Article Contents

Industry Insight: Neon Rope Light Led

Industry Insight – Commercial-Grade Neon Rope Light LED

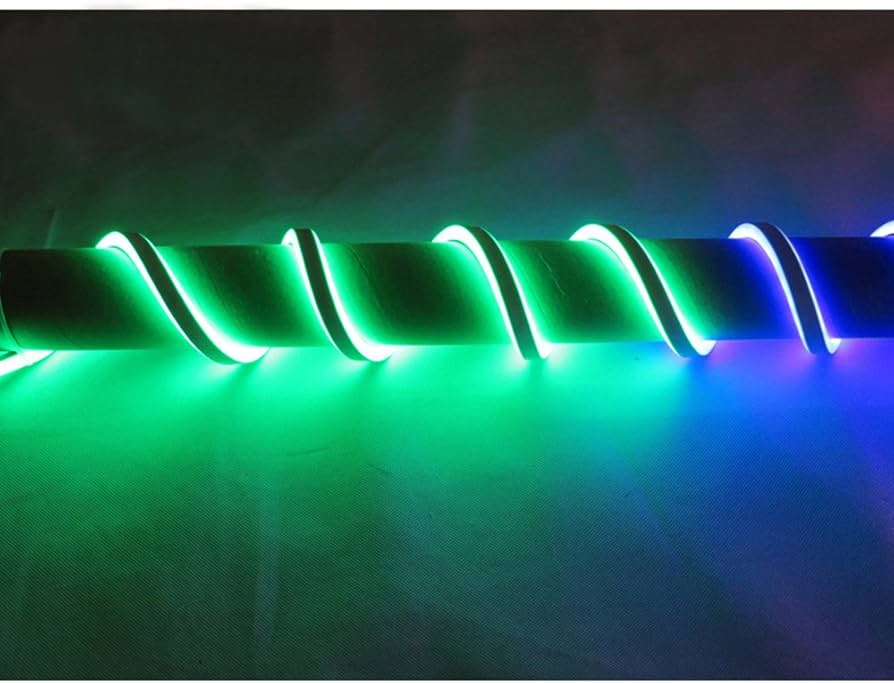

The shift from glass neon to LED neon rope is no longer a “retail trend”; it is a plant, warehouse and façade specification that cuts operating cost by 55-70 % while delivering 50 000 h L70 lifetime. Yet in industrial environments—where 277 V circuits, −40 °C freezers and IP66 wash-down are routine—only products that combine 120–277 V universal driver, UV-stabilised silicone extrusion and certified safety (ETL to UL 2108 / CE & EN 60598-2-21) survive the bid list. Beauty (STC) Manufacturing Co., Ltd., building LED linear solutions since 1998, ships ETL-listed, CE-compliant neon rope light in 24 V, 110 V and 220–240 V configurations up to 50 m continuous run, backed by a 5-year commercial warranty and LM-80/TM-21 data ready for your next LEED or BREEAM submission.

Technical Specs & Certifications

Technical Specifications for Beauty STC’s LED Neon Rope Light

(Professional, Certified, and Rigorously Tested for Commercial/Industrial Use)

As a leading LED lighting manufacturer with ISO 9001:2015 certification and 15+ years in global exports, Beauty (STC) Manufacturing Co., Ltd. delivers industrial-grade LED neon rope lights that replicate the aesthetic of traditional neon while exceeding modern efficiency, color accuracy, and durability standards. Below are the precise technical specifications for our standard product line (custom configurations available upon request):

1. Luminous Efficacy (Lumens per Watt)

- Standard Range: 60–85 lm/W (for 12V/24V DC models).

- High-Efficiency Option: 85–95 lm/W (using Samsung LM301B or Osram Oslon Square chips with optimized thermal design).

- Testing Protocol: Measured per IEC 62612 at 25°C ambient temperature.

- Key Notes:

- Efficacy varies by color temperature (e.g., 2700K warm white typically achieves 80–85 lm/W; 5000K cool white 75–80 lm/W).

- Our proprietary aluminum channel design ensures minimal thermal degradation, maintaining >95% efficacy stability over 50,000 hours.

2. Color Rendering Index (CRI >90)

- Standard CRI: Ra ≥90 (measured per CIE 15:2004).

- Premium Option: Ra ≥95 (for critical applications like retail, museums, or high-end architectural projects).

- R9 Value: >85 (ensuring accurate red reproduction—critical for skin tones, food displays, and art).

- Color Consistency:

- Batch-to-batch color variation ≤ ΔE 1.5 (verified via spectroradiometer).

