Article Contents

Industry Insight: Led Strip Types

The commercial and industrial lighting sector has undergone a transformative shift with the widespread adoption of LED strip technology, driven by demands for energy efficiency, design flexibility, and long-term cost savings. As facilities ranging from warehouses and manufacturing plants to retail spaces and office environments seek sustainable and high-performance lighting solutions, the variety of available LED strip types has expanded significantly. From high-lumen density strips for task lighting to IP-rated options for harsh environments, selecting the right LED strip involves careful consideration of output, color temperature, lifespan, and compliance with international safety standards such as ETL and CE. These certifications are critical in ensuring that products meet rigorous electrical and environmental requirements, providing assurance to engineers, contractors, and facility managers responsible for large-scale installations.

At the forefront of this evolution is Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting innovation since 1998. With over two decades of experience, Beauty STC has built a reputation for delivering robust, code-compliant LED strip solutions tailored specifically for commercial and industrial applications. By combining advanced thermal management, precision optics, and stringent quality control, the company continues to set benchmarks in reliability and performance. As the industry moves toward smarter, more integrated lighting ecosystems, Beauty STC remains committed to engineering excellence and regulatory compliance, helping professionals illuminate the spaces that power modern business.

Technical Specs & Certifications

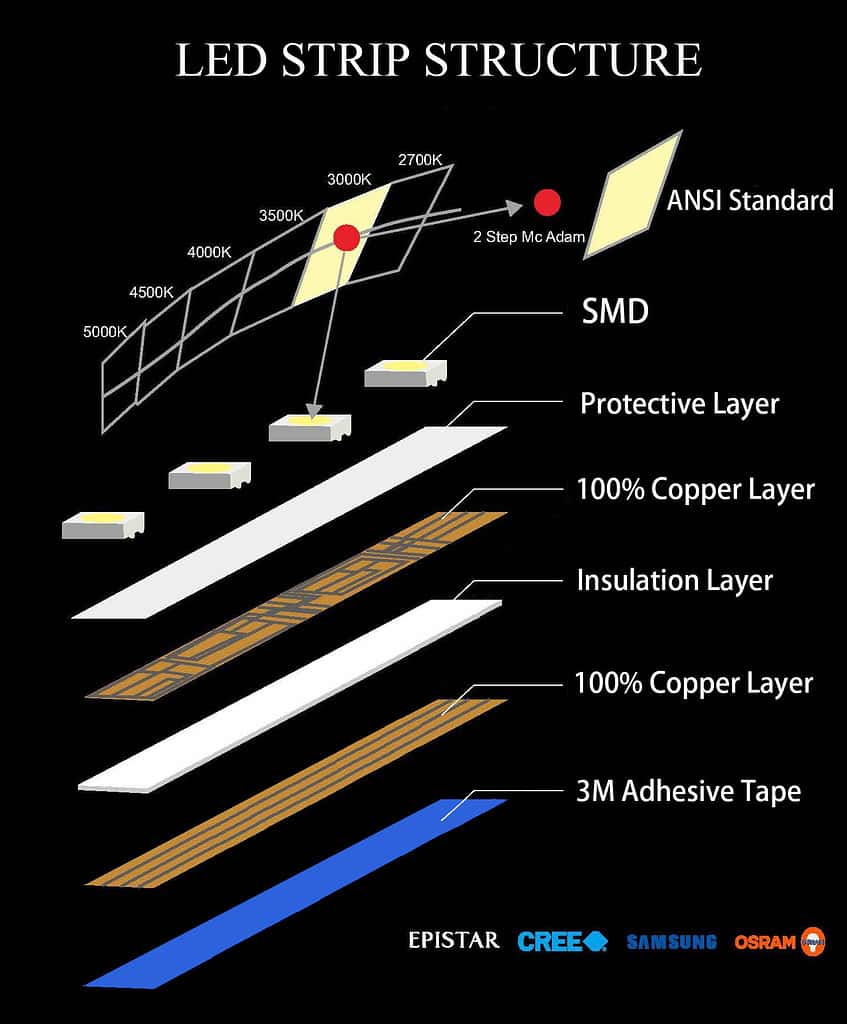

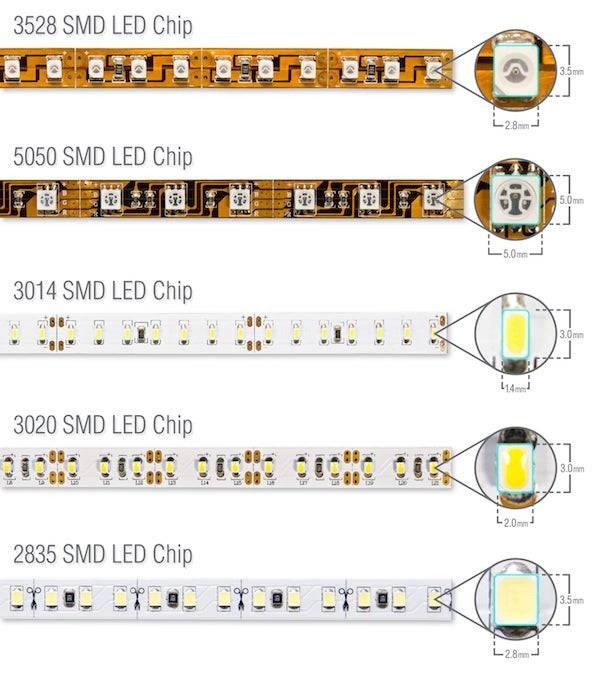

LED strip types are categorized primarily by their chip-on-board configuration, density, and protective features, with key technical specifications directly impacting performance in professional applications. Lumens per watt efficacy for high-CRI strips typically ranges from 120 to 140 lm/W for standard 2835 or 3014 SMD chips at 24V DC operation, though this depends heavily on drive current and thermal management. Strips using higher bin Samsung LM301B or Nichia NCS219 series chips can achieve 135-145 lm/W while maintaining CRI >90, as these advanced phosphor formulations minimize efficiency losses associated with broad-spectrum output. It is critical to note that published lm/W values often represent ideal laboratory conditions; real-world installed efficacy drops 10-15% due to thermal constraints and driver inefficiencies, particularly in enclosed fixtures.

