Article Contents

Industry Insight: Strip Light Adapter

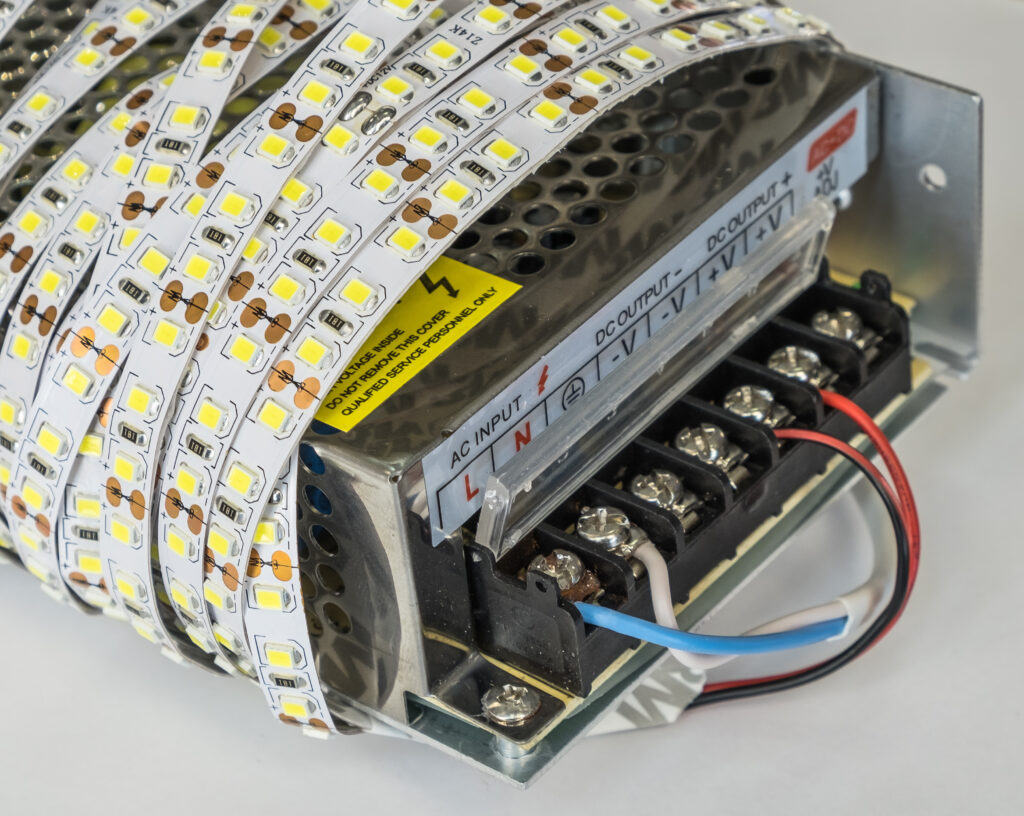

Introduction – The Over-Looked Link in Every LED Strip Installation

Why the Adapter is No Longer an Accessory

In commercial and industrial projects, the LED strip is only half of the system; the adapter is the half that keeps warranties, schedules, and safety ratings intact. A 24 V, 150 W plug-in driver that fails in a Miami hotel retrofit can cost a contractor more in call-backs than the entire lighting package. For European distributors, a non-CE-marked unit can trigger border seizures worth tens of thousands of Euros.

| Key Risk Driver | Consequence for Importer | Mitigation |

|---|---|---|

| No certified safety mark | Local code rejection, liability claim | ETL/cETL or TUV-CE file number on label |

| 10 % voltage tolerance only | Flicker, shortened strip life | 100–240 V universal input, ±5 % regulation |

| Missing current-limiting | Over-drive, color shift, fire hazard | Constant-voltage + overload latch-off |

| Random connector pitch | Field splicing, labor overrun | Factory-terminated 2.1 mm, 2.5 mm, SM, JST or Molex |

Market Demand Snapshot (2023–2026)

| Segment | YoY Growth | Adapter Spec Trend |

|---|---|---|

| Architectural façade | 11 % | IP67, 24 V, PWM synchronized |

| Cold-chain warehousing | 9 % | −30 °C start-up, 90 % efficiency |

| Retail display (EU) | 8 % | ERP Tier-2, <0.2 W no-load |

| Modular office (US) | 10 % | Class 2, 5-year / 50 000 h warranty |

Quality adapters are not a commodity; they are the component that determines whether an LED strip meets the 50 000 h L70 figure printed on the box.