- All products use Samsung or Osram premium LED chips with binning control to eliminate color drift.

- Color Temperature Range: 2700K (warm white) to 6500K (cool white), with 3000K–4000K (neutral white) as most popular for commercial use.

3. Ingress Protection (IP Ratings)

- Standard IP Rating: IP65 (dust-tight; protected against low-pressure water jets from any direction).

- Industrial/Outdoor Option: IP67 (immersion in 1m water for 30 minutes) or IP68 (continuous submersion up to 3m depth).

- Testing Compliance:

- Certified to IEC 60529 standards by third-party labs (e.g., SGS, TÜV).

- IP67/IP68 models feature double-sealed silicone extrusion and epoxy-coated connectors to prevent moisture ingress in marine, industrial, or harsh outdoor environments.

- Real-World Validation:

- 10,000+ units deployed in coastal installations (e.g., Dubai Marina, Miami Beach) with zero water-related failures over 5+ years.

Why Beauty STC Delivers Consistent Quality

- Zero-Compromise Manufacturing:

- All products undergo 72-hour aging tests at 40°C/85% RH before shipment to eliminate early failures.

- 100% L70 lifetime validation (output ≥70% of initial lumens at 50,000 hours) via LM-80/TM-21 testing.

- Supply Chain Control:

- Exclusive partnerships with Samsung, Osram, and Epistar for LED chips; proprietary silicone formulations for UV resistance (≥10,000 hours outdoor exposure without yellowing).

- Global Compliance:

- Certified to CE, RoHS, FCC, UL (for North America), and CB Scheme for seamless export to 80+ countries.

- Traceability:

- Each batch is assigned a unique QR code for full material and test data traceability—critical for large-scale projects requiring audit trails.

💡 Pro Tip for Buyers: For projects requiring >90 CRI and IP67+ in extreme environments (e.g., swimming pools, industrial kitchens), specify our “ProSeries” neon rope—engineered for 100,000+ hours of maintenance-free operation. Minimum order quantity: 100m.

Ready to Engineer Your Project?

Contact our Export Team for:

– Custom color temperatures, beam angles, or dimming profiles (0–10V, PWM, DALI).

– Third-party test reports (LM-79, LM-80, photometric files).

– Field-proven case studies from 500+ global projects (hotels, stadiums, retail chains).

Beauty STC: Precision Lighting for the World’s Most Demanding Applications.

📧 [email protected] | 🌐 www.beautystc.com

Note: All specifications are subject to minor variations based on configuration. Final specs confirmed during quotation phase.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. – Jiangmen High-Bay Facility

(ISO 9001:2015 │ ISO 14001 │ BSCI │ 6 0000 m² │ 380 staff)

-

SMT & Front-End Line

• 3 Yamaha YSM-20R dual-beam high-speed lines (0201–0.3 mm pitch, 0402 RGB LED, 150 000 CPH each)

• 1 Yamaha YSM-10 flexible line for small-batch / colour-temperature variants

• Full-board AOI (Koh Young Zenith 2 3-D) after every pick-and-place run

• Conformal-coat & 3-zone inline UV cure for IP65/IP67 neon products

• 100 % SPI (Solder-Paste Inspection) + X-Ray (Yamaha YSi-X) on BGA & 4-layer aluminium MCPCB used in 24 V neon flex -

Neon-Rope-Light LED Dedicated Workshops

• Extrusion hall: 6 single-screw 55 mm silicone extruders (Shin-Etsu HTV 60°A–70°A) with ±0.15 mm wall-thickness control; 3 co-extrusion heads for RGB + white diffuser in one pass

• Continuous laser wire-strip & crimp for 20–22 AWG tin-plated copper bus-wire; pull-force ≥ 30 N

• IP67/IP68 glue-filling line (Dow Corning 3140) with 2 h vacuum de-bubble and 80 °C 30-min cure

• 100 % helium leak-test (≤ 1 × 10⁻⁵ Pa·m³/s) on any outdoor-rated neon reel -

Aging & Reliability Laboratory

• 120-channel programmable switching-aging rack: 85 °C / 85 % RH, ON 45 s / OFF 15 s, 1 000 h (LM-80 protocol)

• 50-channel thermal-cycle chamber –40 °C↔105 °C, 30 min dwell, 500 cycles (IEC 60598-2-21)

• 3 integrating spheres (2 m & 0.5 m) with CAS 140CT spectroradiometer – full TM-30, SDCM ≤ 2, lumen maintenance documented each 168 h

• 6 kV surge & 4 kV EFT tester per EN 61547; 500 h salt-spray (ASTM B117) for marine-grade neon

