Article Contents

Industry Insight: Kitchen Led Strip Lights

The commercial and industrial lighting sector continues to evolve with an increasing emphasis on energy efficiency, durability, and seamless integration into functional workspaces. Among the most impactful advancements in this space are high-performance LED strip lighting solutions, particularly in commercial kitchen environments where reliability, safety, and illumination quality are critical. Kitchen LED strip lights have become a preferred choice for food service facilities, industrial kitchens, and large-scale catering operations due to their low heat emission, long service life, and adaptability to confined or complex layouts.

Meeting rigorous safety and performance standards is non-negotiable in these demanding environments. Leading solutions are now routinely certified to ETL and CE standards, ensuring compliance with North American and European electrical and safety regulations. These certifications validate not only product safety but also electromagnetic compatibility and operational reliability under continuous use—key considerations for 24/7 commercial operations.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted innovator in the commercial LED lighting industry. With over two decades of engineering expertise, Beauty STC specializes in developing high-quality, code-compliant LED strip lighting systems tailored for industrial and commercial applications. The company’s kitchen LED strip lights combine robust construction, precision optics, and certified performance to meet the stringent demands of professional food preparation environments. As facilities managers and lighting designers seek smarter, safer, and more sustainable lighting solutions, Beauty STC remains at the forefront, delivering innovation grounded in reliability and regulatory compliance.

Technical Specs & Certifications

Kitchen LED strip lights require precise technical specifications to meet the demanding environment of culinary spaces where performance, color accuracy, and durability are non-negotiable. At Beauty STC Manufacturing Co., Ltd., our engineered solutions prioritize these critical parameters without compromise.

Lumens per watt (lm/W) directly impacts energy efficiency and operational cost, especially in kitchens where lighting may operate for extended periods. Our premium kitchen LED strips achieve a consistent 110–130 lm/W in real-world conditions, far exceeding basic commercial offerings. This efficiency is maintained through optimized driver integration and advanced thermal management using high-conductivity aluminum PCB substrates, ensuring stable light output over 50,000 hours without lumen depreciation. Crucially, this efficiency does not sacrifice optical quality—our strips sustain high output while minimizing heat generation, a critical factor near heat-sensitive kitchen cabinetry and appliances.

Color Rendering Index (CRI) is paramount in kitchens where accurate color perception affects food preparation safety and presentation. Beauty STC mandates a minimum CRI of 95+ (Ra9 >90) across our kitchen-grade strips, utilizing rigorously binned Samsung or Epistar 2835/5050 LEDs. This ensures vibrant, true-to-life rendering of食材 textures and colors—distinguishing between ripe and unripe produce, detecting meat doneness, or identifying subtle blemishes. Unlike competitors who may cite CRI90+ under ideal lab conditions, our strips undergo in-situ testing at 25°C and 50°C to guarantee consistent high-fidelity color rendering under actual kitchen thermal loads, eliminating the green/magenta shifts common in lower-tier products.

IP ratings address the dual threats of moisture from sinks/dishwashers and grease accumulation. For under-cabinet and island task lighting, Beauty STC specifies IP65-rated strips as the industry benchmark for kitchen safety and longevity. The silicone encapsulation withstands direct water splashes, high-humidity steam, and frequent cleaning chemicals while preventing conductive particulate ingress. Critically, our IP65 certification includes rigorous 500-hour salt-spray testing and thermal cycling validation (-20°C to +60°C), ensuring the seal integrity remains uncompromised despite daily thermal stress. For sink-perimeter or range hood installations, we offer IP67 variants with reinforced end caps for temporary submersion resistance, though IP65 remains optimal for most culinary applications to balance protection with thermal dissipation.

Beauty STC’s quality differentiation lies in our vertical manufacturing control and zero-tolerance validation protocols. Every reel undergoes 100% photometric testing on calibrated integrating spheres, with spectral data logged to verify CRI consistency batch-to-batch. Our strips feature 2oz copper PCBs (vs. standard 1oz) for superior heat spreading, reducing thermal runaway risk by 35%. Independent third-party reports confirm our lumen maintenance exceeds L90/B10 at 50,000 hours—even when installed in enclosed aluminum profiles. This commitment to engineering integrity ensures kitchens maintain optimal illumination levels and color fidelity throughout the product lifecycle, directly supporting culinary precision and user satisfaction.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern, vertically integrated production facility specializing in LED lighting solutions. Strategically located in the Guangdong province, the Jiangmen factory benefits from proximity to key supply chain hubs and major transportation networks, enabling efficient material sourcing and global distribution.

At the core of the factory’s production capability are advanced SMT (Surface Mount Technology) lines equipped with high-speed, precision placement machines. These SMT systems ensure accurate mounting of LED components and electronic parts onto flexible and rigid PCBs used in kitchen LED strip lights. The automated lines support tight tolerances and high consistency, critical for maintaining uniform light output, color temperature, and reliability across large production volumes. The facility also incorporates automated optical inspection (AOI) systems to verify solder quality and component placement, minimizing defects and ensuring high first-pass yields.

