Article Contents

Industry Insight: Diffused Led Strip

Why Diffused LED Strip Is Rapidly Replacing Fluorescent in Commercial & Industrial Projects

From Visible LEDs to a Seamless Line of Light

In warehouses, retail gondolas, cove ceilings, and refrigeration displays, lighting specifiers are moving away from T8 fluorescents and raw LED tape. The driver is a single requirement: a uniform, dot-free luminance that delivers the efficacy of LED without the pixelation. A properly diffused LED strip eliminates diode imaging, reduces glare (UGR <19), and provides the continuous “neon-like” appearance architects demand while keeping installation costs below extruded aluminum LED profiles.

Compliance Risk: Why ETL & CE Are Non-Negotiable for Importers

A 5 % failure rate in the first 12 months can erase the margin on an entire container. More critically, non-certified strips that slip through customs can trigger on-site re-inspections, project delays, and product recalls. ETL (to UL 2108 & CSA C22.2 No. 250.0) and TUV CE (EN 60598-2-20, EN 62031, EN 61347) are therefore not marketing emblems—they are the minimum technical insurance for:

North American utility rebates

European ERP 2023 conformity & CE documentation dossier

Contractor “approved vendor” lists on tier-one retail fit-outs

Beauty STC Lighting has held dual certification on every flexible strip family since 2010, allowing distributors to quote federally funded projects from California to Norway without secondary lab submissions.

25 Years of Solving the Three Classic Pain Points

Since 1998, Beauty STC Lighting has exported >160 million meters of flexible PCB from our 41,000 m² Jiangmen facility. The most frequent OEM requests we solve are:

| Pain Point Seen in the Field | Root Cause (Low-Cost Strip) | Beauty STC Engineering Fix |

|---|---|---|

| 1. Hot-spots every 10 mm, visible through 120° diffuser | 2835 LED @ 60 LEDs/m, 10 mm pitch | 210 LEDs/m 2216 or 280 LEDs/m 3014, 5 mm pitch + milky PU overlay |

| 2. 30 % lumen loss inside silicone tube | Low-grade TiO₂, 0.6 mm wall | FPC first coated with 0.2 mm PU, then over-extruded with optical-grade PU @ 0.4 mm—total transmission 92 % |

| 3. Color shift >3 SDCM after 6,000 h | Cheap copper PCB (≤0.5 oz) + poor binning | 2 oz rolled copper, 3-step MacAdam SDCM bin, 3,000 K–6,500 K single-BIN shipment |

Market Indicators: Where Demand Is Coming From

| Segment | Annual Growth (CAGR) | Typical Specification Driver |

|---|---|---|

| Cold-chain / food display | 14 % (US) | NSF splash rating, –40 °C startup |

| Architectural cove & millwork | 18 % (EU) | CRI 90+, 3 SDCM, dot-free @ 300 mm |

| Industrial high-bay retrofit | 12 % (NA) | 160 lm/W, 50,000 h L70 @ 45 °C |

| UV-sanitization conveyor | 22 % (Global) | 275 nm UV-C, fused quartz diffuser |

All four segments require the strip to be factory-sealed and certified—exactly the capability we expanded in 2017 with our in-house CNAS-compliant photometric lab and -40 °C ⇢ 85 °C thermal cycling chamber.

OEM & ODM: From Blank PCB to Private-Label Box

PCB width: 5 mm, 8 mm, 10 mm, 12 mm, 20 mm dual row

Voltage: 12 V, 24 V, 36 V, 48 V constant-voltage; 54 V constant-current available

Power increment: 4 W/m ⇢ 28 W/m in 2 W steps without redesign of copper weight

Color options: 1800 K – 6500 K, 660 nm deep red, 730 nm IR, 365 nm UV-A, 275 nm UV-C

Diffuser format: PU flat coat, PU half-dome, silicone extrusion with IK06 impact, IP68 for pool niche

Packaging: 5 m reel, 50 m bulk spool, or pre-cut 305 mm segments with JST on both ends

Lead time for a custom diffused strip with ETL & CE dossier: 18–20 days plus 5 days for third-party witness testing.

