Article Contents

Industry Insight: Strip Lighting Plug In

Strip lighting has become a cornerstone of modern commercial and industrial lighting design, offering unparalleled flexibility, energy efficiency, and ease of installation. Among the various configurations available, plug-in strip lighting systems have emerged as a preferred solution for facilities seeking rapid deployment and scalable illumination. These systems are especially valued in warehouses, retail spaces, manufacturing plants, and cold storage environments, where consistent, low-maintenance lighting is critical to operational efficiency and safety. With growing demand for compliant and reliable lighting solutions, certifications such as ETL and CE have become essential benchmarks, ensuring that products meet rigorous North American and international safety and performance standards.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in high-performance strip lighting solutions, Beauty STC combines advanced thermal management, durable construction, and strict quality control to deliver plug-in systems that stand up to the demands of commercial and industrial environments. Backed by comprehensive ETL and CE certifications, Beauty STC’s plug-in strip lighting products offer installers and facility managers a trusted, code-compliant choice that reduces downtime and supports long-term operational savings. As the industry evolves toward smarter, more sustainable lighting ecosystems, Beauty STC continues to lead with engineered solutions that balance performance, reliability, and ease of integration.

Technical Specs & Certifications

Beauty STC’s plug-in LED strip lighting systems are engineered for professional installations requiring high efficiency, accurate color rendering, and environmental resilience. Our standard specifications for these integrated systems—comprising the LED strip, constant-voltage driver, and plug connector—reflect our commitment to exceeding industry benchmarks while maintaining rigorous quality control throughout manufacturing.

Luminous efficacy for our standard high-CRI plug-in strips ranges from 110 to 120 lumens per watt at 25°C ambient temperature, measured at 3000K to 4000K correlated color temperatures. This efficiency is achieved through proprietary phosphor formulations and optimized 2835 or 5050 LED packages, ensuring minimal thermal derating. Efficacy decreases predictably at lower color temperatures (e.g., 2700K), but we maintain a minimum of 105 lm/W across our portfolio. All efficacy data is validated per IES LM-79 testing protocols using integrating sphere methodology, with results traceable to NIST standards.

Critical to our design is consistent Color Rendering Index performance. All plug-in strips targeting architectural or retail applications maintain a minimum CRI of 92 (Ra) with R9 (saturated red) exceeding 50, verified under 100% operating conditions at 25°C. We extend testing beyond CRI to TM-30-15 metrics, achieving Rf > 85 and Rg > 98 in premium lines. This accuracy stems from tight binning tolerances (within a 3-step MacAdam ellipse) and spectral optimization that avoids the common pitfall of high CRI with poor R9 performance. Independent lab reports are available for each production batch.

IP rating integrity defines our environmental protection. Standard plug-in systems achieve IP65 rating when installed with our proprietary end caps and connectors, utilizing dual-layer silicone encapsulation over the LED array and driver junctions. This surpasses basic IP20 strips housed in aftermarket channels. For wet-location applications, we offer IP67-rated variants with molded driver housings and marine-grade tinned copper conductors, validated through 1,000-hour salt spray testing per ASTM B117 and thermal cycling from -40°C to +70°C. No cosmetic or functional degradation occurs after 50 cycles.

Beauty STC’s quality differentiation manifests in three key areas. First, our in-house driver manufacturing employs Mean Well-certified components with 50,000-hour L70 lifetime ratings, including active PFC circuits for stable operation across 100-277V AC inputs. Second, we enforce 100% automated optical testing during strip assembly, rejecting any segment with luminance variation exceeding ±3% or chromaticity deviation beyond 2-step MacAdam. Third, our plug connectors use gold-plated phosphor bronze contacts with double-locking mechanisms, eliminating the voltage drop and overheating risks common in competitor products. Every system undergoes 48-hour burn-in testing at 1.5x rated load, resulting in field failure rates below 0.3% over a 5-year warranty period. This end-to-end control ensures that “CRI >90” and “IP65” on our spec sheets represent real-world performance, not just laboratory ideals.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern, well-equipped facility dedicated to the production of high-quality LED lighting solutions. Strategically located in the Jiangmen High-Tech Industrial Zone, the factory benefits from streamlined logistics and access to a skilled manufacturing workforce, supporting both domestic and international markets.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines that ensure precise and efficient assembly of LED components. These SMT machines, including high-speed pick-and-place systems and reflow soldering ovens, enable consistent placement of small and complex LED chips and electronic components on flexible and rigid printed circuit boards (PCBs). This level of automation enhances product reliability, improves throughput, and maintains tight quality control throughout the manufacturing process.

