Article Contents

Industry Insight: Led Profiles

The commercial and industrial lighting sector is undergoing a fundamental transformation, driven by the relentless demand for energy efficiency, operational longevity, and seamless architectural integration. Central to this evolution is the strategic adoption of LED profiles, which have moved beyond simple mounting solutions to become critical thermal management and optical control systems. These engineered channels are no longer optional accessories; they are essential infrastructure ensuring LED modules operate within optimal temperature ranges, maximizing lumen maintenance and lifespan while enabling clean, professional installations that meet stringent aesthetic and safety requirements for offices, warehouses, retail spaces, and manufacturing facilities. Crucially, compliance with rigorous safety standards like ETL (North America) and CE (Europe) is non-negotiable for market access and user safety, demanding profiles designed and tested from the outset to meet these exacting electrical and mechanical benchmarks. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of focused expertise to this critical segment. We understand the unique stresses of commercial and industrial environments and engineer our LED profiles not merely to hold LEDs, but to actively enhance system performance, reliability, and compliance, providing specifiers and contractors with solutions built for real-world demands.

Technical Specs & Certifications

LED profiles from Beauty (STC) Manufacturing Co., Ltd. are engineered to meet high-performance standards for both residential and commercial lighting applications. These profiles are designed not only for optimal LED strip integration and thermal management but also to support consistent, high-quality light output through compatibility with premium LED components.

In terms of efficiency, our recommended LED systems paired with Beauty STC profiles typically deliver luminous efficacies ranging from 110 to 140 lumens per watt, depending on the LED chipset, driver configuration, and optics used. This range ensures energy-efficient lighting solutions that reduce power consumption while maintaining excellent brightness levels suitable for task, ambient, and accent lighting.

A critical aspect of light quality is the Color Rendering Index (CRI), which measures how accurately a light source reveals the true colors of objects compared to natural light. Beauty STC emphasizes compatibility with LED strips and modules that offer a CRI greater than 90—specifically Ra >90—ensuring vibrant, natural color reproduction. High CRI lighting is essential in retail, hospitality, healthcare, and residential environments where visual clarity and ambiance are paramount. We recommend partnering our profiles with LEDs featuring CRI90+ and, for premium applications, even CRI95+ or R9 >50 for enhanced red color rendering.

Regarding environmental protection, the IP (Ingress Protection) rating of the complete lighting installation depends on both the LED strip and the profile’s diffuser and end caps. Beauty STC offers profiles designed for a wide range of IP ratings. For damp or high-dust environments such as bathrooms, kitchens, or outdoor installations, our profiles support IP65 and IP67-rated setups when paired with appropriate silicone gaskets, end caps, and diffusers. This ensures resistance to dust, moisture, and water jets, enhancing longevity and reliability.

Beauty STC is committed to quality and precision in every profile. Our products are manufactured using high-grade aluminum alloys for superior heat dissipation, reducing lumen depreciation and extending LED lifespan. Precision extrusion, clean anodized or powder-coated finishes, and tight-tolerance diffusers reflect our dedication to durability and aesthetic integration. All profiles undergo rigorous quality control to ensure dimensional accuracy and consistent performance across large-scale projects.

By combining high lumens per watt, support for CRI >90 LED systems, and compatibility with IP-rated installations, Beauty STC’s LED profiles deliver a robust, future-ready lighting foundation that meets the demands of modern architectural and design standards.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as a core production hub for our LED lighting solutions, emphasizing precision engineering and rigorous quality control. The factory spans a significant footprint designed for efficient material flow and scalable output, housing dedicated zones for extrusion, surface treatment, SMT assembly, aging, and final testing. This integrated setup allows us to maintain strict oversight of the entire production chain for LED profiles and associated components.

The SMT (Surface Mount Technology) production line represents a key technological asset within the Jiangmen facility. We operate multiple high-speed, high-precision Yamaha YS series placement machines, specifically configured for the demanding requirements of LED lighting assembly. These machines handle complex PCBs with component densities typical of modern LED drivers and control modules, achieving placement accuracies within ±25µm and speeds exceeding 60,000 components per hour per line. The dual-lane configuration supports both high-volume production runs and flexible small-batch manufacturing, crucial for meeting diverse client demands. The lines are integrated with automated optical inspection (AOI) systems immediately post-reflow, ensuring immediate detection and correction of soldering defects like bridging, tombstoning, or misalignment before boards proceed to subsequent stages.

