Article Contents

Industry Insight: Led Under Cabinet Lighting Plug In

The commercial and industrial lighting sector faces escalating demands for energy-efficient, reliable, and easily deployable solutions, particularly within task-specific applications like under-cabinet illumination. In environments ranging from high-volume restaurant kitchens and sterile laboratory workspaces to bustling retail displays and precision manufacturing benches, the limitations of legacy fluorescent under-cabinet systems—poor energy performance, frequent maintenance, and complex hardwired installations—are increasingly untenable. Modern plug-in LED under-cabinet lighting has emerged as a critical upgrade path, offering significant reductions in operational costs, superior light quality for detailed tasks, and crucially, simplified installation without the need for permanent electrical modifications or certified electricians. This plug-and-play advantage directly addresses the operational agility and rapid deployment needs of facility managers and business owners, minimizing downtime during installation or reconfiguration. However, commercial viability hinges on rigorous compliance; products must demonstrably meet stringent safety and performance standards, with ETL certification for the North American market and CE marking for Europe being non-negotiable requirements to ensure user safety, insurance compliance, and seamless integration into diverse global infrastructures. Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over 25 years to engineering precisely these types of robust, specification-grade LED lighting solutions. Our deep expertise in commercial and industrial applications informs every design, ensuring our plug-in under-cabinet systems deliver the durability, certified performance, and ease of use demanded by professional environments. As the industry evolves, understanding the intersection of user-centric design, regulatory adherence, and operational efficiency becomes paramount for lighting professionals specifying these essential task lighting tools.

Technical Specs & Certifications

LED under cabinet lighting with plug-in power options are designed for easy installation and reliable performance in kitchen and workspace environments. At Beauty (STC) Manufacturing Co., Ltd., our LED under cabinet lighting solutions are engineered to deliver high efficiency, accurate color rendering, and long-term durability.

Our plug-in LED under cabinet lights typically achieve an efficiency of 90 to 110 lumens per watt, ensuring bright illumination while maintaining low energy consumption. This high lumens-per-watt ratio is achieved through the use of high-quality SMD (Surface Mount Device) LED chips and optimized driver technology, allowing for uniform light distribution and minimal lumen depreciation over time.

Color Rendering Index (CRI) is a critical factor in lighting for task and ambient environments. Beauty STC’s LED under cabinet lighting consistently delivers a CRI greater than 90, with some models reaching CRI 95+. This ensures that colors appear natural and vibrant, which is especially important in kitchen settings where food preparation and color accuracy matter. The high CRI is achieved through precision phosphor coating and strict binning processes during LED manufacturing.

In terms of environmental protection, our plug-in under cabinet LED lights are generally rated at IP20, as they are intended for indoor, dry locations such as above countertops and cabinets. While not designed for direct exposure to moisture or outdoor use, the internal components are protected with conformal coating on the PCBs to resist dust and minor humidity, enhancing reliability and lifespan. For applications requiring higher protection, customized solutions with higher IP ratings can be developed upon request.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control standards in line with ISO 9001 certification. Our products undergo extensive testing for thermal management, electrical safety, and photometric performance. We use premium materials including aluminum heat sinks for efficient thermal dissipation and high-transmission acrylic or polycarbonate diffusers to minimize glare and ensure smooth light output. All drivers are UL or ETL listed and designed for stable performance with minimal flicker, contributing to user comfort and eye health.

In summary, Beauty STC’s plug-in LED under cabinet lighting combines high efficiency (90–110 lm/W), superior color rendering (CRI >90), and robust build quality for reliable indoor use. These features, backed by our manufacturing excellence, make our lighting solutions a trusted choice for residential and light commercial applications.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern, ISO 9001 and ISO 14001 certified manufacturing facility in Jiangmen, Guangdong Province, China. This strategically located factory leverages Jiangmen’s strong industrial infrastructure and supply chain ecosystem for electronics manufacturing. The facility is purpose-built for high-volume, precision LED lighting production, featuring controlled cleanroom environments for critical assembly processes and dedicated zones for different production stages to ensure workflow efficiency and quality control.

The Surface Mount Technology (SMT) production line forms the core of our electronics assembly capability. It is equipped with multiple high-speed, high-precision Yamaha YS Series placement machines, specifically the YS12 and YS24 models. These machines handle components ranging from large electrolytic capacitors down to ultra-miniature 0201 package LEDs and ICs with exceptional accuracy. The line is fully integrated, beginning with automated solder paste printing using GKG printers, followed by component placement, dual-zone nitrogen-reflow soldering in JUKI ovens for optimal joint reliability, and comprehensive Automated Optical Inspection (AOI) using Koh Young systems for 100% solder joint and component placement verification. This SMT line achieves a combined throughput exceeding 50,000 components per hour while maintaining stringent process control, essential for the consistent quality required in LED lighting PCBs.

Rigorous aging and reliability testing are non-negotiable steps in our production process, particularly for LED under cabinet lighting where longevity is critical. Every finished LED module undergoes a mandatory 48-hour continuous burn-in test at an elevated ambient temperature of 50°C within our dedicated environmental aging chambers. These chambers precisely control both temperature and humidity (typically maintained at 40-60% RH) to simulate accelerated stress conditions. During this period, each unit operates at full rated power, and its electrical parameters, light output, and thermal performance are continuously monitored. Any unit exhibiting even minor deviations from specification is automatically flagged and removed from the production flow. Following the burn-in, 100% functional testing verifies photometric performance, color consistency, and driver functionality under load before final packaging.

