Article Contents

Industry Insight: Flexible Neon

In the evolving landscape of commercial and industrial lighting, flexible neon has emerged as a transformative solution, blending aesthetic versatility with robust performance. Originally associated with decorative signage, modern flexible neon technology now serves a broad spectrum of applications—from architectural accent lighting and safety wayfinding in warehouses to dynamic façade illumination and retail branding—where durability, energy efficiency, and design flexibility are paramount. Unlike traditional glass neon, flexible neon is lightweight, shatter-resistant, and easily installable, making it ideal for large-scale or complex installations. With growing regulatory emphasis on safety and performance, leading products in this category are rigorously tested and certified to meet international standards such as ETL and CE, ensuring compliance with electrical safety, electromagnetic compatibility, and environmental directives across global markets.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since its founding in 1998. With over two decades of engineering expertise, Beauty STC has built a reputation for delivering high-quality, code-compliant flexible neon systems tailored for commercial and industrial environments. Their commitment to performance, reliability, and regulatory adherence has made their products a preferred choice for integrators, architects, and facility managers seeking both visual impact and long-term operational value.

Technical Specs & Certifications

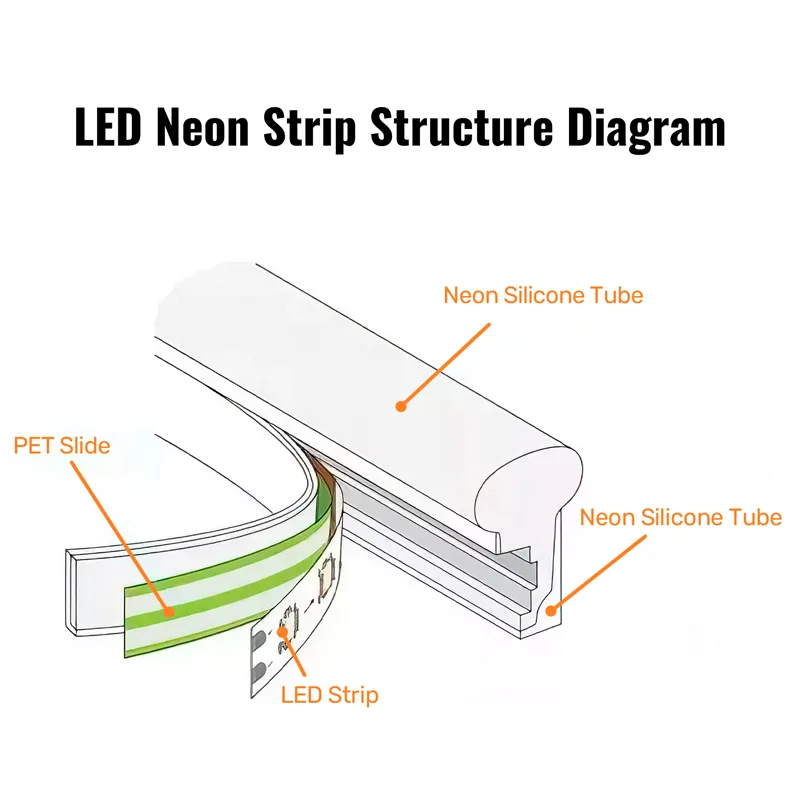

Flexible neon LED lighting, as manufactured by Beauty STC, represents a significant advancement over traditional glass neon, utilizing high-density SMD LED arrays encapsulated within flexible silicone profiles. Our technical specifications are engineered for superior performance in commercial and architectural applications, with rigorous quality control ensuring consistency and reliability.

