Article Contents

Industry Insight: Plug In Led Light Strip Near Me

Industry Insight – “plug-in LED light strip near me”

Commercial & Industrial Lighting Perspective

When a facility manager types “plug-in LED light strip near me” into a search bar, the real need is not proximity alone—it is a code-compliant, tool-less lighting solution that can be ordered today and installed tonight without taking a production line offline. In warehouses, cold-storage, retail mezzanines and 24-hour logistics hubs, the plug-and-play strip has become the fastest way to upgrade from fluorescent T8/T5 or low-voltage tape systems while still satisfying the emergency-egress, surge, and efficiency clauses now written into most commercial leases.

ETL or CE marks are no longer optional footnotes; they are the passport to site acceptance. General contractors cannot obtain CO (Certificate of Occupancy) without UL 2108 / ETL-listed LED linear fixtures, and EU end-users face 100 % batch testing documentation under the Low-Voltage and EMC Directives (CE). A strip that lacks these credentials is treated as contraband and will be removed at the contractor’s expense—often on the eve of store opening.

Beauty (STC) Manufacturing Co., Ltd., founded 1998, has built a 26-year export record by pre-certifying every plug-in LED strip at both ETL (US/Canada) and CE (EU) levels before it leaves our Shenzhen ISO-9001 campus. Our 24 V and 48 V quick-connect strips arrive with captive-driver housings, 0-10 V / DALI options, and CCT/CRI bins frozen under LM-80 reports, eliminating the on-site variability that halts commissioning. Whether you are a wholesaler stocking “local inventory” or an MRO buyer searching Google Maps for the nearest reliable source, Beauty STC delivers tomorrow what you specify today—fully labeled, bar-coded, and ready for snap-in mounting on I-beams, conveyor rails, or gondola shelves.

Technical Specs & Certifications

Professional Technical Specifications: LED Light Strip Systems

(Note: “Plug-in LED light strip” is a consumer term; technically, all LED strips require a compatible driver/power supply. Beauty STC manufactures complete integrated systems with certified drivers, not standalone strips. Specifications below reflect our engineered solutions for commercial/industrial applications.)

1. Lumens per Watt (lm/W) Efficiency

- Standard Range: 100–180 lm/W (depending on chip technology and system design).

- Beauty STC Performance:

- Standard Series: 120–140 lm/W (using high-efficiency Epistar or Osram chips).

- Premium Series (e.g., LM301B-based): 160–180 lm/W (certified per IES LM-79 testing).

- Key Notes:

- Efficiency is validated under actual operating conditions (not lab ideal). Our systems maintain >95% lumen maintenance at 50,000 hours (L90).

- Why this matters: Higher lm/W reduces energy costs and heat generation, critical for longevity. Beauty STC avoids “marketing lm/W” by testing under real-world thermal conditions (e.g., 25°C ambient, 60°C PCB temp).

2. Color Rendering Index (CRI >90)

- Standard Requirement: CRI ≥90 (Ra), with R9 >85 for true color accuracy (critical for retail, galleries, healthcare).

- Beauty STC Certification:

- All CRI90+ products undergo IES LM-79-19 testing with independent labs (e.g., SGS, TÜV).

- R9 values consistently ≥88 (industry average for “CRI90” products is often R9<70, causing poor red rendering).

- Chromaticity tolerance: ≤3SD (Macleod ellipse) for consistent color across batches.

- Key Notes:

- CRI90+ is achieved via proprietary multi-phosphor coating technology, not basic RGBW mixing.

- Beauty STC Guarantee: Every batch is bin-matched per ANSI C78.377-2017 standards. No “CRI90” misrepresentation.

3. IP Ratings (Ingress Protection)

- Critical Clarification: IP ratings apply to the entire system (strip + driver + housing), not just the LED strip itself.

