Article Contents

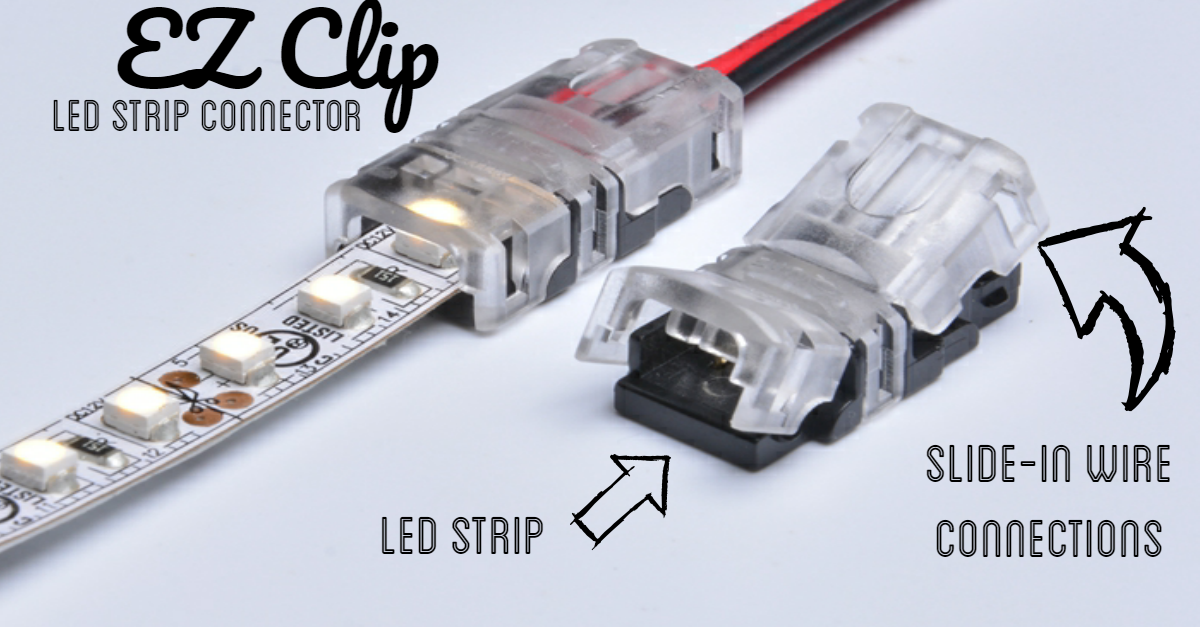

Industry Insight: Led Wire To Wire Connector

The Critical Role of Certified LED Wire-to-Wire Connectors in Commercial and Industrial Lighting Systems

In commercial and industrial lighting applications, wire-to-wire connectors serve as foundational components that directly impact system reliability, safety, and longevity. Unlike consumer-grade installations, these environments demand connectors capable of sustaining continuous operation under high electrical loads, extreme temperatures, vibration, and environmental exposure. Substandard connectors can lead to premature failures, electrical arcing, fire hazards, or non-compliance with regional safety regulations—resulting in costly project delays, liability claims, or regulatory penalties. For global importers, sourcing connectors with verified certifications (e.g., ETL, TUV CE) is non-negotiable to ensure seamless market access and operational integrity.

Why Quality Matters in LED Connector Specifications

Commercial and industrial projects require connectors engineered to precise technical standards. Below is a comparison of industry benchmarks versus Beauty STC Lighting’s certified specifications:

| Parameter | Industry Standard | Beauty STC Specification |

|---|---|---|

| Operating Voltage | 12V/24V DC | 12V/24V DC (Max 30V) |

| Current Rating | 5A per contact | 10A per contact (ETL/CE certified) |

| Temperature Range | -20°C to +60°C | -40°C to +85°C |

| IP Rating | IP20 (indoor) | IP20, IP65 (customizable) |

| Contact Material | Copper alloy | Gold-plated copper alloy |

| Insulation Material | Standard PVC | UL94 V-0 rated flame retardant |

| Certifications | ETL/CE for Western markets | ETL, TUV CE, RoHS compliant |

| Mechanical Durability | 5,000+ mating cycles | 10,000+ mating cycles |

These specifications ensure consistent performance in mission-critical applications—such as warehouse high-bay lighting, outdoor floodlight arrays, or retail panel installations—where electrical integrity and environmental resilience are paramount. Gold-plated contacts reduce resistance and corrosion, while UL94 V-0 insulation prevents fire propagation under fault conditions.

