Article Contents

Industry Insight: Warm Led Tape Light

Elevating Commercial Lighting with Precision Warm LED Tape Solutions

Market Demand Drivers for High-Quality Warm LED Tape

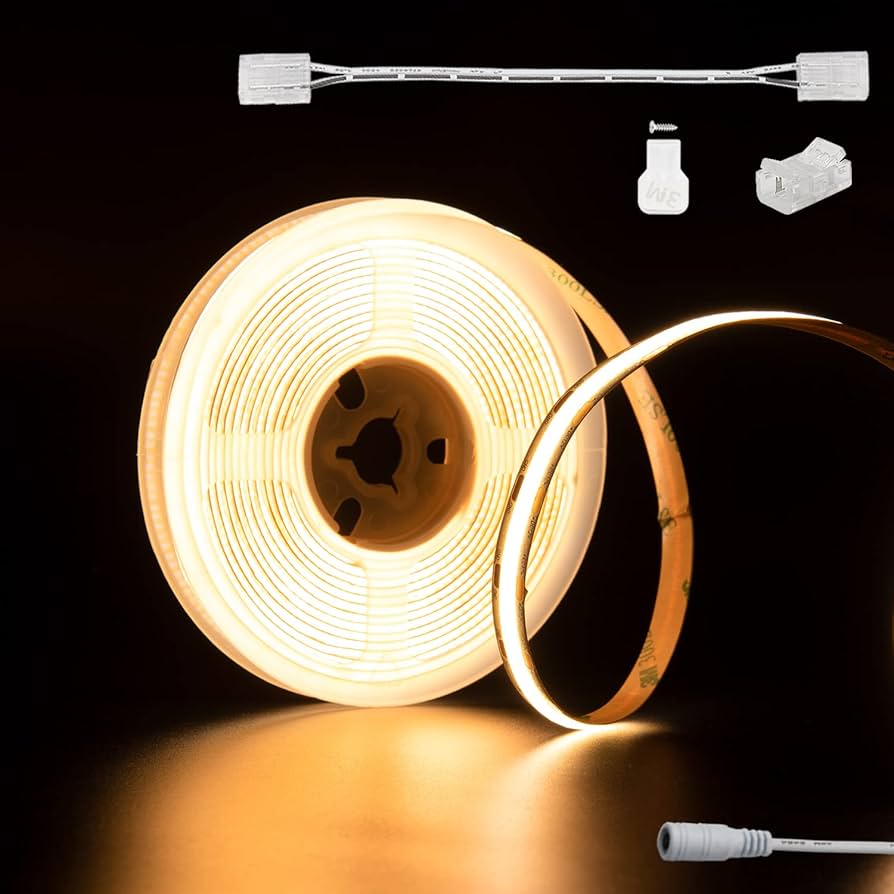

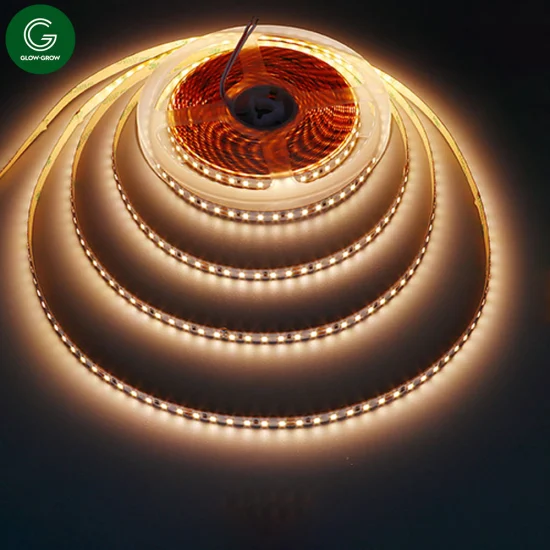

Modern commercial and industrial lighting projects demand adaptable, high-fidelity illumination solutions. Warm LED tape light has become critical in retail displays, hospitality environments, and office spaces where nuanced color temperature control enhances both aesthetics and occupant well-being. The industry shift toward tunable white lighting—particularly dim-to-warm functionality—requires precise CCT transitions from 3000K to 1800K that mimic natural incandescent behavior. Without consistent color rendering (CRI ≥90) and stable dimming curves, these applications suffer from visible color shifts or inconsistent performance. For global importers, meeting these technical specifications while adhering to regional safety standards is non-negotiable for project success.

