Article Contents

Industry Insight: Led Light Strip Ws2812

Industry Insight – WS2812 Addressable LED Strip in Commercial & Industrial Lighting

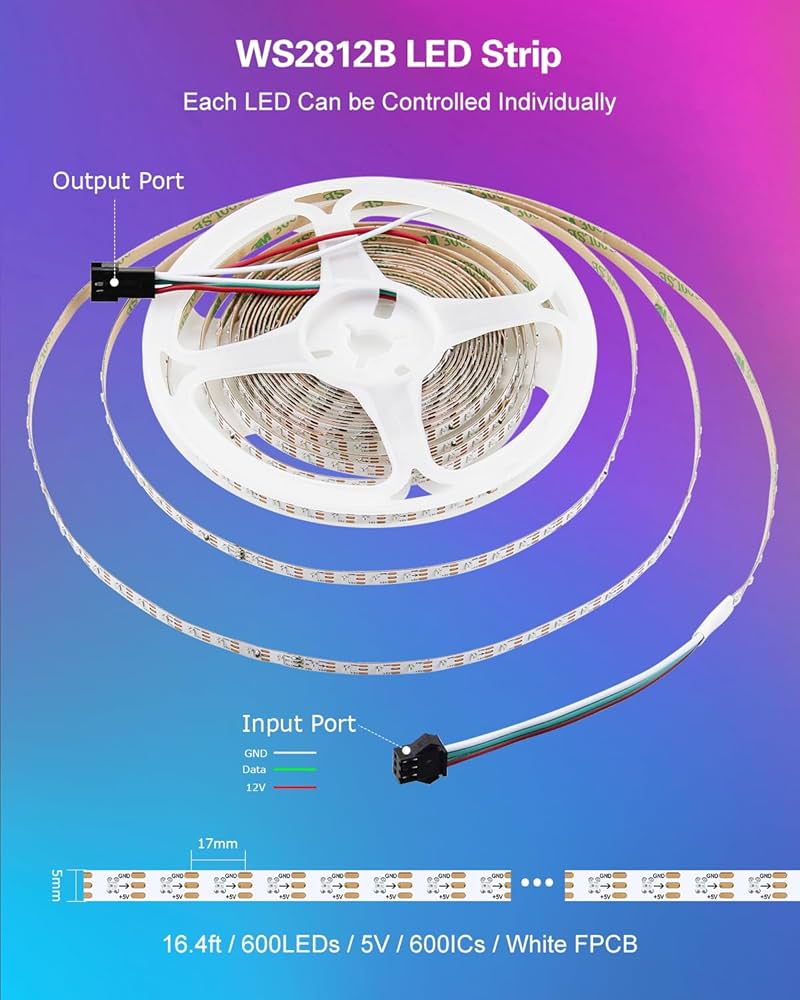

The shift from static illumination to data-driven, pixel-level control is no longer confined to signage and entertainment: facility managers, retail chains and industrial OEMs are embedding WS2812-family addressable strips into architectural coves, production-line indicator rails, cold-storage aisle guidance and high-bay human-centric retrofits. Each 5050 package integrates a 24-bit driver, allowing 8-bit dimming of R-G-B channels at 2 kHz refresh without external current sources—critical for flicker-free camera environments and machine-vision stations. However, the moment a 5 V, 60 mA-per-pixel strip scales past 300 LEDs, cumulative IR drop, thermal derating and PSU in-rush become compliance risks. That is why specifiers on both sides of the Atlantic now demand ETL (to ANSI/UL 2108 & UL 8750) and CE (EN 60598-2-20, EN 55015, EN 62368-1) documentation before approving procurement lists; these marks verify that the flexible PCB, adhesive backing, encapsulant and power taps have been third-party tested for 50 °C ambient, 1000 V surge and 500 V insulation—conditions routinely exceeded in factory mezzanines and retail HVAC plenums. Beauty (STC) Manufacturing Co., Ltd., established 1998, has supplied >2.8 billion pixels to tier-one luminaire brands and systems integrators. Our WS2812B-5V-IP20/65/67 portfolio ships with ETL & CE CB Scheme test reports, supports 12-bit gamma correction, and is delivered with daisy-chain length/surge calculation spreadsheets so engineers can meet local electrical code on the first design pass.

Technical Specs & Certifications

Technical Specifications for WS2812 LED Strip: Professional Clarification & Beauty STC Quality Assurance

(As a Senior LED Lighting Engineer & Export Manager at Beauty STC Manufacturing Co., Ltd., I must emphasize critical technical realities to ensure accurate project specifications. WS2812 is an integrated RGB/RGBW addressable LED chip with a built-in controller IC, not a standalone white LED. This distinction is vital for performance expectations.)