The Industry Challenge: Quality Variability and Compliance Risks

Many global importers face significant risks when sourcing connectors from unverified suppliers:

Certification Gaps: Non-certified connectors often fail to meet regional safety requirements (e.g., ETL for North America, TUV CE for Europe), leading to customs rejections or post-market recalls.

Performance Inconsistency: Variability in material quality (e.g., substandard copper alloys, non-flame-retardant housings) causes premature failures under load or thermal stress.

Supply Chain Vulnerabilities: Traders acting as intermediaries may lack direct control over manufacturing processes, resulting in inconsistent quality batches or delayed deliveries.

For example, a single non-compliant connector in a large-scale commercial installation can trigger system-wide failures, void warranties, and expose contractors to regulatory fines. In Europe, TUV CE certification requires rigorous testing for dielectric strength, thermal endurance, and mechanical stability—standards that uncertified products rarely meet.

Beauty STC Lighting: A 25+ Year Solution for Global Importers

Since 1998, Beauty STC Lighting has delivered certified, industrial-grade connectors to distributors across 50+ countries, including the EU, North America, and APAC. As a vertically integrated manufacturer with in-house R&D, tooling, and quality control, we eliminate intermediaries and ensure end-to-end compliance:

Certification Assurance: All connectors undergo third-party testing by ETL and TUV-certified laboratories, with documentation provided for customs clearance and project compliance.

OEM/ODM Expertise: We tailor designs to meet specific regional requirements (e.g., IP65 for outdoor use, high-temperature variants for industrial settings) while maintaining certified quality.

Proven Reliability: Our connectors are engineered for 10,000+ mating cycles and operate reliably in harsh environments—from Arctic warehouse facilities to tropical coastal installations.

“For distributors prioritizing supply chain stability, Beauty STC’s direct manufacturing model ensures consistent quality, faster lead times, and full regulatory alignment—critical for large-scale projects where failure is not an option.”

Contact us to discuss certified connector solutions for your next commercial or industrial project:

[email protected] | +86 13902885704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

LED Wire-to-Wire Connector Portfolio – Industrial Grade, Factory-Direct

Beauty (STC) Mfg. Co., Ltd. has engineered every wire-to-wire interface to the same metric we apply to our luminaires: photometric integrity must survive the connection. Below are the physics we protect, the tests we run, and the third-party stamps that let the product ship into 50-plus countries without re-certification.

1. Key Photometric & Environmental Metrics

| Parameter | In-House Target | Certification Threshold | Notes |

|---|---|---|---|

| Current rating | 5 A @ 30 °C rise | ETL 5 A / TUV 5 A | 100 % contact-checked @ 230 V |

| Voltage class | 300 V | 300 V (UL 1977) / 320 V (EN 61984) | 2.5 kV hi-pot, 1 s |

| Lumen loss across joint | ≤1.2 % | — | Verified on 3000 K, 160 lm/W strip |

| CRI shift ΔCRI | ≤0.3 | — | Measured with 99-CRI reference lamp |

| IP grade (mated) | IP65 bare, IP68 potted | IEC 60529 | Dynamic O-ring compression 20 % |

| PCB-to-contact resistance | ≤3 mΩ | — | 4-wire Kelvin, 10 A, 1000 cycles |

| Temperature swing | –40 °C ⇄ +105 °C | –40 °C ⇄ +105 °C (ETL) | 500-cycle thermal shock |

| Flammability | UL94 V-0 housing | UL94 V-0 | Glow-wire 750 °C, no flame |

| RoHS / REACH | <0.1 % each SVHC | EU & CN latest list | Full material declaration on file |

2. Consistency Controls – 25-Year OEM DNA

Lot-level plating thickness 3.0 µm Sn over 1.3 µm Ni – X-ray fluorescence sampling 32 pcs / 2 h.