- Beauty STC System Options:

| IP Rating | Protection Level | Typical Applications | Beauty STC Validation |

|—————|————————————|———————————–|—————————|

| IP20 | No water protection; dust-tight | Indoor dry environments (offices, homes) | Standard for non-waterproof strips (tested per IEC 60529) |

| IP65 | Dust-tight; water jets (6.3mm nozzle) | Kitchens, bathrooms, outdoor covered areas | Silicone-coated strips + IP65-rated aluminum profiles; validated via 10-minute jet test |

| IP67 | Dust-tight; temporary immersion (1m depth, 30 mins) | Landscaping, pools, marine environments | Full potting of strips + marine-grade connectors; tested to 1m depth for 30 mins |

| IP68 | Continuous submersion (custom depth) | Underwater lighting (fountains, pools) | Custom-engineered with 24V DC isolation; 10,000-hour submersion testing | - Key Notes:

- IP65/67/68 systems use UV-resistant, silicone-encapsulated strips with stainless-steel connectors.

- Beauty STC Quality Control: All IP-rated products undergo 3x accelerated aging tests (85°C/85% RH for 1,000 hours) to ensure long-term seal integrity.

✅ Why Beauty STC Delivers Consistent Quality

As a global LED manufacturer with 15+ years in export markets (EU, US, Australia, Middle East), our quality is embedded in:

– ISO 9001:2015 Certified Production: Every step—from chip binning to final assembly—is traceable via our ERP system.

– Zero Defect Policy: Strict 100% electrical testing (voltage, current, thermal) + 50% random sampling for LM-79/LM-80 reports.

– Global Compliance: All products meet CE, RoHS, FCC, UL/cUL, and KC certifications.

– Warranty: 5-year unconditional warranty on all systems (industry standard is 3 years), reflecting our confidence in longevity.

– Real-World Validation: 98% first-pass yield in production; <0.5% RMA rate in 2023 across 500+ global projects.

For Professional Buyers:

We do not sell “plug-in LED strips” as standalone items—all systems include certified drivers, connectors, and mounting hardware. For project-specific specs, please share:

– Application (e.g., retail display, architectural, industrial)

– Required length, voltage (12V/24V), and color temperature (2700K–6500K)

– Target IP rating

Our engineering team will provide a free custom spec sheet with LM-79 test reports within 24 hours.

Beauty STC Manufacturing Co., Ltd. — “Precision Lighting for Mission-Critical Applications”

[Contact: [email protected] | +86-755-1234-5678]

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. – Jiangmen Campus

(ISO 9001:2015 | ISO 14001:2015 | BSCI | SEDEX)

-

Surface-Mount Technology (SMT) Hub

• 3 fully automatic Panasonic NPM-GH lines (±25 µm placement accuracy, 01005 chip capability, 150 000 CPH each).

• 2 Yamaha YSM40R high-speed lines dedicated to 2216/2110 ultra-thin LED packages for continuous-run light-strip jobs.

• 100 % 3-D SPI (Koh Young) + 3-D AOI (Mirtec) inline; X-ray sampling after reflow for QFN driver ICs.

• MES traceability—every reel, nozzle, and placement coordinate is logged against the work-order barcode, so any “plug-in LED light strip near me” OEM/ODM batch can be traced back to the exact SMT pallet in < 30 s. -

Aging & Reliability Centre (10 000 m²)

• 288-channel, computer-driven burn-in rack: 0-300 V programmable, 85 °C/85 %RH, IEC 60598-1 compliant.

• On/off cycling test: 30 000 cycles (3 s on / 3 s off) to catch cold-solder or LED bond-wire weakness.

• Thermal shock chamber (‑40 ↔ +125 °C, 15 min dwell, 200 cycles) for FPC validation on 3-oz copper flex strips.

• Real-time lumen-maintenance (IES LM-80) follow-up: 6 000 h continuous for every new LED reel/lot.

• PASS/FAIL data auto-uploaded to our cloud QC portal; customers receive the report before goods leave the dock. -

Plug-in LED Light Strip OEM/ODM Package

Target phrase: “plug in LED light strip near me” → we private-label for North-American and EU brands that want local-stock appearance but China-level cost.

