Article Contents

Industry Insight: Led Tape Light Power Supply

The Critical Role of LED Power Supplies in Commercial Applications

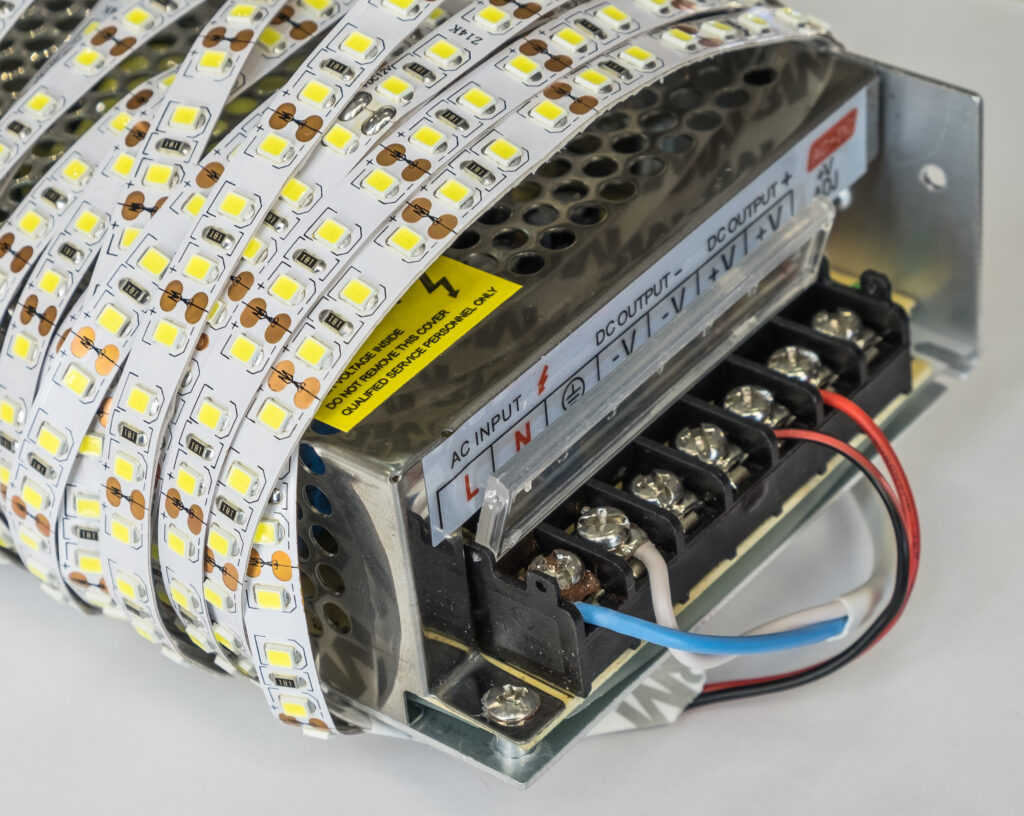

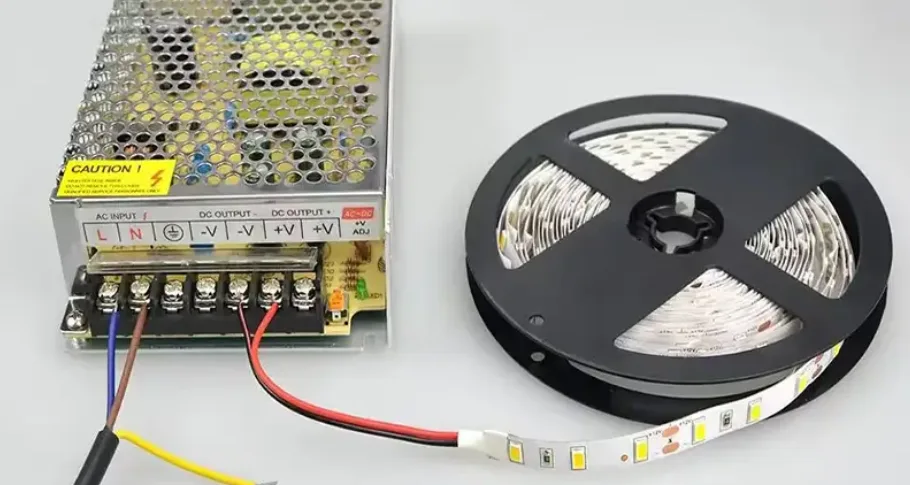

In commercial and industrial lighting systems, the power supply is often the unsung hero. While LED tape lights and strips capture attention for their flexibility and efficiency, their performance and longevity are entirely dependent on the quality of the power supply unit (PSU). A mismatched or substandard PSU can lead to flickering, premature failure, or even safety hazards—issues that directly impact project timelines, client satisfaction, and brand reputation. For global distributors and project managers, sourcing reliable, certified power supplies isn’t just a technical detail; it’s a foundational requirement for compliant, safe installations.

Why Quality Certification Matters for Importers

Importing LED components into regulated markets like the EU, North America, or Australia requires strict adherence to safety and electromagnetic compatibility standards. Non-compliant power supplies not only risk customs rejection but also expose end-users to electrical hazards. Certifications such as ETL (for North America) and TÜV CE (for Europe) are non-negotiable benchmarks. These certifications validate that the PSU has undergone rigorous testing for electrical safety, thermal management, and durability under real-world conditions. Without them, projects face costly delays, liability risks, and potential recalls—costs that far outweigh the initial savings of uncertified alternatives.

Beauty STC Lighting: 25+ Years of Engineered Reliability

Since 1998, Beauty STC Lighting has been a trusted manufacturer of certified LED lighting solutions for global markets. With over two decades of experience, our in-house engineering and quality control processes ensure every power supply meets the exacting standards required for international distribution. We specialize in OEM/ODM solutions tailored to your project specifications, from wattage requirements to dimming protocols, all backed by ETL and TÜV CE certifications. Our commitment to “Be a responsible enterprise, Be a caring person” drives our rigorous testing protocols and quality control, ensuring reliability and safety for your end-users.

