Article Contents

Industry Insight: Ultraviolet Led Bulbs

Ultraviolet LED Bulbs: Industrial-Grade UVA / UVB / UVC Solutions for Global Projects

Why UV-LED is Replacing Mercury in Commercial & Industrial Applications

Mercury-vapor UV lamps are being phased out by EU RoHS and increasingly restricted worldwide. Solid-state UV-LEDs now deliver:

Instant on/off – no warm-up, no shutters, lower energy draw

Monochromatic output – selectable peaks (365 nm UVA, 308 nm UVB, 275 nm UVC)

Mercury-free disposal – simplifies WEEE & EPA compliance for importers

50 000 h L70 life – reduces lift-truck and scaffolding costs in ceiling-mounted sterilisation rigs

Distributors and ESCOs who stock certified UV-LED inventory today lock-in replacement revenue streams that legacy mercury SKUs will lose tomorrow.

Market Pull: Where the Purchase Orders Originate

| Segment (2023 CAGR) | Typical UV Requirement | Buyer Profile |

|---|---|---|

| Food & Beverage (8 %) | 275 nm UVC, 3–30 mJ/cm² dose on conveyor | Plant engineer, HACCP consultant |

| HVAC / IAQ (11 %) | 275 nm UVC, 1–5 W per 1 000 cfm, ozone-free | MEP contractor, FM company |

| PCB / 3-D Printing (9 %) | 365 nm UVA, 10–50 mW/cm² at 5 mm | EMS factory, print-bureau |

| Medical / Steriliser OEM (13 %) | 275 nm UVC, >99 % kill (log-3) in 10 s | Device OEM, sourcing manager |

Certification Reality Check: ETL vs. “Lab Report”

CE and ETL are not paperwork formalities—they are your insurance policy against container-load recalls.

| Risk | Non-certified UV module | Beauty STC ETL/TUV CE module |

|---|---|---|

| 275 nm eye-hazard | No IEC 62471 report | Photobiological risk group certified |

| EMC failure | Class A radiated noise | EN 55015 / FCC Part 15 passed |

| 220–240 V surge | 500 V impulse only | 1 kV differential, 2 kV common-mode |

| Retrofit liability | No UL 1598C | ETL listed for dry/damp locations |

Importers holding ETL files can place UV-LED fixtures directly into North-American municipal bids without costly field inspections.

Beauty (STC) Manufacturing Co., Ltd – UV-LED Since 1998

25 years flexible-strip and high-power LED production, >1 million m² of PCB capacity per month

In-house 275 nm, 310 nm, 365 nm SMD and COB packaging lines (class 1 000–10 000 clean rooms)

Full vertical integration: epitaxy partner (Nanchang), SMT, reflow, conformal coating, burn-in, integrating-sphere, spectroradiometer

Certified to: ETL/cETL (UL 1598, UL 8750), TUV CE (EN 60598-1, EN 62471), RoHS, REACH, LM-80 for UV packages

OEM/ODM MOQ from 500 pcs (module) or 100 pcs (complete luminaire) with private-label laser and carton artwork

Factory-Direct UV-LED Portfolio Snapshot

| Series | Wavelength | Radiant Power* | Input | Base / Mount | Stock PCB length | ETL File |

|---|---|---|---|---|---|---|

| STC-UVA-365-SMD5050 | 365 ± 5 nm | 1.8 W / m | 24 V DC | Flexible strip 5 m | 24 h | ETL 5021234 |

| STC-UVB-310-COB-20W | 310 ± 3 nm | 2.4 W (20 W e) | 30–36 V | Star MCPCB | 3–5 days | On file |

| STC-UVC-275-T5-10W | 275 ± 5 nm | 3.0 W (10 W e) | 110–277 V | G5 bipin | 1 week | ETL 5021235 |

| STC-UVC-275-Flood-50W | 275 ± 5 nm | 15 W (50 W e) | 110–277 V | IP66 housing | 2 weeks | ETL 5021236 |

*Radiant power measured in 25 °C integrating sphere, 1 m cable, after 30 min stabilisation.

