Article Contents

Industry Insight: Rgbw Led Tape

The Critical Role of Certified RGBW LED Tape in Commercial Applications

RGBW LED tape has become an indispensable tool for commercial and industrial lighting projects, enabling dynamic color control, precise white balance, and energy-efficient illumination for applications ranging from architectural accent lighting to retail displays, hospitality environments, and industrial workspaces. However, the global market is saturated with uncertified, low-cost alternatives that compromise safety, performance, and regulatory compliance. For importers, contractors, and architects, these products pose significant risks—including electrical hazards, project delays, costly rework, and legal liabilities. Selecting a supplier with verified certifications and decades of manufacturing expertise is not merely a preference; it is a non-negotiable requirement for project success.

Why Certification Matters for Global Importers

Certifications such as ETL (USA/Canada) and TÜV CE (Europe) represent rigorous third-party validation of electrical safety, thermal management, and environmental compliance. Non-compliant products often fail during customs inspections or field testing, leading to shipment rejections, financial penalties, and reputational damage. Below is a comparative overview of key certification requirements across major markets:

| Market Region | Required Certification | Common Consequences of Non-Compliance |

|---|---|---|

| United States & Canada | ETL, UL Listed | Customs detention, liability claims, project delays |

| European Union | TÜV CE Marking | Import bans, legal fines, market withdrawal |

| Australia | SAA/RCM Certification | Safety hazards, mandatory product recalls |

| Japan | PSE Certification | Rejected shipments, costly rework |

These certifications ensure products meet localized safety standards, reducing risks for end-users while streamlining import processes. For global distributors, this translates to reliable supply chains and minimized regulatory overhead.

The Manufacturing Imperative: Experience Meets Rigor

With 26 years of continuous operation since 1998, Beauty STC Lighting has refined its manufacturing processes to meet the highest international standards. Our facility in Jiangmen, Guangdong, operates under a closed-loop quality management system, ensuring every batch of RGBW LED tape undergoes rigorous testing for lumen consistency, color accuracy, thermal performance, and electrical safety before shipment. This longevity reflects a commitment to quality control that transcends short-term market trends. For OEM and ODM clients, this means:

Customizable configurations tailored to project-specific requirements (e.g., voltage, IP ratings, beam angles)

Consistent performance across large-volume orders, eliminating batch-to-batch variations

Compliance documentation pre-validated for destination markets, reducing time-to-market

Beauty STC Lighting: A Trusted Partner for Commercial Projects

As a global supplier to over 50 countries, Beauty STC Lighting combines technical expertise with manufacturing rigor to eliminate the risks associated with uncertified LED products. Our RGBW LED tape solutions are engineered for commercial-grade reliability, with certifications validated by independent laboratories such as Intertek (ETL) and TÜV Rheinland. Whether you require wet-location rated strips for marine environments or high-CRI white channels for museum installations, our team provides end-to-end support from design through delivery.

| Specification | Beauty STC RGBW LED Tape Specifications |

|---|---|

| Lumen Output | 280–530 lm/ft (adjustable per model) |

| Color Rendering Index (CRI) | ≥90 for white channels |

| IP Ratings | IP20 (indoor), IP65 (outdoor), IP67 (submersible) |

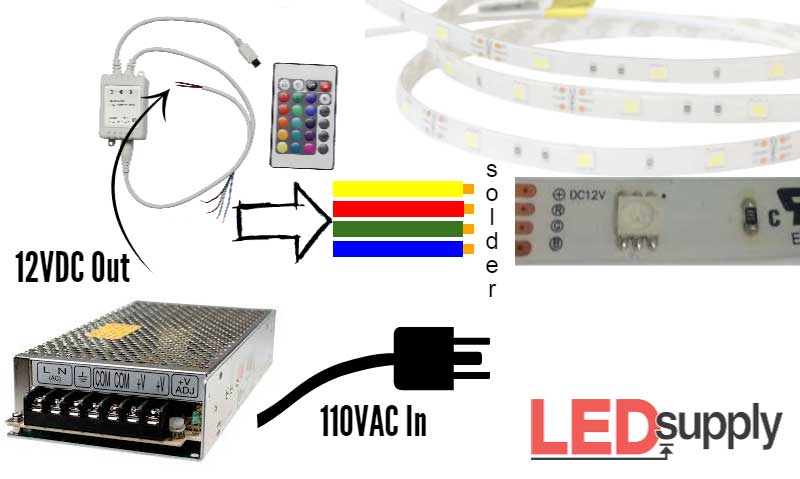

| Voltage Options | 12V DC, 24V DC, 120V AC (customizable) |

| Certifications | ETL (US/Canada), TÜV CE (EU), RoHS compliant |

| Customization | OEM/ODM support for length, connectors, firmware |

For detailed technical specifications, compliance documentation, or project-specific engineering support, contact our team directly:

[email protected] | +86 13902885704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards – RGBW LED Tape

Beauty (STC) Manufacturing Co., Ltd has produced flexible LED assemblies since 1998.