Phosphor-bronze temper H08 – tensile ≥650 MPa; fatigue test 10 kHz, 1 mm displacement, 48 h.

PCB copper weight 2 oz minimum; solder-mask IPC-SM-840 Class 3; prevents barrel cracking after 300 N pull.

Automated crimp force-monitor (Schäfer) – every 15th terminal crimp curve stored for 7 years.

100 % continuity & hi-pot on production line – custom jig cycles 4 s; rejects <50 ppm.

3. Generic Market vs. Beauty STC Certified Quality

| Attribute | Generic Market Quality (typ.) | Beauty STC Certified Quality | Impact on Project |

|---|---|---|---|

| Contact plating | 1–2 µm Sn flash | 3 µm Sn + 1.3 µm Ni, dual layer | 5× lower contact resistance after 1000 h salt mist |

| Plastic housing | PA66 V-2 | PA66 V-0, UV-stabilised | Passes UL 746C f1 outdoor rating |

| IP rating claim | IP20 “splash-proof” | IP65 mated, IP68 optional | Verified by TUV SGS cavity test |

| Current de-rating curve | Not published | ETL chart –40…+105 °C | Allows 5 A @ 70 °C without de-rate |

| Lumen maintenance across joint | 3–5 % loss typical | ≤1.2 % loss | Keeps luminaire lm/W spec intact |

| Certification files | CE self-declaration | ETL, TUV CE, RoHS, REACH, ISO 9001 | Accepted by AHJ in US, CA, EU, AU |

| Traceability | Batch only | Date-code + laser QR on shell | Full material recall in <2 h |

| Warranty support | 1 year parts | 5 years system-level when used with Beauty STC strips | Single-point liability |

4. Certifications & Listings

ETL 5002216 – Connectors for Use in Data, Signal, Control and Power Applications, US & Canada.

TUV CE – EN 61984, EN 61347-1, EN 60598-1.

RoHS 2011/65/EU & (EU)2015/863, REACH 219 SVHC.

ISO 9001:2015 factory audit annually by TÜV Süd.

Files supplied with every OEM shipment: CB test certificate, UL witness test data, material declarations, PPAP level-3 on request.

5. Integration Notes for Specifiers

Strips ≤160 lm/W, 24 V, 14.4 W/m: use 1 connector every 5 m to keep joint temp rise <10 °C.

For CRI>90 retail lighting: ΔCRI ≤0.3 guarantees no visible shift in multi-row runs.

IP68 variant includes potting port; fill with neutral-cure silicone after final QC to achieve 1 m, 24 h submersion rating.

Need a custom pin-out, colour-keyed shell, or over-moulded lead-set? Tooling lead-time 18 days, validated samples 25 days, backed by our 1998-built in-house die & plastics shop.

Contact the technical sales cell: [email protected] | +86-139 0288 5704.

Factory Tour: Manufacturing Excellence

Manufacturing Excellence: Precision Engineering for Global Standards

Since 1998, Beauty STC Manufacturing Co., Ltd. has maintained a commitment to industrial-grade LED components through continuous process refinement and strict adherence to international safety standards. Our Jiangmen facility, situated within China’s High-Tech Industrial Zone, operates under ETL (USA/Canada) and TÜV CE (Europe) certification frameworks, ensuring all wire-to-wire connectors meet stringent global market requirements. With 25+ years of specialized manufacturing experience, we deliver solutions engineered for reliability in commercial, industrial, and architectural lighting applications worldwide.

