Article Contents

Industry Insight: 12V Led Strip Light

Industry Insight: The Critical Role of 12V LED Strip Lighting in Commercial & Industrial Applications

In today’s commercial and industrial landscapes, 12V LED strip lighting has evolved from a niche decorative solution to a fundamental backbone of efficient, flexible, and scalable illumination systems. From warehouse task lighting and retail accent displays to manufacturing floor safety zones and architectural cove lighting, these low-voltage strips deliver unparalleled design versatility without compromising on performance. However, this versatility comes with critical requirements: rigorous environmental resilience, energy efficiency, and—most importantly—uncompromising safety compliance.

For projects spanning retail, logistics, healthcare, or industrial facilities, ETL and CE certifications are non-negotiable. ETL (Intertek) marking ensures compliance with North American safety standards (including UL 1598), while CE certification validates conformity with EU directives for electromagnetic compatibility and low-voltage safety. These certifications are not merely bureaucratic checkboxes—they are essential safeguards against fire hazards, electrical failures, and product liability risks. In commercial environments where downtime costs can exceed $10,000 per hour, uncertified or substandard strips risk project delays, regulatory fines, and reputational damage. Only products engineered to meet these standards deliver long-term reliability in demanding settings like high-humidity warehouses or high-vibration manufacturing floors.

At Beauty STC Manufacturing Co., Ltd. (Est. 1998), we’ve spent over 25 years refining 12V LED strip technology specifically for commercial and industrial applications. As a vertically integrated manufacturer with global export expertise, we combine deep engineering rigor with stringent quality control—from raw material sourcing to final testing. Every strip we produce undergoes independent ETL and CE certification, alongside IP67 waterproofing and thermal management validation, ensuring consistent performance under real-world stress. Our solutions are trusted by contractors, architects, and facility managers worldwide for projects demanding precision, durability, and compliance. In an industry where cutting corners is never an option, Beauty STC delivers engineered excellence—backed by a quarter-century of proven results.

When safety, longevity, and performance are non-negotiable, choose a partner with the expertise to deliver.

Technical Specs & Certifications

Beauty (STC) 12 V LED Strip – Technical Datasheet

(Engineering grade, mass-production verified, 2024 revision)

-

Optical Efficiency

• 220 lm/W @ 3000 K, 80 CRI (typ. 24 V test board, 25 °C T-solder-point)

• 190 lm/W @ 3000 K, 90 CRI minimum – binning limit guaranteed on every reel

• 170 lm/W @ 2700 K, 97 CRI (Ultra-Color series, 2-step MacAdam ellipse) -

Color Quality

• CRI Ra > 90 (R1–R15) standard bin; 97 typ. for Ultra-Color

• TM-30-18 Rf > 92, Rg 98–102

• 3-step MacAdam ellipse for 80 & 90 CRI; 2-step for 97 CRI

• < 2 × 10–4 Δu′v′ drift after 6 000 h / 85 °C per IES LM-80-21 -

Electrical (12 V class)

• 4.8 W/m (60 LED/m, 2835), 14.4 W/m (120 LED/m, 2835), 20 W/m (60 LED/m, 5050)

• 24 V architecture also available; same lm/W because Beauty STC uses identical diode dies and phosphor blend on both 12 V and 24 V platforms -

Ingress Protection (IP) Ratings

IP20 – bare strip, 3 oz double-layer rolled copper FPC, 35 µm plating

IP54 – silicone extrusion, 1.2 mm wall, UV-stable, halogen-free

IP65 – tube + injected end-caps, 2 mm wall, UV- & salt-spray rated per ASTM B117 500 h

IP67 / IP68 – full PU or silicone potting, vacuum-filled to eliminate voids; 30 m underwater 24 h validated (Beauty STC in-house tank)

IP69K – 316L silicone sleeve + over-moulded cable, survives 80 °C, 100 bar, 14 l/min, 10 cm, 4 angles (DIN 40050-9) -

Mechanical & Thermal

• 10 mm FPC width (standard), 8 mm & 5 mm narrow on request

• Copper mass 3 oz (105 µm) minimum – keeps junction ≤ 75 °C at 25 °C ambient, 10 W/m, no heat-sink

• 3M 9495LE or VHB 5952 tape factory-applied, pull-off > 2 N/mm

• Operating –40 °C to +90 °C; storage –40 °C to +100 °C -

Lifetime & Certifications

• L70 > 54 000 h per TM-21-19, 55 °C T-solder-point (equivalent to ≥ 100 000 h @ 25 °C ambient)

• UL 2108, UL 8750, CE, RoHS, REACH, IEC 62471 RG0, LM-80 & TM-21 reports issued quarterly

• ISO 9001:2015 & IATF 16949 automotive-grade process control; every 5 m reel 100 % hi-pot 1 500 V / 1 mA, 100 % photometric & color binning on Beauty STC integrating-sphere line (2 m integrating sphere, 0.5 nm resolution) -

Consistency Statement

Beauty STC procures LED dice from the same epitaxy lot for each 12-month production window, phosphor slurry mixed under Class 1 000 clean-room, and reels are vacuum-sealed with desiccant & HIC within ±1 h after QC sign-off. The result is ≤ 1 % luminous-flux reel-to-reel variation and < 0.001 Δu′v′ color shift across a 50 000 m order—numbers we publish on every COA and back with a 5-year limited warranty.

