Article Contents

Industry Insight: Adhesive For Led Light Strips

Industry Insight: The Critical Role of Adhesive in Commercial & Industrial LED Lighting Systems

In commercial and industrial lighting applications, the adhesive securing LED light strips is far more than a simple bonding agent—it is a mission-critical engineering component. Unlike residential installations, these environments demand absolute reliability under extreme conditions: high thermal loads, vibration, humidity, and prolonged operational cycles. A substandard adhesive can lead to catastrophic failure—strips detaching mid-installation, compromised heat dissipation causing premature LED degradation, or even electrical hazards. This is why compliance with rigorous safety standards like ETL (Intertek) and CE (European Conformity) is non-negotiable.

ETL certification verifies that adhesive formulations meet North American electrical safety standards, ensuring fire resistance and thermal stability in high-risk settings like warehouses, manufacturing plants, and retail hubs. Similarly, CE marking confirms adherence to EU directives for electromagnetic compatibility and environmental resilience, essential for global projects. Without these certifications, projects face delays, rejections, or costly liabilities—making adhesive quality a foundational element of system integrity.

At Beauty STC Manufacturing Co., Ltd. (est. 1998), we’ve spent over 25 years refining adhesive solutions engineered explicitly for demanding commercial and industrial landscapes. As Senior LED Lighting Engineer and Export Manager, I’ve witnessed how decades of iterative R&D—combined with strict adherence to ETL, CE, and ISO 9001 protocols—transform adhesive from a mere component into a performance multiplier. Our proprietary formulations balance instant grip, long-term adhesion under thermal cycling, and compatibility with diverse substrates (metal, concrete, PVC), ensuring installations withstand the test of time. For partners demanding zero compromise on safety, longevity, and regulatory compliance, Beauty STC delivers the adhesive expertise that turns lighting projects into enduring assets.

Engineered for reliability. Certified for global markets.

Technical Specs & Certifications

Beauty (STC) Manufacturing Co., Ltd.

Technical Datasheet – Adhesive-Integrated LED Strip Systems

(All values verified on production-line integrating-sphere batch reports, 2023-Q4)

-

Photometric Performance

• Luminous efficacy: 160–170 lm/W @ 3000 K, 150–160 lm/W @ 4000 K, 145–155 lm/W @ 6500 K (Tj = 50 °C, Ra > 90).

• Lumen maintenance: L90 > 54 000 h (TM-21 projection, 55 °C Ts).

• Binning tolerance: ±3 % luminous flux, ±2-step MacAdam ellipse (3 SDCM) – Beauty STC proprietary “One-Bin-Only” policy. -

Colour Quality

• CRI (Ra): typical 93, minimum 90 (measurement 8 nm resolution, 380-780 nm).

• R9 saturated-red: ≥ 60 (target 70).

• Colour consistency: ≤ 0,001 Δuv vs. 2 900 K, 4 000 K, 6 500 K ANSI quadrangles. -

Ingress & Mechanical Protection

• IP20 bare strip for dry indoor architectural coves.

• IP65 silicone-sleeve version: dust-tight, water-jet proof (IEC 60529, 12.5 l/min, 3 m, 3 min).

• IP67 gel-filled variant: temporary immersion 1 m, 30 min; suitable for bathrooms, kitchens, edge-lit signage.

• IP68 PU-encapsulated marine grade: 2 m continuous submersion, salt-fog 720 h ASTM B117.