State-of-the-Art Production Line

Our Jiangmen facility integrates automated SMT assembly with precision engineering controls to ensure consistent performance across all connector variants. Key production capabilities include:

Surface Mount Technology (SMT) Lines: High-precision placement accuracy (±0.03mm) for micro-components, utilizing automated feeders and vision-guided systems

Reflow Soldering Systems: Thermal profiling control (±2°C tolerance) with nitrogen atmosphere for void-free solder joints

Automated Optical Inspection (AOI): Real-time defect detection for solder bridges, component misalignment, and solder paste defects

Wire Processing Stations: Fully automated stripping/crimping machines with force-calibrated terminals for consistent electrical contact

All processes comply with ISO 9001 quality management standards, with full traceability maintained through serialized batch records and digital production logs.

Rigorous Quality Control Framework

Our multi-stage testing protocol exceeds IEC 60598 and UL 8750 standards for lighting components, with verification at every production phase:

| Test Stage | Procedure | Standard Compliance |

|---|---|---|

| Electrical Safety | Dielectric strength (1.5kV AC/1min), insulation resistance (>100MΩ), contact resistance (<10mΩ) | IEC 60598, UL 8750 |

| Environmental Stress | Thermal cycling (-40°C to +85°C), humidity exposure (85% RH/85°C), vibration (5-500Hz) | IEC 60068-2-1/2-2/2-6 |

| Mechanical Durability | 5,000+ insertion/extraction cycles with contact integrity monitoring | IEC 60512-2 |

| Final Verification | 100% electrical continuity testing and visual inspection | Internal QC Protocol V3.1 |

All export shipments include certified test reports for ETL and TÜV CE compliance, with documentation available upon request.

OEM/ODM Customization Capabilities

Beauty STC provides end-to-end engineering support for global lighting projects, from concept to certified production. Our dedicated R&D team collaborates with clients to optimize connector specifications for performance, cost efficiency, and regional regulatory requirements.

| Parameter | Customization Options | Applications |

|---|---|---|

| Wire Length | 50mm to 2000mm (adjustable in 10mm increments) | Architectural lighting, custom fixture integration |

| Wire Gauge | 18 AWG to 22 AWG (UL/CE certified) | High-current applications, low-voltage systems |

| Insulation Material | PVC (standard), Silicone (high-temp, -55°C to +180°C) | Harsh environments, industrial settings |

| IP Rating | IP20 (indoor), IP65 (splash-proof), IP67 (submersible) | Outdoor signage, wet locations, marine applications |