Every RGBW reel is engineered for 50 000 h L70 life, verified in our Jiangmen EMC-lab and double-checked by TUV & ETL witness-testing.

Below are the parameters we guarantee—lot-to-lot, reel-to-reel, shipment-to-shipment.

2.1 Key Electrical & Photometric Data

| Parameter (per metre, 24 V) | Min | Typical | Max | Unit | Test Condition |

|---|---|---|---|---|---|

| RGB+3000K power | 14.4 | 16.0 | 17.6 | W | Ta = 25 °C, PWM 100 % |

| Luminous flux, RGB+W | 900 | 1000 | — | lm | Integrating sphere, 2 m reel |

| Luminous efficacy | — | 62 | 65 | lm W⁻¹ | White channel only |

| CRI (3000K / 4000K / 6500K) | 90 | 92 | — | Ra | IEC 62717 |

| R9 saturated red | 55 | 65 | — | — | IEC 62717 |

| Chromaticity tolerance | — | 3 SDCM | 5 SDCM | — | MacAdam ellipse |

| Beam angle (flat PCB) | — | 120 | — | deg | 50 % Iθ |

| PWM frequency (on-board) | — | 2000 | — | Hz | Flicker-free <1 % @ 1 k fps |

| Operating temperature | –30 | — | +65 | °C | IEC 60598-2-20 |

| Storage temperature | –40 | — | +80 | °C | IEC 62717 |

| Lifetime (L70B10) | — | 50 000 | — | h | TM-21, 55 °C Ts |

2.2 Mechanical & Environmental Ratings

| Item | Specification | Remark |

|---|---|---|

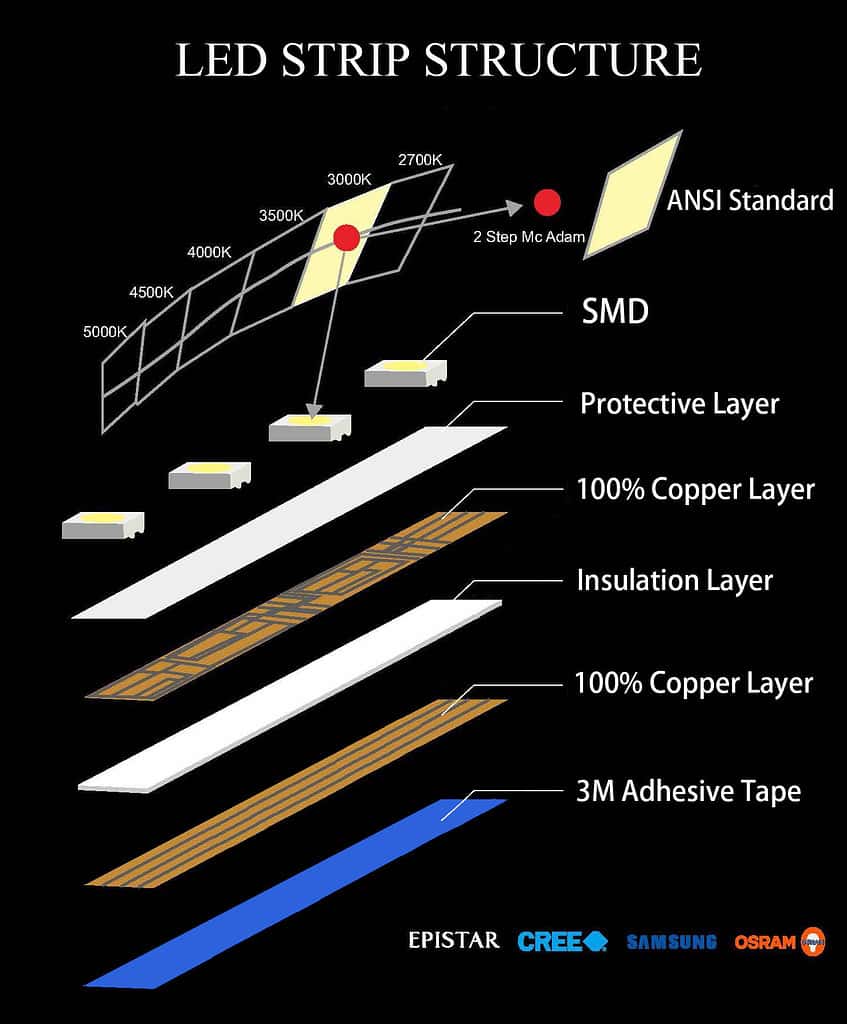

| PCB base | Double-layer rolled copper, ≥2 oz Cu, 0.20 mm dielectric | UL 94 V-0 |