Why Certification Compliance is Non-Negotiable for Global Importers

Market access for electrical products in North America and Europe requires rigorous third-party certifications. ETL (US/Canada) and TUV CE (EU) verify not only electrical safety but also electromagnetic compatibility (EMC), thermal management, and performance consistency. Non-compliant products face customs holds, mandatory recalls, or liability exposure—costing importers significant time and revenue. Beauty STC Lighting’s portfolio is fully certified for Western markets, with each batch undergoing independent testing per UL 1598 and EN 60598 standards. This eliminates regulatory risks while ensuring seamless integration into certified building systems.

Beauty STC Lighting: 25+ Years of Engineering Excellence for Global Markets

Established in 1998, Beauty STC Lighting has built its reputation on technical precision and regulatory adherence. Located in Jiangmen’s High-Tech Industrial Zone, our manufacturing facility combines advanced SMT assembly lines with ISO 9001 quality control protocols. For over a quarter-century, we’ve supplied OEM/ODM solutions to global distributors, ensuring every LED tape light meets exacting specifications. Our dim-to-warm series delivers seamless CCT transitions (1800K–3000K) with ≥95 CRI (Ra), validated by ETL and TUV CE certifications. All products undergo 100% binning for color consistency and thermal stress testing to guarantee longevity in demanding environments.

| Specification | Industry Standard | Beauty STC Compliance |

|---|---|---|

| CCT Range (Dim-to-Warm) | Typically 2700K–1800K | 1800K–3000K seamless transition with ±0.5% Δuv stability |

| CRI (Ra) | Minimum 80 for commercial | ≥95 CRI (Ra), R9 >50 for accurate color rendering |

| Voltage Options | 12V/24V DC | Dual-voltage support with ±5% current stability |

| IP Ratings | IP20 (indoor), IP65 (outdoor) | Certified IP20, IP65, and IP67 options per IEC 60529 |

| Certifications | ETL (US/Canada), CE (EU) mandatory | Fully ETL and TUV CE certified with test reports |

Partner with a manufacturer whose technical expertise and compliance rigor have served global markets since 1998. Contact our engineering team at [email protected] or +86 13902885704 to discuss your project specifications.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards – Warm LED Tape Light

Beauty (STC) Manufacturing Co., Ltd | Est. 1998 | Jiangmen, Guangdong

H3 1. Key Photometric & Electrical Data

All figures measured at 25 °C, Tj = 85 °C, 24 V nominal, 1 m sample.

| Parameter (per metre) | 1800 K “Dim-to-Warm” | 2400 K “Very Warm” | 3000 K “Warm White” |

|---|---|---|---|

| Luminous efficacy | 112 lm/W | 120 lm/W | 126 lm/W |

| CRI (Ra) / R9 | 95 / 90 | 95 / 92 | 95 / 90 |

| Lumen maintenance @50 kh | L90B10 (TM-21) | L90B10 | L90B10 |

| Binning tolerance | 3 SDCM (MacAdam) | 3 SDCM | 3 SDCM |

| Power draw (max) | 14.4 W | 14.4 W | 14.4 W |

| Voltage options | 12 V / 24 V DC | 12 V / 24 V DC | 12 V / 24 V DC |

| Flicker index | <0.001 (IEEE 1789) | <0.001 | <0.001 |

H3 2. PCB & Mechanical Integrity

Base material: Double-layer electrolytic copper, 2 oz (70 µm) minimum, ED copper ≥99.9 % purity.

Thermal conductivity: 1.5 W/m·K dielectric; junction-to-solder-point ∆T < 5 K @14 W/m.

Dimensional stability: ≤0.05 % shrinkage after 288 °C solder-float 10 s (IPC-TM-650 2.4.13).

Bend radius: 10 mm without copper fracture (≥1 000 cycles, ±90°, 1 Hz).

