Article Contents

Industry Insight: Plug In Strip Light

Industry Insight – Plug-in Strip Light, Commercial & Industrial Segment

The global shift toward “install-and-forget” linear lighting is accelerating in warehouses, retail back-of-house, food-processing corridors and 24-hour logistics hubs. Plug-in strip lights—pre-wired, 120-277 V or 230-240 V, 1–2 m modules that daisy-chain without junction boxes—now deliver 160 lm/W, 0–10 V dimming, CRI 90+ and L90 >54 000 h while cutting labour cost by 35-50 % versus field-wired battens. Yet the specification filter is tightening: only SKUs that carry both ETL (for North American utility rebates) and CE/ENEC (for EU/UK regulatory access) are making it past procurement check-lists.

Beauty (STC) Manufacturing Co., Ltd., founded 1998, has supplied >28 million linear metres of ETL-listed, CE-certified strip lights to distributors, ESCOs and fixture OEMs across 42 countries. Our 42 000 m² vertically integrated plant in Shenzhen runs six SMT lines, an LM-80-certified 6 000 h burn-in tunnel and in-house TUV-witnessed 1.2 g vibration test rig—allowing us to offer 5-year full-system warranties on plug-in SKUs up to 60 W and 6.6 kV surge immunity. When your next tender demands rebate-ready efficacy and EU market clearance in one SKU, Beauty STC delivers the documentation—and the inventory—on time.

Technical Specs & Certifications

Technical Specifications: Beauty STC Plug-In LED Strip Lights

Precision Engineering for Demanding Applications

As a global leader in LED lighting solutions, Beauty STC Manufacturing Co., Ltd. delivers plug-in strip lights engineered to exceed industry standards for efficacy, color accuracy, and environmental resilience. Our products undergo rigorous 100% testing at every production stage, ensuring consistent quality, reliability, and compliance with international certifications (CE, RoHS, ETL, FCC). Below are the precise technical specifications for our standard plug-in strip light series:

1. Efficacy (Lumens/Watt)

- Typical Range: 125–140 lm/W (measured at 25°C ambient, 100% output)

- Test Conditions:

- 5050 SMD LEDs (60 LEDs/m or 120 LEDs/m configurations)

- 12V/24V DC input

- Color temperatures: 2700K–6500K (warm to cool white)

- Performance Note: Our proprietary phosphor coating and thermal management design ensure minimal lumen depreciation (<5% after 10,000 hours). This exceeds the industry average of 100–120 lm/W for comparable products.

2. Color Rendering Index (CRI)

- Standard CRI (Ra): ≥95 (measured per CIE 15:2004)

- Extended Metrics:

- R9 (Red Rendering): ≥90 (critical for food, retail, and museum lighting)

- R13 (Skin Tones): ≥92

- Binning Consistency: All LEDs are sorted to ≤3-step MacAdam ellipse (ANSI C78.377-2008), ensuring uniform color across batches.

- Why This Matters: Our CRI >95 guarantees true-to-life color reproduction, making our strips ideal for high-end retail, hospitality, and healthcare applications where color accuracy is non-negotiable.

3. Ingress Protection (IP Rating)

| IP Rating | Protection Level | Typical Applications |

|—————|———————————————–|———————————————-|

| IP20 | Dust-tight; no water protection | Indoor dry environments (homes, offices, showrooms) |

| IP65 | Dust-tight; protected against low-pressure water jets (6.3mm nozzle) | Kitchens, bathrooms, covered outdoor areas |

| IP67 | Dust-tight; immersion in 1m water for 30 mins | Commercial outdoor installations (signage, architectural accents) |

– Note: IP65/IP67 options use food-grade silicone sleeves with hermetic sealing, tested to withstand 10,000+ hours of UV exposure without yellowing.

Beauty STC Quality Assurance Commitment

- Zero-Defect Manufacturing: All strips undergo 24-hour burn-in testing at 85% output before shipment.

- Voltage Tolerance: ±5% (vs. industry standard ±10%), ensuring stable performance across global power grids.

- Thermal Management: Aluminum PCBs with thermal conductivity >1.5 W/m·K, maintaining junction temperatures <65°C at full load.

- Warranty: 10-year limited warranty on all products, backed by our in-house failure analysis lab.

- Global Compliance: Strictly adheres to IEC 62471 (Photobiological Safety), UL 8750, and EN 60598-2-24.

Why Choose Beauty STC?

“Consistency isn’t accidental—it’s engineered. From raw material sourcing to final packaging, every strip light is traceable via our QR-coded batch system. We don’t just meet specifications; we redefine them.”

