Article Contents

Industry Insight: Hardwire Led Strip Lights

The commercial and industrial lighting sector is undergoing a significant transformation, driven by the relentless pursuit of energy efficiency, operational longevity, and seamless integration within demanding built environments. Within this evolution, hardwired LED strip lighting has decisively moved beyond niche applications to become a fundamental solution for architectural cove lighting, task illumination, under-cabinet fixtures, and critical signage in facilities ranging from high-end retail spaces and hospitality venues to manufacturing plants and warehouses. Unlike plug-and-play residential strips, hardwired systems represent the professional standard for permanent installations, eliminating unsightly cords, ensuring robust electrical connections suitable for continuous operation, and meeting stringent building and safety codes essential for commercial viability. Crucially, specifying hardwired LED strips for these environments mandates rigorous certification; ETL listing for North American markets and CE marking for Europe are non-negotiable requirements, verifying compliance with electrical safety, electromagnetic compatibility, and performance standards that protect both installers and end-users while ensuring project approval during electrical inspections. Beauty STC Manufacturing Co., Ltd., a trusted leader in professional LED lighting solutions since 1998, understands these exacting demands. We engineer our hardwired LED strip systems from the ground up for the rigors of commercial and industrial use, prioritizing not only superior optical performance and thermal management but also inherent compliance with ETL, CE, and other global regulatory frameworks, providing specifiers and contractors with reliable, code-compliant products designed for long-term performance and safety in the most challenging settings.

Technical Specs & Certifications

Hardwire LED strip lights are designed for permanent electrical installation, offering a clean, seamless lighting solution suitable for both residential and commercial applications. At Beauty (STC) Manufacturing Co., Ltd., our hardwire LED strip lights are engineered to meet the highest industry standards, emphasizing energy efficiency, color accuracy, and environmental durability.

