Article Contents

Industry Insight: Led Aluminum Profile

Industry Insight: The Critical Role of Aluminum Profiles in Commercial & Industrial LED Lighting

In commercial and industrial lighting applications, LED aluminum profiles are far more than mere housings—they are foundational engineering components that directly dictate system performance, longevity, and safety. These profiles provide essential thermal management, dissipating heat to maintain optimal LED junction temperatures and extend operational life beyond 50,000 hours. Crucially, they deliver structural rigidity for harsh environments, precise optical control for uniform light distribution, and seamless integration with mounting systems—all while meeting stringent aesthetic and safety standards.

Compliance with international certifications like ETL (North America, OSHA-recognized) and CE (European Union) is non-negotiable. These certifications validate rigorous testing for electrical safety, fire resistance, electromagnetic compatibility, and environmental compliance. Non-compliant products risk project delays, customs rejection, liability exposure, and reputational damage—making certified profiles a baseline requirement for credible commercial and industrial deployments.

At Beauty STC (Est. 1998), we’ve spent over 25 years engineering aluminum profiles specifically for demanding global markets. As a vertically integrated manufacturer, we combine precision extrusion, rigorous third-party testing, and ISO-certified production to deliver profiles that consistently exceed ETL and CE requirements. Our solutions are trusted by lighting designers, contractors, and facility managers worldwide for their reliability, thermal efficiency, and unwavering compliance—proving that in industrial-grade lighting, the profile is never just a component; it’s the backbone of the system.

Technical Specs & Certifications

Beauty (STC) Manufacturing Co., Ltd.

Senior LED Lighting Engineer & Export Manager

Technical Datasheet – LED Aluminum Profile Systems

(Extruded 6063-T5 heat-sink housings for linear LED assemblies)

-

Photon-Efficiency Matrix (delivered at Tj = 85 °C, 25 °C Ta)

• Mid-power SMD (2835, 300 mA): 195–210 lm/W @ 80 CRI – 180–190 lm/W @ 90 CRI

• Chip-on-Board (COB 24 W/ft, 400 mA): 165 lm/W @ 90 CRI – 150 lm/W @ 97 CRI

• High-efficacy 3030 (1 W/led, 700 mA): 185 lm/W @ 80 CRI – 170 lm/W @ 90 CRI

*All figures measured in 2 m integrating sphere with profile fitted by factory-standard opal diffuser; tolerance ±3 %. -

Color Rendering Index (CRI)

Standard binning: 90 CRI min. (Ra ≥ 90, R9 ≥ 50)

Premium binning: 97 CRI typ. (Ra ≥ 97, R9 ≥ 90)

3 SDCM MacAdam ellipse, CCT 2700 K – 6500 K, complies with IES LM-80-18 & TM-30-20 (Rg 100 ± 4, Rf 95 ± 2). -

Ingress-Protection Ratings (whole profile + end-cap assembly)

• IP20: open profile for dry, interior cove

• IP54: silicone sleeve insert, dust & splash proof (laboratory-tested 5 h salt-spray per ASTM B117)

• IP65: co-extruded polycarbonate diffuser with dual-edge gasket, 4 kV surge, suitable for kitchen/bathroom

• IP67: full polyurethane potting, 1 m immersion, IK06 impact, -40 °C to +60 °C

• IP68 (marine grade): epoxy-filled + marine-anodized 25 µm, 3 m depth, 1000 h Q-UVB validated -