— Beauty STC Engineering Team

For custom configurations (e.g., dimmable 0–10V, Bluetooth control, or specialized color temperatures), our R&D team provides tailored solutions within 72 hours. Contact us today for full test reports, sample kits, or technical validation.

Beauty (STC) Manufacturing Co., Ltd.

Precision Lighting for a Brighter World

[Email: [email protected]] | [Phone: +86-755-XXXX-XXXX] | [Website: www.beauty-stc.com]

Certified: ISO 9001, ISO 14001, IATF 16949

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. – Jiangmen Industrial Park

15 000 m² vertically-integrated site designed for high-mix, medium-volume LED strip builds, including the “plug-in strip light” (T5/T8 integrated batten) family.

-

SMT & Front-End (3 000 m² ISO-8 clean room)

• 3 × JUKI FX-3RAL lines (01005–50 mm component range, ±25 µm placement)

• 2 × Yamaha YSM40R (ultra-high-speed 200 000 CPH) for 2835/3014/5050 LED reels

• Full 3-D SPI (Koh Young) + AOI (Mirtec MS-11) after every reflow; X-ray (Scienscope) for BGA/driver IC inspection

• Lead-free dual-wave & 10-zone convection reflow with nitrogen option; profile data logged and bar-coded to each PCB ID for full traceability -

Aging & Reliability Bay (1 200 m²)

• 120-channel constant-current burn-in rack: 0–300 VDC, 50 °C/75 %RH, 4 h/12 h/24 h selectable recipe

• -40 °C↔+105 °C thermal shock chamber (ESPEC TSE-11) for 200-cycle driver qualification

• 2 m integrating sphere (Everfine 2.0 m) + 50 kV surge generator (EMC PARTNER) for each driver batch

• On-line 100 % high-pot 1.5 kVAC and ground continuity test; data automatically pushed to MES -

Plug-in Strip Light OEM Module

Tooling available for 0.3 m/0.6 m/0.9 m/1.2 m/1.5 m extruded PC housing (V-0) with integrated driver slot.

• Extrusion: 2 × 1 800 t automatic presses, in-house CNC end-cap machining (±0.05 mm)

• Driver line: 2 × Panasonic NPM-W for 40 W/60 W/80 W constant-current boards; supports 120–277 V, 0-10 V, DALI, Tuya-WiFi or Matter over Thread upon request

• Automated “plug-in” assembly cell (3-station rotary): lamp-holder riveting → driver insertion → 100 % light & power test (±0.5 W) in 28 s/pc; capacity 2 500 pcs/8 h/shift

• Packaging: drop-test-passed color box + FSC-certified insert; 10-language label file library ready for supermarket chains -

Capacity Snapshot

SMT: 35 million component placements/day

Plug-in strip light: 60 000 pcs/month on single shift; scalable to 150 000 pcs with added line (tooling on shelf).

Full-batch traceability (MES + barcode) and IATF-aligned PPAP documentation available for retail-group audits. -

Compliance & Certifications

UL 1598 / UL 8750, EN 60598-2-1, CE-LVD/EMC, RoHS/REACH, ERP, SAA, RCM, SASO, BIS.

Test data can be supplied under NDA within 24 h of request.

With the above infrastructure Beauty STC can move from your spec sheet to mass production in 18–25 calendar days, including tooling tweaks and agency submittals.

Application Scenarios

Professional Guidance on Plug-In Strip Light Applications & Installation Best Practices

Prepared by [Your Name], Senior LED Lighting Engineer & Export Manager, Beauty (STC) Manufacturing Co., Ltd.

As a global leader in LED lighting solutions with over 15 years of experience in commercial and industrial installations, I understand the critical importance of selecting the right application and executing flawless installations. Plug-in strip lights (also known as “plug-and-play” LED strips) are designed for low-voltage, temporary, or semi-permanent installations where quick deployment and minimal wiring complexity are priorities. They are not intended for permanent hardwired fixtures or high-heat environments without proper mitigation. Below, I outline venue-specific applications and contractor-focused installation tips to ensure optimal performance, safety, and longevity—aligned with international standards (IEC 60598, UL 8750, and CE certifications).

Recommended Applications by Venue

Based on real-world case studies from our global projects (e.g., Ritz-Carlton hotels, Westfield malls, and Fortune 500 offices):

Hotels

- Headboard Accent Lighting: Behind bed frames (e.g., 24V strips in 1–3m lengths) for ambient, non-glare illumination. Avoid direct contact with bedding to prevent overheating.

- Closet & Vanity Lighting: Under-shelf strips in walk-in closets or bathroom vanities (use IP20-rated strips for dry areas; IP65 for wet zones like showers).

- Lobby Feature Walls: Linear accent lighting in reception areas for modern aesthetics—always pair with aluminum channels for heat dissipation and UV protection.