Beauty (STC) Manufacturing Co., Ltd – Factory Profile

| Parameter | Data |

|---|---|

| Founded | 1998, Jiangmen, Guangdong |

| Production footprint | 18 000 m² in National High-Tech Zone |

| Core lines | Flexible LED strip, Panel, Flood, UFO high-bay, T8/T5, and matched adapters / drivers |

| Certifications held | ETL/cETL (US & Canada), TUV CE, CB, ERP, RoHS, REACH |

| Export reach | 50+ countries, 800+ OEM SKUs in active circulation |

| Engineering staff | 42 R&D engineers, 6 safety-certification specialists |

What 25 Years of Adapter Building Teaches

-

Certification First, Not Afterward

Every new adapter project starts with UL 8750 + UL 1310 or EN 61347-2-13 test plates. We maintain our own 300 m² in-house lab (Hi-pot, 8 kV surge, −40 °C chamber) so third-party data is repeatable when the NCB inspector visits. -

Connector Integrity

Injection-molded housings use V-0 polycarbonate, 30 % glass-filled, rated 125 °C. Pin plating is 3 µm gold over 50 µm nickel to survive 500 mating cycles—critical for RGBW projects that are disassembled for seasonal exhibits. -

OEM/ODM Ready

From 6 W plug-in to 300 W IP67 metal-case, we private-label for brands that must meet Buy-America or European origin rules. MOQ for custom label is 500 pcs; for modified output cable or connector, 1 000 pcs.

Typical Adapter Portfolio (Factory-Direct)

| Model | Output | Input | Safety Mark | IP | Warranty | OEM MOQ |

|---|---|---|---|---|---|---|

| BSTC-PS-12V60W | 12 V, 5 A | 100-240 V | ETL/cETL, CE | IP20 | 5 year | 500 |

| BSTC-PS-24V150W | 24 V, 6.25 A | 100-277 V | ETL/cETL, TUV CE | IP67 | 5 year | 300 |

| BSTC-PS-24V300W-F | 24 V, 12.5 A | 100-277 V | UL, FCC, TUV CE | IP67 | 5 year | 200 |

| BSTC-RGBW-4P-10 | 24 V, 4 A (×4) | 100-240 V | CE, RoHS | IP44 | 3 year | 1 000 |

All units support PWM dimming, comply with ERP Tier-2 no-load <0.15 W, and carry isolated Class 2 outputs for North American code compliance.

Next Step – Engineering Samples & Certification Files

Global distributors, contractors, and specifiers can request datasheet packages including UL file numbers, ISTMT, TM-21, and connector drawings. Pilot lots ship from our Jiangmen headquarters within 10 working days; larger programs can leverage our bonded warehouse in Rotterdam or Los Angeles for 3-day landed cost quotes.

Contact:

[email protected] | +86-139-0288-5704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for LED Strip Power Adapters

Clarifying Key Technical Parameters

It is critical to distinguish between specifications for LED strips and their power adapters (drivers). While lumens per watt (lm/W) and Color Rendering Index (CRI) are performance metrics for LED strips themselves, power adapters operate under entirely different technical parameters. These include electrical stability, thermal management, and environmental resilience. At Beauty STC, we ensure both LED strips and their compatible power adapters meet rigorous global standards. This section details the critical specifications for power adapters, ensuring system-wide reliability and performance.