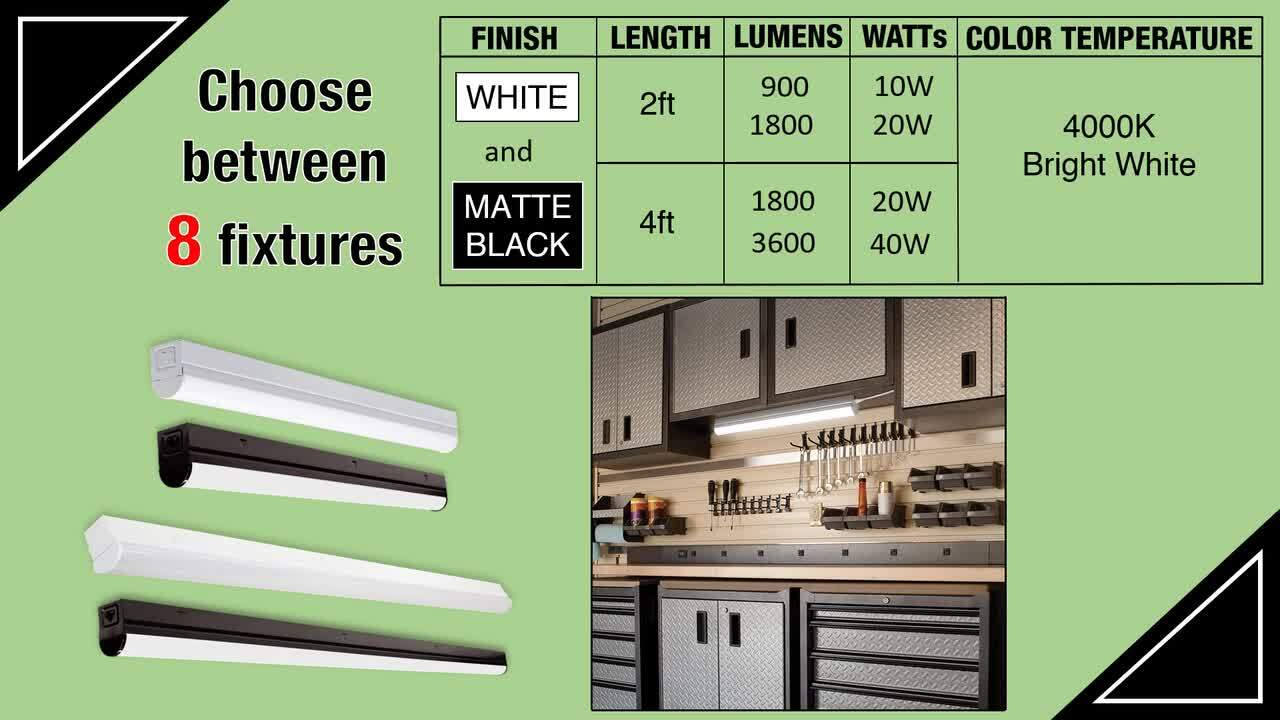

One of the key performance metrics for LED lighting is lumens per watt (lm/W), which measures luminous efficacy. Our hardwire LED strip lights typically deliver between 110 to 130 lumens per watt, depending on the specific model and color temperature. This high efficacy ensures optimal brightness while minimizing energy consumption, making them an energy-efficient lighting solution for long-term use.

Color Rendering Index (CRI) is critical in applications where accurate color representation is essential, such as in retail displays, art galleries, and high-end residential interiors. Beauty STC’s hardwire LED strips consistently achieve a CRI greater than 90, with select high-CRI variants reaching up to CRI 95. This ensures that colors appear natural and vibrant under the light, closely resembling daylight conditions.

In terms of environmental protection, our LED strips are available in multiple Ingress Protection (IP) rated versions to suit various installation environments. IP20-rated strips are suitable for dry, indoor locations where dust and moisture are not a concern. For damp or high-dust areas, we offer IP65-rated strips, which provide protection against low-pressure water jets and complete dust ingress. For fully waterproof applications—such as outdoor under-eave lighting, cove lighting in bathrooms, or outdoor signage—we manufacture IP67 and IP68-rated hardwire LED strips. These are fully sealed, often with silicone coating or extruded jackets, to withstand immersion in water up to 1 meter for extended periods.

At Beauty STC, quality is embedded in every phase of production. We utilize high-grade SMD LEDs, precision-printed circuit boards, and rigorously tested drivers to ensure longevity and consistent performance. Our strips undergo thermal, electrical, and environmental stress testing to guarantee reliability over a rated lifespan of up to 50,000 hours. With RoHS compliance and certifications including UL, CE, and ETL, Beauty STC’s hardwire LED strip lights represent a premium blend of performance, safety, and durability trusted by lighting professionals worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC Manufacturing Co., Ltd. operates a modern LED lighting production facility in Jiangmen, Guangdong Province, strategically positioned within the Pearl River Delta manufacturing hub. This location provides excellent access to raw materials, skilled labor, and major logistics channels. The Jiangmen factory is purpose-built for high-volume, precision LED manufacturing with a strong emphasis on quality control and engineering support, particularly for demanding applications like hardwire LED strip lights.

The surface mount technology (SMT) production line forms the core of our manufacturing capability. We utilize multiple high-speed Yamaha YS24 series SMT placement machines, known for their exceptional precision and reliability in the LED industry. These machines are capable of handling ultra-fine pitch components down to 0201 metric package sizes, which is essential for the dense LED arrays and compact driver circuits required in high-performance hardwire strips. The SMT line includes automated solder paste printers, reflow ovens with precise thermal profiling, and AOI (Automated Optical Inspection) systems after placement and reflow to ensure component accuracy, solder joint integrity, and overall board quality before proceeding to assembly. This level of SMT capability ensures consistent, high-yield production of the complex flexible and rigid PCBs used in our hardwire LED strip products.

Rigorous aging and burn-in testing are critical non-negotiable steps in our process for hardwire LED strip lights, designed for permanent installation where failure is not an option. Every production batch undergoes mandatory 24-hour continuous aging tests at full rated power under controlled ambient temperatures within dedicated environmental chambers. For critical customer projects or specific high-reliability requirements, we implement extended 72-hour aging protocols. Testing occurs both pre-aging for initial functionality verification and post-aging to assess performance stability and identify any infant mortality failures. We meticulously monitor key parameters such as lumen output, chromaticity coordinates, forward voltage, and thermal performance throughout the aging process. This comprehensive approach significantly exceeds basic industry standards and is fundamental to delivering the long-term reliability demanded by hardwire installations in commercial, industrial, and high-end architectural settings.