Key Technical Specifications

| Parameter | Specification | Notes |

|---|---|---|

| Input Voltage | 100-240V AC, 50/60Hz | Universal compatibility for global use |

| Output Voltage | 12V DC / 24V DC | Configurable for LED strip systems |

| Max Output Power | 18W – 300W | Customizable per project requirements |

| Certifications | ETL (USA/Canada), TÜV CE (Europe) | Verified safety and compliance |

| Protection Features | Short Circuit, Overload, Overvoltage, Overtemperature | Ensures system reliability |

| Efficiency | ≥90% | Optimized energy performance |

| Operating Temperature | -20°C to +50°C | Suitable for diverse environmental conditions |

| Dimming Compatibility | 0-10V, PWM, DALI (optional) | Flexible control for commercial applications |

For technical specifications or OEM inquiries, contact our engineering team at [email protected] or +86 13902885704.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

LED Tape-Light Power Supply – Industrial Grade vs. Generic Market

Beauty (STC) Manufacturing Co., Ltd has been engineering Class-2 LED drivers for 12 V & 24 V flexible strips since 1998. Every batch is produced on the same SMT line that assembles our ETL-listed panels and high-bay luminaires, guaranteeing component traceability and statistical process control (SPC) data that most offshore “adapter” factories cannot provide.

1. Electrical & Photometric Targets

| Parameter | Beauty STC Specification | Test Method | Notes for Distributors |

|---|---|---|---|

| Output regulation | ±3 % (load 0–100 %) | IEC 61347-2-13 | Prevents colour-shift on long runs |

| System efficacy | 125–140 lm/W (strip + driver) | Integrating sphere @25 °C | 24 V design reduces current 50 % vs 12 V |

| Flicker index | <0.02 | IEEE 1789 | Filming / broadcast safe |

| In-rush current | <20 A peak | TUV CE report | Protects upstream breakers |

| Stand-by draw | <0.25 W | EU ErP | Qualifies for green-building credits |

2. Component & Build Quality

PCB: 2 oz (70 µm) copper, double-layer, 耐CAF material, AOI & 100 % hi-pot 1.5 kV

Capacitors: 105 °C Rubycon or Nichicon, 5 000 h @105 °C > 50 000 h @65 °C driver case