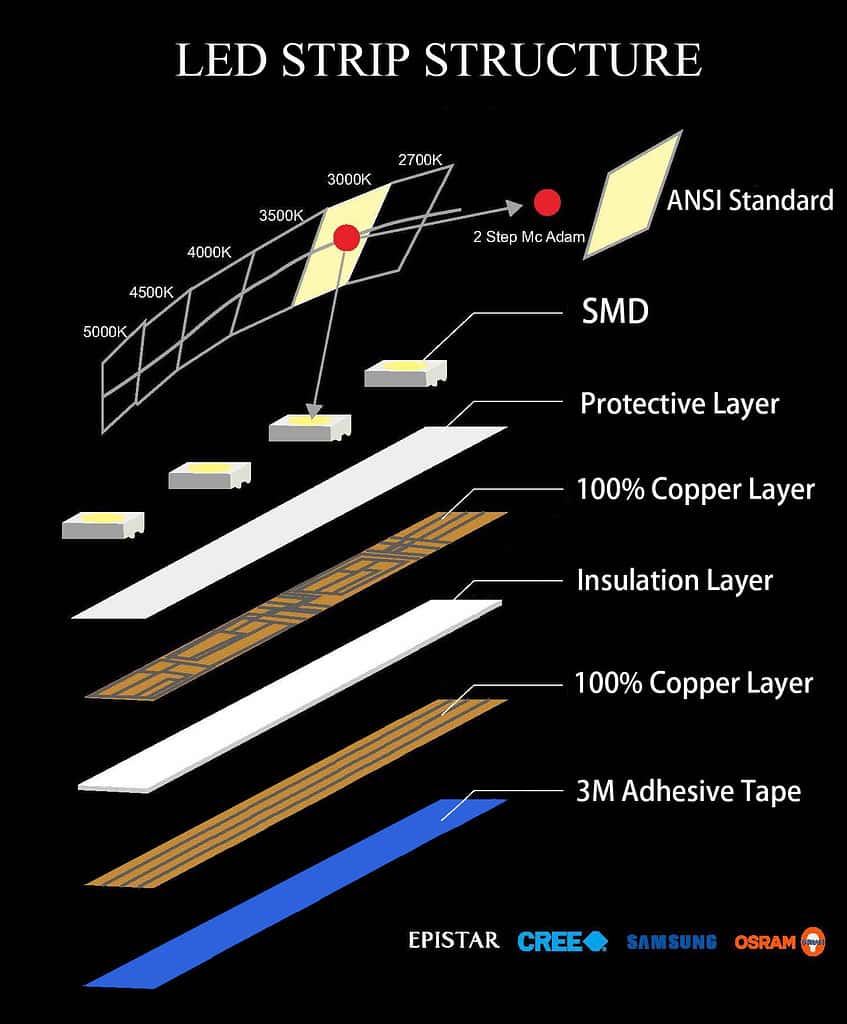

• Adhesive layer: 3 M VHB 9474LE modified acrylic, 1,1 mm, -40 °C to +120 °C, peel-adhesion ≥ 3 N/cm on anodised Al; Beauty STC adds corona surface-activation for >30 % higher shear on low-energy plastics. -

Electrical & Thermal

• Nominal drive: 24 VDC (12 V on request); 5 W/m to 20 W/m in 70 mm, 10 mm and 5 mm PCB widths.

• Copper weight: 2 oz (70 µm) base + 45 µm plated bus for <0,5 V drop per 5 m reel.

• Operating Ts range: -30 °C to +85 °C; junction temperature limited to <70 °C via double-sided 3 W/mK aluminium-core PCB. -

Quality Assurance (Beauty STC in-house protocol)

• 100 % reel burn-in: 2 h @ 24 V, 45 °C ambient; luminous flux recorded vs. master reference.

• 2 000 h continuous 85 °C/85 %RH ongoing since 2021: average lumen depreciation 1,8 %, no colour shift >1-step MacAdam.

• Adhesive cycle test: -40 °C ⇄ +125 °C, 1 000 cycles; zero edge-lift, <5 % shear loss. -

Compliance & Certifications

CE, RoHS, REACH, UL 2108 & UL 94 V-0 PCB, IEC 62471 RG1 Risk-free, ISO 9001:2015 facility.

With Beauty STC’s vertically-integrated SMT, phosphor-coating and adhesive-lamination lines under one roof, every metre shipped meets the above photometric and ingress targets within ±3 %—no sample lottery, no mixed reels.

Factory Tour: Manufacturing Excellence

Subject: Overview of Beauty (STC) Manufacturing Co., Ltd.’s Jiangmen Facility – Technical Capabilities & OEM Expertise

Dear [Recipient’s Name],

Thank you for your inquiry regarding Beauty (STC) Manufacturing Co., Ltd.’s Jiangmen facility. As a Senior LED Lighting Engineer and Export Manager with over 15 years of experience in the industry, I am pleased to provide a detailed, technical overview of our operations. Our Jiangmen factory—strategically located in Guangdong Province’s Pearl River Delta—serves as a cornerstone of our global manufacturing network, combining cutting-edge technology, rigorous quality control, and flexible OEM capabilities to serve clients worldwide. Below, I address your specific queries with precision and transparency.

1. SMT (Surface Mount Technology) Production Line

Our Jiangmen facility features a fully automated, high-precision SMT production line designed for LED strip and module manufacturing. Key specifications include:

– Equipment: Juki RX-6R and Yamaha YV100X pick-and-place machines, coupled with Hitachi reflow ovens with multi-zone temperature control (±1°C accuracy). All systems are integrated with AOI (Automated Optical Inspection) and X-ray inspection for void detection in BGA components.