Core Technical Specifications for Power Adapters

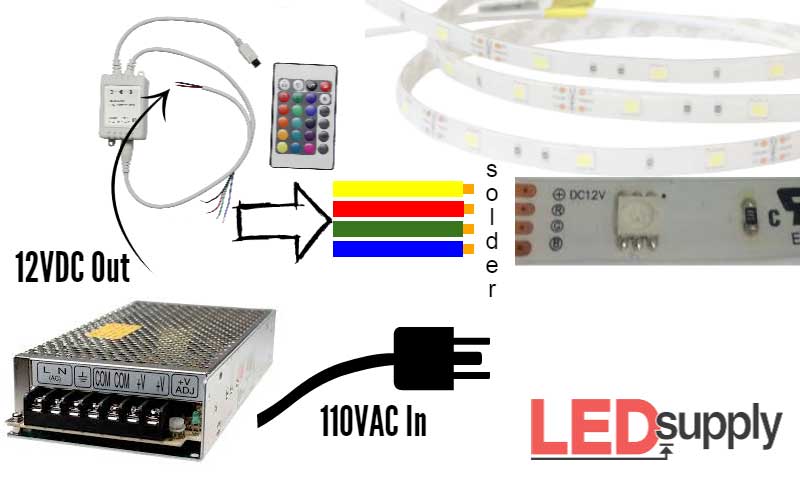

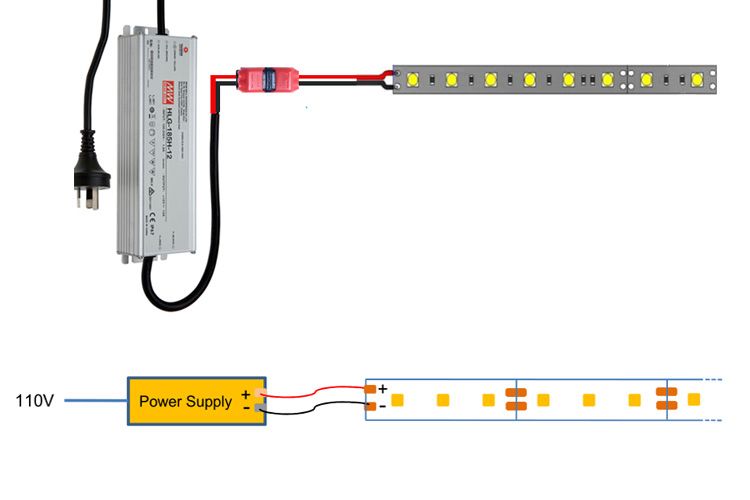

Input/Output Parameters

Input Voltage Range: 100–240V AC (global compatibility)

Output Voltage: Precise 12V/24V DC with ±1% tolerance

Current Capacity: Scalable from 2A to 30A per unit, with overcurrent protection (OCP) at 110% rated load

Efficiency and Power Factor

Efficiency: ≥85% (DOE Level VI compliant), minimizing energy waste and heat generation

Power Factor: ≥0.9 (active PFC circuitry), ensuring compliance with international grid standards

Ripple and Noise

Ripple Voltage: ≤50mV peak-to-peak (tested at full load), critical for preventing flicker and extending LED lifespan

Noise Suppression: EMI/RFI shielding to meet FCC Class B limits

IP Ratings

Indoor (IP20): Basic dust protection for dry environments

Outdoor (IP65/IP67): Dust-tight and water-resistant (15-minute submersion for IP67), certified by TÜV Rheinland

PCB Quality and Component Selection

Base Material: High-Tg FR-4 (150°C+) for thermal stability

Components: Japanese Nichicon capacitors, AOS MOSFETs, and UL-listed transformers

Thermal Design: Copper-clad PCBs with heat-sink integration for 10,000+ hour operational life

Rigorous Quality Assurance Process

Beauty STC’s 25+ years of manufacturing expertise are embedded in every adapter. All units undergo:

In-House Testing: Thermal cycling (-40°C to +85°C), 100% burn-in at 110% load, and 24-hour endurance tests

Certification Compliance: ETL (USA/Canada) and TÜV CE (Europe) certifications verified by third-party labs