Lumens per watt efficacy for Beauty STC flexible neon typically ranges from 70 to 95 lm/W, depending on the specific configuration. This efficiency is achieved through the use of premium Epistar or Seoul Semiconductor LEDs coupled with optimized driver technology. Higher color temperatures (e.g., 4000K-6500K) generally yield the upper end of this range, while warmer tones (2700K-3000K) with CRI>90 may operate at the lower end due to the inherent physics of high-color-rendering phosphor blends. We maintain this balance without compromising output, ensuring our 12mm and 15mm profiles deliver 1200-1800 lumens per meter at standard densities. Crucially, our efficacy figures are validated under real-world operating conditions at 25°C ambient, not idealized lab settings, reflecting actual installation performance.

Color Rendering Index (CRI) consistently exceeds 90 (Ra≥90) across our flexible neon portfolio, with R9 (saturated red) values maintained above 50 to ensure vibrant, natural color representation critical for retail, hospitality, and art installations. This is accomplished through stringent LED binning processes where we selectively source diodes from the tightest chromaticity quadrangles within the ANSI C78.377 standard. Our proprietary phosphor formulations and spectral tuning eliminate the green/magenta spikes common in lower-cost alternatives, resulting in smooth spectral power distributions. Every production batch undergoes spectroradiometric verification using Konica Minolta CS-2000 instruments, with calibration traceable to NIST standards, guaranteeing CRI compliance before shipment.

IP ratings for Beauty STC flexible neon are engineered for demanding environments. Our standard offering achieves IP67 rating (dust-tight and protected against temporary immersion up to 1m for 30 minutes) through a dual-layer liquid silicone rubber (LSR) extrusion process. For critical outdoor or submerged applications, we provide IP68-rated variants (continuous submersion beyond 1m, typically validated to 5m for 72 hours) using medical-grade silicone with enhanced UV stabilization. The seamless overmolding technique eliminates end-cap vulnerabilities seen in competitor products, with all connections sealed via our patented heat-fusion welding process. Rigorous IP validation includes 100% batch testing in controlled immersion chambers per IEC 60529, not just sample-based certification.

Beauty STC’s quality differentiation lies in our vertically integrated manufacturing and obsessive attention to material science. We reject generic PVC or TPE alternatives in favor of platinum-cured silicone with 98% light transmission and -60°C to +200°C operational tolerance, preventing yellowing and maintaining flexibility over 50,000 hours of operation. Our automated production lines feature inline thermal imaging to detect micro-hotspots during curing, while 100% functional testing at 1.5x operating voltage ensures longevity. This commitment results in flexible neon that sustains >90% lumen maintenance at L70 (70,000 hours) with zero field failures attributable to ingress or color shift in over 10 years of global installations. The combination of verified efficacy, true high-CRI output, and military-grade environmental resilience defines Beauty STC’s position as an industry benchmark for professional-grade flexible neon solutions.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern, well-equipped facility specializing in the production of high-quality LED lighting solutions, with a particular focus on flexible neon LED strips. The factory integrates advanced manufacturing technologies and rigorous quality control processes to ensure reliable and consistent product performance.

At the core of the production line are state-of-the-art SMT (Surface Mount Technology) machines, which enable precise and efficient placement of LED components onto flexible printed circuit boards. These SMT machines operate with high speed and accuracy, supporting the production of densely packed and uniformly lit flexible neon strips. The automated SMT line ensures minimal defects, excellent solder joint quality, and high throughput, making it ideal for both large-scale and customized production runs.

Following the SMT process, all products undergo comprehensive aging tests before shipment. The aging test procedures simulate extended operational conditions to verify performance, thermal stability, and longevity. Units are powered on and run continuously for a designated period—typically 24 to 72 hours—under controlled temperature and humidity conditions. This ensures early detection of potential failures and guarantees that only reliable, fully tested products reach customers.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities, particularly for flexible neon LED products. The company supports full customization, including length, color temperature, RGB or addressable control options, voltage requirements, coating color (such as clear, milky, or tinted silicone), and branding with custom labels or packaging. With in-house R&D, engineering support, and flexible production scheduling, Beauty STC can accommodate low to high-volume OEM orders while maintaining short lead times and strict quality standards. This makes the Jiangmen facility a preferred partner for brands seeking tailored, high-performance flexible neon lighting solutions.