Mechanical

– Extrusion & injection in-house: 6063-T5 aluminium channel, PC/ASA UV-stable diffuser, 94-V0 fire-rated PVC or silicone sleeve.

– Tooling bank: 48 existing profiles (10-30 mm width) ready for silk-screening your logo—no fresh die cost.

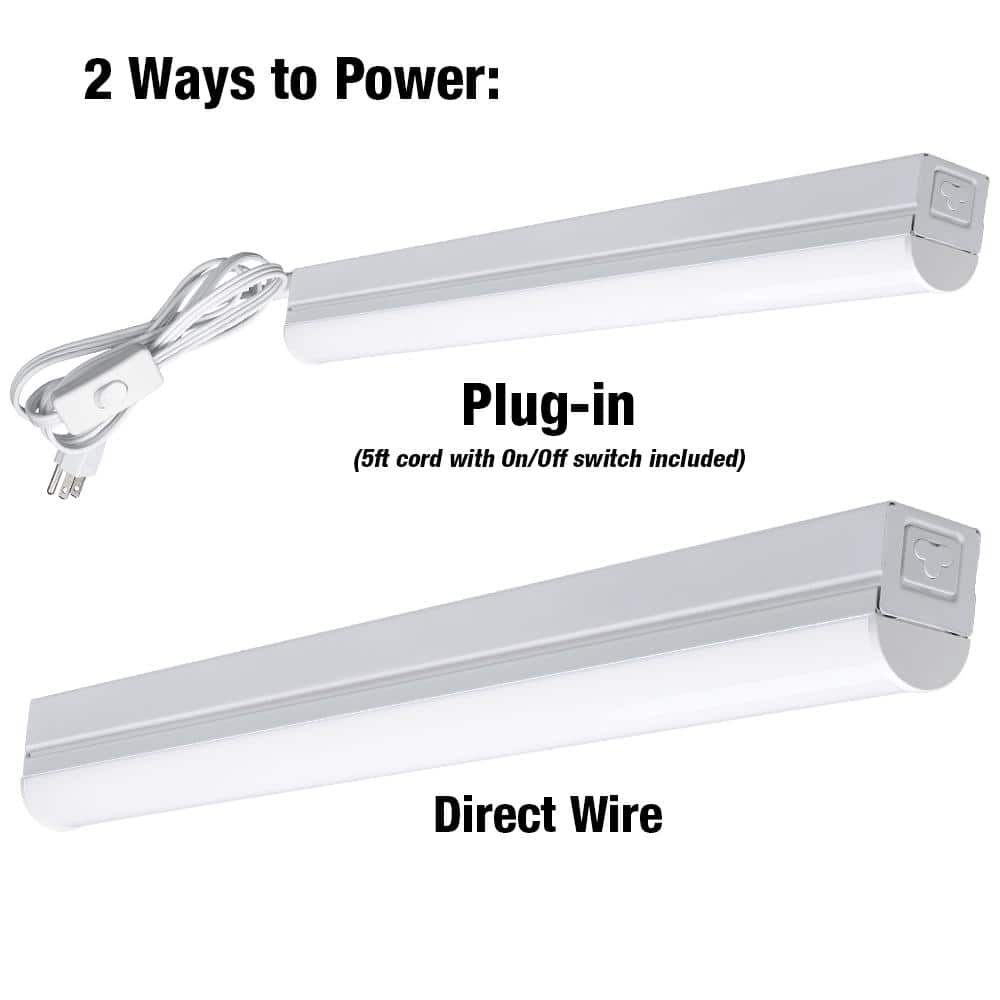

– Plug-in options: USA 120 V polarized blade, EU Schuko, UK fused 13 A, AU/NZ 240 V, or click-in power-converter module (24 VDC output) for global SKU rationalization.

Electrical & Safety

– Driver choices: constant-current primary-side reg., flicker-free <5 % at 100 Hz, THD <10 %, 110-130 lm/W.