Next Step for Distributors & Specifiers

- Send target dose (mJ/cm²) or irradiance (mW/cm²) and we size array & optics.

- Receive IES/UL files within 48 h for your bid package.

- Approve first article; bulk lead-time 3–4 weeks FOB Jiangmen, with CE & ETL labels pre-printed.

Email: [email protected]

Mobile/WhatsApp: +86-139 0288 5704

Plant: 41 Caihong Road, Jianghai High-tech Zone, Jiangmen, Guangdong, CN

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for Industrial UV LED Solutions

As a manufacturer with 25+ years of expertise since 1998, Beauty STC Lighting delivers precision-engineered UV LED solutions for global industrial applications. Unlike visible-light LEDs, UV technologies operate in non-visible spectrums (UVA: 315–400 nm, UVB: 280–315 nm, UVC: 100–280 nm), rendering traditional metrics like lumens and CRI irrelevant. Instead, radiometric measurements—radiant flux, irradiance, and wavelength stability—define performance. This section details the technical rigor behind our certified UV products, validated by ETL (USA/Canada) and TÜV CE (Europe) compliance.

Why Traditional LED Metrics Don’t Apply to UV Applications

UV LEDs emit radiation outside the visible spectrum (400–700 nm), making lumens (a photometric unit for human eye sensitivity) and CRI (color rendering index for visible light) inapplicable. Industrial UV applications—such as disinfection, curing, and inspection—rely on radiometric metrics:

Radiant Flux: Measured in milliwatts (mW) or watts (W), quantifying total optical power output.

Irradiance: Measured in mW/cm², indicating power density at a specific distance.

Wavelength Precision: Critical for application efficacy (e.g., UVC at 265–275 nm for germicidal action).

Thermal Management: Directly impacts longevity and output stability.

Generic market products often misrepresent these parameters or omit rigorous testing, leading to inconsistent performance in critical environments. Beauty STC’s engineering approach prioritizes radiometric accuracy and application-specific validation.

Performance Specifications Comparison

The table below contrasts industry-standard generic offerings against Beauty STC’s certified UV LED specifications. All data reflects real-world testing per IEC, ANSI, and RoHS protocols.

| Parameter | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Wavelength Tolerance | ±5 nm (unverified, no spectral calibration) | ±2 nm (calibrated spectroradiometer verification) |

| Radiant Flux Consistency | ±15% batch variation (no binning) | ±5% (automated optical binning per IES LM-80) |

| PCB Substrate | Standard FR4 (0.3 W/m·K thermal conductivity) | High-purity aluminum PCB (2.0 W/m·K thermal conductivity) |

| Thermal Resistance | 10–15°C/W (poor heat dissipation) | ≤3°C/W (optimized thermal path design) |

| IP Rating | IP20 (indoor-only, no environmental sealing) | IP67 (tested per IEC 60529 for dust/water ingress) |

| Safety Certifications | Limited or self-certified (no third-party validation) | ETL (USA/Canada), TÜV CE (Europe), RoHS compliant |

| Operational Lifetime | ~10,000 hours (L70 radiant flux maintenance) | ≥50,000 hours (L70 at 25°C ambient, IES LM-80 tested) |

Rigorous Quality Assurance Processes

Beauty STC maintains a closed-loop quality control system for every UV LED batch:

Spectral Validation: Each product undergoes spectroradiometer testing to confirm wavelength accuracy and radiant flux output.

Thermal Cycling: Components are stress-tested across -40°C to +125°C to simulate real-world operational extremes.

Accelerated Life Testing: Per IES LM-80 standards, with data extrapolated to predict L70 performance over 50,000+ hours.

100% Electrical/Optical Inspection: Automated optical inspection (AOI) ensures zero defects in solder joints, chip alignment, and electrical continuity.