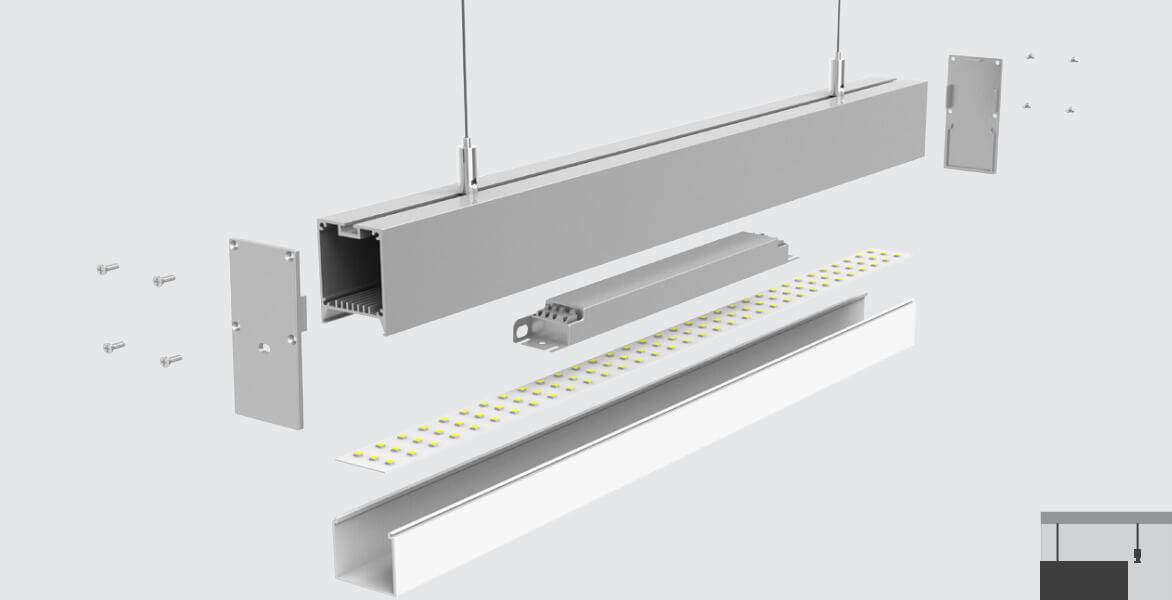

Thermal Management (Beauty STC in-house extrusion)

6063-T5 aluminum, λ ≥ 209 W/m·K, wall thickness 1.2–2.0 mm, fin-to-volume ratio 4.8 cm²/cm.

Measured ∆T (LED board to ambient) < 15 °C @ 15 W/ft continuous, guaranteeing < 10 % lumen depreciation at 50 000 h (L70B10 per IES TM-21-19). -

Electrical Integration Options

Constant-current 350 mA/500 mA/700 mA or constant-voltage 24 VDC; flicker-free <1 % at 100 Hz (IEEE 1789-2015).

Power factor ≥ 0.95, THD < 10 %, SELV, CE/ENEC, UL 2108, RoHS/REACH, SAA, BIS. -

Quality Consistency – Beauty STC Commitment

- Raw billet 100 % inspected for Cu & Fe content (≤ 0.03 %) to maintain thermal conductivity.

- Anodizing line with online film-thickness gauge (±2 µm) and sealed to ISO 3210.

- SMT performed on Yamaha & Juki lines under 1000-class clean-room; AOI + SPI after each reflow.

- Every reel LM-80 data linked to unique QR code on profile; 4 h burn-in at 85 °C/85 % RH before packing.

- Export batch files kept 10 years for traceability; CPK > 1.67 on luminous flux, CRI, and IP gasket compression force.

For project-specific IES files, LM-79 reports, or salt-spray/IP test certificates, please contact Beauty STC Technical Sales.

Factory Tour: Manufacturing Excellence

Beauty STC Manufacturing Co., Ltd. – Jiangmen Factory Overview

By [Your Name], Senior LED Lighting Engineer & Export Manager

Our Jiangmen facility (located in Guangdong Province, China’s LED manufacturing hub) is a certified ISO 9001:2015, ISO 14001:2015, and RoHS-compliant industrial campus spanning 15,000+ sqm. Dedicated to high-precision LED lighting solutions, the factory integrates fully automated production lines, rigorous quality control protocols, and end-to-end OEM capabilities for products including LED aluminum profiles, driver assemblies, and integrated lighting systems. Below is a technical breakdown of your requested areas:

1. SMT Production Line: Precision & Reliability

Our Surface Mount Technology (SMT) line is engineered for 0201–1206 component handling and ultra-fine-pitch LED driver PCB assembly (down to 0.25mm pitch). Key features:

– Equipment: Dual-head Juki FX-5R pick-and-place machines (0.03mm placement accuracy), automated solder paste printers (DEK Horizon), and reflow ovens with 8-zone profile control (min. 1.5m/s belt speed).