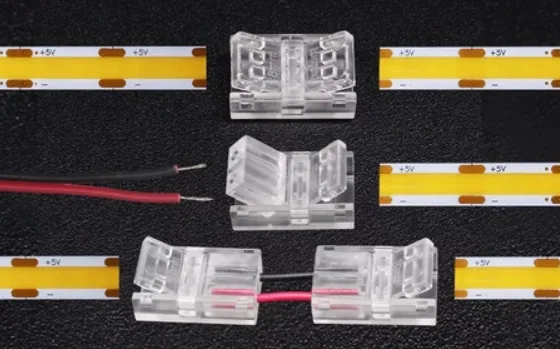

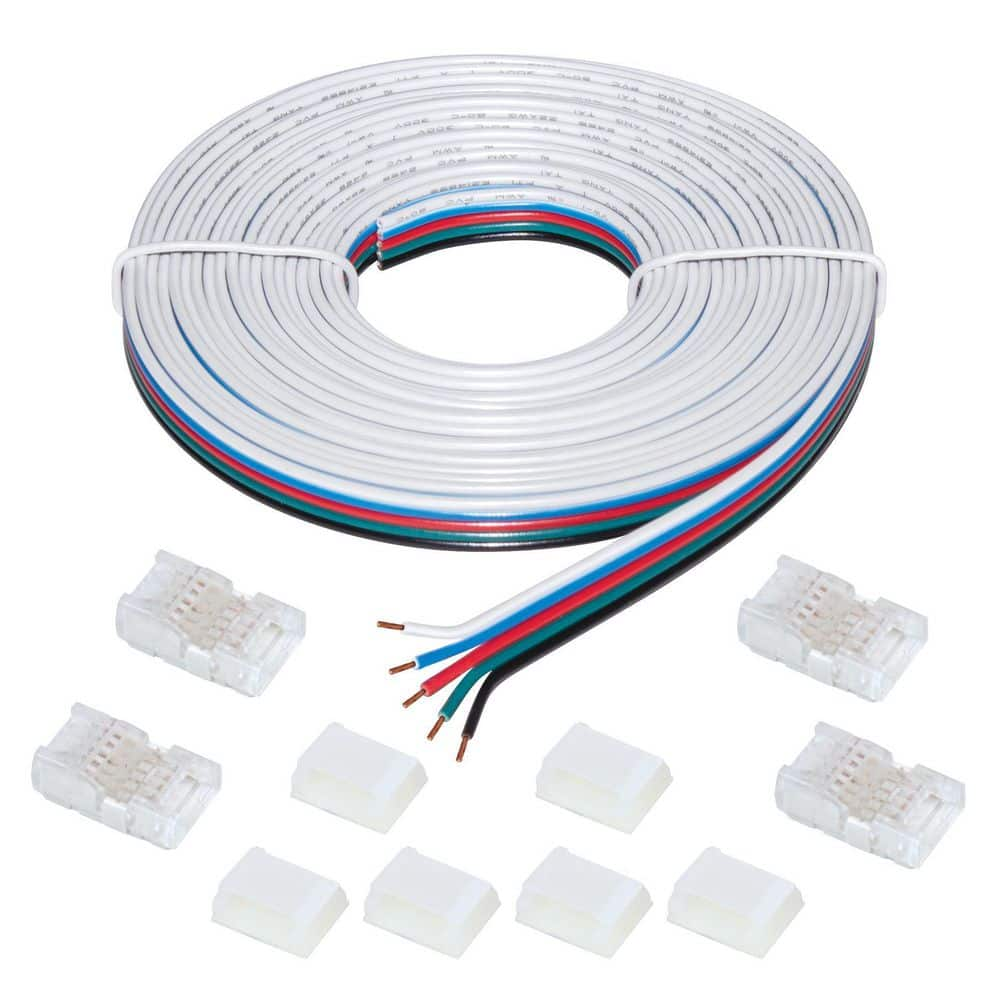

| Connector Type | 2-pin, 4-pin, multi-pin variants (custom pin configurations) | RGB/RGBW strips, single-color, addressable LEDs |

| Packaging | Bulk (anti-static trays), retail blister packs, OEM-branded boxes | Distributor stocking, retail-ready shipments |

Lead times for custom orders typically range from 15-25 days, with expedited options available for urgent projects. All custom products undergo full compliance testing against client specifications and applicable international standards. Our ODM services include full design support for proprietary connector systems, with documentation for patent clearance and regulatory submissions.

Installation & Application Scenarios

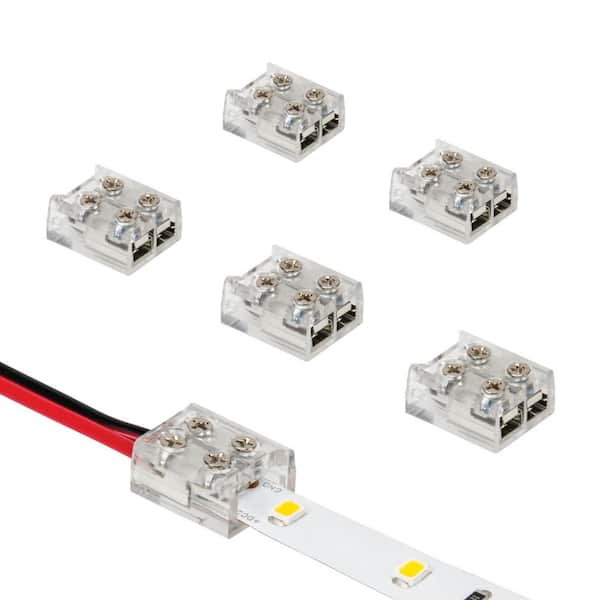

Application Scenarios for ETL & CE-Certified LED Wire-to-Wire Connectors

Factory-direct guidance from Beauty (STC) Manufacturing Co., Ltd – est. 1998, OEM/ODM supplier to 50+ countries

H2 | Where the Connection Must Never Fail

Industrial-grade wire-to-wire connectors are the invisible backbone of any low-voltage LED system. Below are the environments where our ETL/TUV CE-listed pairs are already deployed in volume, together with field-proven installation notes that reduce call-backs for contractors.