Cut increment: 25 mm (24 V) / 50 mm (12 V); laser-cut edge sealed to prevent Cu-oxidation.

H3 3. IP & Ambient Ratings

| Grade | Front | Rear | Application Example | Test Standard |

|---|---|---|---|---|

| IP20 | Clear solder-mask | 3M 300LSE tape | Dry cove, display | IEC 60598-2-20 |

| IP65 | PU gel 0.8 mm | Same | Kitchen toe-kick, bath | IEC 60529 |

| IP67 | Silicone sleeve 2 mm | Optional | Facade, deck | 1 m submersion, 30 min |

| IP68 | PU + sleeve | Optional | Pool, boat | 3 m, 24 h (custom) |

H3 4. Consistency & Traceability Controls

- Bin-on-reel: LEDs pre-binned by flux, Vf, and chromaticity at source; each 5 m roll carries a QR code linking to raw wafer lot.

- Automated optical goniometer: 100 % in-line check for CCT, CRI, luminous flux; rejects >3 SDCM automatically.

- Reflow profile: 11-zone convection, real-time SPI & AOI; solder-paste height controlled ±15 µm.

- 1000 V dielectric hipot: Every completed roll; leakage <0.5 mA.

- IST (Interconnect Stress Test): 500 cycles −40 °C ↔ +125 °C; resistance change <5 %.

H3 5. Certified Quality vs. Generic Market

| Criterion | Generic Market (typ.) | Beauty STC Certified | Reference Method |

|---|---|---|---|

| Copper weight | 1 oz (35 µm) | 2 oz (70 µm) | IPC-4562 |

| Chromaticity spread | 5–7 SDCM | ≤3 SDCM | CIE 1964 |

| CRI (Ra) | 80–85 | ≥95 | CIE 13.3 |

| Efficacy @3000 K | 90–100 lm/W | ≥126 lm/W | IES LM-79 |

| L70 projection | 25 000 h | 54 000 h | TM-21, 85 °C |

| Safety mark | Self-claim | ETL/cETL, TUV CE | UL 2108, EN 60598 |

| RoHS / REACH | Partial screened | Full 219-substance | IEC 62321 |

| Tape adhesive | 0.8 N/cm | 3.0 N/cm (3M 300LSE) | ASTM D3330 |

| Warranty | 1–2 yr | 5 yr (field retrofittable) | Factory limited |

H3 6. Compliance & OEM Readiness

ETL-listed for US & Canada (UL 2108, UL 879), file 5015853.

TUV CB & CE (EN 60598-2-20, EN 62031, EN 62471).

ISO 9001:2015 production site, 25 000 m², 600+ workers.

OEM/ODM: Custom CCT, CRI, pitch, FPC width, logo-print, blister or bulk tray. MOQ 1 000 m per CCT/bin.

For datasheets, IES files or LM-80 reports: [email protected] | +86-13902885704.

Factory Tour: Manufacturing Excellence

Precision Manufacturing Infrastructure and OEM Capabilities

With over 25 years of manufacturing expertise since 1998, Beauty STC Lighting operates a dedicated facility in Jiangmen’s High-tech Industrial Zone. Our production line integrates advanced automation with rigorous quality controls to ensure consistent performance of LED tape light products for global markets. All processes adhere to international standards, with certifications including ETL (USA/Canada) and TÜV CE (Europe) validating compliance for Western market requirements.

Advanced SMT Production Line

High-precision surface-mount technology (SMT) assembly lines enable consistent component placement and soldering for LED strip lights. Our automated SMT machines feature:

0.01mm placement accuracy for micro-components

Controlled reflow profiles to prevent thermal stress

In-line AOI (Automated Optical Inspection) for defect detection

This ensures superior electrical reliability and longevity in all production batches.

Rigorous Aging and Testing Protocols

Each LED tape light undergoes a 48-hour continuous aging test under controlled conditions (40°C ambient temperature). This process validates:

Lumen output stability

Color consistency across the lifespan

Thermal performance under load

Dimming functionality (for tunable products)

All test data is recorded and traceable to individual production batches, supporting our commitment to reliability.