Traceability: Batch-level documentation with component sourcing records for full supply chain transparency

Comparative Analysis: Generic Market Quality vs. Beauty STC Certified Quality

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Efficiency | 75–80% (no DOE compliance) | ≥85% (DOE Level VI certified) |

| Ripple Voltage | >100mV (causes visible flicker) | ≤50mV (tested at full load per IEC 61000-3-2) |

| PCB Components | Generic capacitors, low-grade FR-4 | Japanese Nichicon capacitors, high-temp FR-4, UL-listed |

| IP Rating | IP20 only (unverified claims) | IP20/IP65/IP67 (TÜV-certified testing reports) |

| Certifications | Often incomplete or self-declared | Full ETL (USA/Canada), TÜV CE (Europe) compliance |

| Thermal Management | Minimal heatsinking, 5,000-hour lifespan | Copper-clad PCBs, 10,000+ hour operational life |

OEM/ODM Capabilities for Custom Solutions

Beauty STC leverages its 1998-established manufacturing foundation to deliver fully customizable power adapters:

Design Flexibility: Tailored voltage/current outputs, form factors, and connector types (e.g., 4-pin 10mm female for RGB strips)

Certification Support: Pre-certified designs for ETL/CE markets, reducing time-to-market for global projects

Quality Consistency: ISO 9001-aligned production with 100% automated optical inspection (AOI) for PCB assembly

“Our adapters are engineered to eliminate system-level failures—whether for a high-end architectural project in Berlin or a commercial installation in Tokyo. Certifications like ETL and TÜV CE aren’t checkboxes; they’re the baseline for every unit shipped.”

— Beauty STC Engineering Team

For project-specific technical documentation or custom adapter requirements, contact:

[email protected] | +86 13902885704

Factory Tour: Manufacturing Excellence

Strip-Light Adapter Manufacturing & OEM Capabilities – Jiangmen Plant

Factory Overview

Established 1998 | 25 000 m² campus | 600+ employees | ISO 9001 & ISO 14001 | ETL & TÜV CE data on file with Jiangmen CIQ

SMT → Wave → Assembly → Burn-in → QC → Pack

| Stage | Key Equipment | Process Control | Traceability |

|---|---|---|---|

| SMT | JUKI FX-3R ×6 lines | 0.05 mm placement, 3-D SPI, AOI | Bar-coded PCB |

| Wave & Selective | Nitrogen wave solder, Pillarhouse Jade MK-II | 260 °C ±3 °C, RoHS alloy SAC305 | SPC chart |

| Assembly | 4-pin, 5.5 mm DC-jack, SM connector semi-auto press | Crimp force 30 N ±2 N | IPQC 2 h patrol |

| Aging | 4 h @ 45 °C full load, 1 h ON/OFF cycle | <0.3 % failure threshold | Burn-in log |

| QC | Chroma 8000 (ATE), Hipot 3 kV, Earth bond 25 A | AQL 0.25 / Level II | 7-year record |

OEM / ODM Adapter Menu

| Parameter | Standard Range | Custom Option | MOQ | Lead-Time |

|---|---|---|---|---|

| Output | 12 V / 24 V; 12 W – 60 W | 5 V – 36 V; 120 W max | 500 pcs | 3 weeks |

| Cable Length | 1.5 m, 18 AWG | 0.15 – 3 m, 16-24 AWG | 1 000 pcs | 2 weeks |

| Connector | 5.5 × 2.1 mm, SM 2-pin, 4-pin RGB | Mini-micro, IP68, quick-lock | 1 000 pcs | 3 weeks |

| CCT Label | 3000 K / 4000 K / 6000 K | Any CCT 1800 – 9000 K | 500 pcs | 1 week |

| Housing Colour | Matte white / black | RAL palette | 2 000 pcs | 2 weeks |

| Packaging | Kraft box + manual | Retail blister, Euro slot, private label | 1 000 pcs | 1 week |

All SKUs carry ETL/cETL (UL 2089) & TÜV CE (EN 61347-2-13) files; certificates reference Jiangmen facility registration No. QI-ETL-041998.

