Article Contents

Industry Insight: Led Strip Lights Waterproof Outdoor

Outdoor LED Strip Lights – Why IP65/IP67 and Third-Party Certification Are Now Non-Negotiable for Commercial Projects

From Accent to Infrastructure: The Shift in Outdoor Strip Demand

Over the last five years, outdoor LED strip lighting has migrated from purely decorative outlines to load-bearing elements in façade, hospitality, and public-realm lighting. Architects now specify 24 V or 48 V constant-voltage strips as continuous linear luminaires, expecting:

50 000 h L70 at 45 °C ambient

CRI ≥ 90 for human-centric colour checks

IP65/IP67 for permanent exposure to wind-driven rain, chlorinated splash, or high-pressure washing

Failure on any point triggers call-back costs that dwarf the purchase price, making certification and traceability the first filter in professional procurement—not the last.

Certification Risk Matrix for Importers

| Market | Mandatory Safety | Mandatory EMC | Common Insurance Clause | Typical Penalty if Non-Compliant |

|---|---|---|---|---|

| USA/Canada | ETL/cULus to UL 2108 | FCC Part 15 B | “Listed product” only | Full removal & re-installation at supplier expense |

| EU/UK | TUV/CE to EN 60598-2-21 | EN 55015/61547 | CE technical file on demand | Port seizure + 10 % container value fine |

| Australia | RCM (EESS) | RCM (ACMA) | 5-year warranty bond | Retrofit labour at AUD 120 per man-hour |

Key takeaway: A strip may be “waterproof” yet still illegal to energise if the driver, PCB, or cable is not certified as a complete system. Importers carry joint-and-several liability.

Beauty (STC) Manufacturing Co., Ltd – Factory Profile

| Founded | 1998 (26th year) |

|---|---|

| Plant | 41 Caihong Road, Jianghai High-tech Zone, Jiangmen, Guangdong. 18 000 m² SMT + extrusion + IP68 potting lines |

| Core Range | Flexible LED strip, LED panel, flood, UFO high-bay, T8/T5 linear |

| Export Footprint | 50+ countries; recurring OEM supply to 14 Fortune-500 lighting brands |

| Certifications | ETL/cETL (UL 2108), TUV CE (EN 60598-2-21), RoHS, REACH, ISO 9001:2015 |

| Engineering | 32 R&D staff, 6 LM-80 qualified SMD platforms, in-house 2 kV surge and −40 °C/105 °C thermal chamber |

How We Solve the “Waterproof vs. Certified” Gap

- Dual-Index IP Test – Every reel is batch-verified to IEC 60529 for IP65 (jet) and IP67 (immersion) before sleeving.

- UL-Recognised Assembly – PCB, adhesive, and 20 AWG feeder cable are pre-approved under UL file E469893, eliminating field inspection surprises.

- Closed-Loop Extrusion – PVC or PU jacket co-extruded over the PCB in Class-100 000 clean room; jacket wall thickness ≥ 1.2 mm for UV-B resistance per UL 746C f1.

- Traceability – Date-laser every 0.5 m; QR code links to LM-80, ISTMT, and TM-21 reports required by European Notified Bodies.

Specification Snapshot – Outdoor Workhorses (OEM/ODM Ready)

| Part Code | Voltage | LEDs/m | Power | CCT | CRI | Lumens/m | IP | Bending Ø | Cut Segment | Warranty |

|---|---|---|---|---|---|---|---|---|---|---|

| BSTC-24V-5050-60-IP65 | 24 V DC | 60 | 14.4 W | 2700–6500 K | Ra 90 | 1080 lm | IP65 | 60 mm | 100 mm | 5 yr |

| BSTC-24V-2835-120-IP67 | 24 V DC | 120 | 19.2 W | 3000 K | Ra 95 | 1400 lm | IP67 | 80 mm | 50 mm | 5 yr |

| BSTC-48V-2216-240-IP67 | 48 V DC | 240 | 28.8 W | 4000 K | Ra 90 | 2100 lm | IP67 | 100 mm | 62.5 mm | 5 yr |

Custom options: 12 V/36 V, constant current, RGBW, tunable white 1800–6500 K, DALI/0–10 V, -HT (–40 °C) grade, silicone extrusion for UV-B/ salt-spray environments.