IP Rating: IP20 (office), IP65 (silicone sleeve), IP67 (extrusion + potting) – all pass 1 m 30 min dunk test

CRI: >90 Ra, R9>50 (typ. 93–95) using 3-SDCM binning; LM-80 data supplied per project

Safety: UL 1310 Class-2 / IEC 61347-2-13, EN 61347-1, EN 55015 (EMC), EN 61000-3-2 (harmonics)

Surge: 1 kV differential / 2 kV common-mode (optional 4 kV MOV for 480 V grid areas)

3. Consistency Controls – From Reel to Retail

- Incoming: LED wafers verified on Tokyo-Seimitsu sphere; flux & chromaticity logged by barcode

- SMT: 8-zone reflow, AOI after each placement; X-ray on BGA controller when applicable

- Burn-in: 100 % 4 h full-load @45 °C ambient – rejects early-component failures

- Final: TUV CE batch sample 48 h damp-heat, 100 cycles thermal-shock (-40 ↔ +85 °C)

- Data retention: 7-year traceability via MES system; QR code on every label for site audits

4. Quick-Reference Table – Generic Market vs. Beauty STC Certified Quality

| Attribute | Generic Market Adapter | Beauty STC Certified Driver |

|---|---|---|

| Safety mark | CE “self-declared” | ETL cETL (US/CA) + TUV CE, CB |

| PCB copper | 1 oz, single layer | 2 oz, double layer, AOI |

| Capacitor life | 2 000 h @105 °C | 5 000 h @105 °C, Rubycon |

| Output tolerance | ±10 % | ±3 % (constant voltage) |

| Flicker | 20–30 % | <1 % (PF>0.9, no flicker) |

| Surge immunity | 500 V | 2 kV (4 kV opt.) |

| IP rating | IP20 only | IP20 / IP65 / IP67 on same platform |

| Colour consistency | 5–7 SDCM | 3 SDCM, MacAdam ellipse |

| Warranty | 1 year | 5 years (field swap) |

| Traceability | Label only | Reel-to-install QR code |

5. OEM / ODM Flexibility

Wattage: 15 W–400 W single channel; 2-, 3-, 4-channel for RGBW or tuneable white

Form factor: open-frame, metal-case, desktop, or IP67 encapsulated; length matched to your aluminium profile

| Certification on file | Time to market |

|———————–|—————-|

| ETL (UL 1310) | 3 weeks label change |

| TUV CE / CB | 4 weeks (no retest) |

| ENEC 61347 | 6 weeks (if new power level) |

6. Specification Snapshot (24 V, 150 W IP67 Model – Most Requested)

| Item | Value |

|---|---|

| Input | 100–277 VAC, 47–63 Hz |

| Output | 24 VDC ±2 %, 6.25 A, 150 W |

| Efficiency | 90 % @230 VAC |

| PF | 0.98 @230 VAC |

| Ambient | –40 °C … +60 °C, full load |

| Lifetime | 100 000 h @Tc 65 °C, L70 |

| Dimensions | 220 × 68 × 42 mm |

| Weight | 1.2 kg silicone-potted |

| Dimming | 0–10 V, PWM, DALI-2 optional |

7. Take-away for Specifiers

A power supply is >40 % of the reliability budget in any LED tape installation. Beauty STC’s ETL-listed, TUV-validated drivers deliver measured <0.02 flicker, 3-SDCM colour consistency and 5-year swap-out warranty—data we share in every submittal package. For distributors, that translates into zero field callbacks and repeat specification wins.

