Article Contents

Industry Insight: Led Tape Waterproof

The commercial and industrial lighting sector faces relentless demands for durability and reliability, particularly where environmental exposure is a critical factor. Waterproof LED tape solutions have evolved from a niche consideration to an essential component in applications ranging from parking structures and refrigerated warehouses to outdoor architectural facades and food processing facilities. In these demanding settings, standard lighting products simply cannot withstand moisture ingress, chemical exposure, or physical abrasion, leading to premature failure, safety hazards, and costly downtime. Compliance with rigorous safety and performance standards like ETL (indicating adherence to North American safety requirements) and CE (demonstrating conformity with European health, safety, and environmental directives) is not optional; it is a fundamental requirement for market access and liability mitigation. These certifications validate that a product has undergone stringent independent testing for electrical safety, ingress protection, and operational integrity under specified conditions, providing specifiers and facility managers with essential confidence in real-world performance.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of addressing these complex challenges for over 25 years. Our deep-rooted expertise in LED technology and industrial manufacturing processes allows us to engineer waterproof LED tape solutions specifically designed for the harsh realities of commercial and industrial environments. We understand that true waterproofing extends far beyond a basic IP rating; it requires meticulous attention to material science, sealing methodologies, thermal management, and long-term environmental resilience. At Beauty STC, we combine rigorous in-house testing protocols with adherence to global certifications like ETL and CE to deliver products that ensure operational continuity, reduce maintenance burdens, and provide a secure, long-term lighting investment for demanding professional applications.

Technical Specs & Certifications

The LED tape waterproof offered by Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and reliability in both indoor and outdoor applications. Designed with precision and built to meet international quality standards, these LED tapes deliver exceptional luminous efficacy, color accuracy, and environmental protection.

In terms of efficiency, our waterproof LED tapes achieve a luminous output ranging from 110 to 130 lumens per watt, depending on the color temperature and density configuration. This high lumens-per-watt ratio ensures energy savings without compromising brightness, making them ideal for commercial, residential, and architectural lighting projects where efficiency and long-term operational costs are critical.

Color rendering is a key strength of Beauty STC’s LED tape products. All high-CRI versions are rated at CRI >90, with some variants reaching CRI >95. This superior color fidelity ensures that illuminated surfaces and objects appear natural and vibrant, which is especially important in retail displays, hospitality environments, art galleries, and high-end residential interiors where true color representation is essential.

Regarding environmental protection, our waterproof LED tapes are available in multiple IP ratings to suit diverse application needs. The standard waterproof version is rated IP65, offering protection against dust and low-pressure water jets from any direction, suitable for damp locations such as kitchens, bathrooms, or covered outdoor areas. For fully submersible or harsh environment applications, we offer IP67 and IP68 rated tapes. The IP67 rating ensures protection against temporary immersion in water up to 1 meter for 30 minutes, while IP68 provides continuous submersion protection at depths up to 3 meters, depending on installation conditions. These ratings are achieved through high-quality silicone encapsulation or extruded PVC jackets, ensuring long-term durability and resistance to moisture, UV exposure, and temperature fluctuations.