Next Step – Engineering Sample or Project Pack

Send your lux calculation, length schedule, and control protocol to [email protected]; our engineers return a compliance dossier—including ETL/TUV certificates, LM-80, ISTMT, SD, and IES files—within 24 h.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for Outdoor LED Strip Lights

Outdoor LED strip lighting applications demand precise technical specifications to ensure reliability, safety, and performance in challenging environments. As a manufacturer with over 25 years of experience since 1998, Beauty STC Lighting adheres to international standards for all commercial-grade products. Our ETL (USA/Canada) and TUV CE (Europe) certifications validate compliance with North American and European safety requirements, while our OEM/ODM capabilities allow for tailored solutions that meet exact project specifications. The following technical benchmarks define our commitment to industrial-grade performance.

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Lumens per Watt | 80–100 lm/W; inconsistent output | 120+ lm/W; consistent performance |

| CRI (Ra) | 80–85; poor color fidelity | >90 with R9 >90 for accurate reds |

| IP Rating Certification | Unverified claims; no testing | Certified IP65/IP67 per TUV/ETL |

| PCB Construction | 0.5mm FR-4, 1oz copper; poor thermal management | 1.0mm+ FR-4, 2oz copper; optimized thermal dissipation |

Lumens per Watt and Energy Efficiency

Lumens per watt (lm/W) is a critical metric for outdoor lighting efficiency, directly impacting operational costs and system longevity. Generic market products often report inconsistent outputs between 80–100 lm/W due to substandard LED chips and poor thermal management. Beauty STC Lighting utilizes high-efficiency LED chips and optimized circuitry to consistently achieve 120+ lm/W across all production batches. This efficiency not only reduces energy consumption but also extends the operational lifespan of the product in demanding outdoor conditions, aligning with IEC 62717 standards for lumen maintenance.

Color Rendering Index (CRI) and Accuracy

Accurate color rendering is essential for outdoor applications where visual clarity and safety are paramount. While generic products typically offer CRI (Ra) values of 80–85, resulting in poor color fidelity, Beauty STC Lighting maintains CRI >90 with R9 >90 for true-to-life color reproduction. This is validated through third-party testing per IEC 62717 standards, ensuring consistent performance across all color temperatures and applications. High R9 values are particularly critical for commercial projects requiring accurate red spectrum representation, such as architectural accent lighting or signage.

IP Rating Certification and Real-World Performance

IP ratings for outdoor LED strips must be verified through certified testing to ensure real-world performance. Many generic products claim IP65 but lack proper certification, leading to failure in wet conditions. Beauty STC Lighting products undergo rigorous testing per IEC 60529, with each batch certified by TUV and ETL to meet exact IP65 and IP67 standards. This guarantees protection against water jets (IP65) and temporary immersion (IP67), critical for applications such as patio installations, concrete inlays, and submerged architectural features. All certified products include traceable test reports for compliance documentation.

PCB Construction and Thermal Management

The quality of the PCB directly affects thermal dissipation and product longevity. Generic manufacturers often use thin 0.5mm FR-4 PCBs with 1oz copper, leading to overheating and premature failure. Beauty STC Lighting employs 1.0mm+ FR-4 PCBs with 2oz copper plating, providing superior heat dissipation and mechanical stability. This design ensures stable operation even under continuous use in high-temperature environments, reducing the risk of solder joint failures and maintaining consistent light output. All PCBs are manufactured to IPC-A-600 Class 2 standards for reliability in industrial applications.

Quality Assurance Protocol

Consistency across all production batches is maintained through a multi-stage quality control process. Each batch undergoes thermal cycling tests (-20°C to 60°C), humidity exposure checks (95% RH), and lumen maintenance verification per IEC 62612 standards. All products are traceable via batch numbering, and third-party certifications (ETL, TUV CE) are validated through independent audits. This rigorous protocol ensures that every product meets the exact specifications required for global commercial projects, minimizing field failures and reducing lifecycle costs for end-users.