Next Step: Engineering Sample or Project Quote

For distributors, lighting contractors, and project managers evaluating a dot-free, fully certified diffused LED strip, we provide free 300 mm evaluation samples shipped by DHL within 48 h. All samples ship with the complete ETL & CE technical file to fast-track your submittal package.

Contact:

[email protected]

+86-13902885704 (WeChat & WhatsApp)

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for Professional Applications

For commercial, architectural, and industrial lighting projects, technical precision and verifiable quality standards are non-negotiable. Beauty STC Manufacturing Co., Ltd. delivers diffused LED strip solutions engineered to meet global performance benchmarks, with rigorous adherence to safety, efficiency, and durability requirements. Our 25+ years of manufacturing expertise (established 1998), ETL (USA/Canada) and TUV CE (Europe) certifications, and ISO-aligned quality protocols ensure consistent, project-ready performance across all applications.

Luminous Efficacy & Energy Efficiency

Luminous efficacy (lumens per watt) directly impacts operational costs and system sustainability. Industry-standard generic products typically achieve 80–100 lm/W, often compromised by inconsistent LED binning and suboptimal thermal design. Beauty STC diffused LED strips deliver 110–130 lm/W through optimized high-efficiency LED chips, precision optical engineering, and integrated thermal management. This reduces energy consumption by 15–20% versus conventional offerings while maintaining uniform light distribution—critical for large-scale installations where total lifecycle costs dictate ROI.

Color Rendering Index (CRI) & Light Quality

Accurate color representation is essential for retail, hospitality, and architectural applications. Generic market strips commonly exhibit CRI (Ra) values of 80–85, resulting in visible color distortion and inconsistent hue across segments. Beauty STC utilizes high-CRI LED chips with Ra ≥95, rigorously tested per IES LM-79 standards. Each production batch undergoes strict binning to ensure color consistency within ±3 SDCM (Standard Deviation of Color Matching), eliminating visible shifts in installed environments and meeting demanding architectural specifications for color-critical spaces.

Ingress Protection (IP) Ratings & Environmental Durability

IP ratings for diffused LED strips must be validated through independent, certified testing—not merely claimed. Generic products frequently advertise “IP65” or “water-resistant” without third-party verification, leading to premature failures in wet or dusty conditions. Beauty STC’s IP67-rated strips undergo certified testing per IEC 60529 by TUV and ETL laboratories. This includes rigorous dust ingress tests (0.5mm particles) and high-pressure water jet resistance (100L/min at 10m distance), ensuring reliable performance in outdoor signage, marine environments, and industrial facilities.

PCB Quality & Thermal Management

PCB construction directly determines thermal stability and operational lifespan. Generic strips typically use 1oz copper PCB with inconsistent thickness (±15% tolerance), causing hotspots, lumen depreciation, and reduced longevity. Beauty STC employs 2oz copper PCB with precision-machined thermal vias and aluminum substrates where required. This design ensures uniform heat dissipation (≤10°C temperature variance across the strip), maintaining >90% lumen output at 50,000+ hours under standard operating conditions (25°C ambient).

Comparative Quality Standards

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Luminous Efficacy (lm/W) | 80–100 | 110–130 |

| CRI (Ra) | 80–85 | ≥95 |

| IP Rating Verification | Unverified claims (no independent testing) | Certified IP67 (TUV/ETL tested per IEC 60529) |

| PCB Copper Weight | 1oz (inconsistent thickness) | 2oz (uniform, thermal vias) |

| Quality Control | Random sampling | 100% testing, traceable batch records |

Quality Assurance Protocols

Every Beauty STC diffused LED strip undergoes comprehensive validation prior to shipment:

100% electrical testing: Voltage tolerance (±5%), current stability, and flicker-free operation verified per IEC 61000-4-15.

Thermal cycling: 1,000 cycles between -20°C and 60°C to simulate real-world environmental stress.

Lumen maintenance testing: 1,000-hour accelerated aging to project 50,000-hour performance.

Traceability: Full batch documentation (including LED binning data, PCB specifications, and test reports) maintained for 10+ years.