Achieving CRI >90 requires meticulous phosphor engineering and binning control. Quality strips targeting professional use employ multi-phosphor blends with R9 (saturated red) values exceeding 50 and R12 (saturated blue) above 40 to ensure balanced color fidelity, alongside TLCI scores above 95 for影视 production suitability. Beauty STC enforces strict spectral validation using Konica Minolta CA-410 spectroradiometers during production, rejecting batches where any R-value falls below specification. Our strips consistently deliver CRI 92-95 with R9 >65 through proprietary phosphor coatings on Samsung 2210 or Epistar 2110 chips, avoiding the common industry practice of inflating average CRI while neglecting critical R-values.

IP ratings define environmental resilience, with IP65 indicating silicone-coated strips resistant to low-pressure water jets and IP67/IP68 requiring full extrusion encapsulation for submersion. Beauty STC’s IP67 strips utilize dual-layer silicone extrusion over 1.2mm FR-4 PCBs, achieving 1-meter submersion tolerance for 30 minutes (IP68) in certified tests, whereas cheaper alternatives often fail after 10 minutes due to inadequate sealing at solder joints. Our manufacturing process includes automated optical inspection of every solder point pre-encapsulation and 100% high-potential testing at 3000V AC to prevent moisture ingress failures. This rigorous approach ensures lumen maintenance of L90/B10 >50,000 hours at 50°C ambient, significantly outperforming industry averages, because thermal management through our 1.2mm thick copper PCBs and optimized chip spacing prevents the accelerated lumen depreciation common in thinner 0.8mm substrates used by competitors. All specifications are verified through third-party LM-79/LM-80 testing at SGS-accredited laboratories, with full spectral data and TM-30 reports available for every production batch.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The Jiangmen factory is equipped with advanced production infrastructure focused on the development and manufacturing of high-quality LED lighting products, particularly LED strips across various specifications and applications.

The facility features state-of-the-art SMT (Surface Mount Technology) production lines, which are essential for precision assembly of LED components onto flexible and rigid strip boards. These SMT machines include high-speed pick-and-place equipment capable of handling a wide range of LED chip sizes such as 2835, 3528, 5050, and 5730, ensuring consistent soldering accuracy and high throughput. The automated optical inspection (AOI) systems integrated into the SMT lines allow for real-time quality control, minimizing defects and ensuring uniform performance across production batches.