| Copper thickness tolerance | ±0.25 oz | Measured by X-ray fluorescence |

| LED package | 4-in-1 RGBW 5050, 20 mA per die | Epistar/Toyoda Gosei |

| Pixel pitch | 16.7 mm (60 LED m⁻¹) or 8.33 mm (120 LED m⁻¹) | Custom spacing available |

| Width × Height | 12 mm × 2.2 mm (IP20) | 14 mm × 4.5 mm (IP65) |

| IP rating options | IP20, IP65 (PU glue), IP67 (silicone tube), IP68 (co-extrusion) | Certified per IEC 60529 |

| Bending radius | ≥30 mm | 1000-cycle mandrel test |

| Adhesive | 3M 9495LE + red VHB layer | –40 °C to +150 °C |

| solderability | 245 °C ±5 °C, 5 s, 95 % wetting | J-STD-002 |

| Maximum run length | 5 m @ 24 V (single-feed) | Voltage-drop <5 % |

| Cut increment | Every 50 mm (12 V) or 100 mm (24 V) | Printed cut marks + copper bus |

2.3 Certifications & Factory Controls

North America: ETL listed to UL 2108 & CSA C22.2#207, file 5023348.

Europe: TUV CE, EN 60598-2-20, EN 62031, EN 62471, EN 55015, RoHS/REACH.

Photobiological risk group: RG0 (exempt).

Production traceability: 2-D code on every 0.5 m section → links to LM-80 raw data, bin code, operator ID, reflow profile.

Incoming QC: 100 % high-resolution AOI for solder joints, 5 kV hipot for 3 s.

Aging: 100 % loaded 4 h @ 60 °C before vacuum-pack.

Shipment sample: 0.5 % of every batch sent to third-party lab for 6 kV surge, –40 °C↔+105 °C thermal-shock (50 cycles).

2.4 Generic Market vs. Beauty STC Certified Quality

| Critical-to-Function Item | “Generic” Market Reel | Beauty STC Certified Reel |

|---|---|---|

| Copper weight | 1 oz, <17 µm | 2 oz, 35 µm minimum |

| Lumen maintenance (6 k h) | 85 % typical | 94 % (TM-21 projection) |

| CRI | 80 ±5 | 90 ±2, R9 ≥55 |

| Chromaticity binning | 7 SDCM, mixed reels | 3 SDCM, single bin per reel |

| PCB temperature rise | 35 K @ 15 W m⁻¹ | 18 K @ 16 W m⁻¹ |

| IP65 glue yellowing ΔYI | 10 after 1 000 h 85 °C | ≤3 (PU UV-stabilised) |

| ESD capability (HBM) | 1 kV | 8 kV on LED, 2 kV on driver |

| Certifications | Self-declared CE only | ETL + CE, test reports on file |

| Warranty | 1 year | 5 years (conditions apply) |

2.5 Consistency Tools Used in Jiangmen Plant

- Bin-on-reel policy: LEDs picked from the same 1 nm wavelength and 1 SDCM white bin.

- Automated solder-paste jetting (PVA): ±15 µm repeatability → eliminates cold-joint risk.

- Inline spectroradiometer (Everfine HAAS-2000): every 0.5 m recorded; out-of-spec sections automatically rejected.

- Thermal-camera feedback: adjusts reflow zone temperature in real time to keep ΔT across PCB <5 °C.

- Vacuum+Moisture-barrier packaging: <5 % RH, 60 °C bake 8 h before sealing—prevents micro-cracks during overseas freight.

For OEM colour-tuning, longer runs, or specific IP68 underwater ratings, e-mail technical drawings to [email protected]. Our tooling shop can deliver custom PCB width, 24 V or 36 V architecture, and matched DMX/Bluetooth controllers within 15 working days.