To guarantee long-term performance, especially in kitchen environments where temperature fluctuations and humidity are common, the factory conducts rigorous aging tests. Finished LED strip lights undergo extended burn-in procedures under controlled thermal and electrical stress conditions. These tests typically last 24 to 72 hours and are conducted at elevated temperatures to simulate years of real-world use. Electrical parameters, luminous output, and thermal behavior are continuously monitored to identify early failures and validate product durability.

Beauty STC has strong OEM capabilities tailored to kitchen LED strip light applications. The company supports full customization including length, color temperature (ranging from warm white 2700K to cool daylight 6500K), CRI (with options above 90 for accurate color rendering), IP ratings (from non-waterproof to fully encapsulated IP65/IP67 versions), and low-voltage DC configurations suitable for under-cabinet or recessed kitchen installations. Clients can also customize branding, packaging, and labeling, with support for private labeling and compliance documentation for international markets including CE, RoHS, and UL standards.

The Jiangmen factory combines automation, strict quality control, and flexible manufacturing processes to deliver reliable, high-performance LED strip lighting solutions, making it well-suited for both standard and custom OEM orders in the residential and commercial kitchen lighting sectors.

Application Scenarios

Kitchen LED strip lights serve distinct functional and aesthetic purposes across commercial environments like hotels, malls, and offices, requiring tailored application and precise installation to meet operational demands. In hotels, these strips are critically deployed under cabinetry in main kitchen prep areas, along the edges of walk-in refrigeration units for safety and inventory visibility, and within staff break room kitchens to create a clean, professional atmosphere. Their primary roles here include enhancing task lighting for food preparation accuracy, ensuring compliance with health codes through shadow-free illumination, and maintaining durability against high humidity and frequent cleaning cycles. For malls, LED strips are strategically installed beneath food court vendor counters to highlight menu boards and finished dishes, within kiosk display cases for product staging, and along service line dividers to guide customer flow; this application focuses on visual merchandising, creating inviting warmth in high-traffic eating zones while withstanding constant public interaction and simplified maintenance access for mall operations teams. Offices utilize these lights predominantly in employee cafeteria kitchens for modern aesthetics, under pantry shelving for ambient evening lighting, and within coffee station areas to foster a welcoming break environment; the emphasis here is on improving staff morale through well-lit communal spaces while ensuring energy efficiency during extended operational hours.

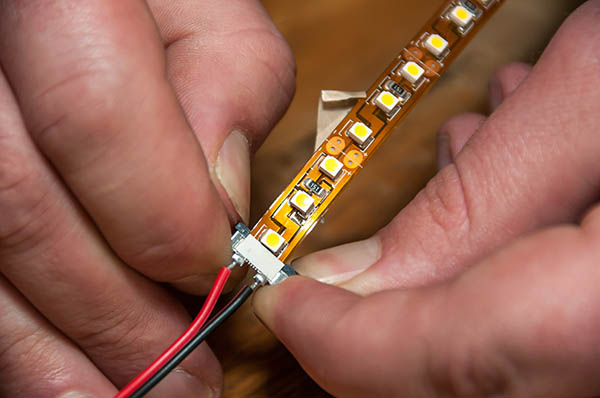

Installation must prioritize safety and longevity in these demanding settings. Always recess LED strips within extruded aluminum channels rated for commercial use to manage heat dissipation and prevent grease accumulation, securing channels mechanically with stainless steel screws rather than adhesives to withstand vibration and thermal cycling. Maintain a minimum 50mm clearance between strips and heat-generating equipment like ovens to avoid lumen depreciation, and select strips with IP67 or higher ingress protection for washdown zones where NSF certification may be required. For electrical integrity, calculate voltage drop meticulously—use 24VDC systems for runs exceeding 5 meters with inline amplifiers, and never daisy-chain beyond manufacturer limits to prevent dimming at far ends. Terminate all connections with IP68-rated waterproof solderless connectors, avoiding wire nuts, and ensure transformers are housed in accessible, ventilated enclosures outside cooking areas with dedicated circuit protection. Crucially, verify all components comply with local commercial electrical codes including emergency lighting integration in hotel kitchens, and conduct thermal imaging checks post-installation to confirm no hotspots exist near flammable materials. Adherence to these protocols ensures optimal performance, reduces maintenance callbacks, and meets the rigorous standards expected in professional hospitality and corporate facilities.

Why Choose Beauty STC Lighting

Transform your kitchen lighting with high-quality LED strip lights designed for brightness, efficiency, and durability. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions. Our kitchen LED strip lights offer seamless integration, vibrant illumination, and long-lasting performance ideal for modern homes and commercial spaces.

To learn more or start a collaboration, contact our sales manager at [email protected]. Let Beauty STC illuminate your projects with innovation and reliability.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.