Our OEM capability for plug-in LED under cabinet lighting is a significant strength. We offer comprehensive turnkey solutions tailored to specific customer requirements. This includes engineering support for customizing optical designs (beam angles, CCT options), mechanical form factors (lengths, profiles, mounting systems), driver configurations (universal input, specific plug types like NEMA 1-15P for North America, EU Schuko, AU plug), and dimming compatibility (TRIAC, 0-10V, DALI). The factory excels at rapid prototyping, typically delivering functional samples within 30 days of finalizing specifications. We manage the entire process from component sourcing (with strict approved vendor lists) through SMT assembly, aging, final assembly, and packaging, ensuring compliance with all relevant safety standards (UL/cUL, ETL, CE, SAA, etc.) for the target market. Our engineering team works closely with OEM partners to optimize designs for manufacturability and cost-effectiveness without compromising on the thermal management and reliability essential for plug-in under cabinet products. This deep integration of SMT capability, stringent aging protocols, and flexible OEM engineering support makes the Jiangmen facility a robust partner for branded under cabinet lighting solutions.

Application Scenarios

LED under cabinet lighting plug in fixtures are versatile and energy-efficient lighting solutions that can enhance both functionality and ambiance in a variety of commercial and hospitality environments. They are particularly well-suited for use in hotels, malls, and offices, especially in areas where task lighting or accent lighting is needed beneath countertops, shelves, or cabinetry.

In hotels, these lights are commonly installed under kitchenette cabinets in suites, behind front desks for clerical work, or beneath vanity cabinets in staff preparation areas. They provide guests and staff with improved visibility while maintaining a sleek and unobtrusive appearance. The plug-in design allows for easy installation without requiring hardwiring, which is especially beneficial in retrofit projects or leased spaces where permanent electrical modifications are restricted.

In malls, LED under cabinet lighting can be used in kiosks, information desks, food service counters, and retail displays. The lighting helps highlight products, improves visibility for transactions, and adds a professional look to service areas. Since many mall tenants operate in temporary or semi-permanent spaces, the plug-in feature offers flexibility and quick setup without the need for extensive electrical work.

In office environments, these lights are ideal for use under overhead cabinets in break rooms, beneath workbenches in shared workspaces, or along shelving units in reception areas. They support productivity by reducing eye strain in low-light conditions and contribute to a modern, well-lit workspace. The plug-in option is especially convenient in office renovations or when reconfiguring furniture layouts.

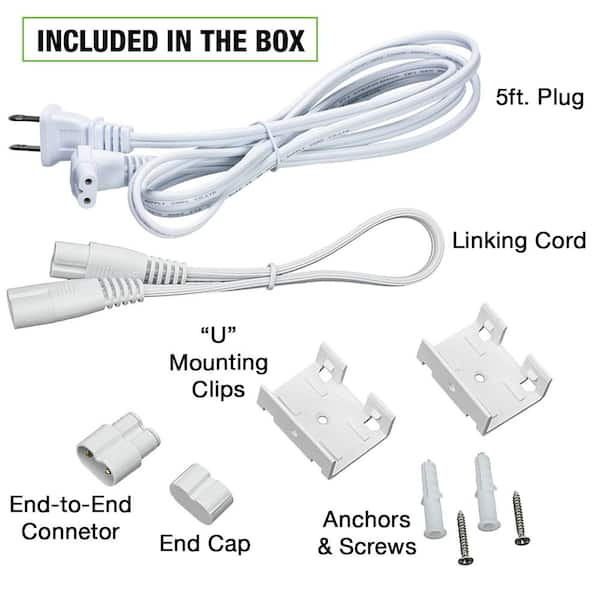

For successful installation, start by measuring the length of the cabinet or surface to ensure proper coverage and determine how many light fixtures or strips are needed. Position the lights toward the front edge of the cabinet to maximize downward illumination and minimize shadows. Clean the mounting surface thoroughly with isopropyl alcohol to ensure strong adhesion if using adhesive-backed strips. For heavier fixtures, consider using the included mounting clips or screws for added stability.

Ensure the power outlet is easily accessible and located nearby, as the cord length may limit placement options. Use cord covers or raceways to manage cables neatly and maintain a professional appearance, especially in customer-facing areas. Always verify that the lighting color temperature matches the ambient environment—typically 3000K to 4000K is ideal for creating a warm yet functional atmosphere.

Finally, test the lights before finalizing the installation and check for any flickering or uneven brightness. Choose high-quality LED products from reputable manufacturers like Beauty (STC) Manufacturing Co., Ltd. to ensure longevity, consistent performance, and compliance with safety standards.

Why Choose Beauty STC Lighting

Transform your kitchen or workspace with Beauty STC’s premium plug-in LED under cabinet lighting solutions designed for effortless installation and superior performance. As a trusted manufacturing partner, Beauty STC delivers precision-engineered lighting systems that combine energy efficiency, flicker-free illumination, and flexible dimming capabilities tailored for residential and commercial applications. Our plug-in under cabinet lights eliminate complex wiring hassles while maintaining the high lumen output and color accuracy professionals demand. Partner with Beauty STC to access reliable, code-compliant lighting products backed by rigorous quality control and dedicated engineering support.

Elevate your projects with lighting that enhances functionality and aesthetics without compromising on safety or simplicity. Contact our dedicated partnership manager today at [email protected] to discuss custom configurations, volume pricing, and technical integration support. Let Beauty STC’s expertise in LED innovation become the foundation of your next successful installation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.