Article Contents

Industry Insight: Led To Power Supply

In the rapidly evolving landscape of commercial and industrial lighting, the transition from traditional illumination systems to LED technology has become a cornerstone of energy efficiency, operational reliability, and long-term cost savings. At the heart of this transformation lies one of the most critical components—the LED power supply, also known as the LED driver. As LED fixtures demand stable, efficient, and intelligent power delivery, the performance and compatibility of the power supply directly influence system longevity, safety, and compliance. In commercial and industrial environments—where lighting operates continuously under demanding conditions—the importance of robust, certified drivers cannot be overstated.

Regulatory standards such as ETL and CE have become essential benchmarks, ensuring that LED power supplies meet rigorous requirements for electrical safety, electromagnetic compatibility, and environmental resilience. These certifications are not only a testament to product quality but also a prerequisite for market access and code compliance across North America and Europe. As building codes and energy regulations grow stricter, specifying ETL- and CE-certified drivers has become a non-negotiable element in sustainable lighting design.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in the design and manufacturing of high-performance LED drivers for commercial and industrial applications. With over two decades of engineering expertise, Beauty STC delivers reliable, code-compliant power solutions that support the evolving needs of modern lighting systems. From warehouses and manufacturing facilities to office complexes and retail spaces, Beauty STC’s ETL- and CE-certified drivers provide the backbone of efficient, durable, and future-ready LED lighting installations.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. provides comprehensive LED lighting solutions where the integration of the LED module and its dedicated power supply (driver) is critical for achieving optimal performance and reliability. When specifying the relationship between the LED light source and its power supply, it is essential to understand that key metrics like lumens per watt (system efficacy), Color Rendering Index (CRI), and Ingress Protection (IP) ratings are characteristics of the complete luminaire system, not isolated components. The driver’s efficiency directly impacts the overall system lumens per watt, while the LED package and phosphor formulation determine the CRI capability. The luminaire’s mechanical design, including the driver housing and sealing, dictates the achievable IP rating. Beauty STC rigorously designs and tests the entire system to meet or exceed demanding specifications.

System efficacy, measured in lumens per watt (lm/W), quantifies the total useful light output of the luminaire relative to the total electrical power input, including losses from the driver. Beauty STC achieves system efficacies typically ranging from 130 lm/W to 160+ lm/W for standard white light products (3000K-4000K) under real-world operating conditions. This high efficacy results from our selection of premium high-efficiency LED chips combined with ultra-efficient, low-loss constant current drivers featuring >94% typical efficiency. Crucially, Beauty STC reports system efficacy, not just bare LED chip efficacy, ensuring transparency. We account for all optical losses, thermal derating, and driver conversion losses in our published figures, providing specifiers with accurate real-world performance data. Our thermal management systems, using advanced heat sink designs and thermal interface materials, maintain LED junction temperatures low, preventing significant lumen depreciation and efficacy drop during operation.

Achieving a CRI greater than 90, particularly with strong R9 (saturated red) values above 50, requires meticulous LED phosphor engineering. Beauty STC utilizes premium multi-phosphor LED packages specifically formulated to deliver CRI values consistently exceeding 90 (Ra >90) across our product lines, with many solutions reaching Ra 95+. We prioritize high R9 values (typically >70) and extended spectrum rendering (Rf and Rg per TM-30) to ensure vibrant, natural color reproduction critical for retail, hospitality, and healthcare applications. This high fidelity is maintained across the product’s lifetime due to our stringent binning processes and robust thermal management, preventing phosphor degradation. Beauty STC does not sacrifice spectral quality for higher lumen output; our R&D focuses on balancing efficacy with exceptional color accuracy, validated through third-party spectroradiometer testing per ANSI C78.377 and IES LM-79 standards.

IP ratings define the luminaire’s resistance to dust and moisture ingress, protecting both the LED module and the internal power supply. Beauty STC designs luminaires to meet specific environmental demands, offering standard IP ratings including IP20 for dry indoor use, IP44 for damp indoor/outdoor locations (e.g., covered walkways), IP65 for outdoor exposed areas (resistant to low-pressure water jets), and IP67 for temporary submersion (up to 1 meter for 30 minutes). Achieving high IP ratings like IP67 requires seamless integration: the driver is potted within a fully sealed compartment using high-grade silicone, optical lenses feature precision gaskets, and housings undergo rigorous die-casting or extrusion processes to eliminate gaps. Every Beauty STC luminaire undergoes 100% production line IP verification testing per IEC 60529, not just sample testing, ensuring consistent field reliability against environmental stressors.