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services

With 25+ years of LED manufacturing expertise since 1998, Beauty STC Lighting’s Jiangmen facility integrates industrial precision with advanced automation to deliver certified RGBW LED strip solutions for global markets. Our factory operates under ISO 9001 quality management systems, with all products rigorously tested to meet ETL (USA/Canada) and TÜV CE (Europe) standards. This commitment to technical excellence ensures consistent performance, safety, and compliance for commercial and industrial applications worldwide.

Advanced SMT Production Line

Our manufacturing process begins with fully automated Surface Mount Technology (SMT) assembly. High-speed pick-and-place machines and precision reflow soldering systems ensure accurate component placement and robust solder joints. Each PCB assembly undergoes Automated Optical Inspection (AOI) to detect defects at the microscopic level before progressing to subsequent stages. This eliminates human error and guarantees uniformity across all production runs—critical for maintaining color consistency and electrical reliability in RGBW LED strips.

Rigorous Quality Assurance Protocols

Every batch of LED strips undergoes multi-stage testing aligned with international standards. Our QC protocols ensure products meet or exceed industry benchmarks for performance, safety, and longevity:

| Test Type | Standard | Procedure | Frequency |

|---|---|---|---|

| Component Inspection | ISO 9001 | AOI for solder joints and component placement | In-process |

| 72-Hour Aging Test | IEC 62471 | Continuous operation at rated load; temperature and voltage monitoring | 100% of batches |

| Lumen & Color | LM-79, IEC 62717 | Spectroradiometer measurements at 25°C ambient | Each batch |

| Waterproof Test | IEC 60529 | Submersion or spray testing for IP-rated products | Pre-shipment |

OEM/ODM Customization Capabilities

Our factory supports end-to-end OEM/ODM solutions tailored to global project requirements. From bespoke lengths to specialized packaging, we provide scalable manufacturing with strict tolerance controls and transparent lead times:

| Customization Type | Options | Tolerance | Lead Time |

|---|---|---|---|

| Length & Cut Points | 1m–100m; cut intervals (50mm, 100mm, 12″) | ±1mm | 7–10 days |

| CCT & Color | White: 2700K–6500K; RGBW spectrum (16.7M colors) | ΔCCT ±100K | 10–15 days |

| Packaging | Branded boxes, bulk packaging, custom inserts | As specified | 5–7 days |

| IP Ratings | IP20 (indoor), IP65, IP67, IP68 (outdoor/wet) | N/A | 12–18 days |

All custom configurations undergo identical certification testing as standard products. For projects requiring regional compliance (e.g., UL, KC), we provide full technical documentation and certification support upon request.

Global Compliance & Certification

Beauty STC Lighting’s manufacturing processes are designed to meet the strictest international standards. Every RGBW LED strip—whether standard or OEM—passes independent third-party testing for electrical safety, photometric performance, and environmental durability. Our ETL and TÜV CE certifications cover all core product lines, and we maintain full traceability of materials from raw components to finished goods. This ensures seamless integration into projects targeting North American, European, and other regulated markets.

For technical specifications, certification documents, or project-specific inquiries, contact our engineering team:

[email protected] | +86 13902885704

Installation & Application Scenarios

Application Scenarios for Factory-Certified RGBW LED Tape

(ETL/TUV-CE, 25-year OEM/ODM experience since 1998)

1. Hospitality & Commercial Interiors

| Zone | Recommended Spec | Installer Notes |

|---|---|---|

| Hotel lobbies, ballrooms, suites | 24 V, 14.4 W/m, 4-in-1 5050 RGBW, 3000 K white node | Mount in 15 mm aluminium profile with PC opal diffuser to hide individual dies; use Class-2 isolated driver, ETL-listed for 120–277 V input. |

| Shopping-mall feature ceilings | IP54 silicone-sleeved tape, 60 LED/m, CRI ≥ 90 (white channel) | Feed every 5 m from both ends to keep colour consistency Δu′v′ ≤ 0.003; loop-through junction boxes must be TUV-CE rated. |

2. Architectural Façade & Landscape

| Facade Type | Product Code | Field Practice |

|---|---|---|

| Glass curtain wall backlight | BEA-RGBW-24V-60-10W, outdoor -40 °C to +60 °C | Install on 3 M VHB aluminium track; apply neutral-cure silicone at every 50 cm to allow thermal movement; control cable ≤ 20 m from DMX512 decoder to avoid voltage drop. |

| Underwater pool rim | IP68 PU-filled, 12 mm width, 24 V, 19.2 W/m | Use marine-grade 316 SS mounting clips every 30 cm; power supply off-site in ventilated IP65 cabinet, GFCI-protected, ETL-listed. |