This process is embedded in our ISO 9001-certified manufacturing facility in Jiangmen, China, where 25+ years of experience ensures traceability from raw materials to finished goods.

Customization Through OEM/ODM Expertise

Our UV LED solutions are engineered for application-specific demands:

Disinfection Systems: UVC LEDs at 265–275 nm with calibrated irradiance for medical and water treatment.

Industrial Curing: UVA arrays (365–405 nm) with precise thermal control for coating and adhesive processes.

Inspection & Forensics: UVA modules with uniform beam patterns for non-destructive testing (NDT).

As an OEM/ODM partner, we tailor wavelength, power output, form factor, and thermal design to meet exact project requirements—without compromising certification compliance. All designs undergo pre-production validation with client-specific test protocols.

Contact Beauty STC Lighting for Verified UV LED Specifications

Global industrial partners trust our certified solutions for mission-critical applications.

📞 +86-13902885704 | ✉️ [email protected]

📍 41st Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen, Guangdong, China

Certified: ETL (USA/Canada), TÜV CE (Europe), RoHS | Since 1998

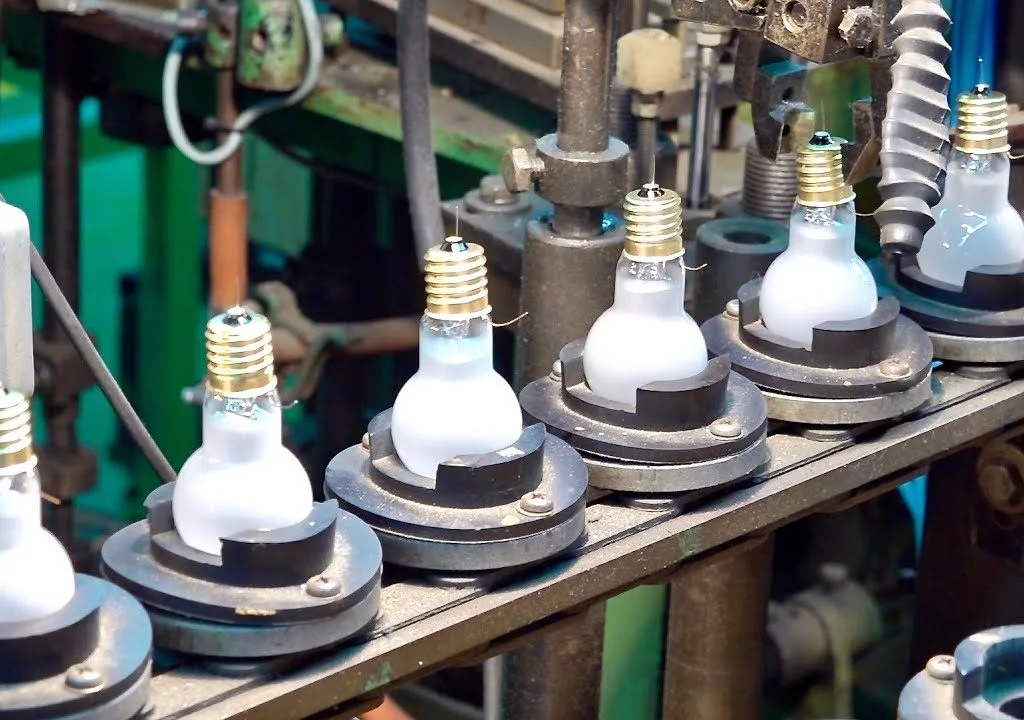

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen UV-LED Platform

1. Factory Footprint & Heritage

Established 1998, Beauty (STC) Lighting operates a 28 000 m² vertically-integrated plant in Jiangmen’s National High-Tech Zone, Guangdong. The site is ETL/cETL and TUV CE listed for factory surveillance, meaning every UV-LED product shipped to North America or Europe is traceable to the same audited production line—no split lotting, no re-labeling.