This commitment to standardized, auditable processes aligns with our ISO 9001 quality management system and supports OEM/ODM requirements for global projects. Whether specifying custom CCT ranges, IP-rated variants, or integrated dimming protocols, Beauty STC ensures technical consistency from prototype to production—without compromise.

For project-specific technical documentation or certification reports, contact our engineering team directly: [email protected] | +86-13902885704.

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

Beauty (STC) Manufacturing Co., Ltd. has operated from a 20,000 m² vertically-integrated plant in Jiangmen’s High-tech Industrial Zone since 1998. The facility is ETL/TUV CE dual-listed and ships diffused LED strip to 50+ countries under OEM, ODM and white-label programs.

SMT & Precision Assembly Line

| Process Zone | Key Equipment (2024) | Capability / Accuracy | Cert. Ref. |

|---|---|---|---|

| SMT-1 | Yamaha YSM20R (2×) | 48,000 cph, ±35 µm @ 3σ | ETL 5018449 |

| SMT-2 | Juki KE-3020V (3×) | 0.5 mm pitch, 01005 chip | TUV CE 0598 |

| Reflow | Heller 1912 MKIII (8-zone) | ΔT ≤ 5 °C, nitrogen option | IPC-J-STD-001 |

| conformal coating | PVA Delta 6 selective spray | 25–75 µm thickness, UV trace | IEC 60598-2-22 |

| Binning & reel seal | EVERFINE LED-2000 integrating sphere | 1 nm resolution, SDCM ≤ 3 | LM-80 data on file |

All diffused strip reels are produced on 8 mm punched carrier tape (Ø330 mm) for automatic pick-and-place compatibility.

Aging & Reliability Protocol

- Pre-burn-in: 100 % full-load aging @ 45 °C for 2 h (visual & IR scan).

- Batch burn-in: 50 pcs per lot, 12 h @ 60 °C, 0/50 failure target.

- Thermal shock: –40 °C ↔ +85 °C, 50 cycles, solder-joint inspection.

- Photometric drift: ΔCCT ≤ 100 K, ΔFlux ≤ 5 % after 1,000 h continuous.

Raw LM-80/TM-21 data are supplied to OEM partners on request for project-specific L70/B10 reports.

QC & Traceability

| Checkpoint | AQL | Tooling / Software | Record Retention |

|---|---|---|---|

| incoming PCB | 0.65 | OGP ZIP 250 | 10 years |

| solder paste SPI | 0.4 | Koh Young Zenith | digital twin |

| in-line AOI | 0.1 | Mirtec MV-6 | barcode reel ID |

| finished strip | 0.25 | Hipot 3 kV, Earth | batch QR code |

| packaging OQC | 0.65 | Carton drop 1 m | photo archive |

Every diffused strip carries a laser-etched 14-digit code linking to diode bin, SMT shift, and operator ID—critical for large-scale roll-outs where sections may be replaced years later.

OEM / ODM Customisation Matrix

| Parameter | Standard Range | Extended Option (tooling) | MOQ | Lead-Time |

|---|---|---|---|---|

| Length / cut | 5 m, 10 m reels | 50 m continuous, 24 V | 1 km | 10 days |

| CCT | 2400–6500 K | 1800 K, 7000 K | 500 m | 7 days |

| CRI | 80, 90 | 95 (special phosphor) | 1 km | 14 days |

| PCB width | 8 mm, 10 mm, 12 mm | 5 mm, 15 mm | 2 km | 10 days |

| Coating finish | silicone diffuse, IP65 | PU IP68, nano-coating | 1 km | 12 days |

| Packaging | neutral brown box | colour sleeve, QR code | 500 m | 5 days |

| Logo / part-no. | n/a | laser on PCB or label | 100 m | 3 days |

Engineering samples (≤ 30 m) ship within 72 h for distributor field tests. Full PPAP Level-3 documentation (control plan, CPK, IR spectra) is available for tender submissions.

Responsible Manufacturing

The plant runs on 35 % solar rooftop (1.2 MW) and maintains ISO 14001 waste-sorting streams. All diffused strips are RoHS/REACH compliant and packed in FSC-certified cartons—aligning with EU green-procurement clauses increasingly written into hotel and retail tenders.