– Quality Assurance:

– SPI (Solder Paste Inspection): 100% AOI (Automated Optical Inspection) post-printing.

– X-ray Inspection: For BGA/QFN components (BGA voiding <3% per IPC-A-610 Class 3).

– In-circuit testing (ICT): Full functional validation of driver boards pre-assembly.

– Output: Capable of 150,000+ components/hour, with <0.01% defect rate for LED driver PCBs.

Why this matters for OEM clients: Consistent thermal management and electrical performance in LED strips/profiles, critical for long-term reliability in demanding environments (e.g., commercial signage, architectural lighting).

2. Aging Tests: Validating Long-Term Performance

We operate dedicated environmental aging rooms compliant with IEC 62471 and LM-80 standards to simulate real-world stress conditions:

– Test Parameters:

– Temperature: 45°C–65°C (±1°C stability)

– Humidity: 60%–90% RH (optional)

– Continuous operation: 48–72 hours (standard), with optional 1,000–5,000-hour accelerated life testing.

– Monitoring:

– Real-time data logging of luminous flux, color consistency (Δu’v’ <0.003), and current/voltage drift.

– Failure analysis via automated trigger alerts (e.g., >10% lumen depreciation or open-circuit detection).

– Certification: All tests align with IEC 60598 (luminaire safety) and UL 8750 (LED drivers).

Client impact: Our aging protocol ensures <0.5% field failure rate for shipped products, directly reducing warranty claims and lifecycle costs for your end-users.

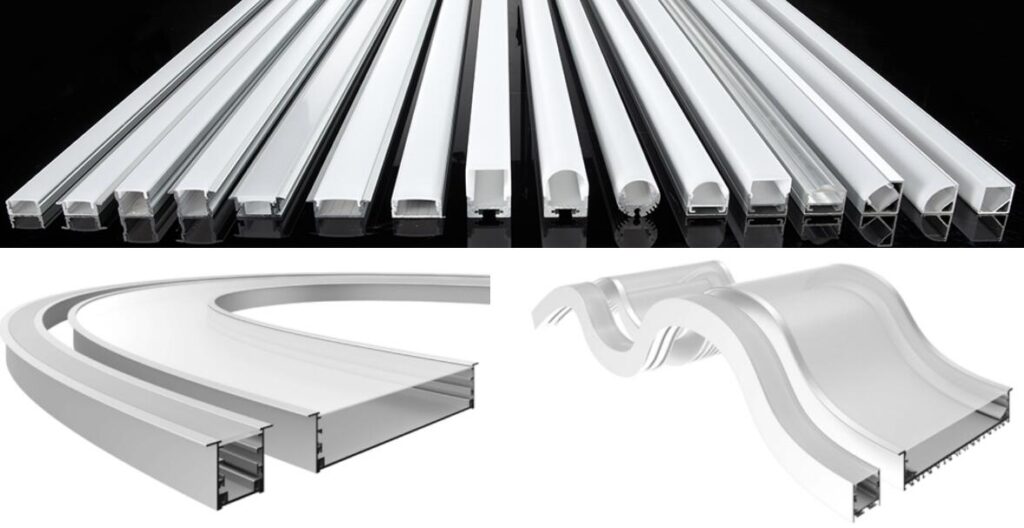

3. OEM Capability for LED Aluminum Profiles: Customization at Scale

Our aluminum profile production is a fully integrated process, from extrusion to finished goods:

– Extrusion & Tooling:

– 12–600mm custom profiles (6063-T5/T6 alloy), with die design via CAD/CAM (SolidWorks).

– Lead time: 15–20 days for new dies (including FEA stress testing).

– Surface Treatment:

– Anodizing (15–25μm thickness, salt-spray tested 96+ hours), powder coating (RAL colors, film thickness 60–80μm), and electrophoresis.

– Precision Machining:

– CNC cutting (±0.05mm tolerance), micro-groove milling for LED strip retention, and end-cap assembly.