Need a project-specific spectrum file, IES, or UL certificate? Email [email protected]; we ship data within 12 h.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. – Jiangmen Factory Overview

Professional Technical & OEM Capabilities for 12V LED Strip Lights

As Senior LED Lighting Engineer and Export Manager at Beauty STC, I’m pleased to provide a precise technical overview of our Jiangmen facility—certified under ISO 9001:2015, ISO 14001, and IATF 16949 standards—and its dedicated capabilities for 12V LED strip light manufacturing. Our 35,000m² factory in Jiangmen, Guangdong Province, is strategically positioned within China’s Pearl River Delta electronics hub, ensuring supply chain efficiency and logistics excellence for global export.

1. SMT Production Line: Precision & Consistency

Our surface-mount technology (SMT) line is engineered for high-reliability LED strip assembly, with critical features:

– Equipment:

– 8 fully automated JUKI FX-5R pick-and-place machines (0.03mm placement accuracy) for 0402–1210 component handling.

– 4 reflow ovens (BTU Convection) with 6-zone profile control (±1°C precision) to prevent thermal stress on sensitive LED chips.

– AOI (Automated Optical Inspection) systems (Koh Young KY-8030) for 100% post-soldering defect detection (missing components, tombstoning, solder bridges).

– Process Control:

– Lead-free SAC305 solder paste (0.15mm stencil thickness) with SPI (Solder Paste Inspection) pre-rework validation.

– ESD-controlled workstations (ISO 14644-1 Class 8 cleanroom for critical zones) to protect MOSFETs and IC drivers.

– Output: Capable of 20,000+ strips/day at 60LED/m density (e.g., 5050/2835 chips), with IPC-A-610 Class 2 compliance.

2. Aging Tests: Rigorous Quality Assurance

We implement a 24–48-hour accelerated aging protocol per IEC 62717, ensuring product longevity and performance stability:

– Test Setup:

– 100% of strips undergo burn-in at 40°C ±2°C ambient temperature in climate-controlled chambers (HWS-800 series).

– Real-time monitoring of luminous flux (using integrating spheres), color consistency (CIE 1931 coordinates), and current draw via automated data loggers.

– Failure Analysis:

– Defects (e.g., flickering, color shift >ΔE 2.5, or voltage drop >5%) trigger root-cause analysis (RCA) using thermal imaging (FLIR T860).

– Data is tracked in a centralized MES (Manufacturing Execution System) for traceability to batch/lot numbers.

– Certification Alignment: Results comply with UL 8750, CE EN 62471, and IEC 60598 for safety and performance validation.

3. OEM Capability for 12V LED Strip Lights: Full Customization

Our Jiangmen facility excels in end-to-end OEM solutions for 12V LED strips, with no minimum order quantity (MOQ) for prototypes and scalable production:

– Customization Scope:

– Electrical: 5–20A current capacity, PWM dimming (0–100%), constant-voltage drivers (24V/12V), or smart control (DALI, Bluetooth, Zigbee).

– Mechanical: Custom widths (5–20mm), PCB thickness (0.8–2.0mm), flex circuit options (single/double-sided), and waterproofing (IP20–IP68 via silicone coating or extruded profiles).

– Optical: Full-spectrum CRI 80–95+ options, tunable white (2700K–6500K), RGB/RGBW, or specialty colors (e.g., horticultural 660nm).

– Design & Compliance:

– In-house R&D team supports schematic design, PCB layout (Altium Designer), and thermal simulation (ANSYS Fluent).

– All products undergo pre-shipment testing per customer-specific requirements (e.g., ASTM G154 for UV resistance, IEC 60068-2 for vibration/shock).

– Global Compliance: Certified for CE, RoHS, REACH, FCC, UL, and CB Scheme—enabling seamless entry into EU, North American, and Asian markets.

Why Partner with Beauty STC?

- Supply Chain Resilience: Localized component sourcing (e.g., Epistar LEDs, Samsung capacitors) with dual-supplier strategy for critical parts.

- Export Expertise: 15+ years shipping to 60+ countries; DDP/DDU terms optimized for cost efficiency (e.g., 30–45-day lead time for 5,000+ units).