For project quotations or third-party audit appointments, contact:

[email protected] | +86 139 0288 5704

Installation & Application Scenarios

Strategic Application Scenarios for Diffused LED Strip Light Systems

Diffused LED strip lights are engineered for uniform light distribution, eliminating hotspots and glare while providing consistent illumination across diverse architectural applications. Designed for commercial and industrial projects requiring precision lighting, these systems are certified for global markets and manufactured to stringent quality standards. Below are industry-specific applications and technical considerations for contractors and designers.

Commercial Interiors – Precision Lighting for High-End Environments

In commercial interiors, diffused LED strips provide seamless ambient lighting that enhances spatial perception while meeting strict design and safety requirements. Key applications include hotel lobbies, retail displays, and office environments where uniform illumination and color accuracy are critical.

| Parameter | Hotel Lobbies | Retail Displays | Office Spaces |

|---|---|---|---|

| IP Rating | IP20 | IP20 | IP20 |

| CCT Range | 2700K–3000K | 2700K–4000K | 3500K–4000K |

| CRI | ≥90 | ≥95 | ≥90 |

| Power Density | 4–6W/m | 6–8W/m | 4–6W/m |

| Mounting | Aluminum channel | Aluminum channel | Aluminum channel |

| Key Requirement | Soft ambient glow; no glare in high-end spaces | Accurate product color rendering; brand-specific color matching | Uniform indirect lighting; reduced eye strain |

Note: Beauty STC’s ETL-certified strips for North American markets and TUV CE-compliant units for Europe ensure compliance with regional electrical and safety standards. All products undergo 100% binning for consistent color performance.

Architectural Facades & Exterior Applications

Exterior applications demand robust weather resistance and long-term durability. Beauty STC’s diffused LED strips feature IP67-rated enclosures and UV-stable materials, ensuring reliable performance in harsh environmental conditions. Common applications include building outlines, landscape accent lighting, and commercial signage.

| Parameter | Building Facades | Landscape Lighting | Commercial Signage |

|---|---|---|---|

| IP Rating | IP67 | IP67 | IP65 |

| CCT Range | 3000K–4000K | 2700K–3000K | 3000K–5000K |

| Power Density | 6–10W/m | 4–8W/m | 6–10W/m |

| Voltage | 24V DC | 24V DC | 24V DC |

| Material | UV-resistant silicone sleeve + aluminum channel | UV-resistant silicone sleeve | Corrosion-resistant aluminum channel |

| Key Requirement | Long-run capability; corrosion-resistant for coastal climates | Weatherproof installation; minimal maintenance | High visibility; consistent brightness across 50+°C temperature swings |

All exterior-grade strips are manufactured to IEC 60598 standards, with 10-year warranty coverage for UV stability and waterproofing performance. Certifications include ETL (UL 1598) and TUV CE (EN 60598-1) for global regulatory compliance.

Specialized Technical Installations

For specialized environments such as museums, healthcare facilities, and industrial workspaces, diffused LED strips offer tailored solutions with high CRI, precise color control, and glare-free illumination. These installations require adherence to specific technical standards and regulatory compliance.

| Parameter | Museums/Galleries | Healthcare Facilities | Industrial Offices |

|---|---|---|---|

| IP Rating | IP20 | IP20 | IP20 |

| CCT Range | 3500K–4000K | 4000K | 4000K–5000K |

| CRI | ≥95 | ≥90 | ≥80 |

| Power Density | 4–6W/m | 4–6W/m | 6–8W/m |

| Key Requirement | Museum-grade color fidelity; dimmable to 1% | Non-glare lighting for patient comfort; compliance with IEC 60601-1 | Task-specific illumination; vibration-resistant mounting |

Beauty STC’s OEM capabilities support custom CRI tuning (e.g., R9 >90 for museum applications) and specialized connectors for healthcare environments. All products comply with IEC 62471 photobiological safety standards.