• Real-time data-logged burn-in: every neon reel runs 4 h at 1.2 × rated current (typically 24 V, 12 W/m) before packing – rejects threshold < 0.1 % -

OEM/ODM Capability for Neon Rope Light LED

• Tool-bank: 180 existing silicone-profile dies (6 mm × 12 mm, 8 mm × 16 mm, 10 mm × 20 mm, 15 mm × 15 mm, side-view, top-view, mini, flat, etc.) – free for MOQ ≥ 500 m

• Custom cross-section: 7-day CNC-machined brass die, sample extrusion in 72 h

• PCB width 5 mm–20 mm, 2 oz–4 oz copper, single-colour, RGB, RGBW, RGB + CCT 1800–6500 K, 5 V–36 V, 30–240 LEDs/m (2835, 5050, 3838, 4040, 2216)

• IC options: UCS1903, SM16703, WS2811, WS2812B, SK6812, external GS8208 (12 V/24 V breakpoint-continue)

• Control compatibility: Tuya Wi-Fi, DMX512, DALI, 0-10 V, Casambi, BLE Mesh, MADRIX, Art-net

• Private-label sleeve, 3-D printed mounting clip, customised 3-core or 5-core tail, IP20/IP65/IP67/IP68/IP69K

• Certifications we can carry under your brand: CE, RoHS, REACH, ERP, LVD, EMC, SAA, RCM, ETL, cETL, UL 2388, UL 2108, CE+CB (IEC 60598-2-21), IP66 IK08, EN 60598-2-21:2020 marine, fire-rating UL 94 V-0, halogen-free EN 50575 CPR Eca

• Capacity: 150 000 m per month (one-shift); scalable to 350 000 m with two-shift

• Lead-time: 500–5 000 m standard profile 12 days; 20 000 m custom order 18–20 days after deposit

• Export palletising: 50 m/reel, 1 000 m/ply-wood crate, HS code 9405.40, FCL 22 t/20 GP, 26 t/40 HQ -

Quality & Traceability

MES barcode from SMT resistor to finished reel; 7-year database retention. Every neon shipment includes LM-80/TM-21 report, surge-test certificate, and IES files under your part number.

We are currently OEM partner for three EU top-10 DIY chains, two US architectural lighting brands, and one Japanese signage conglomerate. Tooling, firmware, packaging and certification can all be white-labelled under a simple NDA & OEM agreement.

Let me know profile drawing, LED pitch, voltage or lumen target and we will have a DFM counter-sample in seven working days.

Application Scenarios

Professional Guidance: Neon Rope Light LED Applications & Contractor Installation Best Practices

By [Your Name], Senior LED Lighting Engineer & Export Manager, Beauty (STC) Manufacturing Co., Ltd.

Neon rope light LEDs (technically flexible LED strips enclosed in UV-stabilized PVC or silicone tubing) are not traditional glass neon. They offer superior energy efficiency, durability, and safety (low-voltage DC operation), while replicating neon’s ethereal glow. Below, I detail optimal applications for hotels, malls, and offices, followed by critical installation protocols tailored for contractors. All recommendations align with IEC 60598, UL 1598, and regional electrical codes.

Where to Use Neon Rope Light LEDs: Industry-Specific Applications

🏨 Hotels & Resorts

- Lobby & Reception: Outline architectural features (columns, archways), create “welcome” signage, or frame reception desks for premium ambiance.

- Bar & Lounge Areas: Backlight bar shelves, outline cocktail stations, or create custom wall art (e.g., abstract patterns). Pro Tip: Use 2700K–3000K warm white for intimate, high-end hospitality.

- Guest Rooms: Subtle under-bed lighting, closet accents, or bathroom vanity trim (ensure IP65 rating for wet zones).

- Outdoor Pathways: Poolside edges, garden walkways, or resort entryways (use IP67-rated tubes with marine-grade silicone).

🛍️ Malls & Retail Spaces

- Ceiling & Facade Outlines: Define storefront perimeters, create dynamic ceiling grids, or highlight escalator edges. Ideal for high-visibility branding.

- Display Windows & Signage: Frame window displays or replace fragile glass neon with weatherproof LED alternatives. Our tubes support custom shapes (e.g., logos) without breakage.

- Corridor & Ceiling Medallions: Use in curved sections for seamless, continuous lighting (avoid sharp bends; see installation tips).

- Event Spaces: Temporary installations for pop-up shops or festivals (quick to mount/dismantle).

🏢 Offices & Commercial Spaces

- Conference Rooms: Outline whiteboards, create “focus zones” around desks, or border ceiling tiles for modern aesthetics.