Reliability & Compliance Snapshot

| Test | Standard | Pass Criteria | In-House Lab |

|---|---|---|---|

| MTBF | MIL-HDBK-217F | >50 000 h @ 25 °C | ✓ |

| Surge | IEC 61000-4-5 | 1 kV L-N | ✓ |

| Thermal | IEC 60598-1 | ΔT < 35 K @ 40 °C Ta | ✓ |

| Burn-in | Internal | 4 h full load, 45 °C | ✓ |

Next Step for Specifiers

Send wiring diagram, target length, and plug type to [email protected]. CAD drawing returned within 24 h with BoM & EXW Jiangmen pricing.

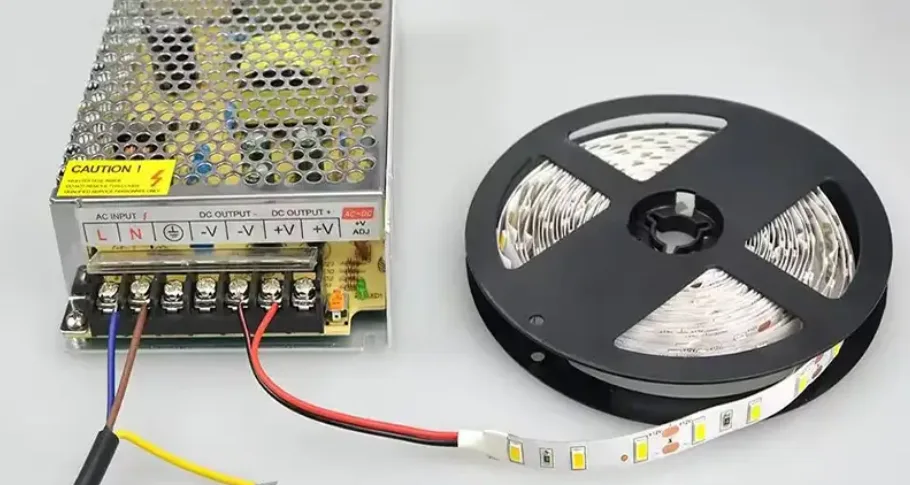

Installation & Application Scenarios

Strategic Application Scenarios for Strip Light Adapters

Selecting the appropriate strip light adapter is critical for ensuring reliable performance, safety compliance, and longevity in commercial lighting installations. Beauty STC Lighting, established in 1998 and certified to ETL (USA/Canada) and TUV CE (Europe) standards, provides industrial-grade adapters engineered for diverse applications. Our 25+ years of manufacturing expertise and OEM/ODM capabilities ensure solutions meet rigorous global market requirements. This section outlines key use cases and contractor-focused installation best practices.

Hotels & Hospitality

Hotels and hospitality venues require versatile lighting solutions that support dynamic ambiance control while maintaining reliability across 24/7 operations. Adapters must deliver consistent dimming performance, low flicker, and thermal stability to ensure guest comfort and safety.

Installation Best Practices:

For long runs exceeding 5 meters, utilize 24V DC systems with 18–20AWG wiring to minimize voltage drop.

In wet areas (e.g., bathrooms, pool decks), specify IP65-rated connectors and seal all junctions with silicone compound.

Use drivers with active Power Factor Correction (PFC) to comply with EU energy regulations (EN 55015) and reduce harmonic distortion.

Commercial Retail & Shopping Malls

Retail environments demand high CRI (≥90) for accurate product color rendering and rapid installation for frequent display updates. Adapters must support modular connectivity and stable output under variable load conditions.

Installation Best Practices:

Employ plug-and-play SM connectors (e.g., 2-conductor male SM) for display lighting to enable tool-free replacement.

Verify adapter current ratings exceed total strip load by 20% (e.g., 10A driver for 8A strip load) to prevent thermal stress.

In food retail zones, ensure components meet NSF/ANSI Standard 2 for hygiene compliance.