Contractor Installation Best Practices

Successful deployment of diffused LED strip systems requires adherence to technical protocols and regional compliance standards. Key practices include:

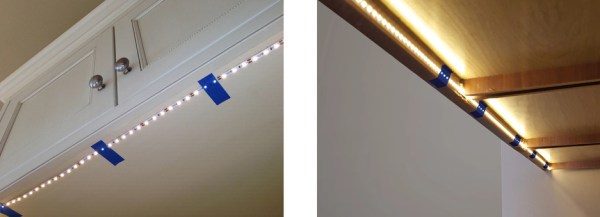

Aluminum Channel Mounting:

Use extruded aluminum channels (e.g., 10mm width) to dissipate heat, enhance diffusion, and protect the LED strip. This extends lifespan by 30% compared to surface mounting alone.

Voltage Drop Management:

For runs exceeding 5 meters, use 24V DC systems. Calculate total wattage (e.g., 6W/m × 10m = 60W) and ensure power supplies are rated at 120% of system load (e.g., 72W PSU for 60W load).

Connection Protocols:

Solder connections for permanent installations; use IP68-rated waterproof connectors for wet environments. Avoid mechanical connectors in high-vibration zones (e.g., industrial facilities).

Compliance Verification:

Confirm ETL (US/Canada) or TUV CE (EU) certifications for all projects. Beauty STC’s products undergo third-party testing per UL 8750 and EN 62471 standards.

OEM Customization:

For unique project specifications (e.g., custom lengths, connector types, or color temperatures), leverage our 25+ years of manufacturing expertise. We support 5–100m custom lengths, 2700K–6500K CCT ranges, and proprietary diffuser coatings for specialized applications.

As a manufacturer since 1998, Beauty STC Lighting delivers certified, factory-direct solutions for global commercial projects. Our quality control processes include 100% L70 testing and thermal cycling validation to ensure reliability in extreme conditions.

Contact for Technical Specifications:

[email protected] | +86 13902885704

Certifications: ETL (USA/Canada), TUV CE (Europe) | ISO 9001:2015 Compliant

Why Choose Beauty STC Lighting

Partner with a Factory That Has Already Solved Your Diffused-Strip Headaches

(H2 – factory-direct, no fluff)

25 Years of Continuous Production, 50+ Countries of Field Data

Since 1998 Beauty (STC) Manufacturing Co., Ltd has shipped diffused LED strip solutions to distributors, contractors and lighting architects across Europe, North America, Australia, Japan, Korea, Russia and SE-Asia. The same Jianghai-based production lines that passed ETL (US/Canada) and TUV CE audits in 2005 are still running 24/7 today—giving you a supply partner whose process stability is validated by time, not marketing copy.

Certifications That Keep Your Containers Moving

| Market | Certification File | Lab / Standard | Renewal Cycle |

|---|---|---|---|

| USA & Canada | ETL cETLus | Intertek UL 2108 + CSA 250.13 | Annual |

| Europe | TUV CE | TÜV SÜD EN 60598-2-20, EN 62031 | Bi-annual |

| Global | RoHS / REACH | SGS | Per batch |

No conditional “tested to” statements—each diffused strip reel carries the file numbers your customs broker asks for.

OEM & ODM Ready—From Silicone Extrusion to Spectrum Tuning

Extrusion line: 1 200 kg/day silicone capacity, 180 °C continuous vulcanisation → seamless 5 m & 10 m dot-free jackets

SMT line: 1 200 000 chips/24 h, 0.5 mm pitch pick-and-place → CRI 90 – 98, 180 – 300 LEDs/m available

Binning & TIR testing: 1 nm bin width, 2 SDCM standard (3 SDCM max)

Logistics: weekly FCL/LCL consolidation to Hamburg, Los Angeles, Dubai, Sydney

Send us your spectral-power file, CCT tolerance or IP67 mechanical drawing—we return a locked BoM, timeline and PPAP within 72 h.

Next Step—Engineering Samples in 7 Days

Email the specification sheet to [email protected] or message +86-139 0288 5704 (WeChat / WhatsApp). We will ship a 300 mm evaluation coil, complete LM-80 & ISTMT data, and a copy of the ETL/TUV CE files so your technical team can verify compliance before the PO is even raised.

Beauty STC Lighting – responsible production, caring people, since 1998.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).