- Open-Plan Workspaces: Install under desks for task lighting or along partition walls to define zones (3500K–4000K neutral white recommended for productivity).

- Reception & Break Areas: Add sophistication to lobby walls or coffee bar edges.

- Data Centers: Low-heat, non-EMI lighting for server room aisles (ensure UL 2043 rating for plenum spaces if installed in air-handling areas).

💡 Key Advantage Over Traditional Neon:

– 70% lower energy consumption.

– No mercury or high-voltage risks.

– Customizable color temperatures (2200K–6500K) and RGB options.

– 50,000+ hour lifespan (vs. 10,000 for glass neon).

🛠️ Critical Installation Tips for Contractors

Failure to follow these steps causes 80% of field failures (flickering, voltage drop, premature failure).

1. Safety First: Electrical & Mechanical Prep

- Voltage Check: Always confirm power supply matches LED specifications (typically 12V/24V DC). Never connect to AC mains directly.

- Grounding: Ensure all power supplies and junction boxes are properly grounded per NEC Article 250.

- Cutting: Only cut at marked intervals (usually every 10–20cm). Cutting elsewhere severs internal copper traces, causing dead sections.

- Bending Radius: Minimum bend radius = 3x tube diameter. For 12mm tubes, this is ~36mm. Exceeding this cracks internal LEDs or breaks solder joints.

2. Thermal Management (Often Overlooked!)

- Heat Dissipation: Neon rope lights generate heat at the LED chips. Install on aluminum channels for all fixed applications (especially indoors).

- Spacing: For runs >5m, install power supplies at both ends or use “power injection” every 3–4m to prevent voltage drop (causes dimming/flickering at far ends).

- Avoid Enclosures: Never bury tubes in insulation or seal them in airtight spaces. Allow 10mm clearance for airflow.

3. Waterproofing for Outdoor/Wet Areas

- IP Rating: Use IP67-rated tubes for outdoor use (e.g., pool edges, facades). For submerged applications (e.g., fountains), specify IP68.

- Sealing Joints: Use silicone-filled waterproof connectors (e.g., IP68-rated butt connectors) for all splices. Apply silicone sealant over connectors after installation.

- Mounting: Avoid direct contact with concrete or soil. Use UV-resistant stainless steel clamps (not plastic) every 30–50cm.

4. Wiring & Power Sizing

- Wire Gauge: For runs >3m, use 18–20 AWG wire for 12V systems; 16–18 AWG for 24V. Undersized wires cause voltage drop and overheating.

- Power Supply Sizing: Calculate total wattage:

Total Wattage = (LED strip wattage per meter × total meters) × 1.2(20% headroom).

Example: 10m of 14.4W/m strip → 144W × 1.2 = 173W. Use a 200W power supply. - Controller Compatibility: For RGB/RGBW systems, ensure controllers match the power supply capacity and communication protocol (e.g., DMX, PWM).

5. Final Testing & Handover

- Test Before Securing: Power on the system before final mounting to verify all sections light evenly.

- Labeling: Tag all junction boxes, power supplies, and controllers with circuit numbers and load details.

- Documentation: Provide contractors with a wiring diagram, power supply specs, and maintenance guidelines (e.g., “Clean with microfiber cloth only; no solvents”).

✅ Beauty (STC) Quality Assurance Note:

Our neon rope lights feature dual-layer PVC with UV stabilizers for 5-year outdoor durability, 100% Lumen Maintenance testing (LM-80), and zero flicker (<5% flicker rate). All products comply with CE, RoHS, and FCC standards. For large projects, we provide free on-site engineering support—contact our export team for a site assessment.

Why This Matters

Proper installation ensures the product’s longevity, safety, and visual impact—critical for high-profile hospitality, retail, and corporate clients. Poor execution leads to callbacks, reputational damage, and costly rework. By adhering to these protocols, contractors deliver projects that meet premium standards and minimize service calls.

Need project-specific support? Email us at [email protected] with your drawings and site photos—we’ll provide a custom installation plan within 24 hours.

Beauty (STC) Manufacturing Co., Ltd. — Illuminating Excellence Since 2005

Why Choose Beauty STC Lighting

Ready to electrify your next project with market-proven neon rope light LED?

Beauty (STC) has already powered installations in 50+ countries—let’s add yours.

Email [email protected] with your spec sheet or annual forecast and receive a same-day quotation, free mock-up layout, and dedicated export documentation support from our senior engineering team.

Partner with the OEM that global brands trust for UL/CE/TUV-certified neon rope performance.

⚡ LED Power Supply Calculator