Office & Corporate Environments

Office spaces prioritize visual comfort with consistent color temperature (3500K–4000K) and flicker-free operation to reduce eye strain. Adapters must support dimming for task lighting flexibility while maintaining efficiency.

Installation Best Practices:

For cove lighting installations exceeding 10 meters, use 24V strips with 12–14AWG wiring to maintain voltage integrity.

Mount drivers in ventilated enclosures with ≥5cm clearance for thermal management.

Specify 0-10V or DALI-compatible drivers for seamless integration with building management systems (BMS).

Architectural Facades & Exterior Applications

Exterior installations require adapters with robust environmental protection to withstand UV exposure, moisture, and temperature extremes. IP67 or higher ratings are non-negotiable for long-term reliability.

Installation Best Practices:

Use silicone-sealed 4-pin female connectors (e.g., 10mm pitch) for RGB strips to prevent moisture ingress at connection points.

Install adapters within NEMA 4X-rated enclosures for outdoor use, with grounding via 6AWG copper wire.

Derate current capacity by 25% in high-ambient-temperature environments (e.g., >40°C) to ensure thermal safety margins.

Technical Specifications & Compliance

Beauty STC Lighting’s adapters undergo rigorous in-house testing per ISO 9001 standards. All products comply with Western market regulations and support OEM customization for voltage, current, IP ratings, and dimming protocols.

| Adapter Type | Voltage | Current Rating | IP Rating | Key Features | Certifications |

|---|---|---|---|---|---|

| Standard Plug-in Driver | 12V/24V DC | 5A–10A | IP20 | PWM dimming, active PFC, low-noise operation | ETL (UL 1310), CE (EN 61347) |

| Waterproof Driver | 12V/24V DC | 10A–20A | IP67 | Silicone encapsulation, UV-resistant housing | ETL Outdoor, TUV CE (EN 60598-1) |

| RGB Controller Adapter | 12V/24V DC | 3.5A–5A | IP65 | 4-pin 10mm female connector, multi-channel | ETL, TUV CE (EN 60598-2-22) |

| High-Power Driver | 24V DC | 15A+ | IP65 | Overload protection, thermal shutdown | ETL, TUV CE (EN 61000-6-3) |

All specifications are customizable via OEM/ODM services. Contact us for project-specific engineering support.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Strip-Light Adapter Supply You Can Specify with Confidence

Factory-Certified for North America & Europe

| Certification Scope | Standard | File No. | Application |

|---|---|---|---|

| Safety, 12 V & 24 V adapters | UL 2089 / CSA C22.2 No. 223 | ETL 5021777 | Plug-in & desktop models ≤ 60 W |

| EMC & LVD | EN 61347-1/-2-13, EN 55015 | TUV CE 44 78 8067301 | CE-marked strips & drivers |

All certificates are renewed annually; test data kept on file for 10 years to support your own project submittals.

25 Years of Strip-Light Hardware (Est. 1998)

4 OEM assembly lines dedicated to 12 V / 24 V adapters, connectors, and extension leads

Tooling shop in-house: new injection molds in 18 days, no MOQ surcharge for custom keying

100 % hi-pot, ground-bond, and full-load burn-in before shipment; Cpk ≥ 1.33 on DC plug fit

Global Logistics Footprint

| Region | In-Stock Warehouse | Typical L/T to Door | Duty Paid Option |

|---|---|---|---|

| USA West | Los Angeles | 7 days | Section 321 de-minimis ≤ 800 USD |

| EU North | Rotterdam | 9 days | Union Customs Code (T2L) |

| AU East | Sydney | 10 days | FTA CN-AU 0 % duty |

We currently ship to 50 + countries; last 12-month on-time delivery score = 97.4 %.

Ready to Specify?

Send your adapter schedule—voltage, current, plug type, cord length—to:

[email protected]

Tel / WhatsApp: +86-139 0288 5704

Engineering drawings returned within 24 h with FOB Jiangmen pricing and ETL/TUV CE data sheets attached.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).