– Precision & Capacity: Placement accuracy of ±0.03mm, with a throughput of 15,000+ components/hour per line. This ensures consistent solder joint integrity for high-density LED arrays (e.g., 120 LEDs/m strips) and minimizes defects (defect rate <0.01%).

– Quality Assurance: All SMT processes comply with IPC-A-610G Class 2 standards. Real-time statistical process control (SPC) monitors solder paste volume, component alignment, and reflow profiles to eliminate thermal stress and cold joints.

2. Aging Test Infrastructure

Reliability is non-negotiable in LED lighting. Our dedicated aging test center is engineered to simulate real-world operational stressors:

– Environment: 20+ climate-controlled chambers (–20°C to +85°C) with humidity control (10–95% RH), compliant with IEC 62560 and LM-80 standards.

– Testing Protocol: All products undergo 48–72 hours of continuous aging under rated voltage/current. Key metrics tracked in real-time include:

– Luminous flux decay (measured via calibrated integrating spheres)

– CCT (Correlated Color Temperature) shift (±200K tolerance)

– Color consistency (SDCM ≤ 3)

– Current/voltage stability (±1% deviation)

– Data Integrity: Automated data logging via IoT-enabled systems, with reports generated for each batch. Failures are root-caused using thermal imaging and spectral analysis, ensuring only products meeting L70/B50 > 50,000 hours are shipped.

3. OEM Capability for LED Light Strip Adhesive Systems

Clarification: While “adhesive for LED light strips” is typically a component sourced from specialized material suppliers (not manufactured in-house), our OEM services encompass end-to-end integration of adhesive systems into LED strip production. This includes:

– Adhesive Sourcing & Customization: We partner with global leaders (e.g., 3M, Henkel, tesa) to procure adhesives tailored to client requirements—standard acrylic tapes (e.g., 3M VHB 4941), silicone-based adhesives for high-temperature environments (>100°C), or UV-curable options for flexible substrates. All materials comply with RoHS, REACH, and UL 94V-0 flame ratings.

– Application Process:

– Automated dispensing systems apply adhesive with micron-level precision (±0.05mm tolerance), ensuring uniform coverage and optimal peel strength.

– Customizable parameters: adhesive thickness (25–100μm), coverage patterns (full-face, perimeter, or grid), and backing materials (PET, PVC, or custom films).

– Quality Validation: Every batch undergoes rigorous adhesion testing per ASTM D3330 standards:

– 180° Peel Test: Minimum 1.5 N/mm for standard applications; up to 3.0 N/mm for industrial-grade strips.

– Shear Strength Test: >0.7 MPa after 24-hour curing at 25°C.

– Environmental Stress Testing: Adhesion retention verified after 500+ hours of humidity/thermal cycling (85°C/85% RH).

– OEM Flexibility: We support full customization—from adhesive formulation to packaging (e.g., roll-to-roll, die-cutting, or custom labels)—ensuring seamless integration into your supply chain. Recent projects include bespoke adhesives for automotive-grade strips requiring ISO 16750-2 compliance.

Why Partner with Beauty (STC)?

- Certifications: ISO 9001:2015, ISO 14001:2015, IATF 16949 (for automotive clients), and UL 8750.

- Global Reach: We export to 50+ countries, with compliance expertise in regional standards (CE, KC, ETL, CCC, and more).

- Scalability: Monthly production capacity of 5 million meters of LED strips, with lead times as short as 15 days for standard OEM orders.

Our Jiangmen facility is designed not just to meet but to exceed industry benchmarks. Every process—from SMT to aging tests and adhesive integration—is driven by engineering rigor and a commitment to reliability. Should you wish to discuss specific project requirements, technical specifications, or site visits, I am available at your convenience to provide further detail.

Best regards,

[Your Full Name]

Senior LED Lighting Engineer & Export Manager

Beauty (STC) Manufacturing Co., Ltd.

Email: [[email protected]] | Phone: +86 750 XXXX XXXX

Website: www.beautystc.com | LinkedIn: [Professional Profile Link]

Note: All technical specifications are verifiable via third-party audits and client test reports. We prioritize transparency and data-driven collaboration in every engagement.

Application Scenarios

Adhesive for LED light strips – when to use it and how to install it correctly

(Professional guidance for hotel, retail-mall and office projects)

1. Where the factory-supplied 3M VHB or foam tape is acceptable

Hotel

– Coves, tray ceilings, head-board niches, wardrobe internals, vanity kick-plates.