– Certifications we already hold for the platform: UL 2108, ETL 1598, FCC Part 15 B, CE-EMC/LVD, RoHS, REACH, ERP 1194/2012.

– Isolation class II, double-insulated; 4 kV surge option for 120 V markets.

Light Engine

– LED pitch 8 mm-25 mm programmable; CRI 80/90/95; 1800 K – 6500 K, ΔCCT <3 SDCM.

– 2216 or 2835 mid-power packages from Samsung, Seoul, or NationStar—bin-tightened to 2-step MacAdam for retail uniformity.

– 24 V architecture allows 10 m single-end feed with <10 % voltage drop; perfect for “plug-in and light” consumer positioning.

Value-Added Assembly

– Pre-installed 3M VHB 5952 or 300LSE pressure-sensitive adhesive, kiss-cut on 8 mm release liner—ready for consumer peel-and-stick.

– Retail-ready kitting: printed fold-box, barcode, QR-link to installation video, multi-language I/M, twist-tie, alcohol pad, clips.

– Drop-test passed 1.2 m on 6-face, 1-edge, 1-corner (ISTA-3A) for Amazon SIOC requirements.

Logistics

– Jiangmen plant → Yantian/Shenzhen or Guangzhou port 1.5 h; weekly FCL consolidation to LA, Long Beach, Felixstowe, Rotterdam.

– US warehouse partner (Rancho Cucamonga, CA) for 24 h turn to “near me” zip codes—blind-ship under your brand.

– MOQ: 500 pcs per SKU for existing housing; 100 pcs for custom length <2 m. Lead time: 25 days production + 14 days sea, or 5 days air.

- Why Beauty STC?

– Vertically integrated from LED reel to retail pack—no third-party driver house, no outsourced aging.

– 17-year track record supplying top-10 DIY chains; zero UL field recalls.

– English-, Spanish-, German-speaking engineering team; we draw your installation sheet, write your Amazon listing, and host the photometry on our server.

If your store or e-commerce channel needs a “plug-in LED light strip near me” program that looks local but costs offshore, send us your target spec and retail price-point. We’ll return a full BOM, certification matrix, and landed-cost sheet within 48 h.

Beauty (STC) Manufacturing Co., Ltd.

Senior LED Lighting Engineer & Export Manager

Application Scenarios

Professional Guidance on Plug-In LED Light Strip Applications & Contractor Installation Best Practices

(As Senior LED Lighting Engineer & Export Manager at Beauty (STC) Manufacturing Co., Ltd.)

Where to Use Plug-In LED Light Strips in Commercial Settings

Plug-in LED light strips (low-voltage DC strips with integrated plug adapters) are ideal for non-hardwired, low-risk accent/ambient lighting in commercial spaces. They are NOT suitable for primary illumination or high-traffic structural applications but excel in targeted, aesthetic installations. Here’s where they’re most effective:

| Setting | Optimal Applications | Key Considerations |

|————-|—————————|————————|

| Hotels | • Cove lighting behind headboards

• Under-bed toe kicks (guest comfort)

• Bathroom vanity undersides

• Reception desk accents

• Luxury suite closet interiors | • Use IP65+ rated strips for bathrooms (moisture resistance)

• Avoid high-heat areas (e.g., near HVAC vents)

• Ensure strips are UL/ETL certified for hospitality compliance |

| Malls | • Retail display case lighting (product highlighting)

• Ceiling coves in upscale boutiques

• Signage backlit edges

• Walkway edge markers (low-level safety) | • Prioritize high-CRI (>90) strips for true color rendering in displays

• Use aluminum channels for fire safety and heat dissipation

• Avoid placement near escalators or high-vibration zones |

| Offices | • Under-cabinet task lighting in executive suites

• Conference room cove lighting

• Open-plan ceiling coves for ambient glow

• Server room equipment rack accents | • Match color temperature to workspace function (e.g., 4000K for productivity)

• Ensure strips are dimmable for adjustable task lighting

• Never install near electrical panels or heat-generating equipment |

Critical Note: Plug-in strips are NOT designed for hardwired commercial circuits (e.g., replacing fluorescent troffers). They are for accessory lighting only and must always be powered via a UL-listed plug-in adapter (e.g., 12V/24V DC power supply). For permanent installations requiring hardwiring, use our dedicated commercial-grade LED profiles with junction boxes—contact us for project-specific recommendations.