Beauty STC’s commitment to quality is embedded in every stage of production. Our vertically integrated manufacturing allows strict control over critical processes: LED wafers undergo EL testing, drivers are subjected to a 5-stage verification process including burn-in and harmonic analysis, and final assemblies are tested under thermal load for 24+ hours. We exceed standard IEC and UL requirements, implementing proprietary thermal cycling and salt spray tests. This results in industry-leading L70 lifetimes of 50,000 to 100,000 hours (TM-21), minimal lumen maintenance degradation, and driver survival rates exceeding 99.5% at 5 years. Beauty STC luminaires deliver not just the specified lumens per watt, CRI, and IP rating on day one, but maintain these critical performance parameters reliably throughout their operational life, minimizing total cost of ownership and ensuring customer satisfaction in demanding applications worldwide.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory is designed to support high-volume, precision manufacturing of LED lighting products and related components, with a strong emphasis on quality control, efficiency, and scalability.

At the core of the production process is a fully automated Surface Mount Technology (SMT) line, which ensures accurate and reliable placement of electronic components onto printed circuit boards (PCBs). The SMT machines used in the Jiangmen facility are high-speed, high-precision units capable of handling a wide range of component sizes and package types. These machines are integrated with automatic optical inspection (AOI) systems to verify solder joint quality and component placement immediately after reflow, significantly reducing defects and improving first-pass yield rates.

To ensure product reliability and longevity, the factory conducts comprehensive aging tests on both finished LED luminaires and key components such as LED drivers and power supplies. Units are subjected to extended operation under elevated temperature and voltage conditions, typically for durations ranging from 4 to 24 hours, depending on product specifications. These aging tests help identify early failure modes and validate thermal management, driver stability, and overall system performance before products are released for shipment.

Beauty STC has robust OEM capabilities, particularly in the integration of LED light sources with custom power supplies. The company supports clients in developing tailored solutions where LED modules or arrays are matched precisely to proprietary or application-specific drivers. This includes designing and manufacturing complete LED-to-power supply systems optimized for performance metrics such as efficiency, dimming compatibility, thermal behavior, and electromagnetic compatibility (EMC). The engineering team works closely with clients to customize form factors, electrical characteristics, and protection features (e.g., IP ratings, surge protection) to meet diverse market and regulatory requirements.

Overall, the Jiangmen factory combines advanced automation, rigorous testing protocols, and flexible OEM services to deliver high-quality, reliable LED lighting solutions for global markets.

Application Scenarios

The phrase “LED to power supply” is not standard industry terminology. What you are referring to is the LED driver, which is the critical power supply component that converts mains AC voltage to the low-voltage DC or constant current required by LED modules or luminaires. Selecting and installing the correct LED driver is fundamental to performance, longevity, and safety in any commercial lighting application. Below is guidance tailored specifically for hotels, malls, and offices, followed by essential installation practices.

In hotel environments, LED drivers are indispensable throughout the property but require specific considerations per area. Guest room lighting, particularly dimmable wall sconces and bedside fixtures, demands high-quality trailing-edge or ELV dimmable drivers compatible with the building’s low-voltage control system to ensure smooth, flicker-free dimming down to 1% for ambiance. Bathrooms and spa areas necessitate drivers with a minimum IP65 rating to withstand humidity and occasional water exposure, preventing premature failure. Lobby and corridor applications often utilize constant voltage drivers (e.g., 24V or 48V) for flexible LED tape installations in coves and under reception desks, where consistent color temperature is vital for brand image. Ballrooms and meeting rooms require drivers with robust surge protection due to frequent switching and potential grid fluctuations from high-power AV equipment, alongside compatibility with the venue’s advanced lighting control protocols like DALI-2 for scene setting.

Shopping malls present unique challenges due to scale, high ceilings, and demanding operational hours. Atrium and skylight replacement projects heavily rely on high-wattage constant current drivers (e.g., 700mA or 1050mA) for high-bay or linear pendant fixtures, where thermal management within the driver is critical to handle continuous 18+ hour operation under intense summer conditions. Retail storefront lighting, especially for high-end boutiques, requires precision constant current drivers with tight binning tolerances to maintain exact color rendering across multiple fixtures, avoiding visible discrepancies in merchandise display. Emergency lighting systems mandate integrated or separate LED drivers certified to EN 62384 or UL 924 standards, providing the required 90-minute backup duration while seamlessly transitioning during power loss. Long corridor and parking garage lighting benefits from 0-10V or DALI controllable drivers enabling occupancy sensing and daylight harvesting, significantly reducing energy costs across vast square footage.