Multi-Stage Quality Control

| QC Stage | Key Checks | Testing Protocol |

|---|---|---|

| Material Inspection | PCB thickness, LED binning, adhesive peel strength | ISO 9001, IEC 62612 |

| SMT Process | Solder paste volume, component alignment, reflow temperature | IPC-A-610 Class 2 |

| Post-Assembly | Continuity, initial lumens, color consistency | IEC 62471, IEC 62493 |

| Aging Test | 48-hour continuous operation at 40°C | Lumen output stability, color consistency, thermal performance |

| Final Inspection | CRI (≥90), CCT deviation (±150K), dimming curve accuracy | ETL/CE certification requirements |

Tailored OEM/ODM Solutions for Global Markets

Customization Capabilities

Our OEM/ODM services provide flexibility for global project requirements. Key customization options include:

| Customization Parameter | Options | Notes |

|---|---|---|

| Length | 1m increments up to 50m reels | Custom cutting marks for on-site trimming |

| CCT Options | Standard: 1800K, 2700K, 3000K, 4000K, 5000K, 6500K Tunable White: 3000K→1800K dim-to-warm |

Smooth transition during dimming cycle |

| CRI | ≥90 (standard), ≥95 (premium) | High-fidelity color rendering for retail and hospitality |

| Voltage | 12V DC, 24V DC | Compatible with leading drivers and controllers |

| IP Rating | IP20 (indoor), IP65 (outdoor), IP67 (submersible) | Sealing options for environmental protection |

| Packaging | Retail boxes, bulk reels, custom branding | OEM labeling, specific quantity per reel, moisture-resistant packaging |

Certified Compliance for Western Markets

Beauty STC Lighting maintains ETL (USA/Canada) and TÜV CE (Europe) certifications for all LED tape light products. Our manufacturing processes are validated through third-party testing to ensure compliance with North American and European safety and performance regulations. This includes rigorous electrical safety testing, photobiological safety (IEC 62471), and EMC compliance. All products undergo traceable quality documentation, enabling distributors to meet regional regulatory requirements without additional certification overhead.

For technical specifications or custom project inquiries, contact our engineering team at [email protected] or +86 13902885704.

Installation & Application Scenarios

Application Scenarios for Warm LED Tape Light

Factory-direct guidance from Beauty (STC) Manufacturing Co., Ltd – ETL & TUV CE listed since 1998