Beauty STC possesses substantial OEM capability specifically tailored for hardwire LED strip light solutions. We offer full turnkey manufacturing services encompassing custom PCB design and layout, component sourcing and qualification, SMT assembly, strip fabrication (including specialized soldering for hardwire connections), rigorous testing, and final packaging. Our engineering team works closely with clients to modify existing designs or develop entirely new hardwire strip configurations to meet exact specifications for voltage (including constant current drivers), color temperature, CRI, lumen density, IP rating, flexible or rigid form factor, and connectorless termination points. We support low to high-volume production runs with flexible MOQs and provide comprehensive engineering documentation, including detailed test reports and compliance documentation. Our ISO 9001 certified quality management system underpins this OEM service, ensuring consistent adherence to client technical requirements and international safety standards like UL, CE, and RoHS. With over 15 years of focused LED manufacturing experience, the Jiangmen factory is equipped to handle complex hardwire strip projects from concept through to certified mass production.

Application Scenarios

Hardwired LED strip lights are commonly used in commercial and hospitality environments such as hotels, malls, and offices due to their clean appearance, energy efficiency, and design flexibility. These installations require a direct electrical connection to the building’s mains power supply, eliminating the need for visible plug-in drivers or power supplies, which enhances aesthetics and ensures long-term reliability.

In hotels, hardwired LED strip lights are ideal for cove lighting in lobbies and guest rooms, under-bed or toe-kick lighting, backlighting headboards or mirrors, and accent lighting in corridors and lounges. The seamless integration supports ambient lighting schemes that enhance guest experience while maintaining a sleek, modern look.

In malls, these lights are frequently installed in coves around atriums, above false ceilings, along escalator handrails, and within display niches or signage. Their flexibility allows designers to highlight architectural features and guide foot traffic with dynamic lighting effects. Hardwiring ensures continuous operation across large areas without the clutter of external power adapters.

In offices, hardwired LED strips are used for under-cabinet lighting, within suspended ceiling perimeters, along stair edges for safety, and to illuminate workspaces with indirect lighting. This contributes to a professional and well-lit environment while reducing glare and energy consumption.