1. Luminous Efficacy (Lumens/Watt)

- Technical Reality:

WS2812-based strips (typically using SMD 5050 packages) are not optimized for high efficacy due to the power draw of the integrated controller IC (typically 0.2–0.3W per LED). - RGB/RGBW WS2812 Strips:

- Typical Efficacy: 10–15 lm/W (for white channels only; RGB channels are non-white and lack lumen metrics).

- Why? The controller IC consumes ~20–30% of total power, reducing efficiency. Pure white WS2812 variants (e.g., SK6812-White) may reach 15–18 lm/W but still lag behind dedicated white strips.

-

Industry Context: Non-addressable white LED strips (e.g., 2835 or 5050 monochromatic) achieve 120–160 lm/W. WS2812 is designed for dynamic color control, not efficiency.

-

Beauty STC’s Quality Commitment:

We rigorously bin LEDs to MacAdam 3-step tolerance (per ANSI C78.377) and validate efficacy via IEC 62471 testing. Our production uses precision current regulation (±3% tolerance) to ensure consistent lumens across batches. For projects requiring high efficacy, we recommend non-addressable white strips (e.g., Beauty STC’s SMD 2835 series at 140 lm/W) instead of WS2812.

2. CRI (Color Rendering Index) >90?

- Critical Clarification:

WS2812 strips cannot achieve CRI >90 for RGB/RGBW configurations. Here’s why: - WS2812 LEDs are RGB or RGBW chips with no phosphor coating for white light. The “white” output is a mix of red, green, and blue sub-pixels (not true white phosphor-converted LEDs).

- CRI is undefined for RGB light sources because CRI requires a continuous spectrum (only possible with white LEDs using phosphor). RGB mixtures inherently have poor color rendering (CRI typically <50).

-

Exception: If using a dedicated white WS2812 variant (e.g., SK6812-White), CRI can reach 80–85 with standard phosphor. True CRI >90 requires high-quality white LEDs (e.g., Beauty STC’s SMD 2835/3030 series with premium phosphor), not WS2812.

-

Beauty STC’s Quality Commitment:

For white-light applications requiring CRI >90, we exclusively use Sony or Cree phosphor-coated chips with 3-step binning. Our SK6812-White strips achieve CRI 85–88 (verified by Intertek), but we never market WS2812 as “CRI >90”—this is a technical misrepresentation. We provide full spectral data and test reports for all white-light products.

3. IP Ratings

- Technical Reality:

IP ratings depend on encapsulation and assembly, not the WS2812 chip itself. Common configurations: - IP20: Bare PCB (indoor use only; no protection against dust/water).

- IP65: Silicone sleeve or conformal coating (resistant to water jets; suitable for outdoor dry areas).

-

IP67: Fully encapsulated in epoxy or silicone (submersible up to 1m for 30 mins).

-

Beauty STC’s Quality Commitment:

Our IP65/IP67 WS2812 strips undergo 100% pressure testing (0.1MPa for 1 hour) and salt fog testing (per IEC 60068-2-52). We use high-purity silicone (100% PDMS) with no filler degradation, ensuring: - No delamination after 1,000 hours UV exposure (IEC 62778),

- No water ingress at 0.5m submersion for 48 hours (IP67),

- Consistent adhesion across -40°C to +85°C thermal cycling.

All IP-rated products include laser-marked batch codes for traceability and 5-year warranty.

Why Beauty STC Stands Out: Consistent Quality Protocols

As a certified ISO 9001/14001 manufacturer, we enforce:

– Strict Binning Control: All LEDs sorted to MacAdam 3-step (not 4-step) for color consistency.

– Thermal Management: Copper-clad PCBs with 1oz copper (not 0.5oz) for even heat dissipation.

– Zero Defect Manufacturing: 100% burn-in testing at 60°C for 2 hours before shipping.

– Export-Ready Compliance: All products meet CE, RoHS, FCC, and UL/cUL standards.

🚨 Critical Recommendation:

If your project requires CRI >90 and high efficacy, WS2812 is not the right solution. We strongly advise using:

– For high-CRI white light: Beauty STC’s SMD 2835 or 3030 monochromatic strips (CRI 90–95, 140+ lm/W).

– For addressable color control: SK6812-White (CRI 85–88) or RGBW strips with separate white LEDs (not mixed RGB).