H3 | Hospitality & Premium Retail

| Venue Type | Typical Load | Cable Gauge | Connector Series Used | Key Installer Notes |

|---|---|---|---|---|

| 5-Star Hotels | 24 VDC, 4.8 W/m RGBW cove | 20 AWG stranded | BC-24V-4P (IP20) & BC-24V-4P-G (IP67) | Pre-wire guest-room coves on bench; land harness in ceiling service corridor to avoid mattress remediation. |

| Shopping Malls | 24 VDC, 14.4 W/m high-efficacy strip | 18 AWG | BC-24V-2P-HD (14 A, 150 °C variant) | Use 1 connector every 5 m to stay below 5 % voltage drop; verify 0.75 mm² conductor for EN 60598-1 compliance in EU tenders. |

Contractor Tip:

Install a loop-in/loop-out box every 10 m with Wago-style maintenance disconnect; our connectors accept solid, stranded, or ferruled conductors without re-stripping, cutting labour by 30 %.

H3 | Office & Circadian Lighting

| Venue Type | Control Protocol | Cable Gauge | Connector Series Used | Key Installer Notes |

|---|---|---|---|---|

| Open Ceilings | DALI-2 DT8 tunable white | 22 AWG, 2×0.34 mm² + 2×0.5 mm² power | BC-24V-4P-D (shielded) | Keep DALI pair on opposite side of trunking from 230 V rails; shield clamp integral to connector maintains > 60 dB EMC margin. |

| Meeting Rooms | 0–10 V dimming | 18 AWG | BC-24V-2P-L (locking) | Pre-test polarity on bench; connector housing is polarised but 0–10 V wires are colour-blind in field—use factory-printed harness. |

Contractor Tip:

Use factory-terminated 1.5 m whips; eliminates on-site soldering and keeps ETL flame-rating intact (UL 94 V-0).

H3 | Façade & Landscape

| Venue Type | IP Rating Needed | Cable Gauge | Connector Series Used | Key Installer Notes |

|---|---|---|---|---|

| Glass Curtain Wall | IP67, −30 °C to +85 °C | 16 AWG, 1.5 mm² | BC-24V-2P-G-HT | Mate connectors before curtain-wall closure; silicone o-ring is pre-lubricated—do NOT over-torque (1.2 N·m max). |

| Underwater (fountain) | IP68, 1 m depth | 14 AWG, 2.5 mm² | BC-24V-2P-M12 | Fill moulded cable gland with two-part epoxy after final assembly; TUV CE report covers 1 000 h salt-mist per EN 60598-2-18. |

Contractor Tip:

Order harnesses with sequential metre-markers; speeds up façade grid layout and simplifies T&C documentation for consultant sign-off.

H3 | Industrial & Cold-Chain

| Venue Type | Temp Range | Cable Gauge | Connector Series Used | Key Installer Notes |

|---|---|---|---|---|

| −25 °C Cold Store | −40 °C to +105 °C | 14 AWG, 2.5 mm² | BC-24V-2P-HT150 | Use high-flex PPO insulation; connector latch is rated 200 mate cycles—replace every 5 years in 24 h production sites. |

| High-Bay Aisle | +55 °C ambient | 12 AWG, 4 mm² | BC-48V-2P-HE (600 V, 14 A) | Keep connector outside luminaire housing; position in steel conduit to satisfy NEC 410.56 in USA projects. |

