted with advanced Surface Mount Technology (SMT) production lines, which are critical for the precise and efficient assembly of LED strip light components. These SMT machines ensure high-speed placement of small electronic parts onto printed circuit boards (PCBs), delivering consistent quality and reliability in every batch. The SMT process is fully automated, incorporating automatic solder paste printing, component placement, reflow soldering, and AOI (Automated Optical Inspection) systems to detect defects and ensure product integrity before proceeding to the next stage.

A key part of the quality assurance process at the Jiangmen facility is the aging test procedure. All LED strip lights and their components undergo rigorous aging tests under controlled conditions that simulate extended usage. These tests typically run for 24 to 72 hours at elevated temperatures and full operational power to identify early failure points, verify thermal performance, and ensure long-term stability. The data collected during aging helps improve product design and manufacturing consistency, reinforcing Beauty STC’s commitment to durability and high performance.

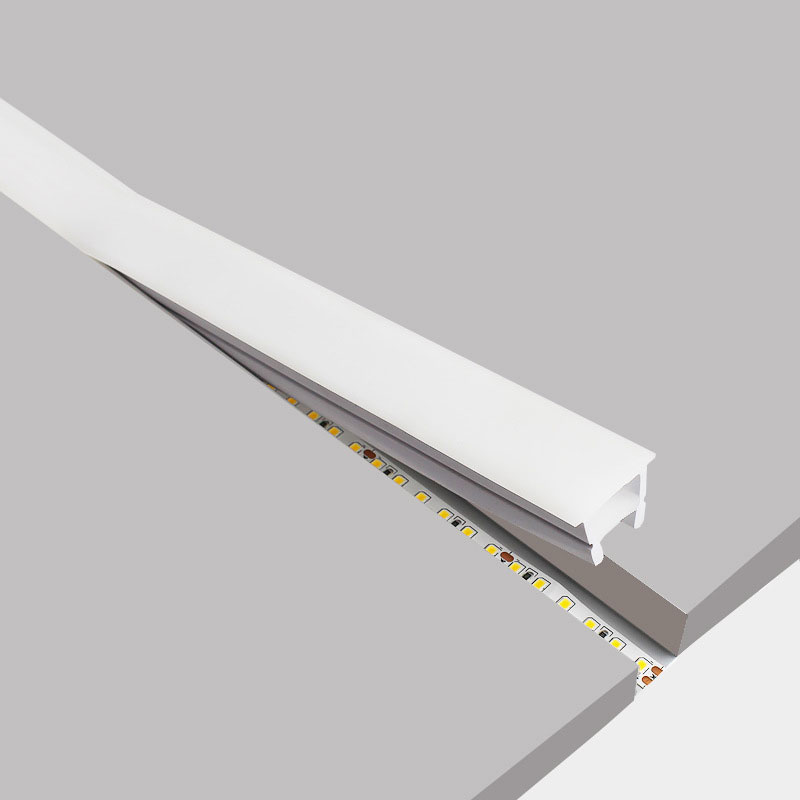

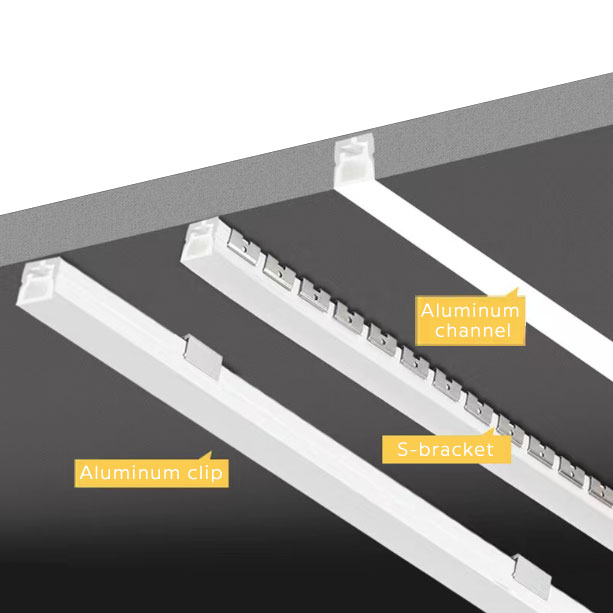

In addition to full LED strip light production, Beauty STC offers strong OEM (Original Equipment Manufacturer) capabilities for custom covers used in LED strip light systems. These covers—commonly made from polycarbonate (PC) or polymethyl methacrylate (PMMA)—are designed to diffuse light evenly, protect the LED strips, and enhance aesthetic appeal. The factory can customize covers in various shapes, lengths, color temperatures, and diffusing levels (such as milky, clear, or frosted) to meet specific client requirements. With in-house mold development, extrusion capabilities, and precision cutting, Beauty STC supports low to high-volume OEM orders with fast turnaround times and strict adherence to quality standards.

Overall, the Jiangmen factory combines automation, rigorous testing, and flexible manufacturing to deliver reliable, high-quality LED lighting solutions and components tailored to global customer needs.

Application Scenarios

Covers for LED strip lights serve critical functional and aesthetic purposes in commercial environments like hotels, malls, and offices, where lighting quality directly impacts user experience, safety, and brand perception. In hotels, covers are essential for cove lighting in lobbies, hallways, and guest room headboards or under cabinets to create a seamless, glare-free ambient glow that enhances luxury and comfort. Exposed strips would appear unrefined and cause visual discomfort, undermining the premium atmosphere. For malls, covers are indispensable in retail display lighting, cove ceilings, and signage to ensure uniform illumination without visible dots or hotspots, which is vital for showcasing merchandise effectively and maintaining a high-end shopping environment. Uncovered strips would create distracting inconsistencies that diminish product appeal. In offices, covers are non-negotiable for under-cabinet task lighting, partition coves, and architectural features to eliminate harsh glare that causes eye strain and reduces productivity, while providing the clean, professional finish expected in corporate settings.

Installation requires meticulous attention to detail to maximize performance and longevity. Always select covers specifically engineered for the LED strip’s width and beam angle to prevent dark spots or excessive diffusion; mismatched profiles compromise optical quality. Thoroughly clean mounting surfaces with isopropyl alcohol to ensure strong adhesion for adhesive-backed channels, as dust or oils cause premature detachment. Maintain precise alignment during installation using laser levels, especially for long runs, to avoid visible gaps or uneven light distribution that detracts from the intended effect. Allow adequate thermal expansion gaps—typically 2–3 mm per meter—between cover sections in environments with significant temperature fluctuations like malls with high foot traffic, preventing warping or cracking. For recessed channels, verify the cover’s IP rating matches the location; use IP65-rated polycarbonate covers in hotel pool areas or mall restrooms to resist moisture and cleaning chemicals. Crucially, test the entire LED system for at least 30 minutes before final sealing to identify any flickering or thermal issues, as trapped heat from inadequate ventilation can drastically shorten LED lifespan. Finally, choose UV-stable materials like STC’s anti-yellowing polycarbonate for all installations, particularly in sunlit hotel atriums or mall entrances, to prevent discoloration that degrades light quality within months. Proper cover selection and installation transform basic LED strips into a refined, durable lighting solution that meets commercial demands.

Why Choose Beauty STC Lighting

Transform your LED lighting projects with high-quality covers designed to enhance performance and aesthetics. At Beauty STC, we specialize in precision-engineered covers for LED strip lights that deliver superior diffusion, durability, and seamless integration. Partner with us to access custom solutions, consistent quality, and expert support tailored to your specifications.

To learn more or discuss your project needs, contact our team at [email protected]. Let Beauty STC be your trusted manufacturing partner in lighting innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.