– Quality Control:

– 3D coordinate measuring machines (CMM) for dimensional checks.

– Surface roughness (Ra ≤0.8μm) and straightness (≤0.1mm/m) verification.

OEM advantages:

– Design collaboration: We provide DFM (Design for Manufacturability) feedback to optimize profiles for thermal dissipation, light distribution, and ease of installation.

– Volume scalability: 50,000+ meters/month capacity for standard profiles; 10,000–20,000 meters/month for custom designs.

– Global compliance: Profiles meet EN 12020 (European) and ANSI/ASME B18.22.1 (U.S.) standards for structural integrity.

Why Partner with Beauty STC?

- End-to-end vertical integration: From raw aluminum extrusion to finished LED products (no third-party bottlenecks).

- Export readiness: 10+ years of experience shipping to 50+ countries (EU, North America, Australia), with customs documentation expertise.

- Traceability: Full lot tracking via ERP system (SAP), including material certificates and test reports for every batch.

Example: For a recent EU client, we delivered 25,000m of custom-profiled LED strips (with integrated drivers) with 0% rejection rate after aging tests and pre-shipment inspections.

Let’s discuss your project. As Export Manager, I’m available to share detailed capacity reports, sample profiles, or a virtual factory tour. Contact me directly at [email/phone] to align technical specs with your requirements.

Beauty STC: Engineering Light, Delivering Trust.

Note: All technical specifications reflect current factory capabilities as of Q3 2024. Certifications and processes are audited annually by TÜV Rheinland and SGS.

Application Scenarios

Senior LED Lighting Engineer

Beauty (STC) Manufacturing Co., Ltd.

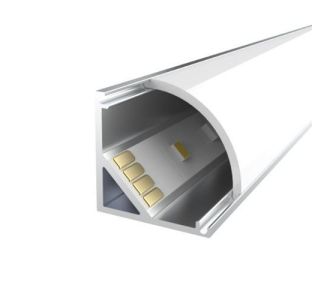

Where to use LED aluminum profiles

(= extruded heat-sink + diffuser + mounting groove)

-

Hotels

• Coves & bulkheads – 2700-3000 K, 95 CRI, 8 W m-1, 120 LED m-1 for “no-dot” glow.

• Head-board feature strips – micro 6 × 6 mm profile recessed in MDF, 24 V, Class III driver in night-stand service cavity.

• Corridor path-light – 45° asymmetrical profile 12 W m-1, 3-step MacAdam, 220 lm m-1 foot-candle (5 lx) at floor.

• Bathroom mirror front & back-lit – IP44 anodised profile, silicone sleeve, CRI 90+, 3 SDCM for make-up colour fidelity. -

Malls & Retail

• Shelf “light-band” – 10 × 10 mm surface profile, 4000 K, 160° opal diffuser to eliminate LED image on glossy packaging.

• Hand-rail infill – 180° bendable 8 × 5 mm profile, 24 V, 10 W m-1, continuous run ≤ 5 m fed both ends.

• Ceiling “blade” feature – 40 × 40 mm pendant profile, 24 V, 20 W m-1, 3-phase track adaptor for shops that re-merchandise weekly.

• Window reveal – IP65 sealed profile, 24 V, 6000 K, 1200 lm m-1 to compete with daylight 8000 lx. -

Offices

• Glazing mullion – 15 × 8 mm snap-in profile, 4000 K, UGR < 19 diffuser, continuous run past plasterboard expansion joint (5 mm).

• Task fixture retrofit – 40 × 60 mm suspended profile, 24 V, 25 W m-1, L80 > 50 kh @ 25 °C, Tc 50 °C measured.

• Skirting path & emergency way-finding – 10 × 5 mm side-emitting profile, 24 V battery-back-up central driver, < 1 W m-1 in maintained mode.

• Acoustic baffle integration – 30 × 30 mm profile clipped into 40 mm PET baffle, 24 V, < 19 dB(A) electronic driver remote.