Application Scenarios

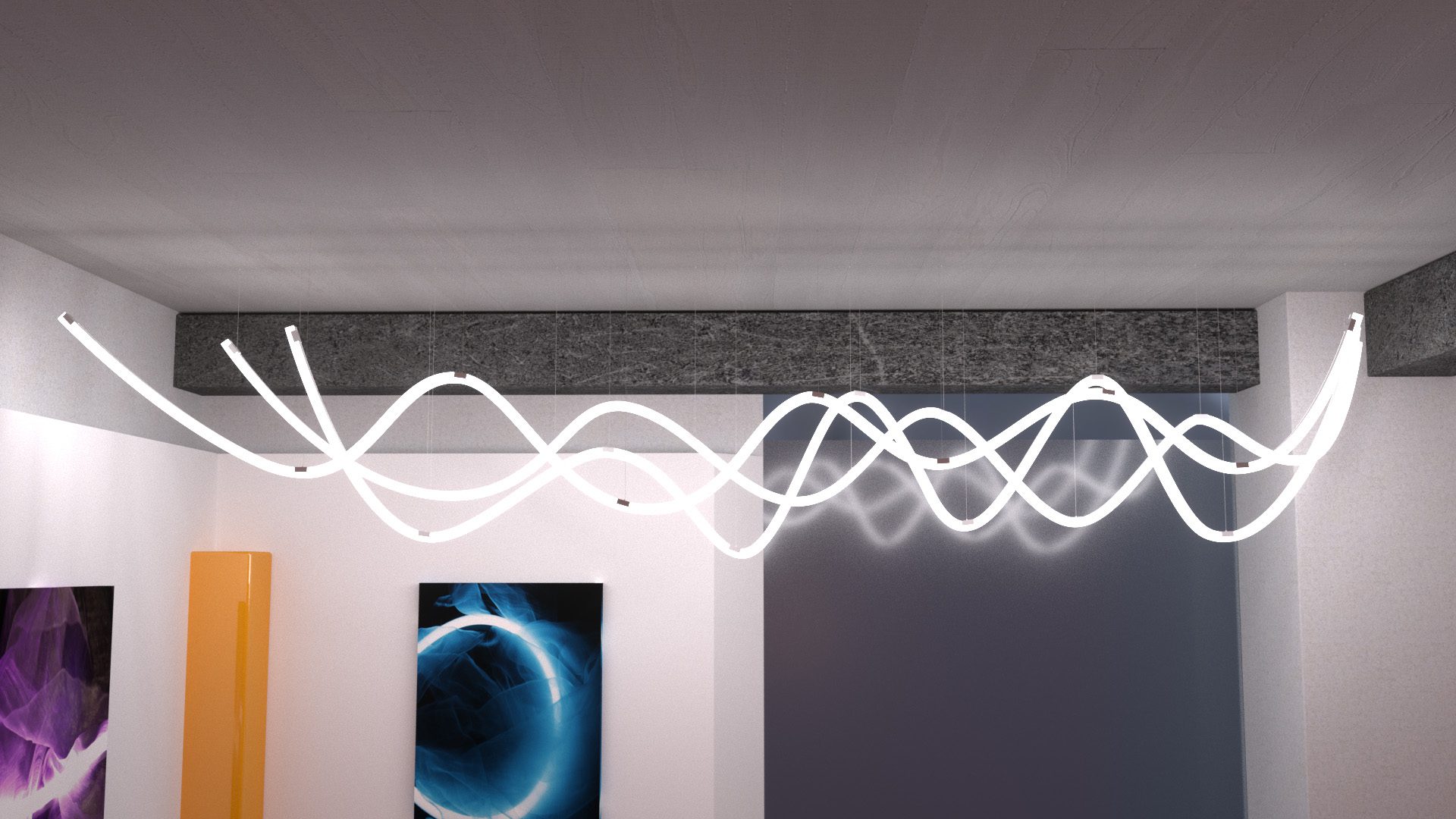

Flexible neon lighting offers significant advantages over traditional glass neon in commercial environments due to its durability, energy efficiency, lower operating temperature, and design flexibility. Its application across hotels, malls, and offices should focus on enhancing aesthetics, guiding movement, reinforcing branding, and creating specific atmospheres while ensuring practicality and safety.