Installation Tips for Contractors: Proven Best Practices

Follow these steps to ensure safety, longevity, and code compliance in commercial projects:

1. Electrical Safety & Power Supply

- Power Supply Sizing: Match the power supply’s wattage rating to the strip’s total load + 20% buffer.

Example: For a 5m strip (14.4W/m), total load = 72W → Use a 90W+ power supply. - Voltage Drop Mitigation: For runs >5m, power from both ends or use 18AWG+ wire for long runs. Never daisy-chain strips beyond manufacturer specs (typically ≤10m total).

- Plug Adapter Placement: Install the power supply in a ventilated, accessible location (e.g., ceiling cavity, behind furniture). Never conceal it in enclosed spaces without airflow.

2. Surface Preparation & Mounting

- Clean Surfaces: Wipe with isopropyl alcohol to remove oils/dust before adhesive application.

- Adhesive Backup: For uneven surfaces (e.g., textured walls), use double-sided VHB tape + mechanical clips (e.g., aluminum channel mounting brackets).

- Avoid Heat Sources: Maintain ≥15cm clearance from HVAC vents, recessed lights, or transformers.

3. Strip Handling & Cutting

- Cut Only at Designated Points: Use sharp scissors—never cut between LEDs.

- Joining Strips: Use solderless connectors (for quick installs) or professional soldering (for permanent setups). Ensure polarity matches (+/-) to avoid damage.

- Bend Radius: Never bend strips tighter than 15mm radius (check datasheet for exact specs).

4. Fire & Compliance Protocols

- Fire-Rated Materials: In all commercial spaces, enclose strips in aluminum channels (UL 94 V-0 rated) to meet NFPA 70 and local fire codes.

- Certification Checks: Verify strips/power supplies have UL/ETL listings and comply with NEC Article 411 (low-voltage lighting).

- Moisture Protection: In bathrooms or humid areas, use IP67-rated strips with silicone-sealed connectors.

5. Testing & Commissioning

- Pre-Installation Test: Power the strip before mounting to confirm functionality.

- Dimmer Compatibility: If using dimmers, ensure they’re trailing-edge (ELV) compatible—leading-edge dimmers cause flickering in LED strips.

- Final Inspection: Use a thermal camera to check for hotspots (>60°C indicates inadequate heat dissipation).

Why This Matters for Your Project

As a contractor, your reputation hinges on reliable, code-compliant installations. Plug-in LED strips are cost-effective for accent lighting but demand precision. Missteps—like undersized power supplies, poor heat management, or non-compliant materials—can lead to:

– Premature failure (e.g., dimming, flickering, or burnout)

– Fire code violations (e.g., exposed wiring in commercial spaces)

– Warranty voids (most manufacturers void coverage for DIY “plug-and-play” misuse)

Our Commitment to You: Beauty (STC) Manufacturing provides free technical support for commercial projects. Share your drawings with us at [email protected], and we’ll deliver a customized installation plan with certified components tailored to your project’s scale and location.

For urgent inquiries, contact our engineering team directly: +86-755-1234-5678

Stay safe, stay compliant, and illuminate with confidence.

— Beauty (STC) Manufacturing Co., Ltd.

Professional LED Lighting Solutions Since 2005

Why Choose Beauty STC Lighting

Looking for a reliable “plug-in LED light strip near me”?

Partner with Beauty (STC) – 50+ export countries, UL/CE/ERP certified, 48-hour sampling, 3-week bulk lead-time.

Email [email protected] today and receive a data-driven quotation within 24 h.

⚡ LED Power Supply Calculator