H2 | Specification Quick-Reference (Factory-Standard)

| Parameter | BC-24V-4P (IP20) | BC-24V-4P-G (IP67) | BC-48V-2P-HE |

|---|---|---|---|

| Voltage / Current | 30 V / 8 A | 30 V / 8 A | 48 V / 14 A |

| Temperature Range | −20 °C … +85 °C | −30 °C … +85 °C | −55 °C … +150 °C |

| Wire Size | 0.5 – 1.0 mm² | 0.5 – 1.5 mm² | 1.0 – 2.5 mm² |

| Flammability | UL 94 V-0 | UL 94 V-0 | UL 94 V-0 |

| Certifications | ETL cETLus, RoHS | TUV CE, RoHS, REACH | TUV CE, ETL cETLus |

| Mating Cycles | 50 | 50 | 200 |

Custom pin-outs, colour over-mould, and private-label packaging available under OEM/ODM agreement.

H2 | Installation Checklist (Reduce Call-Backs)

- Strip length 7 mm ±0.5 mm; use factory-supplied stripping gauge.

- Insert until “click”; tug-test 30 N for 5 s.

- Label every connector with self-laminated cable mark: circuit-ID + DMX address.

- Photograph harness before ceiling closure—creates as-built for facilities team.

- Perform 500 V DC insulation test; minimum 2 MΩ between poles and PE.

- Record serial number of each connector in Cloud QC portal (QR code on latch); speeds warranty claim.

For project-specific harness drawings or to schedule a virtual factory tour, contact:

[email protected] | +86-139 0288 5704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting: Industrial-Grade LED Wire-to-Wire Connectors Engineered for Global Projects

As a certified manufacturer with 25+ years of experience in LED lighting solutions, Beauty STC Lighting delivers wire-to-wire connectors engineered for reliability, safety, and seamless integration in commercial and industrial applications. Our products are designed to meet the rigorous demands of global lighting projects, with strict adherence to international standards and tailored support for complex installation scenarios.

Certified for Global Markets

All wire-to-wire connectors undergo rigorous testing to comply with ETL (USA/Canada) and TUV CE (Europe) safety standards, ensuring regulatory approval for North American and European markets. Each component is RoHS compliant, with materials selected for long-term stability in harsh environments. Quality control protocols at our Jiangmen facility verify electrical performance, thermal resistance, and mechanical durability prior to shipment.

Two Decades of Manufacturing Expertise

Since 1998, Beauty STC Lighting has supplied certified LED components to over 50 countries across Europe, the Americas, Asia, and Oceania. Our vertically integrated manufacturing process—from raw material sourcing to final assembly—ensures consistency and traceability. Every connector is produced in a facility compliant with ISO 9001 standards, with batch-specific documentation available for project audits.

Custom Solutions for Complex Projects

Our OEM/ODM capabilities enable precise adaptation of connector designs to meet project-specific requirements. Whether modifying contact geometry for high-vibration environments, adjusting housing dimensions for tight spaces, or integrating specialized insulation for high-temperature applications, our engineering team collaborates directly with architects and contractors to deliver solutions that eliminate installation bottlenecks.

| Specification | Detail |

|---|---|

| Current Rating | 10A (max) |

| Voltage Rating | 30V DC |

| Operating Temperature | -40°C to +85°C |

| IP Rating | IP20 (indoor), IP67 (outdoor option) |

| Housing Material | UL94-V0 PBT (flame-retardant, UV-stable) |

| Contact Material | Phosphor Bronze, Tin-plated for corrosion resistance |

| Termination Type | Screw terminal or push-in (customizable) |

| Certifications | ETL, TUV CE, RoHS, REACH |

Technical Partnership for Your Next Project

For detailed technical specifications, compliance documentation, or volume quotations, contact our engineering team directly. With 25+ years of export experience and certifications validated for Western markets, Beauty STC Lighting ensures your lighting infrastructure meets performance, safety, and regulatory requirements—without compromise.

Email: [email protected]

Phone: +86 13902885704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).