In hotels, flexible neon excels in high-impact guest experience areas. Use it to outline the reception desk curve for a welcoming glow, trace architectural features like archways or ceiling coves in lobbies to add depth, or define pool edges and spa areas where safety and ambiance are critical. It works well for subtle room numbering on corridors, providing clear, low-glare guidance without disturbing guests. Avoid direct installation above beds or in areas requiring very bright task lighting. Ensure all installations in wet areas like pools or spas use IP67-rated or higher flexible neon with fully sealed power supplies mounted outside the splash zone, and always integrate with the building management system for dimming to transition from vibrant daytime to relaxing evening scenes.

Malls benefit from flexible neon’s ability to create dynamic, brand-focused environments. Install it extensively for storefront signage, particularly for high-end retailers wanting custom shapes without glass fragility risks. Use it to highlight feature walls, escalator handrails, or food court booth dividers where curved lines enhance flow. Directional signage for restrooms or exits gains visibility with consistent, even illumination. Crucially, prioritize vandal resistance by embedding the neon within robust aluminum channels with diffusers in high-traffic zones, and ensure all cabling is concealed within structural elements. Thermal management is vital in enclosed displays; maintain at least 10mm clearance around the neon strip within channels and avoid coiling excess length, as trapped heat drastically shortens lifespan. Always calculate voltage drop for runs exceeding 5 meters and use appropriate gauge wiring or additional power feeds to prevent dimming at the far end.

For offices, flexible neon serves both functional and motivational purposes. Implement it for modern, low-glare reception logos or company name walls to establish brand identity immediately. It’s highly effective for subtle wayfinding—outlining stair edges, marking meeting room names on glass partitions, or defining collaborative zones in open plans without visual clutter. Under-cabinet lighting in break rooms or executive offices provides ambient task lighting. Critical considerations include avoiding installation where it causes screen glare; position it below eye level or shielded from direct line of sight to workstations. Use 3000K to 4000K color temperatures to match office lighting schemes—warmer tones in lounge areas, cooler in focused work zones. Ensure all mounting channels are securely fastened to solid substrates like drywall studs or metal framing, never relying solely on adhesive in permanent installations, and verify compatibility with standard 0-10V or DALI dimming systems integrated into the office lighting controls for seamless operation.

Installation universally requires precise preparation. Measure and cut the flexible neon only at designated cut marks using sharp scissors to avoid damaging internal circuits. Always mount it within manufacturer-specified aluminum channels designed for thermal dissipation and physical protection; direct surface mounting on non-ventilated substrates causes overheating. Secure channels every 300mm with appropriate fasteners for the surface type. Power supplies must be sized at 20% above total wattage, installed in accessible locations with adequate airflow, and grounded per local electrical codes. Test all segments before final mounting and conceal all wiring within raceways or building cavities. Never exceed the maximum run length specified by the manufacturer without additional power injection, as this leads to inconsistent brightness and premature failure. Adhering to these guidelines ensures optimal performance, longevity, and safety across all commercial applications.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s flexible neon solutions—durable, energy-efficient, and fully customizable for any creative or commercial application. As a trusted leader in LED innovation, we offer seamless integration, competitive pricing, and reliable performance for projects of all scales. Partner with Beauty STC to bring your designs to life with superior quality and expert support.

For collaboration opportunities or product inquiries, contact our sales manager at [email protected] and discover how our flexible neon technology can elevate your next project.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.