Aging testing is a non-negotiable step rigorously applied to all LED profile assemblies and critical components before shipment. Our dedicated aging chamber area utilizes large-scale, temperature-controlled environmental chambers capable of maintaining precise conditions between 25°C to 65°C with controlled humidity. Standard aging protocols involve continuous operation at elevated temperatures (typically 50°C-55°C) for a minimum of 72 hours, significantly exceeding basic industry norms. During this period, automated monitoring systems continuously track critical parameters including forward voltage, current draw, lumen output, and thermal performance across every unit. Any unit exhibiting parameter drift beyond stringent internal tolerances is automatically flagged for failure analysis and corrective action, ensuring only units demonstrating proven stability and reliability reach the customer. This extended burn-in process is fundamental to minimizing infant mortality in the field.

Our OEM capability for LED profiles is a significant strength developed and executed at the Jiangmen site. We offer comprehensive turnkey solutions starting from raw aluminum extrusion. Clients can specify exact profile dimensions, thermal management requirements, and optical characteristics, which our engineering team validates for manufacturability and performance. The factory handles the full process: precision extrusion of aluminum alloys (primarily 6063-T5), cutting to custom lengths, meticulous surface preparation, and a range of finishing options including anodizing (clear, black, colored) and powder coating to achieve specific aesthetic and durability requirements, including various IP ratings when combined with appropriate diffusers and end caps. We integrate SMT-assembled PCBs, drivers, and connectors seamlessly into the profiles per client specifications. Crucially, this OEM service extends beyond manufacturing to include collaborative engineering support for thermal design, optical optimization, and compliance testing, alongside robust supply chain management and ERP-integrated production tracking for full transparency and on-time delivery. The Jiangmen facility’s integrated capabilities ensure consistent quality and scalability for OEM partners demanding high-performance, custom LED linear lighting solutions.

Application Scenarios

LED profiles are essential components in modern architectural and decorative lighting design, offering both functional and aesthetic benefits. They are widely used across various commercial and hospitality environments such as hotels, malls, and offices due to their ability to enhance ambiance, provide uniform illumination, and protect LED strips.

In hotels, LED profiles are commonly installed in guest rooms, lobbies, corridors, and wellness areas. They are used for cove lighting along ceilings, under bed frames, in wardrobes, and within bathrooms to create a soft, welcoming glow. Recessed linear lighting in hallways using LED profiles ensures even light distribution while maintaining a sleek, modern appearance. The integration of diffusers in the profiles helps eliminate the dotted effect of individual LEDs, delivering a smooth and continuous light line that elevates the luxury feel of the space.

Malls benefit from LED profiles in both functional and decorative applications. They are frequently used in cove lighting around atriums, above storefronts, and along escalator handrails to guide visitor flow and highlight architectural features. Back-of-counter lighting in kiosks and accent lighting on display shelves enhance product visibility. The durability and clean finish provided by LED profiles make them ideal for high-traffic areas, where aesthetics and reliability are critical.

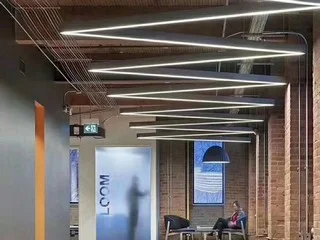

In office environments, LED profiles contribute to a professional and well-lit workspace. They are often installed in dropped ceilings, under shelves, along stair edges, and in partition walls to provide indirect lighting that reduces glare and eye strain. Task lighting in reception desks or meeting room tables using discreet LED profiles improves functionality without compromising design. In open-plan offices, linear lighting with profiles can define zones and support a modern, organized look.

When installing LED profiles, proper planning and technique are crucial for optimal performance and appearance. First, ensure the surface is clean, dry, and level before mounting the profile. Use appropriate brackets or clips at regular intervals—typically every 30 to 50 cm—to maintain alignment and prevent sagging, especially for longer runs. For recessed installations, verify the cavity depth and width match the profile dimensions, allowing space for thermal dissipation. Always install the LED strip correctly within the profile channel, ensuring it is centered and secured with adhesive or mounting clips. Attach the diffuser only after the LED strip is properly seated to avoid shadows or uneven light output. In high-temperature areas, choose aluminum profiles for better heat dissipation, which extends the lifespan of the LEDs. Finally, for seamless multi-section runs, use joiners to connect profiles and align the diffusers carefully to maintain a continuous visual line.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s precision-engineered LED profiles designed for superior performance and seamless integration. Our aluminum extrusions combine advanced thermal management with optical excellence ensuring consistent light distribution and extended fixture longevity across architectural and commercial applications. Partner with Beauty STC to access customizable solutions backed by rigorous engineering standards and in-house technical support. Contact our dedicated partnership manager directly at [email protected] to discuss tailored profiles for your next project. Let us help you achieve flawless illumination outcomes through collaborative engineering expertise.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.