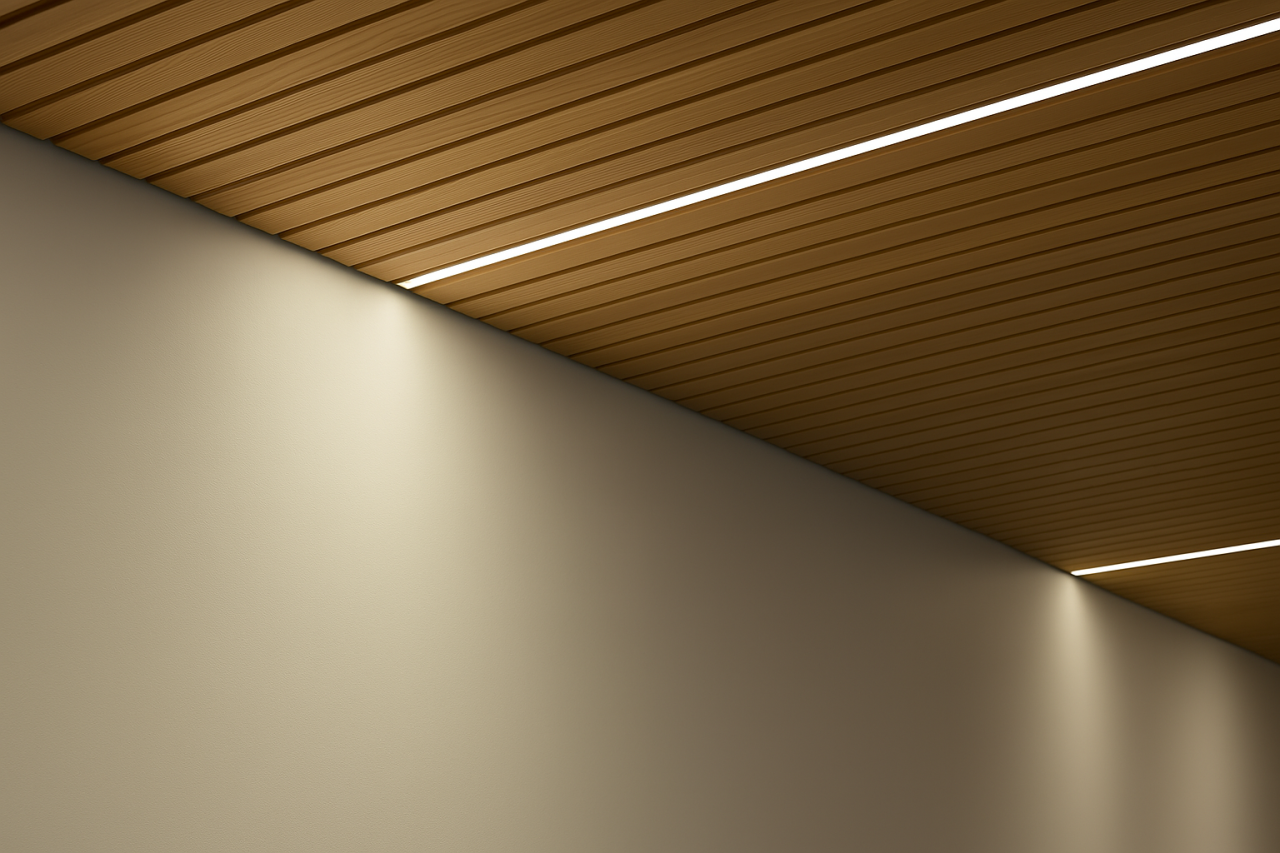

H2 Where Warm LED Tape Light Adds Value

| Segment | Typical CCT Range | CRI | Key Cert. | OEM Value-Add |

|---|---|---|---|---|

| Boutique hotels, guest corridors | 1800 K – 2700 K (dim-to-warm) | ≥ 95 | ETL cETL, TUV CE | Custom length reels, private-label sleeve |

| High-end retail, window displays | 2400 K – 3000 K | ≥ 95 | ENEC, RoHS | Colour-bin matched to corporate identity |

| Corporate reception & lift lobbies | 2700 K – 3500 K | ≥ 90 | ETL, CE, CB | 24 V constant-voltage driver pre-wired |

| Façade coves & soffits | 2200 K – 3000 K | ≥ 90 | IP65, IK06 | 3-step MacAdam ellipse for façade consistency |

| Cruise-ship cabins & theatres | 1800 K – 3000 K | ≥ 95 | Marine LR, CE | Fire-retardant silicone sleeve (UL 94 V-0) |

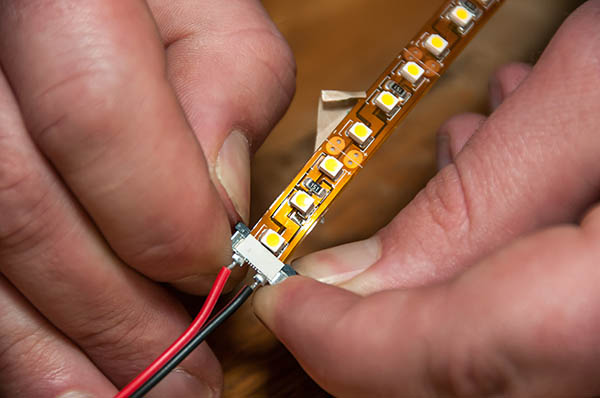

H3 Installation Notes for Contractors

-

Surface Prep

Aluminium extrusion mandatory for runs > 1 m; maintains TJ ≤ 65 °C and L70 > 54 000 h.