3. Office & Human-Centric Lighting

| Area | Spec | Compliance |

|---|---|---|

| Open-plan ceiling coves | 4000 K white channel + RGB accent, 120 LED/m, flicker-free <1 % @ 1 kHz | Driver must meet IEEE 1789-2015; integrate with DALI-2 DT8 tunable-white driver for circadian scheduling. |

| Video-conference backdrop | 24 V, 10 mm pitch, 3-oz copper FPC for ≤ 5 % voltage drop on 10 m run | Maintain 10 cm separation from microphone cables; shielded DMX required to prevent AF interference. |

4. Retail & Museum Display

| Application | Optical Data | Mounting Detail |

|---|---|---|

| Shelf edge lighting | 160° dome lens, 530 lm/ft white, RGB saturation 16 million colours | Clip into anodised 45° asymmetric profile; feed every 2.4 m; colour-calibrate with X-Rite i1 to ΔE2000 < 2. |

| Artwork wall wash | 24 V, 24 W/m, CRI 95, R9 > 90 | Set back 30 cm from wall, 15° tilt; use anti-glare honeycomb louver; dim 0–100 % via DMX512 RDM. |

Contractor Installation Checklist (Factory-Direct OEM Notes)

-

Voltage Drop Rule

24 V system: max 2.5 % drop.

Table – Max Run vs. Cross-Section

| Tape Power | 2-oz FPC | 3-oz FPC | Parallel Feed Both Ends |

|—|—|—|—|

| 10 W/m | 5 m | 7 m | 10 m |

| 14.4 W/m | 3.5 m | 5 m | 7 m |

| 19.2 W/m | 2.5 m | 4 m | 5 m | -

Thermal Management

Operating case temp must stay ≤ 70 °C per ETL test report.

Use aluminium profile ≥ 10 mm²/m surface area; apply thermal tape 3 W/m·K. -

DMX512 Addressing

Allocate 5 channels per RGBW pixel (R-G-B-W-Dimmer).

Terminate last decoder with 120 Ω resistor; use ETL-listed isolated splitters every 32 devices. -

Wiring & Codes

18 AWG stranded, 300 V, 105 °C, VW-1 between sections.

Junction boxes IP66, TUV-CE EN 60598-2-20; keep low-voltage ≤ 60 V DC to avoid conduit per NEC 411. -

Commissioning Tools (OEM Support)

Beauty STC provides factory DMX patch file & spectral report (.csv) for every reel.

On-site NIST-traceable calibration available for projects > 5 km.

Need project-specific length, CCT, or IP-rating? Email technical drawings to [email protected]; 48-hour OEM quote with ETL/TUV-CE data pack.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting: Your Trusted RGBW LED Strip Source

Global Compliance & Certification Assurance

Beauty STC Lighting adheres to rigorous international standards to ensure product safety, performance, and market readiness. Our certifications validate compliance for critical global markets:

| Certification Body | Region Covered | Key Standards |

|---|---|---|

| ETL (Intertek) | USA & Canada | UL 1598, UL 2108 |

| TÜV Rheinland CE | European Union | EN 60598, EN 62368-1, IEC 60598 |

| RoHS | Global | EU Directive 2011/65/EU (Hazardous Substance Restrictions) |

25+ Years of Industrial Manufacturing Expertise

Established in 1998, Beauty STC Lighting has maintained a vertically integrated manufacturing process with consistent quality control from raw materials to finished goods. Our 25+ years of experience in LED technology ensures precision-engineered RGBW LED strips that meet the demanding requirements of commercial, industrial, and architectural projects worldwide. All products undergo strict testing protocols to guarantee longevity, color accuracy, and thermal stability under real-world conditions.

OEM/ODM Capabilities for Global Projects

We provide end-to-end customization for distributors and project stakeholders, with full technical and logistical support:

| Service | Details |

|---|---|

| Custom Formulations | Tailored color temperatures (2700K–6500K), lumen output (250–650 lm/ft), and quad-chip configurations for precise color rendering |

| Private Labeling | Full branding, packaging, and labeling per your specifications, including custom box designs and documentation |

| Technical Support | Dedicated engineering team for project-specific R&D, thermal management, and installation optimization |

| Global Logistics | FOB, CIF, and DDP shipping options to 50+ countries, with compliance documentation for customs clearance |

For technical specifications, sample requests, or project consultations, contact our international sales team directly:

[email protected] | +86 13902885704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).