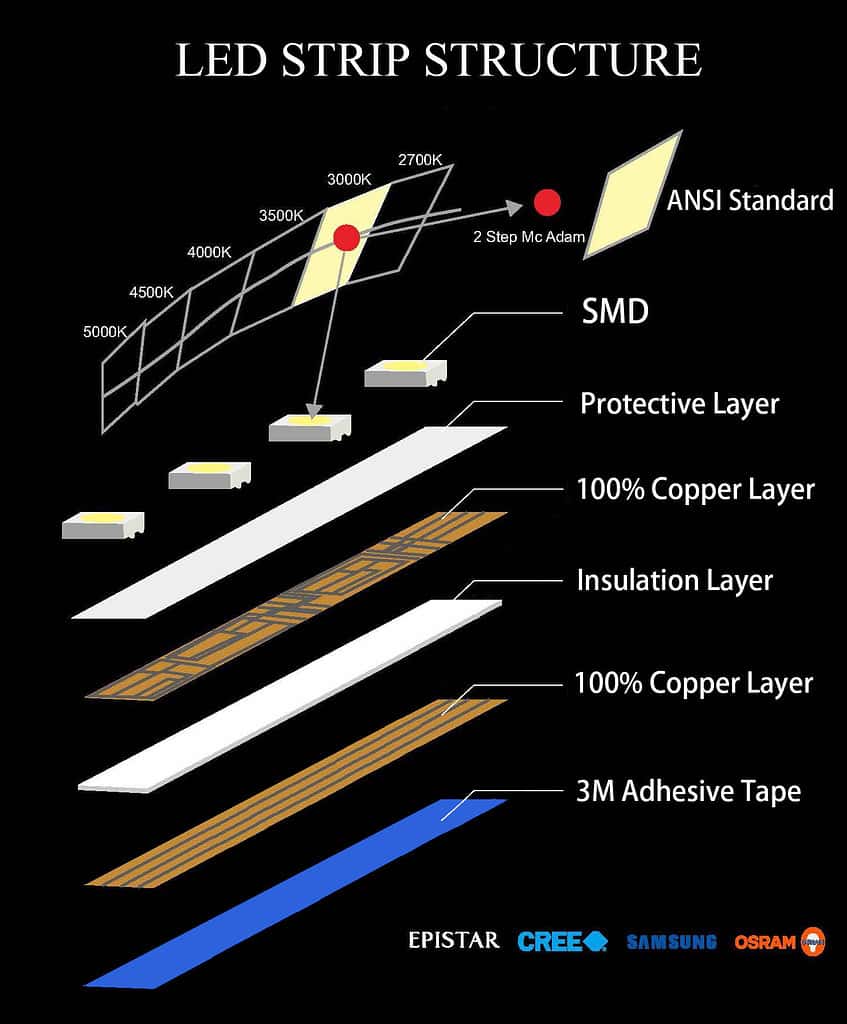

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout the production process. Our LED tapes are manufactured using premium-grade SMD LEDs, copper PCBs for optimal heat dissipation, and consistent soldering techniques to ensure reliability and longevity. Each batch undergoes stringent testing for luminous output, color consistency, and ingress protection compliance. With over two decades of expertise in LED lighting solutions, Beauty STC is committed to delivering products that combine advanced technology, robust construction, and superior optical performance, making our waterproof LED tapes a trusted choice for demanding lighting applications worldwide.

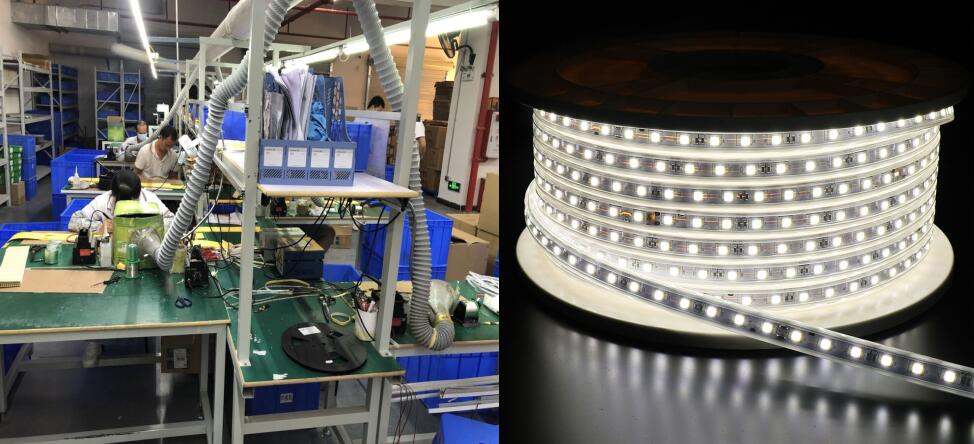

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as a key production hub for our LED lighting solutions, operating under stringent quality management systems compliant with ISO 9001 standards. The factory spans over 20,000 square meters and integrates advanced automation with rigorous quality control processes specifically tailored for high-volume LED product manufacturing, including specialized lines for flexible LED tape production.

Our SMT production lines feature state-of-the-art Yamaha YS24 modular placement machines capable of handling components down to 0201 metric package sizes with ±25μm placement accuracy. These dual-lane systems operate within a climate-controlled environment maintained at 22±2°C and 45-55% RH, critical for consistent solder paste performance. Each line incorporates 3D SPI systems for pre-reflow solder paste inspection and automated optical inspection (AOI) stations with multi-angle cameras for post-placement verification, ensuring component alignment and polarity accuracy exceeding 99.98% yield rates. The reflow ovens utilize nitrogen-assisted zones with precisely calibrated thermal profiles to prevent micro-cracking in sensitive LED packages during soldering.

Aging and reliability testing constitutes a non-negotiable phase in our production workflow. Completed LED tape reels undergo mandatory 72-hour continuous burn-in at 50°C ambient temperature with full-rated current loading, monitored by automated data logging systems tracking voltage, current, and thermal performance. This extended aging process occurs in dedicated environmental chambers certified to UL 50E standards, allowing us to identify early-life failures through statistical analysis of lumen maintenance and chromaticity shift. For waterproof products, aging integrates IP68 verification where samples undergo thermal cycling between -20°C and 60°C while submerged in water at 1.5m depth, followed by insulation resistance testing at 500VDC to verify dielectric integrity after stress exposure.

Our OEM capabilities for waterproof LED tape are engineered for complete client customization. The facility supports turnkey solutions from PCB design through final packaging, including specialized processes for IP65, IP67, and IP68 rated products. We implement dual waterproofing methodologies: precision robotic dispensing of optical-grade silicone conformal coating for flexible strips, and seamless PVC jacketing extrusion for rigid tape variants. Clients can specify custom wavelengths, lumen packages, cut lengths, reel sizes, and connector types with our engineering team providing DfM feedback within 48 hours. The factory maintains UL, CE, and TÜV-certified material traceability systems, allowing us to produce to exact client specifications while managing all regulatory compliance documentation. Prototyping lead times average 10-15 days with full production scaling within 30 days of final approval, supported by in-house tooling capabilities for custom extrusion dies and connector molds.