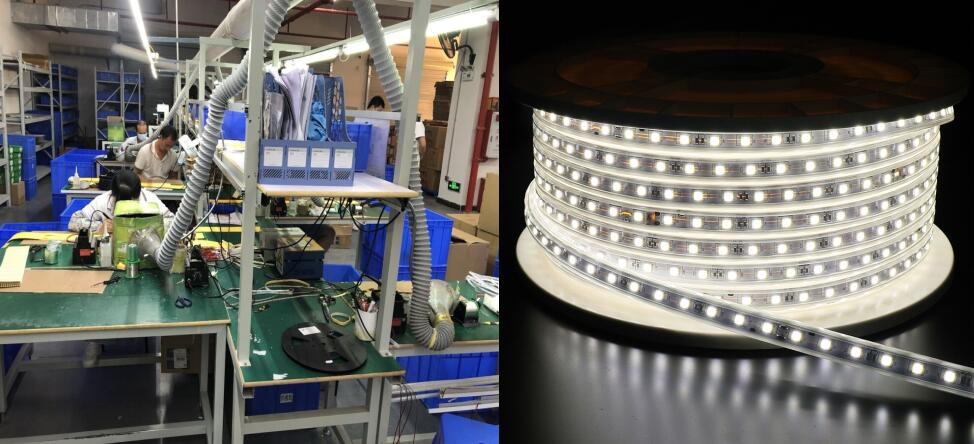

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

Beauty (STC) has operated from a single 28 000 m² campus in Jiangmen’s High-tech Industrial Zone since 1998. The entire vertical workflow—from bare PCB to IP68 finished roll—runs under one roof, enabling 7-day OEM sampling and 3-week FOB delivery for 40-ft HQ container lots.

1. SMT & Precision Assembly Line

| Stage | Equipment / Parameter | Key Control Point |

|---|---|---|

| PCB loading | Full-auto AGV feeding | ESD wrist-strap audit 100 % |

| Solder paste | DEK Horizon 03i, 0.1 mm stencil, SPI 3-D check | ≥ 90 % area, ≤ 10 % void |

| Pick-and-place | Juki FX-3R (×8 lines) 0402–3030 pkg | 30 µm @ 3 σ placement |

| Reflow | Vitronics Soltec 10-zone, lead-free | Profile logged every 4 h |

| AOI | KOH YOUNG 8030-2 | 100 % coverage; defects < 50 PPM |

| LED binning | Integrated sphere + CMS-3000 | 3 SDCM binning standard |

2. Waterproof Treatment Workflow

| Rating | Process Chain | Test Pressure | Pass Criterion |

|---|---|---|---|

| IP65 | PU glue, 1.2 mm thickness, 3-sided coating | 80 kPa, 30 s | No ingress |

| IP67 | Extruded silicone sleeve + dual-end RTV | 1 m water, 30 min | < 0.2 g weight gain |

| IP68 | PU potting + vacuum + silicone over-extrusion | 5 m water, 24 h | No bubble stream |

All outdoor reels are baked 2 h @ 60 °C prior to potting to eliminate trapped moisture.

3. Aging & Reliability Lab

Burn-in: 100 % of reels, 4 h @ 85 °C / 85 % RH, 220 VAC for 110 V strips, 24 VDC for low-voltage types.

Switch cycle: 30 s ON / 30 s OFF, 500 cycles.

Thermal shock: –20 °C ↔ +80 °C, 50 cycles (AEC-Q101 method).

Lumen maintenance: 6000 h on-going, TM-21 projection ≥ L70 50 000 h for 2835 mid-power, ≥ L90 36 000 h for 5050 high-power.

4. QC & Traceability Protocol

| Checkpoint | Tool | Record | Retention |

|---|---|---|---|

| Raw LED | Integrating sphere & IV curve | BIN, Lot, Date code | 5 years |

| SMT | AOI & X-ray | Image & CSV | 3 years |

| Waterproof | IP tester & weighing scale | Bar-code linked | 3 years |

| Final | 1.5 kV hipot & ground bond | PDF report | 5 years |

Every carton label carries a QR code; distributors can retrieve the original reflow profile, waterproof batch resin, and LED BIN within 30 s.

5. OEM / ODM Capability

Mechanical

Length: 50 mm – 200 m continuous (110 V COB), 5 m – 50 m (24 V).

Width: 5 mm, 8 mm, 10 mm, 12 mm, 20 mm.

Profile: bare board, aluminium PCB, 3 oz Cu for ≥ 20 W/m.

Optical

CCT: 1800 K – 6500 K, ± 2 SDCM, or tunable 1800-6500 K.

CRI: Ra 80 (std), Ra 90, Ra 95+, R9 > 90.

Efficacy: up to 210 lm/W @ 3000 K (2835, 60 LED/m).

Electrical

Voltage: 12 V, 24 V, 36 V, 48 V, 110 V, 230 V AC integrated driver.

Power: 4 W/m – 40 W/m.

Control: 0-10 V, DALI-2, DMX512, Zigbee, Casambi, Tuya Wi-Fi.

Environmental

Operating –40 °C to +60 °C; UV-stable PU for > 5 yr outdoors.

Salt-spray 720 h per ASTM B117 (coastal projects).

Packaging & Documentation

Retail box, spool + anti-static bag, or contractor bucket.

Custom barcode, multi-language insert, ETL & CE DoC included.