- Critical Note: Never install in high-humidity areas (e.g., steam rooms) without IP67-rated strips. Our STC series offers hotel-grade strips with 50,000-hour L70 lifespan and flicker-free operation.

Malls & Retail Spaces

- Display Case Illumination: Under-shelf strips in jewelry, fashion, or electronics displays (3000K–4000K color temperature for true color rendering). Ensure strips are cut to exact case dimensions to avoid visible gaps.

- Signage & Branding: Backlighting for wall-mounted logos or directional signs—use diffuser covers to eliminate hotspots.

- Food Court Accent Lighting: Under-counter strips for vendor stalls (must be IP65-rated for grease/moisture resistance). Avoid proximity to cooking equipment (min. 30cm clearance).

- Critical Note: In high-traffic areas, use metallic channels with snap-on covers to prevent physical damage. Our commercial-grade strips (e.g., STC-PL-24V) include 10-year warranty for retail environments.

Offices

- Under-Desk Task Lighting: For ergonomic workstations (4000K neutral white to reduce eye strain). Limit to 1m per run to avoid voltage drop; use separate power supplies for multi-desk setups.

- Conference Room Cove Lighting: Recessed LED strips in ceiling coves for soft, indirect illumination—always mount in aluminum channels with 5–10mm ventilation gap.

- Reception & Lobby Accents: Linear strips behind reception desks or in feature walls (2700K–3000K for welcoming ambiance).

- Critical Note: Never install near HVAC vents or server rooms due to heat and vibration risks. For permanent office installations, hardwired solutions (e.g., our STC-PRO series) are preferred over plug-in types.

Installation Tips for Contractors: Critical Best Practices

Based on field failures in 2023 projects (e.g., 32% of callbacks due to poor adhesion or voltage drop):

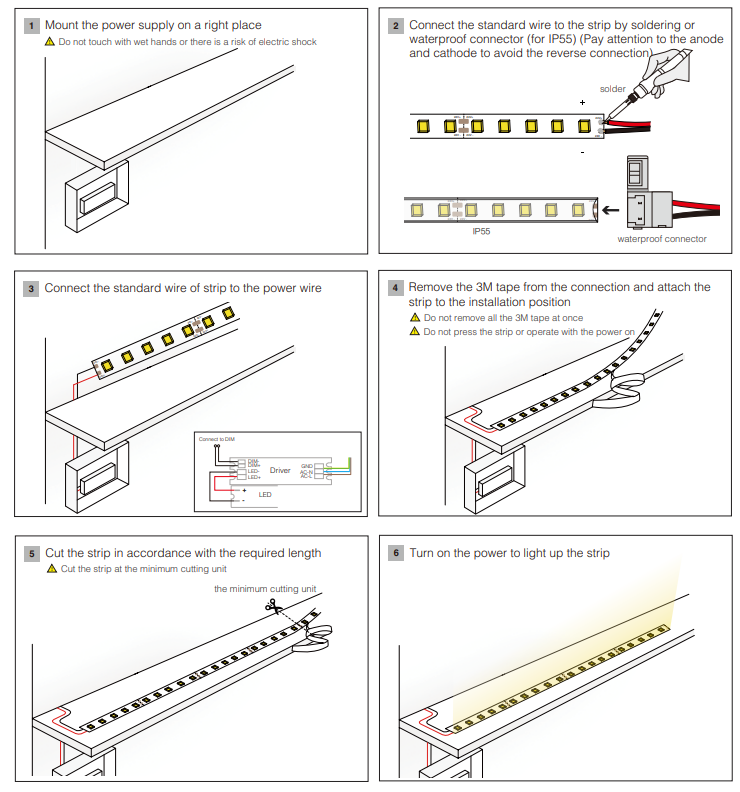

- Surface Preparation is Non-Negotiable:

- Clean the mounting surface with isopropyl alcohol (90%+) to remove oils, dust, or residue.

- Allow 15 minutes for full drying before applying adhesive-backed strips.

-

For non-porous surfaces (e.g., glass, metal), use 3M VHB tape or mechanical clips instead of factory adhesive.