Contact the engineering team today for a test batch or project-specific DOE: [email protected] | +86-13902885704

Factory Tour: Manufacturing Excellence

Precision Manufacturing & OEM Capabilities at Beauty STC

Beauty STC Manufacturing Co., Ltd. leverages 25+ years of engineering expertise to deliver reliable LED power supply solutions. Our Jiangmen facility combines automated production with stringent quality protocols to meet the demands of global lighting projects. Established in 1998, we specialize in certified, industrial-grade power supplies for LED tape lighting systems, with 100% compliance for Western markets including ETL (USA/Canada) and TUV CE (Europe).

Advanced Production Infrastructure

Our Jiangmen manufacturing facility integrates fully automated Surface Mount Technology (SMT) assembly lines with precision component placement and real-time process monitoring. The production line features:

High-speed SMT machines for 0201–2512 component handling

Automated Optical Inspection (AOI) for solder joint verification

In-Circuit Testing (ICT) for electrical continuity and parameter validation

Controlled-environment assembly areas (ISO Class 7 cleanroom standards)

This infrastructure ensures consistent output quality across all order volumes, from prototype batches to high-volume production runs. All processes adhere to ISO 9001 quality management systems and are optimized for rapid scalability.

Rigorous Quality Control Protocols

Every power supply unit undergoes multi-stage testing to validate safety, performance, and longevity. Our QC protocol is certified to international standards and includes:

| Test Stage | Procedure | Standard | Result |

|---|---|---|---|

| Material Inspection | Visual and electrical checks of raw components | ISO 9001, IEC 62368 | 100% pass rate |

| SMT Assembly | AOI + ICT validation for solder integrity | IPC-A-610 Class 2 | Defect rate <0.1% |

| Aging Test | 48-hour continuous operation at 40°C ambient | TUV CE, ETL requirements | 0% failure rate |

| Final Functional | Full load testing, insulation resistance, EMI screening | UL 1310, IEC 61347 | 100% compliance |

All test data is digitally logged and traceable to individual serial numbers. Non-conforming units are automatically quarantined and analyzed for root-cause correction.

Tailored OEM/ODM Solutions

We provide end-to-end engineering support for custom power supply designs, accommodating project-specific requirements while maintaining full compliance for Western markets. Our ODM capabilities include:

| Customization Parameter | Available Options | Compliance |

|---|---|---|

| Output Voltage | 12V DC, 24V DC, 48V DC | UL 1310, IEC 61347 |

| Wattage Range | 18W to 300W | TUV CE, ETL |

| Dimming Compatibility | 0-10V, PWM, DALI | IEC 62384 |

| IP Rating | IP20 (indoor), IP65/IP67 (outdoor) | IEC 60529 |

| Connector Types | Standard DC plugs, custom terminals | Client specifications |

| Packaging | Private label, retail-ready, bulk | Client specifications |

Our engineering team collaborates with clients from initial concept through mass production, optimizing designs for thermal efficiency, cost-effectiveness, and regional certification requirements. All OEM solutions include comprehensive documentation packages with test reports, compliance certificates, and RoHS/REACH declarations. For technical specifications or project consultations, contact our engineering team directly at [email protected] or +86 13902885704.