RoHS 2.0, REACH, Prop-65 test files supplied on first order.

6. Compliance & Certification Matrix

| Standard | Scope | File Number | Valid Until |

|---|---|---|---|

| ETL ANSI/UL 2108 | Low-voltage lighting systems | 5013348 | 2026-09 |

| ETL UL 879 | Sign components | 5021901 | 2026-12 |

| TUV EN 60598-2-22 | Emergency lighting | R50354678 | 2027-04 |

| CE LVD 2014/35/EU | All strips > 50 V | 0477-2023-CE-LVD | 2028-03 |

| CE EMC 2014/30/EU | EMC immunity | 0477-2023-CE-EMC | 2028-03 |

| RoHS 2011/65/EU + (EU)2015/863 | 10 restricted substances | BE-RoHS-2301 | Rolling |

Certificates are downloadable 24/7 via our distributor portal; hard copies ship with every first container of a new model.

7. Logistics & Lead-Time

| Quantity | OEM Sample | Mass Production | FOB Shenzhen |

|---|---|---|---|

| < 500 m | 7 days | – | – |

| 1 000 – 10 000 m | 10 days | 15 days | 18 days |

| Full 40 ft HQ (≈ 80 km) | 12 days | 21 days | 24 days |

We maintain buffer stock of neutral IP65 24 V 3000 K 10 W/m and 6000 K 15 W/m reels for rush orders, reducing project delays.

For custom length lists, CCT tuning, private-label sleeves, or matched driver kits, send drawings or BIM schedules to [email protected]; our NPI team will revert with a DFM report and formal BOM within 24 h.

Installation & Application Scenarios

Application Scenarios for Professional Outdoor LED Strip Installations

With over 25 years of manufacturing expertise since 1998, Beauty STC Manufacturing Co., Ltd. delivers industrial-grade waterproof LED strip solutions certified to ETL (USA/Canada) and TUV CE (Europe) standards, ensuring compliance with global safety regulations for outdoor applications. Our OEM/ODM capabilities enable tailored specifications for diverse commercial and architectural projects, with factory-direct quality control at every production stage.

Architectural Facades & Building Outlines

Structural lighting for building exteriors demands precise light distribution, thermal stability, and weather resistance. Beauty STC’s IP65-rated strips with integrated aluminum channels provide uniform illumination across joints, edges, and cornices while managing heat dissipation to prevent hotspot degradation.

Critical Specifications:

IP65 for standard facade elements; IP67 for sub-structural joints

Aluminum channel mounting for mechanical protection and thermal management

ETL-certified drivers and components for NEC compliance

Industry Best Practice:

For historic or high-wind zones, specify strips with reinforced silicone encapsulation to withstand wind loads up to 150 km/h without delamination.

Commercial Exterior Spaces (Hotels, Shopping Malls)

Commercial properties require lighting that balances aesthetics, safety, and regulatory compliance. Beauty STC’s tunable white and RGB options enable dynamic branding while maintaining IP67 protection for high-traffic zones near water features, entryways, and canopy edges.

| Feature | Specification |

|---|---|

| Voltage | 12VDC / 24VDC (24VDC recommended for runs >15m) |

| Lumen Output | 150–300 lm/ft (standard), up to 400 lm/ft (high-output) |

| CRI | ≥90 (standard), ≥95 (high-CRI for color-critical applications) |

| Color Temperature | 2700K–6500K, tunable white (2700K–6500K) options |

| Certifications | ETL, TUV CE, RoHS compliant |

Contractors in Europe and North America consistently specify Beauty STC strips for projects requiring UL 2108 compliance for wet-location fixtures.

Landscaping & Hardscaping Integration

Pathways, garden edges, and retaining walls require flexible, low-profile lighting that withstands soil moisture, UV exposure, and minor submersion. Beauty STC’s IP65-rated strips with UV-stabilized silicone encapsulation maintain color consistency for 50,000+ hours in direct sunlight.

Key Installation Considerations:

Embed strips in pre-formed drainage channels to prevent water pooling

Use 0.75mm² copper core wires for runs exceeding 10m to minimize voltage drop

Apply silicone sealant to all splice points before backfilling

Marine & Poolside Environments

Saltwater exposure demands specialized materials and higher IP ratings. Beauty STC’s IP68-rated strips with marine-grade encapsulation and 316L stainless steel connectors meet stringent requirements for pool decks, docks, and yacht lighting.