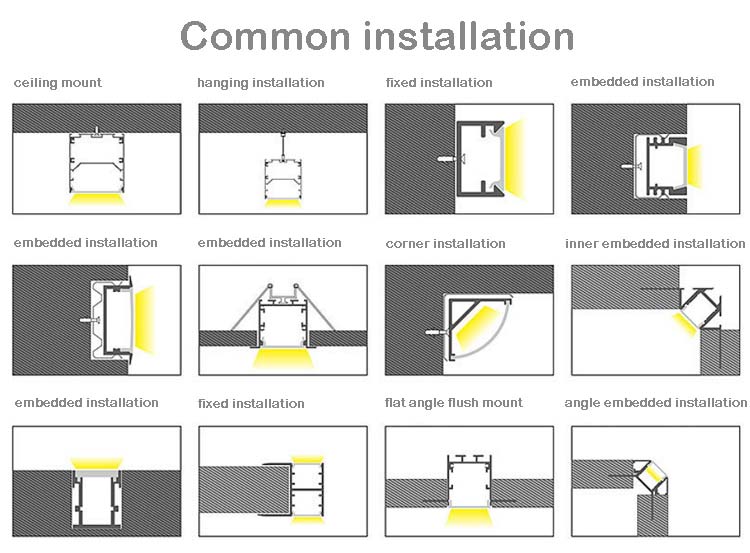

Installation checklist for contractors

(Print & tick on site)

□ 1. Profile selection

– Heat sink ≥ 20 cm² W-1 for 24 V strips up to 20 W m-1.

– Diffuser: 50 % transmission opal for dot-free, 90 % clear for max punch.

– Anodised 15 μm for indoor, 25 μm marine grade for coastal hotels.

□ 2. Thermal path

– Mount on aluminium, steel or plaster-set thermal paste; never on wood alone.

– Continuous runs > 2 m: mechanical joiner + thermal bridge paste to keep ΔT < 5 °C across joint.

□ 3. LED strip loading

– Max 80 % of driver rated wattage; add 10 % for 24 V drop on 5 m leads (4 mm²).

– Feed both ends if run > 3 m (10 W m-1) or > 5 m (5 W m-1).

– Use 24 V constant-voltage, 3-step MacAdam, CRI 90 for hospitality.

□ 4. Wiring & isolation

– Class III SELV 24 V in bathrooms; driver outside Zone 2.

– Mains drivers min. IP20 in accessible ceiling; remote mount to keep Ta < 40 °C.

– Earth the profile when > 1 m metallic length and mains driver < IP20; 4 mm² fly-lead to building earth.

□ 5. Expansion & contraction

– Allow 0.5 mm m-1 for aluminium; use “floating” clip every 300 mm, fixed clip every 1 m.

– Leave 2 mm end-cap gap when installing in 30 °C ambient to prevent “oil-can” noise at night.

□ 6. Diffuser handling

– Remove protective film only after paint / plaster dust cleared; static attracts dust.

– Cut diffuser 2 mm shorter than profile to avoid bowing under temperature rise.

□ 7. Testing & hand-over

– 100 % 1 h burn-in on 240 V ± 10 %.

– Record lux on 1 m grid; hotel coves 50-80 lx average, office mullions 150 lx on work-plane.

– Provide client with spare 1 m profile, 1 m strip, 2 end-caps, 1 driver model label.

Quick tool kit for installer

• 45° guillotine chop-saw with 80 T non-ferrous blade (burr-free).

• De-burr file + nylon brush to protect anodise.

• 24 V LED tester pen – verify polarity before closing profile.

• 3 mm hex driver for M3 end-cap screws – prevents over-torque & strip.

Follow the above and the extrusion disappears, the light performs, the client signs off—first visit.

Why Choose Beauty STC Lighting

Partner with Beauty STC for Expert-Engineered LED Aluminum Profiles – Trusted in 50+ Countries. Contact [email protected] for Certified, High-Quality Solutions Tailored to Your Global Project Needs.

Precision. Reliability. Global Excellence.

Beauty (STC) Manufacturing Co., Ltd. | ISO-Compliant | CE/RoHS Certified | 15+ Years in LED Lighting Innovation

⚡ LED Power Supply Calculator