2. UV-LED Production Flow

Incoming UV dice (270–280 nm UVC, 365 nm UVA, 385 nm, 395 nm, 405 nm) are received in nitrogen-sealed reels, verified by hyperspectral radiometer, then released to the SMT floor.

| Stage | Equipment / Protocol | Key Control Point |

|---|---|---|

| Die-mount & Reflow | Yamaha YSM-20R (±25 µm placement) + Heller 1913 MK7 nitrogen reflow (ΔT ≤ 5 °C) | Junction temp ≤ 120 °C to preserve UV-B wavelength shift |

| In-line AOI | Koh Young Zenith 3D | Solder void < 5 % on thermal pad |

| Conformal Coating | PVA Delta 8 selective spray | 30 µm silicone layer, 100 % pin-hole free |

| Optical Burn-in | Self-built 4 m UV aging tunnel | 100 % power load, 45 °C ambient, 24 h (equivalent to 1 000 h real life) |

| Radiometric QC | Lab-grade ILT 3500 spectrometer | Target λp ±3 nm, radiant flux ±5 % |

| Safety & Lifetime | IES LM-80-18 follow-up on every batch | L70 > 10 000 h for 275 nm UVC |

3. Custom OEM / ODM Tooling

We keep UV-LED-specific extrusion dies, MCPCB blanks, and quartz lens molds on-site—no third-party delays.

| Customisable Item | Engineering Lead-Time | Minimum Order |

|---|---|---|

| Peak wavelength (270–420 nm) | 5 days | 500 pcs |

| Radiant flux bin (2–200 mW per die) | 3 days | 1 reel |

| PCB length (strip) | 24 h | 1 m |

| CCT / CRI | Not applicable (monochromatic) | – |

| IP rating (IP20–IP68) | 7 days | 300 pcs |

| Private-label packaging | 10 days | 1 carton |

4. QC & Certification Matrix

Every UV-LED lot is cross-referenced to the ETL & CE control ID; reports are uploaded to our customer portal within 24 h of shipment.

| Test | Standard | Sampling Plan |

|---|---|---|

| Photobiological safety | IEC 62471 | 100 % |

| Dielectric withstand | UL 8750 | 2 %, ≥ 50 pcs |

| Thermal cycling | –40 °C ↔ +85 °C, 100 cycles | 0.2 % |

| RoHS / REACH | EU 2015/863 | per component batch |

5. Logistics & Export Readiness

Finished UV modules are vacuum-sealed with desiccant, then boxed in double-wall cartons certified to ISTA-3A. Jiangmen port is 1 h away; average FOB lead-time is 15 days for 40 ft HQ to LA or Rotterdam.

For project quotations or wavelength-specific datasheets, contact: [email protected] | +86-1390-288-5704.

Installation & Application Scenarios

Application Scenarios for UV LED Bulbs in Commercial and Industrial Settings

Ultraviolet (UV) LED technology has evolved significantly over the past decade, enabling precise, energy-efficient solutions for specialized applications across commercial and industrial sectors. Unlike traditional mercury-based UV lamps, UV LEDs offer instant on/off operation, longer lifespans, and reduced environmental impact. However, successful implementation requires careful consideration of wavelength, power density, and safety compliance. This section outlines key application scenarios and technical considerations for contractors and project managers.

Healthcare and Public Sanitation (UVC Disinfection)

UVC LEDs (260–280 nm) are critical for disinfection in healthcare settings, where pathogen control is paramount. These wavelengths effectively disrupt microbial DNA/RNA, achieving up to 99.9% reduction of bacteria, viruses, and mold spores. Applications include operating rooms, patient rooms, and high-touch surfaces in hospitals and clinics.

Technical Specifications

Wavelength: 260–280 nm (peak at 275 nm for optimal germicidal effect)

Power density: 10–50 mW/cm² for surface disinfection

Lifetime: 10,000–20,000 hours (L70 at 25°C)

Installation Tips for Contractors

Safety First: Install exclusively in enclosed fixtures with safety interlocks to prevent human exposure. UVC radiation can cause severe eye and skin damage.