To ensure long-term performance and durability, Beauty STC implements comprehensive aging tests as part of its quality assurance protocol. Completed LED strip lights undergo rigorous burn-in procedures, typically operating at full power for extended periods—usually 24 to 72 hours—under controlled thermal and electrical conditions. This process helps identify early component failures, verifies thermal management effectiveness, and confirms consistent light output and color stability before products are shipped.

The Jiangmen factory has strong OEM (Original Equipment Manufacturer) capabilities, particularly for strip lighting products with plug-and-play functionality. Beauty STC can customize LED strip length, color temperature, lumen output, IP rating, and power supply configurations to meet specific customer requirements. The company supports branding services, including private labeling, custom packaging, and tailored connectors or end caps for plug-in compatibility with various driver systems. Their engineering team works closely with clients to develop solutions that integrate seamlessly into different applications, such as architectural lighting, retail displays, or residential installations.

Overall, Beauty STC’s Jiangmen facility combines advanced manufacturing technology, strict quality control, and flexible OEM services to deliver reliable, high-performance LED strip lighting solutions tailored to diverse market needs.

Application Scenarios

Plug-in LED strip lighting offers significant flexibility for accent, task, and ambient lighting in commercial environments due to its ease of installation and reconfiguration without permanent wiring. In hotels, this solution is particularly effective for under-cabinet lighting in minibars and hospitality stations within guest rooms, providing subtle illumination without harsh glare. It is also ideal for vanity lighting around mirrors in bathrooms, creating even, shadow-free illumination for grooming, and for cove lighting in lobbies or corridors to enhance architectural features with a soft, welcoming glow. The plug-in nature allows housekeeping or maintenance staff to easily disconnect sections for cleaning or replacement without requiring an electrician, reducing operational downtime.

Within retail malls, plug-in strip lighting excels for backlighting product displays and signage in kiosks or pop-up shops where permanent installation is impractical. It is commonly used beneath shelves in boutique stores to highlight merchandise with focused downlighting, creating visual interest and drawing customer attention. Temporary event spaces within malls benefit significantly from this technology, as the strips can be rapidly deployed and reconfigured for seasonal promotions or exhibitions. The low-voltage, plug-and-play design ensures safety in high-traffic public areas and simplifies compliance with temporary occupancy electrical codes, while the ability to cut and reconnect sections accommodates diverse display layouts.

For office environments, plug-in LED strips serve well as under-desk task lighting to reduce eye strain during focused work, and under floating shelves or cabinetry in reception areas for a modern aesthetic. They are practical for illuminating the interiors of open-plan workstation pods or collaborative zones where adjustable accent lighting enhances the workspace ambiance. Conference rooms utilize them effectively for cove lighting to create a professional yet comfortable atmosphere during meetings. The key advantage here is the minimal disruption during installation or reconfiguration as office layouts evolve, avoiding the need for ceiling cuts or conduit runs associated with hardwired systems.