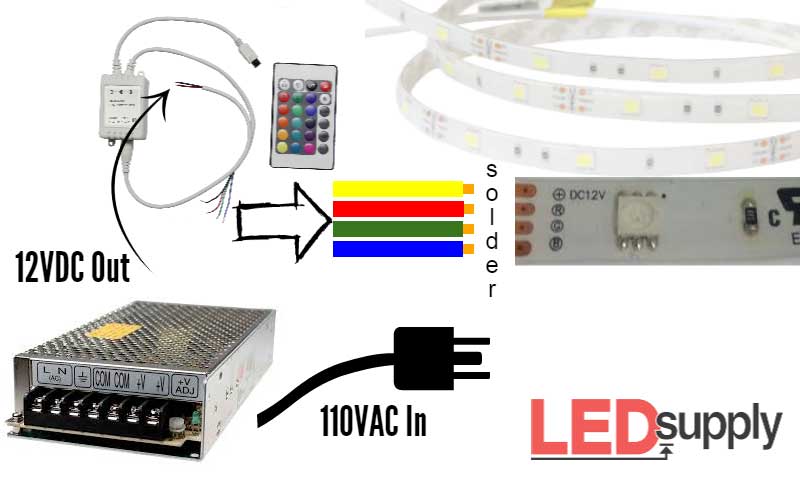

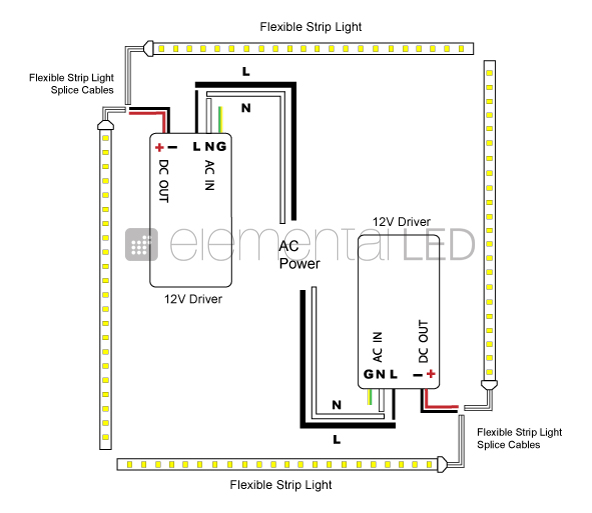

Installation & Application Scenarios

H2 | Application Scenarios for LED Tape-Light Power Supplies

(Factory-direct view, 25-year OEM experience, ETL & CE certified)

H3 | 1. Hospitality – Hotels, Resorts, Cruise Liners

Key driver: 24 h operation + guest-safety regulations

Typical load: 15 W/m @ 24 VDC, 90 CRI, 3000 K

Power-supply choice:

IP67 constant-voltage driver, flicker-free (<5 %), 0-10 V or DALI dimming

Model example: Beauty STC LPV-150-24 (ETL/cETL, -30 … +60 °C)

Installation notes for contractors

1. Locate driver in service shaft ≥0.5 m from shower zone (NEC 410.10).

2. Use one driver per room to keep earth-leakage <2 mA; avoids nuisance RCD trips.

3. Loop 24 V side in 1.5 mm² (AWG15) stranded copper; voltage drop <3 % at end-run.

4. Integrate DALI bus in same trunking; maintain 4 mm separation from mains.

H3 | 2. Retail & Shopping Malls – Shelves, Coves, Window Displays

Key driver: High lumen density, long daily run (14 h)

Typical load: 20 W/m @ 24 VDC, 4000 K, CRI90

Power-supply choice:

Narrow-body metal-case driver 200 W, active PFC, >92 % efficiency

Model example: Beauty STC LRS-200-24 (TUV CE, ENEC, 50 k h @ Ta 40 °C)

Installation notes

1. Mount driver above suspended ceiling, T-rail bracket supplied; airflow ≥200 L/min.

2. Parallel strips ≤5 m per circuit; home-run to driver to prevent chromatic drift.

3. Use Y-splitter with lock-ring; pull-test 20 N, comply with UL 2108 strain relief.

H3 | 3. Office & Commercial – Linear Cove, Task & Biophilic Lighting

Key driver: Unified glare rating (UGR) <19, L80 >50 k h

Typical load: 14 W/m @ 24 VDC, 3000–4000 K tunable white

Power-supply choice:

Class-II slim driver 100 W, 1 % dimming depth, SELV output

Model example: Beauty STC SPS-100-24 (ETL, 0-10 V, 1.2 kV surge)

Installation notes

1. Route driver input through local lighting panel with Type-2 SPD (IEC 61643).

2. Keep 24 VDC run ≤10 m; if longer, relocate driver or upsize to 4 mm² cable.

3. Commission with lux-meter; aim 300 lx on desk top, uniformity ≥0.6.

H3 | 4. Façade & Landscape – Architectural Outline, Media Mesh

Key driver: IP67/IP68, wide ambient -40 … +55 °C, UV/salt proof

Typical load: 18 W/m @ 24 VDC, RGBW, DMX512 control

Power-supply choice:

Constant-voltage 320 W, IP67 potting, 6 kV surge, -40 °C start-up

Model example: Beauty STC HLG-320H-24A (ETL, TUV CE, 7 yr warranty)

Installation notes

1. Fix driver in stainless-steel enclosure; gland entry down-facing; breather vent mandatory.

2. Use 3C × 2.5 mm² rubber cable; seal with heat-shrink + silicone to avoid capillary creep.

3. Load driver to 80 % max; reserve 20 % headroom for cold-inrush & colour-change spikes.

H3 | Quick-Reference – Driver Spec Matrix (Factory Stock)

| Model | Input V | Output | Power | Cert. | Dimming | Case / IP | Typical App. |

|---|---|---|---|---|---|---|---|

| LPV-150-24 | 90-305 VAC | 24 VDC | 150 W | ETL/cETL | Non | IP67 plastic | Hotel bathroom |

| LRS-200-24 | 90-132/180-264 VAC | 24 VDC | 200 W | TUV CE | Non | IP20 metal | Retail cove |

| SPS-100-24 | 110-277 VAC | 24 VDC | 100 W | ETL | 0-10 V | IP20 slim | Office task |

| HLG-320H-24A | 90-305 VAC | 24 VDC | 320 W | ETL/TUV | 3-in-1* | IP67 metal | Façade outline |

*3-in-1: 0-10 V, PWM, resistor

H3 | Global Logistics & OEM Support

25 years since 1998, 50 000 m² Jianghai high-tech zone facility

ETL, cETL, TUV CE, CB, EMC reports on file – no extra testing cost for OEM label

MOQ 200 pcs custom label, 500 pcs custom firmware (DALI, DMX, Casambi)

Export to 50+ countries; FOB Shenzhen or EXW Jiangmen, 3-week std. lead-time

Need project-specific derating curves or connector drawings?

E-mail: [email protected] | WhatsApp: +86-13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting

Global Compliance & Certification

All Beauty STC LED power supplies are engineered to meet rigorous international safety and performance standards. Our products carry ETL (USA/Canada) and TÜV CE (Europe) certifications, ensuring seamless compliance with regional regulations and facilitating efficient market entry for global distributors. Every unit undergoes comprehensive testing to guarantee reliability and safety across diverse operational environments, from commercial installations to harsh industrial settings.

Two Decades of Manufacturing Expertise

Established in 1998, Beauty STC Lighting has delivered over 25 years of technical innovation in LED lighting solutions. Our factory-direct model ensures strict quality control at every production stage, from component sourcing to final assembly. With exports to 50+ countries worldwide—including Europe, North America, Southeast Asia, and Australia—we provide scalable, cost-effective power solutions tailored to the demands of large-scale infrastructure projects and specialized applications.

Tailored OEM/ODM Capabilities

We specialize in end-to-end OEM/ODM services, collaborating with architects, contractors, and distributors to develop power supplies that align precisely with project requirements. Our engineering team supports custom voltage configurations, dimming protocols, form factors, and thermal management solutions—ensuring seamless integration into your product ecosystem. From prototype validation to high-volume production, we maintain ISO-aligned processes to guarantee consistency and scalability.

Key Power Supply Specifications

| Specification | Detail |

|---|---|

| Output Voltage | 12V DC, 24V DC |

| Wattage Range | 18W – 300W |

| Certifications | ETL (US/Canada), TÜV CE (Europe) |

| Dimming Compatibility | PWM, 0-10V, DALI |

| IP Rating | IP20 (Indoor), IP67 (Outdoor Options) |

| Operating Temp. | -20°C to +50°C |

| Efficiency | ≥90% |

Ready to integrate certified, factory-direct power solutions into your projects?

Contact our technical team for specifications, compliance documentation, or custom engineering support.

Email: [email protected]

Phone: +86 139 0288 5704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).