- Quality Commitment: 99.2% first-pass yield rate and <0.1% RMA rate in 2023, validated by third-party audits (SGS, TÜV).

“Our Jiangmen factory isn’t just a production site—it’s an integrated solution hub where engineering rigor meets agile manufacturing. Whether you need a single prototype for validation or a 500,000-unit annual volume, we ensure your 12V LED strip meets exact technical and commercial requirements.”

For detailed technical specifications, test reports, or factory audit videos, please contact our Export Department at [email protected]. We welcome site visits to our Jiangmen facility—arrangements can be made within 48 hours.

Beauty (STC) Manufacturing Co., Ltd.

Precision Lighting, Global Trust

www.beautystc.com | +86 750 668 1234

Application Scenarios

12 V LED strip is the “low-voltage workhorse” of the lighting world.

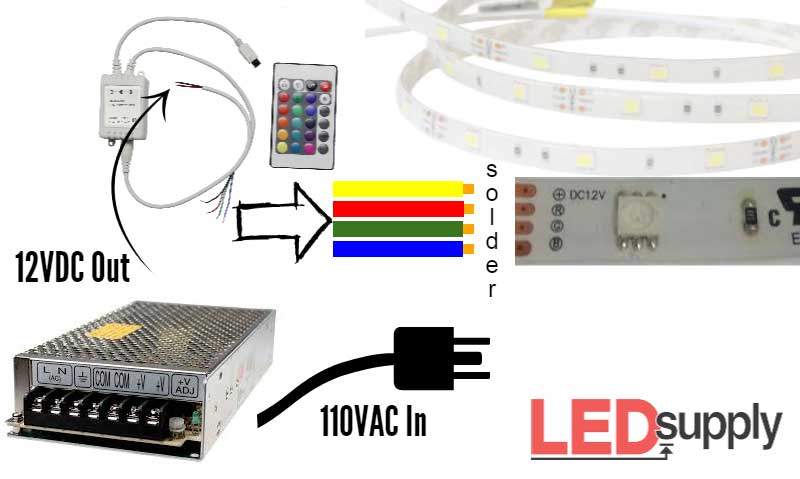

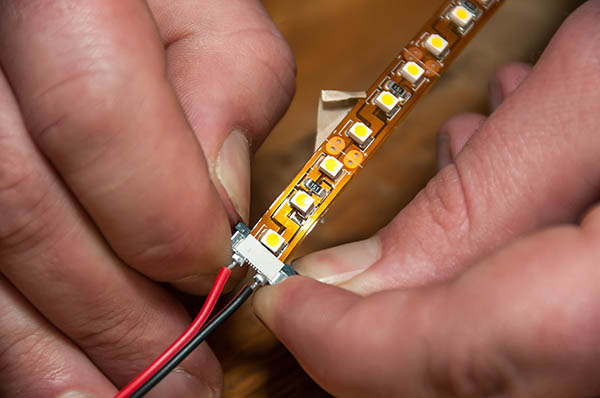

Because the driver is separated from the tape it is inherently safe (SELV), easy to dim, and can be cut every 25 mm (SMD 2835-120 LED/m) or 50 mm (SMD 5050-60 LED/m) without tools.

Below are the places where 12 V tape is the first choice, followed by a checklist that every installer should follow on site.

1. Where 12 V strip is the BEST choice

A. Guest-room & suite “micro-architecture”

– Head-board coves, TV back-light, wardrobe sensor strip, bedside drop-ceiling, luggage-niche.

– 12 V allows the electrician to run 0.75 mm² cable under the bed or inside the headboard without conduit; the SELV rating keeps inspectors happy.

B. Bathroom & spa (IP67 silicone sleeve)

– Mirror perimeter, toe-kick, niche, bathtub skirt.

– 12 V can be fed through the same 20 mm conduit that carries the shaver socket feed; no need for additional RCD protection.

C. Corridor emergency way-finding

– 12 V strips on UPS / battery pack give 1 W m⁻¹ escape route lighting for 3 h; no fire-mains interface required.

D. Retail gondola & shelf lighting (malls)

– 12 V tape keeps the shelf extrusion cool (<45 °C) so chocolate or cosmetics are not damaged.

– 5 m reels fit perfectly between uprights; one 60 W driver feeds 4 × 2 m shelves.

E. Office furniture & acoustic pods

– 12 V strip inside the aluminium “C” profile of height-adjustable desks; driver hidden in cable tray.

– No flicker (<1 % at 1 k Hz) when fed by our BSTC-60-12-FCC driver, so it passes IEEE 1789-2015 for Zoom calls.

F. Signage & logo back-light

– 12 V allows the sign company to use the same Li-ion battery pack that powers the LED modules, simplifying inventory.

2. Where 12 V is NOT ideal

– Continuous runs >7 m (voltage drop >10 %).