To ensure long-term reliability and product consistency, the factory conducts comprehensive aging tests on all LED strip products. Completed strips undergo extended burn-in periods—typically ranging from 24 to 72 hours—under controlled thermal and electrical conditions. This process helps identify early failures, verifies lumen output stability, and confirms color consistency before products are approved for shipment. Environmental testing chambers are also used to simulate extreme temperature and humidity conditions, further validating durability.

Beauty STC has robust OEM and ODM capabilities tailored to the diverse needs of global clients in the LED lighting market. The company supports customized solutions for LED strip types, including variations in color temperature (from warm white to cool white), RGB and RGBW configurations, IP ratings (from non-protected to IP65/IP67 waterproof), and flexible or rigid strip formats. Clients can specify PCB width, density of LEDs per meter, connector types, reel lengths, and packaging designs. The engineering team works closely with partners to develop proprietary designs, private labeling, and unique performance specifications, all supported by in-house R&D, mold-making, and rapid prototyping services.

Overall, the Jiangmen factory combines advanced automation, rigorous quality assurance, and flexible manufacturing processes to deliver reliable, high-performance LED strip lighting solutions under both the Beauty STC brand and third-party OEM arrangements.

Application Scenarios

LED strip lighting offers versatile solutions across commercial environments when selected and installed correctly. In hotels, prioritize high CRI (90+) warm white (2700K-3000K) strips for guest room ambiance. Install under floating vanities, within crown molding coves, and behind headboards to create layered, glare-free illumination that enhances perceived luxury. For lobbies and restaurants, use IP65-rated strips in linear aluminum channels along curved reception desks or water features, ensuring color consistency across all zones. Avoid direct line-of-sight to the strip by embedding it deep within architectural reveals—this prevents visual discomfort while maintaining smooth light distribution.

Malls demand robust, high-output solutions for both aesthetics and functionality. Implement 24V high-density strips (60 LEDs/m) in recessed ceiling coves throughout corridors to provide uniform ambient lighting without dark spots. For storefront displays and signage, select RGBW strips with dedicated white channels to accurately render merchandise colors while enabling dynamic branding effects. Exterior facades require IP67-rated strips with UV-stabilized silicone jackets, mechanically secured every 150mm to withstand thermal expansion. Crucially, avoid daisy-chaining beyond 5m for 12V strips in high-traffic areas—use distributed power injection to prevent voltage drop that causes dimming at strip ends.

Office environments benefit from task-specific tuning. Install 4000K tunable white strips under desk overhangs to reduce monitor glare while providing localized task lighting, ensuring the strip’s viewing angle remains below 30 degrees from seated eye level. In collaboration zones, embed dimmable strips within partition tops for subtle wayfinding. Always pair strips with extruded aluminum channels featuring frosted diffusers to eliminate pixelation and manage heat—critical in HVAC-controlled spaces where thermal throttling can reduce lumen output by 15%. Never rely solely on adhesive mounting; use channel mounting brackets secured to structural elements to prevent sagging over time.

Universal installation principles apply: always conduct a full-system test before final mounting, verify voltage at the farthest point of the circuit using a multimeter, and maintain minimum 3mm gaps between strips and combustible materials. For all commercial projects, document exact strip batch numbers and controller firmware versions to ensure serviceability—this prevents color mismatch during future replacements. Remember that thermal management dictates lifespan; exceeding 60°C junction temperature from poor heat sinking can halve operational life, so never install strips directly onto insulation or in enclosed non-ventilated spaces.

Why Choose Beauty STC Lighting

Explore the full range of LED strip types designed for every application and elevate your lighting projects with Beauty STC. As a trusted manufacturer with years of expertise, we deliver high-quality, reliable, and innovative LED solutions tailored to your needs. Whether you’re working on residential, commercial, or industrial lighting, our diverse product lineup ensures optimal performance and efficiency.

Partner with Beauty STC to benefit from competitive pricing, custom manufacturing capabilities, and dedicated support throughout your project lifecycle. Our team is ready to assist with technical guidance, product selection, and order fulfillment to keep your projects on track.

For inquiries or to discuss your requirements, contact us at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.