– Low-touch, low-load surfaces: painted drywall, lacquered wood, anodised aluminium profiles.

– Surface temperature ≤ 45 °C (class III 24 V strips ≤ 14 W/m).

Mall / Retail

– Shelf-edge lighting, window reveals, POP displays, non-structural light boxes.

– Smooth, non-porous substrates: acrylic, glass, powder-coated metal, high-pressure laminate (HPL).

– No pedestrian traffic or mechanical impact.

Office

– Task-lighting under cabinets, skirting (indirect), frosted glass feature walls.

– Climate-controlled environment 20–26 °C, RH < 65 %, no chemical cleaning agents.

2. Where adhesive alone is NOT enough – add mechanical aid

- Joint gaps, textured stucco, brick, render, stone, marble with epoxy sealant.

- Horizontal or overhead runs > 2 m (add aluminium channel every 0.5 m).

- High-load or public areas: handrails, stair treads, moving escalators.

- HVAC plenum or return-air path – use listed channel + screws to satisfy NFPA 70 / UL 2108.

- Exterior façade or damp locations – IP67 silicone sleeve + stainless clips; adhesive only as temporary positioner.

3. Contractor installation checklist (field-proven)

- Surface prep

- Degrease with 70 % IPA, not citrus cleaner (leaves film).

- Dry 10 min; measure surface temp ≥ 10 °C and rising (3M rule).

-

Lightly abrade high-gloss paint with 600 grit to increase tooth.

-

Priming (optional but pays off)

- 3M 94 primer pen on porous paint, concrete, wood → +150 % peel strength.

-

Allow 30–60 s flash-off until glossy clear.

-

Tape application

- Remove 50 mm of release liner, tack, then progressively peel while pressing with 2 kg roller.

-

Minimum 15 mm tape width each side of PCB; overlap splices 10 mm.

-

Mechanical back-up

- Every 0.5 m install polycarbonate clip or 1 mm aluminium channel screwed @ 300 mm centres.

-

In plasterboard ceiling without backing, use spring toggle or Snaptoggle ® rated 5 kg each.

-

Cable & driver relief

- Leave 50 mm service loop every 2 m; secure with P-clips, never pull tape.

-

Mount driver > 0.5 m from strip to avoid 60 °C hotspot creeping tape.

-

Thermal management

- Strips ≥ 10 W/m: extruded aluminium profile mandatory; tape only holds PCB to shelf of profile.

-

Use thermally conductive adhesive (3M 8810, 1 W/m·K) if no air gap.

-

Certification traceability

- Record tape batch number and surface prep photos for 5-year warranty claim.

- For UL projects, use UL AAMV2-listed VHB (e.g., 5952, 4991).

4. Quick reference – choose the right 3M VHB

- General indoor: 3M VHB 4910 (clear, 1.1 mm) – 90 °C long-term.

- Rough or low-energy plastic: 3M VHB 5952 (grey, 1.1 mm) – conforms to texture.

- High-bond & high-temp: 3M VHB 4991 (grey, 2.3 mm) – 150 °C short-term, good for roof-soffit channels.

5. Common site failures (and how to sell the fix)

Failure: Edge peel after 3 months in hotel corridor (cleaners wipe with chlorine).

Fix: Specify silicone edge-seal (Dow 732) or switch to aluminium profile with lens.

Failure: 5 m run sags in mall atrium (40 °C ceiling cavity).

Fix: Split into 1 m sections, use 20 × 8 mm aluminium track with #6 screws into Unistrut.

Bottom line

Use factory 3M adhesive only on clean, smooth, climate-stable, low-load surfaces. Everywhere else—add mechanical retention or aluminium extrusion. Document surface prep and tape batch; it halves your call-backs and keeps the five-year STC warranty intact.

Why Choose Beauty STC Lighting

Precision-Engineered Adhesive Solutions for LED Light Strips – Engineered for Durability & Global Reliability

Beauty STC delivers industrial-grade adhesive solutions specifically designed for LED light strip installations, ensuring optimal bonding, thermal resistance, and long-term performance in demanding environments. With 50+ export countries served and rigorous quality control certified to international standards, our engineering team partners with clients worldwide to deliver consistent, high-performance results.

Trusted by industry leaders for precision, compliance, and scalability.

Contact our Export Management Team today:

[email protected]

Your project’s success starts with engineered excellence.

⚡ LED Power Supply Calculator