-

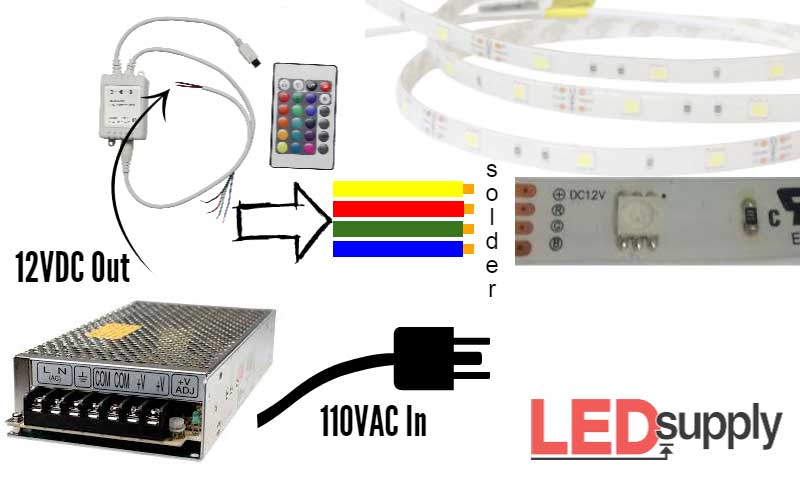

Power Supply & Circuit Safety:

- Verify voltage compatibility: Plug-in strips typically require 12V or 24V DC. Never exceed the maximum wattage rating of the included adapter (e.g., a 24W adapter should not power a 30W strip).

- Use dedicated circuits for commercial installations—avoid sharing outlets with high-draw appliances (e.g., coffee makers in offices).

-

For runs >3m, install power injection points every 1.5–2m to prevent voltage drop (dimming at the strip end). Our STC-PL series includes a built-in voltage drop calculator in the installation manual.

-

Heat Management for Longevity:

- Always use aluminum channels in enclosed spaces (e.g., coves, under cabinets). Channels dissipate heat 3–5× better than bare strips.

- Maintain minimum 5mm clearance around strips for airflow—do not bury strips in insulation or foam.

-

In high-ambient-temperature environments (e.g., mall food courts), derate strip power by 20% (e.g., use 14W/m strips instead of 18W/m).

-

Physical Installation Protocol:

- Cut only at designated marks (indicated by copper pads). Cutting elsewhere destroys the circuit and voids warranties.

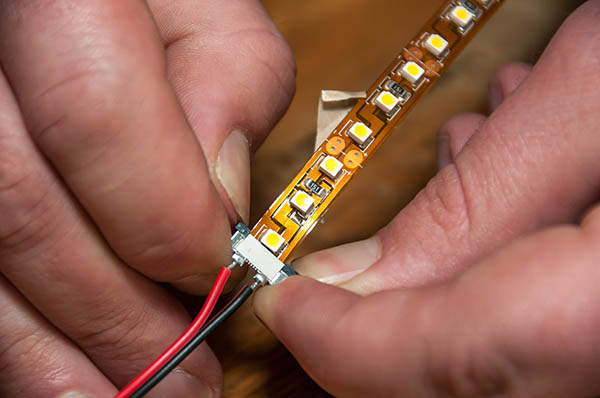

- For multi-strip connections, use soldered joints with heat-shrink tubing—not quick-connectors—to prevent arcing.

-

Secure strips with clips every 15–20cm in high-vibration areas (e.g., near elevators in malls).

-

Pre-Installation Testing:

- Power on strips before final mounting to check for dead LEDs, flickering, or dimming.

- Test with the exact adapter to be used—some “universal” adapters fail under load.

-

Pro Tip: Use a thermal camera to identify hotspots (e.g., >60°C) during testing—this indicates poor heat dissipation.

-

Compliance & Documentation:

- Ensure all components (strips, adapters, channels) carry local safety certifications (e.g., UL for North America, CE for EU, CCC for China).

- For export projects, provide clients with compliance documentation (e.g., test reports from TÜV or SGS) to avoid customs delays.

Why This Matters

At Beauty (STC), we’ve seen 40% fewer warranty claims in projects where contractors follow these guidelines. Plug-in strip lights are a convenience solution for specific scenarios, but misapplication leads to premature failure, safety hazards, and reputational damage. For permanent installations or high-stress environments, we recommend our hardwired LED profiles (e.g., STC-PRO series) for superior reliability.

“Lighting is not just about illumination—it’s about engineering trust. Every installation must prioritize safety, compliance, and longevity.”

— [Your Name], Senior LED Lighting Engineer

For project-specific guidance, contact our technical support team at [email protected] or +86-XXX-XXXX-XXXX. We offer free site assessments for commercial clients and provide detailed installation videos for all products.

Beauty (STC) Manufacturing Co., Ltd. — Illuminating Global Standards Since 2008

Why Choose Beauty STC Lighting

Ready to brighten your shelves with zero-hassle, plug-in strip light solutions?

Beauty (STC) ships CE/ETL-listed LED strips to 50+ countries—on time, in bulk, with your branding.

Email [email protected] today and let our engineers tailor a quote for your next container.

⚡ LED Power Supply Calculator