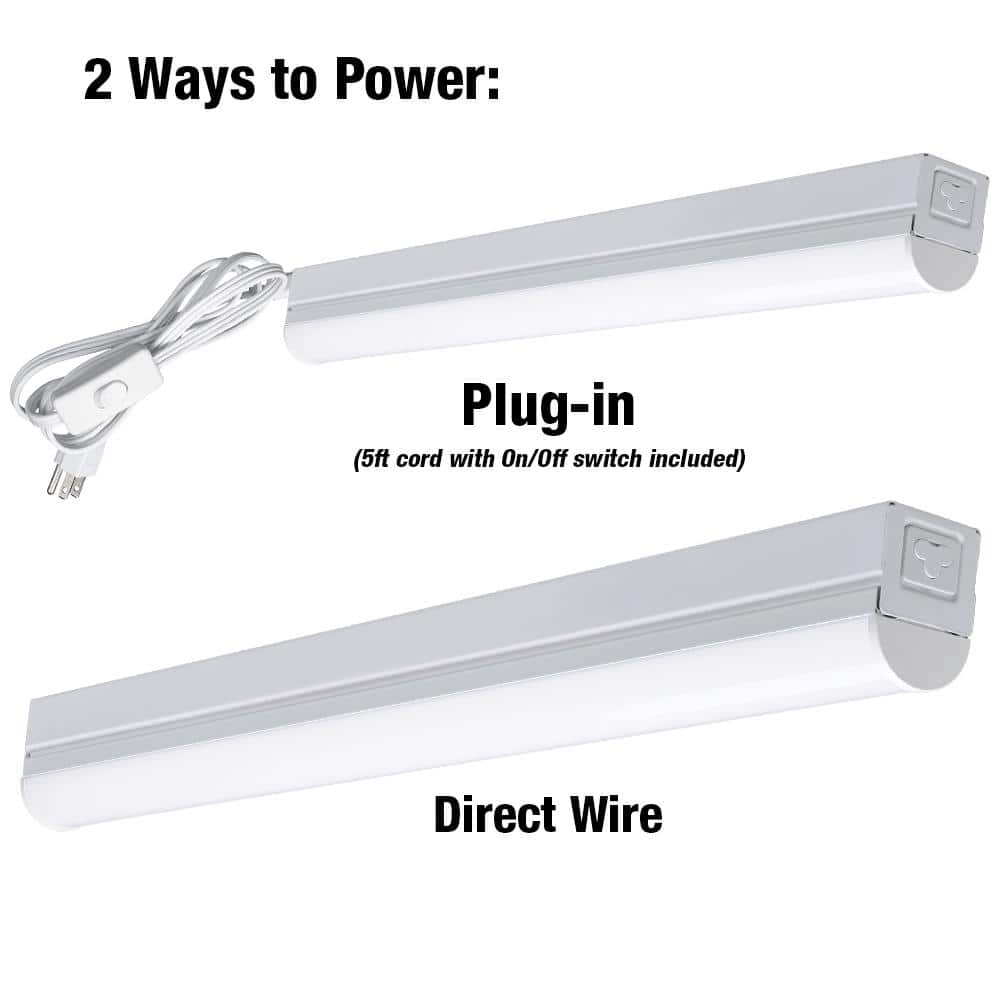

Installation requires careful planning to ensure safety and longevity. Always verify the power supply’s voltage and current rating matches the strip’s specifications exactly to prevent overheating or premature failure. Use only the manufacturer-recommended connectors and avoid daisy-chaining multiple strips beyond the maximum run length specified in the datasheet, typically 5 meters for 12V or 10 meters for 24V systems, to mitigate voltage drop that causes dimming at the far end. Maintain adequate spacing between strips and any combustible materials per local fire codes; never install within fully enclosed fixtures unless the strip is explicitly rated for such use. Ensure all connections are secure and insulated, preferably using solderless connectors designed for the specific strip type, and route the power cord away from high-traffic areas to prevent tripping hazards or cord damage. Crucially, confirm the entire assembly complies with local electrical regulations, such as UL Class 2 listing in North America, and have installations performed or verified by a qualified electrician to meet commercial building safety standards. Test the system thoroughly before final mounting to identify any connection issues or inconsistencies in light output.

Why Choose Beauty STC Lighting

Looking for reliable and high-quality strip lighting solutions? Discover our easy-to-install plug-and-play strip lighting systems designed for seamless integration and superior performance. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting innovation. For inquiries and collaboration opportunities, contact us at [email protected] and let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.