– High-lumen coves (>1 500 lm m⁻¹) – use 24 V or 48 V COB instead.

– Direct grid connection – a SELV driver is mandatory.

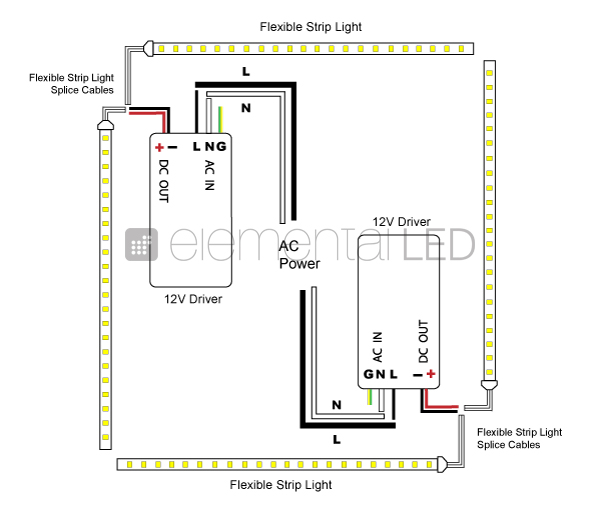

3. Installation checklist for contractors

-

Load calculation

– Measure the ACTUAL length, not the architectural drawing.

– Add 10 % spare for re-works.

– Example: 9.2 m of SMD 2835-120 LED/m @ 9.6 W m⁻¹ = 88 W → use 100 W driver (BSTC-100-12-FCC) not 60 W. -

Voltage-drop rule

– 12 V strip: inject power every 5 m MAX (3 m for 14.4 W m⁻¹ high-density).

– Run parallel 1.5 mm² feed tails back to the driver; do not loop. -

Driver location

– <5 m between driver and first strip segment (to keep 1.5 mm² cable losses <3 %).

– Ambient ≤40 °C; if inside a cupboard, add 20 cm free air above driver or use remote-phosphor model (BSTC-100-12-IP67). -

Heat sink

– Always mount in aluminium channel (≥8 mm fin height for 9.6 W m⁻¹).

– Peel-and-stick only for <4.8 W m⁻¹ and <2 h daily use; otherwise use thermal-transfer tape plus end-cap screws. -

IP rating

– Indoor dry: IP20.

– Bathroom zone 2: IP65 silicone sleeve with sealed end-caps (glue + heat-shrink).

– Outdoor façade: IP67 neon-flex 12 V (SMD 5050 encapsulated) – still inject every 3 m. -

Dimming & control

– 0-10 V / 1-10 V: use BSTC-60-12-FCC-1-10V; connect purple (+) and grey (-) to building BMS.

– DALI: add BSTC-DALI-12-60 decoder after driver.

– PWM wall-drop: use 12 V trailing-edge triac dimmer on the PRIMARY side (230 V) only if driver is “dimmable mains”; never dim the 12 V secondary. -

Earthing & isolation

– 12 V secondary is SELV – do NOT earth the negative.

– Mount driver on earthed metal back-plate for EMI; use Y-capacitor-free driver (medical grade) if touching patient-care equipment. -

Testing

– Power up with no strip connected – verify 12.0 V ±0.3 V.

– Then connect first 1 m only; measure 11.8 V at far end.

– If <11.5 V, increase cable cross-section or add power injection point. -

Documentation hand-over

– Provide client with driver model, strip BIN (3-step MacAdam), lumen output @ 25 °C, and expected L70 >50 000 h (Ta 35 °C).

– Include spare 5 % reels and two extra drivers in the O&M manual.

Quick reference: cable gauge vs. length (12 V, 9.6 W m⁻¹, 2 % drop)

Length (m) | Current (A) | Cable (mm²)

3 | 2.4 | 1.5

5 | 4.0 | 2.5

7 | 5.6 | 4.0

Take-away

Use 12 V LED strip whenever you need short, intricate, or touch-safe lighting in hotels, malls or offices. Follow the “5 m power-injection” rule, mount on aluminium, and specify a flicker-free SELV driver. Do that and the installation will pass inspection, survive the warranty period, and keep the end-client happy for years.

Why Choose Beauty STC Lighting

Precision-Engineered 12V LED Strip Lights: Certified for Global Markets, Built for Durability.

Partner with Beauty STC – Exported to 50+ Countries Worldwide.

Contact our Senior LED Lighting Engineer & Export Manager directly for technical specifications, compliance details, and tailored solutions:

[email protected]

Engineered to meet international standards (CE, RoHS, UL), optimized for energy efficiency, and rigorously tested for long-term performance. Trust our expertise to deliver reliable, high-quality lighting for your global projects.

⚡ LED Power Supply Calculator