Critical Requirements:

GFCI protection per NEC Article 680.23 for all submerged installations

100% silicone-potted connections to resist chloride corrosion

ETL certification confirming compliance with wet-location safety standards

Installation Best Practices for Contractors

Proper installation ensures longevity and performance in harsh environments. Follow these industry-standard protocols:

Voltage Drop Management:

For 12VDC strips, limit runs to ≤10m; for 24VDC, extend to ≤25m. Calculate voltage drop using the formula:

Voltage Drop (V) = (Current (A) × Length (m) × 2) × Wire Resistance (Ω/m)

Connection Sealing:

Use IP67-rated waterproof connectors (e.g., M12 or IP67 quick-connect terminals)

Apply silicone sealant (e.g., Dow Corning 795) to all splice points before enclosure sealing

Thermal Management:

Always mount strips in aluminum channels with thermal conductivity ≥1.5 W/mK. For high-output strips (>300 lm/ft), add heat sinks at 1m intervals.

Code Compliance:

Adhere to NEC Article 411 for low-voltage lighting systems

Verify local building codes for outdoor wet-location requirements (e.g., IEC 60598-2-3 for Europe)

Beauty STC provides detailed installation manuals, technical support, and OEM customization for project-specific needs. Contact our engineering team at [email protected] for certified compliance documentation and voltage drop calculations.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Factory-Direct, Code-Compliant, Export-Ready

Why Global Specifiers Choose Our IP65/IP67 LED Strip Platform

| Project Risk Factor | Beauty STC Advantage | Proof Point |

|---|---|---|

| Code rejection | Dual safety mark – ETL (US/Canada) & TÜV CE (EU) | Tested to UL 2108, EN 60598-2-20, LVD & EMC compliant |

| Moisture failure | IP65/IP67 rated with PU/ silicone extrusion | 500 h 85 °C/85 %RH & 168 h salt-fog passed |

| Colour inconsistency | 3-SDCM binning, 99 %CRI option | MacAdam ellipse control on 2 400 K–6 500 K CCT |

| Supply chain delay | 25 000 m² ISO-9001 plant, 25 lines, 24 h shift | 15-day standard lead-time, 5-day priority |

| Custom optics | In-house SMT & extrusion | OEM length, lumen, CCT, CRI, PCB width 5–20 mm, RGBW, tunable white, DMX512, 24 V & 48 V |

Snapshot Specification – Outdoor Waterproof Strip (Most-Ordered SKU)

| Parameter | Value |

|---|---|

| Ingress | IP67 (silicone tube + sealed ends) |

| Voltage | 24 V DC (12 V & 36 V on request) |

| Power | 14.4 W/m (300×2835), up to 28.8 W/m (600×2835) |

| Efficacy | 125 lm/W typ., 150 lm/W high-efficacy bin |

| CCT | 2 200 K – 6 500 K, RGB & RGBW, 1 800 K – 3 000 K tunable |

| CRI | Ra 90 std., Ra 95 & R9 > 90 optional |

| Beam | 120° |

| Operating | –40 °C to +85 °C, 5 %–95 % RH |

| Lifetime | L70 > 54 000 h @ 45 °C (IES TM-21) |

| Warranty | 5 years full replacement |

| Length | Reel 5 m std.; cut 25 mm; OEM 50 m reel |

| Approvals | ETL cETLus, TÜV CE, RoHS, REACH, ERP |

Export Track Record – 50+ Countries, Zero Re-Call

Europe: DE, NL, BE, FR, IT, ES, SE, NO, FI, PL, CZ, AT, CH

Americas: US, CA, MX, BR, CL, AR

Asia-Pacific: AU, NZ, SG, MY, TH, VN, JP, KR, RU

Middle-East: UAE, SA, TR

OEM/ODM Workflow – From Gerber to Container in 4 Weeks

- DIALux/AGi32 file review → optimise LED pitch & current density

- Prototype & LM-79 report (3 days)

- Customer field trial approval

- Bulk production & 100 % IP67 pressure-pot test

- ETL/TÜV CE witness testing if new part number

- Neutral white box or colour sleeve printing; UPC/QR code on request

Next Step – Talk to the Factory

Email: [email protected]

Mobile/WhatsApp: +86-13902885704

Plant visit: 41th Caihong Road, Hi-tech Zone, Jiangmen, Guangdong, CN (45 min from Guangzhou Baiyun Airport)

Share your project schedule or annual forecast and receive a same-day quotation with duty-paid Incoterms. Since 1998, Beauty STC Lighting remains the quiet workhorse behind many of the world’s best-selling architectural LED strips—let us engineer yours.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).