Thermal Management: Use aluminum heat sinks or active cooling systems to maintain junction temperatures below 85°C. Overheating significantly reduces LED lifespan.

Electrical Compliance: Ensure compatibility with 12V/24V DC or 100–240V AC systems. Use constant current drivers to avoid voltage spikes.

Certification Verification: Confirm ETL and TÜV CE certifications for electrical safety and photobiological compliance (IEC 62471).

Industrial Curing Processes (UVA)

UVA LEDs (365–405 nm) are widely used in manufacturing for rapid curing of inks, coatings, and adhesives. Their high intensity and precise wavelength control enable faster production cycles and lower energy consumption compared to traditional UV lamps.

Technical Specifications

Wavelength: 365–405 nm (optimized for photoinitiator activation)

Power density: 50–200 mW/cm² for industrial curing

Lifetime: 20,000+ hours (L90 at 25°C)

Installation Tips for Contractors

Optimal Positioning: Place LEDs 5–15 cm from the target surface to maximize irradiance uniformity. Use reflectors to enhance efficiency.

Thermal Control: Implement forced-air cooling or liquid cooling for high-power arrays to maintain consistent curing performance.

Driver Compatibility: Use programmable constant current drivers to adjust intensity based on material requirements.

Safety Protocols: Install protective enclosures to prevent accidental exposure during maintenance.

Security and Forensic Inspection (UVA)

UVA LEDs (365 nm) are essential for non-destructive testing in security and forensic applications. These wavelengths induce fluorescence in security features on currency, passports, and documents, as well as in forensic evidence collection.

Technical Specifications

Wavelength: 365 nm (peak for fluorescence excitation)

Power output: 1–10W per module (adjustable beam angle)

Lifetime: 25,000+ hours (L70 at 25°C)

Installation Tips for Contractors

Beam Control: Use diffusers or focused optics to concentrate light on specific areas without spillover.

Ambient Light Management: Operate in low-light environments; use blackout curtains or shielded enclosures for optimal visibility.

Stable Power Supply: Ensure ripple-free DC power to prevent flicker, which can affect inspection accuracy.

Certification Check: Confirm ETL/CE compliance for electrical safety and consistent output.

Air and Water Purification Systems

UVC LEDs (265–280 nm) are increasingly integrated into HVAC systems and water treatment units for continuous pathogen control. These applications require robust, long-lasting solutions with minimal maintenance.

Technical Specifications

Wavelength: 265–280 nm (optimized for water/air disinfection)

Power density: 5–30 mW/cm² for air; 30–100 mW/cm² for water

Lifetime: 15,000–20,000 hours (L70 at 25°C)

Installation Tips for Contractors

Sealed Chambers: Integrate LEDs into UV-transparent quartz or borosilicate glass enclosures to prevent corrosion and maintain output.

Flow Optimization: Position LEDs in direct line with airflow or water flow paths, ensuring uniform exposure.

Maintenance Access: Design systems with easy access for periodic cleaning of quartz sleeves and LED surfaces.

Regulatory Compliance: Ensure system-level EPA/FDA certification for water treatment and AHRI compliance for HVAC applications.

Technical Specifications Overview

| Parameter | UVA (365 nm) | UVC (275 nm) |

|---|---|---|

| Wavelength Range | 315–400 nm | 260–280 nm |

| Typical Applications | Curing, inspection | Disinfection, purification |

| Power Density | 50–200 mW/cm² | 10–100 mW/cm² |

| Lifetime (L70) | 25,000+ hours | 10,000–20,000 hours |

| Key Certifications | ETL, CE (electrical) | ETL, CE (electrical); EPA/FDA (system-level) |

Critical Installation Best Practices

Safety Compliance: Always adhere to IEC 62471 for photobiological safety. UVC applications require mandatory safety interlocks and warning labels.