Office buildings prioritize driver performance characteristics that support occupant well-being and energy efficiency. Open-plan workspaces require ultra-quiet constant current drivers (acoustic noise < 20dB) to prevent distracting hum in quiet environments, alongside high PF (>0.95) and low THD (<10%) to minimize electrical pollution on shared circuits with sensitive IT equipment. Task lighting at individual workstations often uses compact, efficient constant voltage drivers for under-cabinet LED strips, where precise 1-10V dimming integration with local controls is essential. Conference rooms need drivers fully compatible with the installed control system (e.g., DALI-2 for group addressing) to support quick scene changes without flicker. Critical server rooms and data halls require drivers with extended operating temperature ranges (-25°C to +70°C) and conformal coating to withstand elevated ambient temperatures and potential condensation during cooling system cycles.

Proper installation is non-negotiable for reliability. Always verify the driver’s output specifications (voltage/current/wattage) match the connected LED load exactly, including a 20% safety margin for constant voltage systems. Mount drivers in locations with adequate airflow, never enclosed in tight plenums or buried under insulation; maintain at least 50mm clearance around all sides, especially for high-wattage units. In large facilities like malls, avoid daisy-chaining multiple drivers on a single circuit branch—use individual fused circuit protection per driver as per NEC/IEC standards to prevent cascading failures. Ensure all wiring uses correct gauge for the run length to prevent voltage drop, particularly critical for 12V or 24V constant voltage systems in expansive hotel corridors or mall walkways. Secure all connections with proper torque to terminal screws to avoid arcing, and always connect the driver’s ground terminal directly to the building’s earth ground. Finally, label every driver with its circuit number and load details during installation—this is crucial for future maintenance in complex office or hotel infrastructure where access might be difficult. Adhering to these practices prevents the majority of field failures we observe in commercial deployments.

Why Choose Beauty STC Lighting

Transform your lighting projects with reliable, high-performance solutions. Partner with Beauty (STC) Manufacturing Co., Ltd., your trusted expert in LED to power supply integration. Backed by years of engineering excellence and innovation, we deliver seamless compatibility, durability, and efficiency across every product line. Whether you’re developing commercial, industrial, or residential lighting systems, our tailored solutions ensure optimal performance and long-term value.

Take the next step in building smarter, more efficient lighting ecosystems. Contact us today at [email protected] to discuss your requirements and discover how Beauty STC can power your success.

⚡ LED Power Supply Calculator

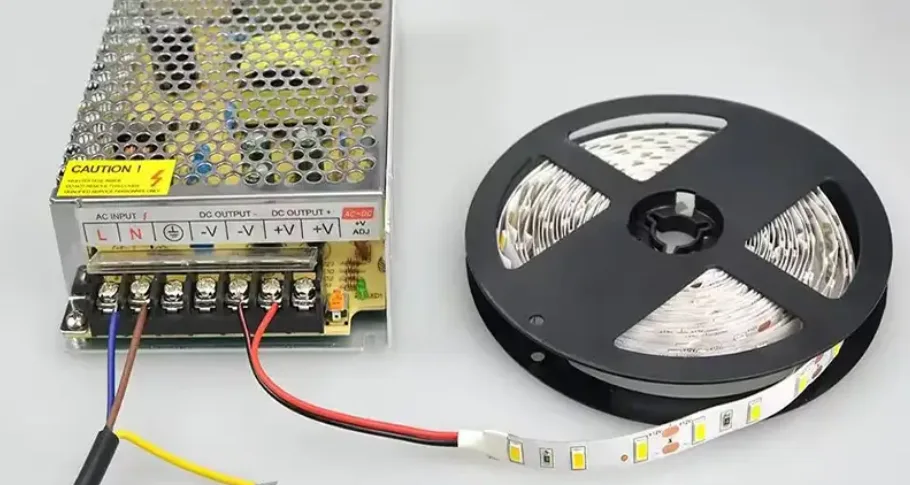

Estimate the power supply needed for your LED strip project.