Application Scenarios

LED tape waterproof is ideal for environments where moisture, humidity, or outdoor exposure is a concern. While hotels, malls, and offices are predominantly indoor spaces, there are specific areas within these buildings where waterproof LED tape is highly beneficial.

In hotels, waterproof LED tape should be used in bathrooms, both in guest rooms and public areas, where high humidity levels can damage non-waterproof lighting. It is also suitable for poolside lighting, spa areas, and outdoor walkways or canopies where exposure to water is likely. Underwater lighting in decorative fountains or water features within hotel lobbies or courtyards also requires waterproof LED tape.

In malls, waterproof LED tape is best applied in restrooms, food courts with high steam levels, and any outdoor signage or façade lighting. It can also be used along drainage areas, exterior canopies, or architectural features exposed to rain. Decorative lighting in indoor water features or aquariums within the mall also demands waterproof specifications.

In offices, typical use is limited, but waterproof LED tape may be necessary in restrooms, pantry or kitchen areas with potential water exposure, or in outdoor office building signage and entryways. Some modern office designs incorporate indoor green walls or water features where moisture-resistant lighting is essential.

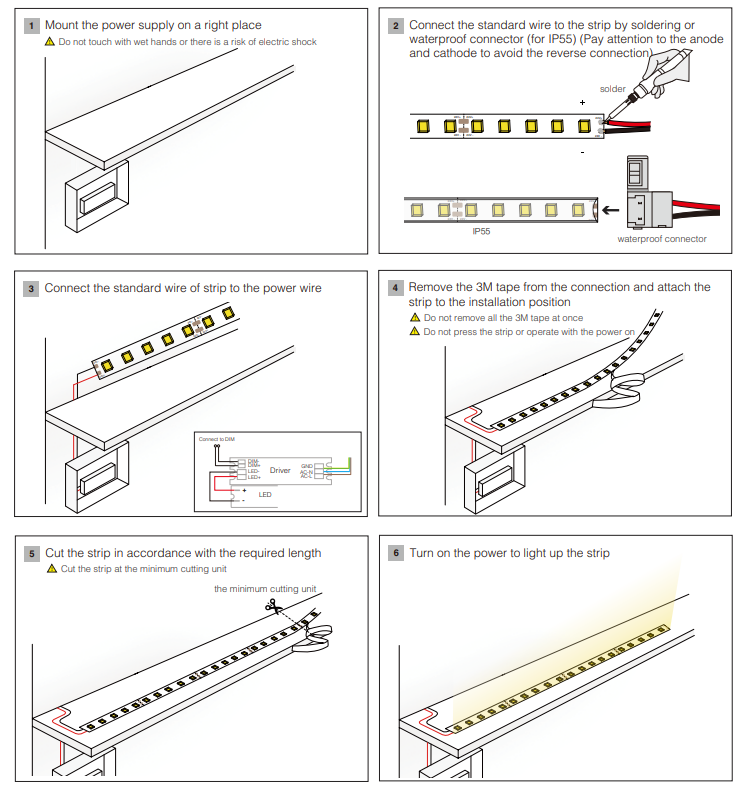

For installation, always ensure the surface is clean, dry, and free of dust or grease before applying the tape. Use appropriate mounting clips or aluminum channels to secure the tape, especially in high-moisture areas, as channels also help with heat dissipation and provide a more uniform light output. Make sure all connections, including splices and power supplies, are properly sealed using waterproof connectors or silicone gel junctions. The power supply must be located in a dry, accessible area and should be rated for outdoor or damp location use if connected to waterproof tape. Avoid sharp bends in the tape—follow the manufacturer’s minimum bending radius to prevent damage to the LEDs or circuitry. Finally, test the installation before sealing or covering the tape to ensure consistent illumination and proper functionality.

Why Choose Beauty STC Lighting

For demanding outdoor and wet environment applications, reliable waterproof LED tape is non-negotiable. At Beauty STC, we engineer high-performance waterproof LED tape solutions built to withstand harsh conditions, featuring robust IP67 and IP68 ratings, superior UV resistance, and long-term durability without signal degradation or color shift. Our meticulously sealed strips ensure consistent, brilliant illumination for architectural cove lighting, marine installations, landscape features, and challenging commercial projects where moisture and environmental stress are constant factors.

Partner with Beauty STC to integrate industry-leading waterproof LED tape into your next project and eliminate installation failures and costly callbacks. Our engineering team provides tailored support from specification through production, guaranteeing you receive the optimal waterproof solution for your specific requirements. Reach out to our dedicated partnership manager today at [email protected] to discuss your application and discover how our engineered reliability drives project success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.