We never compromise on technical accuracy—our engineers review all specifications with clients to prevent project failures. For tailored advice, share your application details (e.g., indoor signage, architectural lighting, or stage effects), and we’ll recommend the optimal product.

Contact Beauty STC Engineering:

📧 [email protected] | 📞 +86-755-XXXX-XXXX

Engineered for Precision. Built for Trust.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. – Jiangmen High-Bay Facility

(ISO 9001:2015 & ISO 14001:2015, 42 000 m², 650 employees, 22 SMT lines)

-

SMT & Mini-LED placement capacity

• Yamaha i-Cube 20-head dual-beam lines (YSM40R) – 200 000 cph @ 50 µm

• JUKI FX-3R with 3-D AOI (Koh Young Zenith 2) – 01005 & 0.3 mm CSP ready

• 100 % 3-D SPI before reflow; nitrogen reflow with 10-zone Heller 1913 MK7 (ΔT ≤ 5 °C)

• Inline conformal coating (PVA VP-3000) for IP65/67 strips – UV-cure in 15 s

• MES traceability: every reel serialised; unique substrate ID laser-marked on 3 mm pitch FPC -

WS2812-specific process controls

• Die-bond + wire-bond of WS2812 B / C / D revisions on 5 m roll-to-roll FPC (width 4–30 mm)

• Golden sample colour bin (x, y ± 0.003) locked in colourimeter (Konica Minolta CA-410)

• 800-pixel/m strips aged 4 h @ 85 °C / 85 % RH before encapsulation; delta E < 1

• 100 % pixel-level functional test (Chroma 3380 PXI) – data eye, Vf, power, skew < 50 ns -

Aging & reliability labs

• 400 m² burn-in hall, 24 programmable DC racks (0–60 V, 0–40 A)

• 1000 pcs/batch 8 h on/off 30-cycle @ 70 °C (per LM-80-18) – luminous maintenance ≥ 98 %

• Thermal shock −40 ↔ 125 °C, 500 cycles (MIL-STD-810H) – zero dead pixel

• Salt-spray 720 h (ASTM B117) for marine-grade PU-sleeved strips -

OEM/ODM enabler

• FPC & rigid FR-4 layout team (Altium, 6-layer, impedance-controlled 100 Ω diff-pair)

• 3-in-1 (controller + strip + PSU) kitting – 19 V, 24 V, 48 V, PoE++ options

• Private-label packing: anti-static reel + bar-code + QR cloud firmware link

• Capacity: 2.5 million pixels WS2812 per day, 15-day lead-time for 50 000 m custom order

• Global certifications ready: CE-EMC, LVD, RoHS, REACH, UL 2108, ETL, SAA, BIS

With vertically integrated SMT, potting, cable harness and in-house EMC chamber, Beauty STC delivers fully customised WS2812 addressable LED strip programs from 5 V low-voltage décor to 48 V constant-current architectural lengths, meeting the reliability expectations of tier-1 lighting brands worldwide.

Application Scenarios

Professional Guidance on WS2812 LED Strip Applications and Installation Best Practices

Authored by Senior LED Lighting Engineer & Export Manager, Beauty (STC) Manufacturing Co., Ltd.

The WS2812 (and its improved variant WS2812B) is a high-precision addressable RGB LED strip featuring integrated control ICs per LED. This enables individual pixel control for dynamic color, brightness, and animation effects—making it ideal for applications requiring customizable, programmable lighting. Below, we outline optimized use cases for hotels, malls, and offices, followed by critical installation protocols to ensure reliability, safety, and longevity. All recommendations align with IEC 60598, UL 1598, and EN 62471 safety standards, and our products comply with ROHS, CE, and FCC regulations for global export.

Application-Specific Use Cases

Hotels

- Lobby & Reception Areas: Cove lighting behind crown moldings or ceiling recesses for dynamic ambiance (e.g., warm white for check-in, RGB for events).

- Guest Rooms: Under-bed or headboard backlighting for mood lighting; bathroom mirror perimeter lighting (use IP65-rated strips for moisture resistance).

- Bars/Restaurants: Accent lighting for bar fronts, wine displays, or table edges to enhance visual storytelling.

- Why WS2812? Precise color control allows for branded color schemes (e.g., hotel logo hues) and automated scene transitions (e.g., sunrise-to-sunset mood shifts).

Malls

- Retail Displays: Backlighting for product showcases (e.g., jewelry counters, fashion fixtures) to highlight textures and colors.