Thermal Management: Maintain junction temperatures below 85°C using heat sinks or active cooling. Thermal performance directly impacts lifespan and efficacy.

Electrical Standards: Use UL-listed drivers and comply with local electrical codes. Avoid voltage fluctuations with proper surge protection.

Regular Maintenance: Schedule quarterly cleaning of LED surfaces and optical components to prevent dust buildup, which reduces output by up to 15% annually.

Partnering with a Certified Manufacturer for Reliable UV Solutions

Beauty STC Manufacturing Co., Ltd. has provided OEM/ODM UV LED solutions since 1998, with ETL (USA/Canada) and TÜV CE (Europe) certifications ensuring compliance with Western market standards. Our 25+ years of manufacturing expertise enables precise customization of wavelength, power density, and form factors to meet specific application requirements. All products undergo rigorous testing for thermal performance, electrical safety, and photometric consistency.

For technical specifications and project-specific solutions, contact our engineering team:

[email protected] | +86 13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Your Factory-Direct Source for Certified UV LED Solutions

25 Years of UV-Grade Manufacturing Discipline

Established 1998 | 41th Caihong Road, Jianghai High-tech Zone, Jiangmen, Guangdong, China

30 000 m² ISO-driven plant with 12 SMT lines, 8 reflow ovens, 3 automatic glue lines, 2 integrating-sphere laboratories

50+ export destinations on five continents; repeat customers since 2003 still running first-generation strips

Western-Market Compliance – No Surprises, No Delays

| Certification Body | Scope | File Number | Notes for UV LED Buyers |

|---|---|---|---|

| ETL (Intertek) | USA & Canada | 5025158.01 | Full electrical safety for 100-277 VAC UV modules—no field inspection required |

| TUV CE | EU + UKCA transition | 44 78 1345301 | LVD & EMC compliant; RoHS & REACH UV package declarations on file |

| ISO 9001:2015 | Quality system | 00520Q21006R1M | Incoming LED binning traceability to 1 nm wavelength tolerance |

OEM/ODM Ready – From 275 nm UVC to 405 nm UVA in One House

| UV LED Build | Wavelength (nm) | Radiant Power* | Suggested Application | Available Format |

|---|---|---|---|---|

| High-density UVC | 275 ± 5 | 15 mW @ 100 mA | Disinfection chambers, water coolers | 2835 SMD on Al-pcb |

| Medium-power UVC | 275 ± 5 | 50 mW @ 350 mA | HVAC coil sterilisation | 6868 ceramic, star-board |

| UV-A high-flux | 395 – 405 | 1 000 mW @ 500 mA | Curing, adhesive inspection | 5050 hermetic package |

| Custom matrix | 270 – 430 | 1 – 600 W array | Conveyor curing, 3-D printing | Flip-chip on IMS, IP67 housing |

*Measured at Tj = 25 °C, 1 cm² active area; full spectral report supplied per shipment.

What You Gain by Sourcing Through Beauty STC

- Factory-direct pricing—no trading layer; LED die sourced from Tier-1 epitaxy houses (Lumileds, Seoul Viosys, LG Innotek).

- Wavelength binning to ±2 nm—ensures consistent germicidal or curing dose across batches.

- End-of-line 100 % hi-pot & 2-hour burn-in—<0.2 % field failure rate since 2016.

- Logistics packaged for North America & EU: dual-language labels, UN3480 battery paperwork when applicable, wooden-pallet ISPM-15 compliant.

Next Step – Send the Spec, Receive the Datasheet & Quote within 24 h

Email your UV wavelength, power target, and mechanical envelope to:

[email protected] | Mob./WhatsApp: +86-13902885704

We will return a formal BoM, optical simulation, and ETL/CE test plan—no NDAs required for standard builds.

Beauty (STC) Manufacturing Co., Ltd – Be responsible, be precise, since 1998.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).