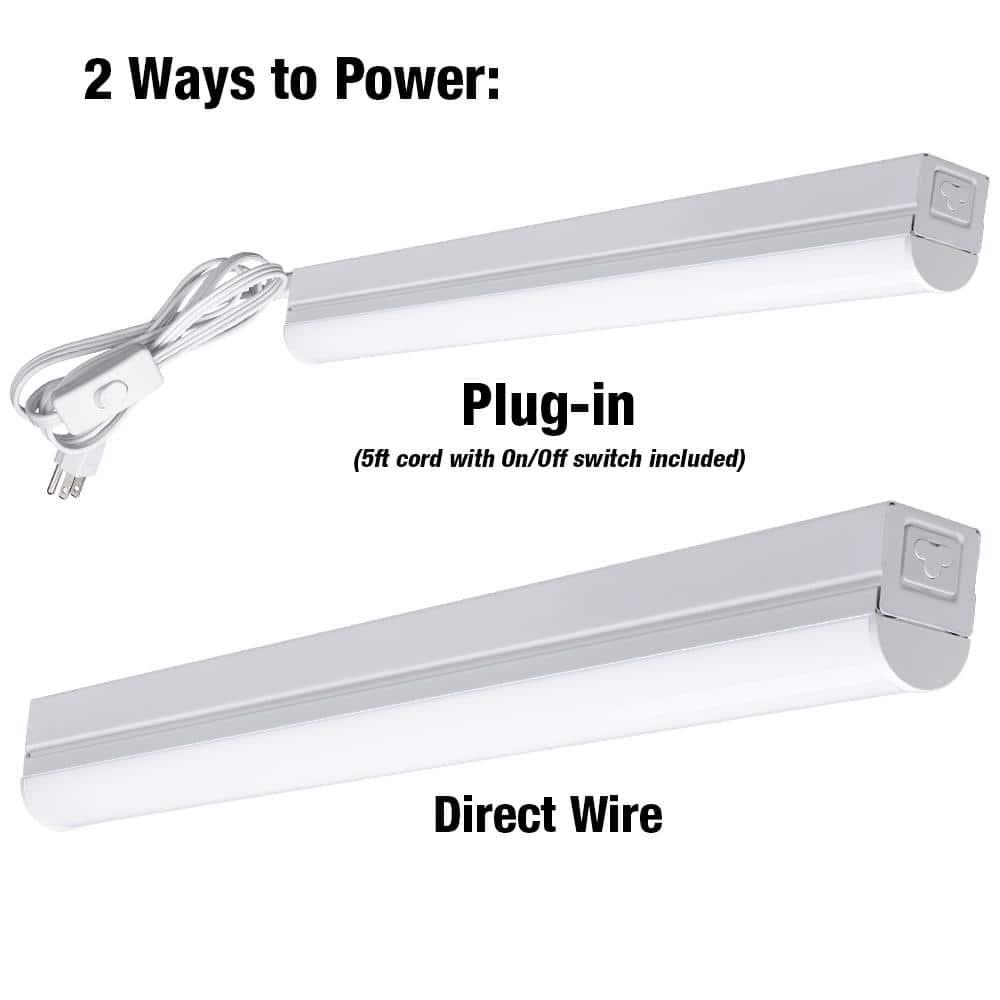

When installing hardwired LED strip lights, proper planning and electrical safety are essential. First, ensure the power is turned off and follow local electrical codes. Use a qualified electrician for all hardwiring tasks. Choose LED strips compatible with constant voltage (typically 12V or 24V DC) and pair them with a suitable hardwired LED driver located in an accessible area for maintenance. The driver must be correctly rated for the total length and power draw of the strip to avoid overheating.

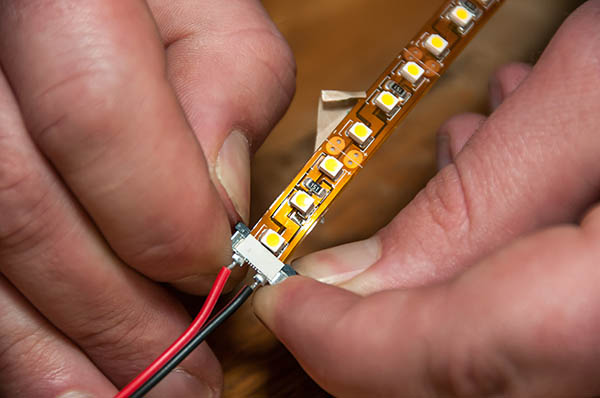

Mount the LED strip on clean, dry surfaces using the adhesive backing or mounting clips. Avoid sharp bends and never cut the strip except at designated cut points. Use soldered or screw-terminal connections for reliable wiring—avoid snap-on connectors in permanent installations. Seal any outdoor or high-moisture area connections with silicone or waterproof junction boxes. Finally, perform a test run before final concealment to verify functionality and color consistency.

Why Choose Beauty STC Lighting

For professionals seeking reliable and high-performance hardwired LED strip lighting solutions, Beauty STC Manufacturing Co. Ltd. stands as your dedicated engineering partner. Our hardwired LED strips are meticulously engineered for seamless integration into permanent architectural and commercial installations, eliminating the need for visible plugs or transformers while ensuring stable, long-term operation. We prioritize precision in voltage regulation, thermal management, and color consistency across every reel, meeting rigorous UL/cETL safety standards for confidence in demanding environments.

As an experienced OEM/ODM manufacturer, Beauty STC collaborates closely with electrical contractors, lighting designers, and building developers to customize specifications including lumen output, color temperature, beam angles, and flexible circuit configurations. Our engineering team provides comprehensive technical support from prototyping through volume production, ensuring your project requirements are met without compromise.

Elevate your next installation with hardwired LED strips built for durability and professional results. Partner with Beauty STC for engineered lighting solutions that deliver. Contact our engineering management team directly at [email protected] to discuss your project specifications and discover how our manufacturing expertise can support your goals.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.