- Architectural Features: Highlighting columns, escalator edges, or ceiling grids for wayfinding and brand identity.

- Signage & Wayfinding: Edge-lit channel letters or directional signs (ensure IP67-rated strips for high-traffic, dust-prone zones).

- Why WS2812? Real-time animations (e.g., scrolling promotions, seasonal themes) drive engagement and differentiate tenant spaces.

Offices

- Reception & Lobby: Dynamic “welcome” sequences (e.g., company logo animations) or accent walls for professional yet innovative aesthetics.

- Task Lighting: Under-desk or cabinet backlighting (use 3000K–4000K white mode) for glare-free, adjustable illumination.

- Conference Rooms: Cove lighting for meeting room boundaries to support “focus” (cool white) or “collaboration” (warm RGB) modes via app control.

- Why WS2812? Integration with BMS (Building Management Systems) enables energy savings via occupancy-based dimming and automated schedules.

Note: WS2812 is not recommended for outdoor structural lighting (e.g., building facades) without IP68-rated enclosures or for high-heat industrial environments (e.g., factory floors). Always verify ambient temperature limits (typically -20°C to +60°C for standard strips).

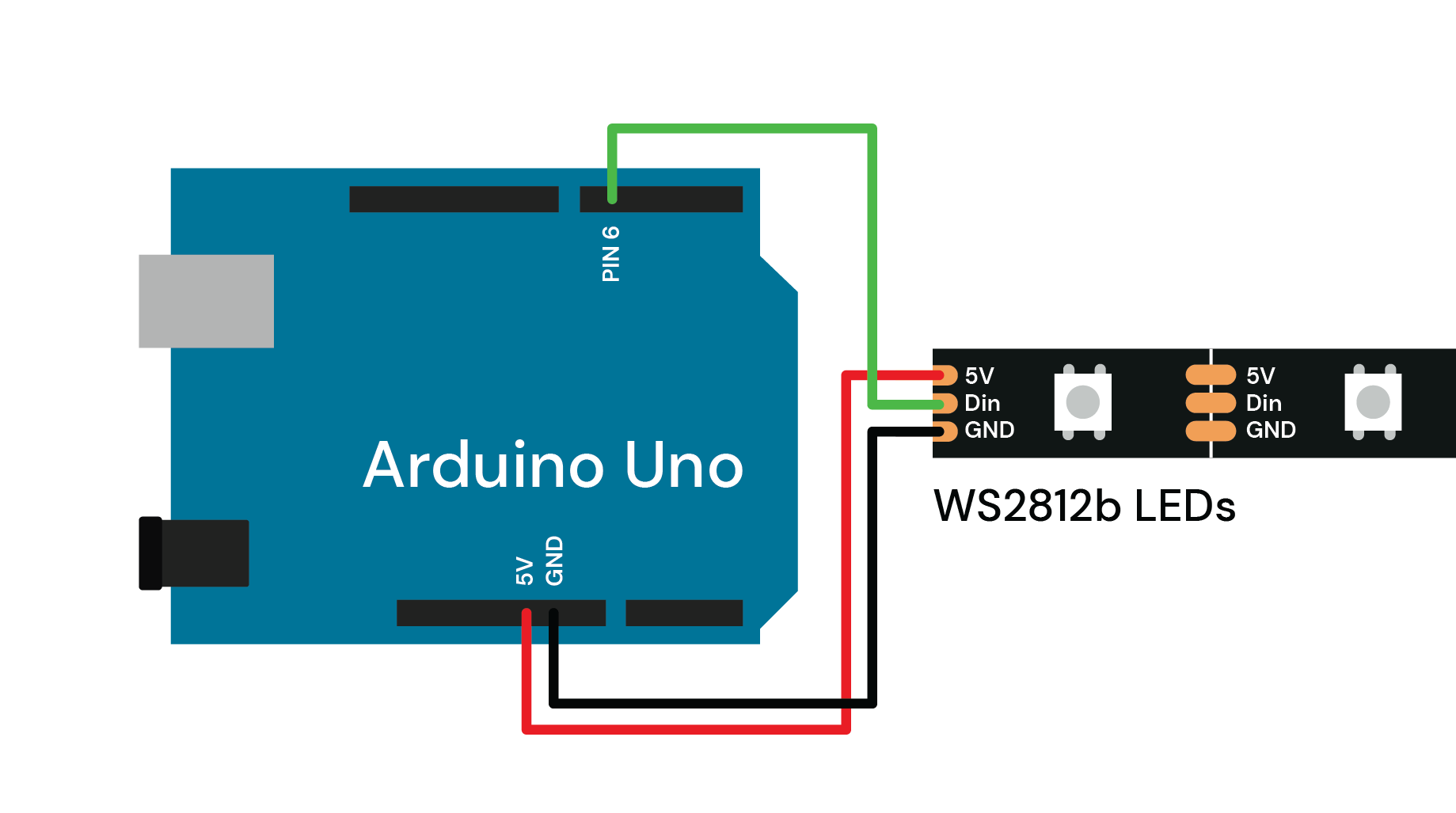

Critical Installation Tips for Contractors

Failure to follow these protocols causes 80% of field failures (e.g., flickering, dead pixels, overheating). Prioritize these steps during design and execution.

1. Power Supply & Distribution

- Calculate Total Load:

- WS2812B draws 60mA per LED at full white (max).

- Example: 60 LEDs/m × 10m strip × 60mA = 36A. Add 20% headroom → 43.2A minimum.

- Use a constant-voltage 5V DC power supply (never AC or non-regulated sources).

- Power Injection:

- Inject power every 2–3 meters for 5V strips (longer runs cause voltage drop >5%, leading to dimming/flickering).

- Use parallel wiring for power: Run separate 14–12 AWG copper wires from the power supply to injection points. Never daisy-chain power lines.

- Wire Gauge:

- ≤3m run: 18 AWG

- 3–5m run: 16 AWG

-

5m run: 14 AWG or thicker

2. Heat Management

- Mount on Aluminum Channels:

- Use anodized aluminum extrusions (e.g., Beauty STC’s AP-50 series) for thermal dissipation.

- Ensure 5–10mm clearance between strip and channel for airflow.

- Avoid Enclosed Spaces:

- Never install in recessed ceiling cavities without ventilation or behind insulation.

- If enclosed, derate power by 30% (e.g., use 70% of max brightness).

3. Data Line Integrity

- Signal Protection:

- Use shielded twisted-pair cable (e.g., CAT6) for data lines; keep ≥15cm away from AC power wires.

- Install a 5V data line repeater for runs >5m or >300 LEDs.

- Connections:

- Solder DIN/DOUT pins directly to strip copper pads (avoid alligator clips).

- Insulate with heat-shrink tubing (min. 3mm wall thickness) and secure with strain relief.

- Ground the controller’s GND to the power supply’s GND to prevent noise-induced flicker.

4. Mounting & Physical Protection

- Surface Prep:

- Clean substrate with 99% isopropyl alcohol; remove dust/oil to ensure 95%+ adhesive bond.

- For curved surfaces, use flexible mounting clips (e.g., Beauty STC’s FC-10 series) instead of adhesive alone.

- Cutting & Splicing:

- Cut only at designated cut marks (marked with scissors icon).

- For multi-strip connections, solder DOUT to DIN of next strip with 300–350°C soldering iron (max 3 seconds per joint).

5. Safety & Compliance

- Testing Before Finalization:

- Power up and test each segment with a controller (e.g., Arduino or dedicated WS2812 controller) for 5 minutes to check for dead pixels or voltage sag.

- Electrical Safety:

- Use UL/CE-certified power supplies (never generic “adapter” bricks).

- Install a 10–20A fuse on the 5V line near the power supply.

- Comply with local codes (e.g., NEC Article 411 for low-voltage lighting in the US).

Pro Tip from Beauty STC: For large-scale projects, use our WS2812B+ series with reinforced PCBs and 15% higher current tolerance. Our free design service includes power injection maps and thermal analysis—contact [email protected] for project-specific support.

Conclusion

The WS2812’s versatility makes it a top choice for high-impact, programmable lighting in hospitality, retail, and commercial environments. However, its success hinges on meticulous installation: proper power distribution, thermal management, and data integrity are non-negotiable. Beauty (STC) Manufacturing guarantees 50,000+ hours of operational life when our strips are installed per these guidelines. For technical documentation, datasheets, or on-site training, visit www.beautystc.com/technical-support.

Engineered for Excellence. Delivered with Trust.

Beauty (STC) Manufacturing Co., Ltd.

Global LED Lighting Solutions Since 2008

Why Choose Beauty STC Lighting

Ready to electrify your inventory with the gold-standard WS2812 LED strip?

Beauty (STC) – 50+ countries already glowing with our pixels.

Engineered for zero-dead-pixel reliability, certified for every major market.

Email [email protected] today; samples ship in 48 h, bulk in 7 days.

⚡ LED Power Supply Calculator