Clean substrate with IPA; 3M VHB tape achieves 1·5 N cm⁻² after 24 h. -

Thermal Management

Beauty STC warm tape is 14 W m (120 LED m, 24 V). Use 2 W m⁻¹ K⁻¹ heat-sink extrusion for surface temperatures < 55 °C to preserve 1800 K chromaticity shift < 2 SDCM. -

Voltage Drop Rule

24 V system: inject power every 5 m for 14 W m load; 12 V system every 2·5 m.

Factory pre-tinned 20 AWG flying leads on OEM reels reduce field solder joints by 30 %. -

Dim-to-Warm Wiring

0-10 V / DALI module mounted max 20 m from first LED; use Belden 9418 (2-pair, 0·75 mm²) for < 5 % voltage drop.

Compatibility verified with Lutron Diva, Dynalite, and Helvar systems – ETL driver number BSTC-DTW24-ETL. -

Outdoor IP Rating

IP65 version uses PU nanocoating on PCB + silicone tube; IP67/IP68 available on 5 m MOQ.

UV-stable silicone prevents 2000 h colour shift Δu′v′ < 0·003 (IES LM-80-18). -

Code Compliance

UL 2108 low-voltage lighting systems – ETL listed driver (BSTC-24V-200W-ETL) supplied with Class 2 output.

TUV CE complies with EN 60598-2-21 for surface-mounted flexible chains. -

Field Cut & Re-Seal

Cut only on printed scissors mark; re-seal IP65 with Beauty STC RTV-1 neutral-cure silicone.

End-cap with heat-shrink tube restores IP rating in 45 s (UL 157 tested).

H3 Quick-Order Matrix (OEM, factory lead-time 3 weeks)

| Reel Length | LEDs m | Power | CCT Range | Part Number | Cert. |

|---|---|---|---|---|---|

| 5 m | 120 | 14 W m | 1800-3000 K dim-to-warm | BSTC-DTW-24V-120-5M | ETL, CE |

| 5 m | 60 | 10 W m | 2400 K fixed | BSTC-WW-24V-60-5M | ETL, CE |

| 10 m | 120 | 14 W m | 2200 K fixed | BSTC-WW-24V-120-10M | ETL, CE |

All reels shipped on 335 mm diameter anti-static reels, bar-coded for distributor inventory systems.

For project-specific extrusion drawings, LM-79 data, or to lock production slots, contact:

[email protected] | +86-13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting

As a trusted manufacturer with over 25 years of experience, Beauty STC Lighting delivers high-performance warm LED tape solutions engineered for global markets. Our products meet rigorous international standards, ensuring seamless integration into commercial and residential projects worldwide.

Global Compliance & Quality Assurance

All Beauty STC LED tape products are certified for key international markets, including:

ETL (USA/Canada): Compliance with UL standards for electrical safety and performance.

TUV CE (Europe): Meets EU safety, health, and environmental requirements.

These certifications ensure your projects comply with local regulations, reducing market entry barriers and liability risks.

25+ Years of Technical Expertise

Established in 1998, Beauty STC has honed its manufacturing processes through decades of industry evolution. Our in-house R&D team and strict quality control protocols guarantee consistent performance, color accuracy, and longevity – critical factors for professional lighting applications.

Custom OEM/ODM Solutions

We specialize in tailoring products to your exact specifications:

CCT Flexibility: Dim-to-Warm options (3000K–1800K) or fixed CCT from 1800K to 6500K

High CRI Options: >95 for accurate color rendering

Voltage & IP Ratings: 12V/24V DC, IP20 (indoor) to IP67 (outdoor)

Custom Packaging & Branding: Private labeling, custom box designs, and tailored documentation

| Specification | Detail |

|---|---|

| CCT Range (Dim-to-Warm) | 3000K to 1800K |

| CRI | >95 |

| Voltage Options | 12V DC, 24V DC |

| IP Rating | IP20 (standard), IP65/IP67 (optional) |

| Dimming Compatibility | 0-10V, PWM, TRIAC |

| Max Run Length | 5m (12V), 10m (24V) |

| LED Density | 60–120 LEDs/m |

Ready to Partner?

Contact our global sales team to discuss your project requirements. With 50+ countries served and a commitment to technical excellence, we deliver reliable, certified solutions tailored to your needs.

Email: [email protected]

Phone: +86 13902885704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).