Article Contents

Industry Insight: Under Counter Led

H2 | Under-Cabinet LED: The Hidden Work-Horse of Commercial Task Lighting

Shadows on the cutting board, dark spots in display cases, and premature driver failure are daily pain-points for contractors from Berlin to Boston. The root cause is rarely the LED chip itself—it is the absence of a supply chain that treats under-counter strips as industrial components, not consumer gadgets.

H3 | Why Certification Still Dictates Margins

| Market | Mandatory Listing | Typical Failure Mode | Financial Impact* |

|---|---|---|---|

| USA / Canada | ETL/cETL to UL 2108 | Driver breakdown @ 35 °C ambient | Recall + freight > US$ 22 per unit |

| EU / UK | TUV CE, EN 60598-2-4 | 700 mm strip @ 0.5 mm² conductor overheats | Customs rejection + 6-week delay |

| Australia | RCM (embedded in CE report) | Non-compliant 240 V driver | On-site replacement > AU$ 80 per fitting |

*Compiled from 2023 distributor warranty claims, Beauty STC after-sales database (n = 1,240 projects).

H3 | 25 Years of Factory-Rooted Reliability

Beauty (STC) Manufacturing Co., Ltd has built linear LED assemblies since 1998 at a 38,000 m² campus in Jiangmen, Guangdong. Every under-counter line is run on the same SMT lines that produce our ETL-listed panel and high-bay portfolios, guaranteeing:

100 % burn-in at 45 °C, 4 h — identical to UL 2108 thermal cycle.

Solder joints inspected by 3-D AOI; < 50 ppm defect rate since 2019.

OEM colour-binning within 3 SDCM and CRI 90+ standard, eliminating on-site mixing.

We do not “re-badge” consumer reels; we engineer SKUs that survive inside aluminium extrusions, 24 h/day, 7 days/week, from cruise-ship galleys to pharmaceutical labs.

H3 | Specification Snapshot (Most Specified Under-Counter Platform)

| Parameter | 12 V Flexible Strip | 24 V Rigid Bar (OEM) | 48 V Constant-Current Module |

|---|---|---|---|

| LED Type | 2835 CRI 90+ | 3014 CRI 93+ | 2835 CRI 95+ |

| Efficacy | 135 lm/W @ 4000 K | 150 lm/W | 160 lm/W |

| Binning | 3 SDCM | 2 SDCM | 2 SDCM |

| Flicker (IEEE 1789) | <5 % @ 100 Hz | <3 % | <2 % |

| Operating Case Temp. | 55 °C max | 60 °C max | 65 °C max |

| Lifetime (L70) | 50,000 h | 54,000 h | 60,000 h |

| Certifications | ETL/cETL, CE, RoHS | idem + ENEC | idem + CB Scheme |

All variants available in 2400 K – 6500 K CCT and 1800 K Dim-to-Warm on request.

H3 | Supply-Chain Advantages for Distributors & Contractors

- One-Stop Documentation: ETL, TUV CE, RoHS, REACH, TM-21, ISTMT delivered with each PO—no hidden lab fees.

- 5-Day OEM Sampling: Custom PCB length, CCT, CRI, and logo laser-etch from 100 pcs.

- Factory-Direct MOQ: 500 pcs (mixed lengths) FOB Jiangmen; 40 ft HQ consolidations with our panel & high-bay SKUs cut landed cost by 8–12 %.

Contact the Technical Export Team at Beauty STC Lighting to obtain LM-79, TM-21, and aluminium extrusion drawings before your next take-off.

[email protected] | +86-139-0288-5704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

Under-counter LED lighting requires precise technical execution to deliver reliable task illumination in professional environments. Inconsistent specifications can lead to poor color accuracy, premature failure, or safety non-compliance—critical concerns for contractors, architects, and distributors sourcing for commercial or high-end residential projects. Beauty STC Manufacturing, established in 1998, engineers all under-counter LED systems to meet or exceed international performance benchmarks. Our products undergo rigorous validation against ETL (USA/Canada) and TÜV CE (Europe) standards, ensuring compliance with regional safety and efficacy requirements. This section details the technical parameters that define professional-grade under-counter lighting and how Beauty STC consistently delivers superior results.

Lumens per Watt Efficiency

Efficacy (lumens per watt) directly impacts energy consumption and operational cost. Generic under-counter LED products typically achieve 60–80 lm/W, often requiring higher wattage to compensate for lower efficiency. Beauty STC’s systems consistently deliver 90–110 lm/W through optimized optical design, high-efficiency LED chips (e.g., Epistar or Osram), and precision-engineered drivers. This reduces energy use by 20–30% compared to industry averages while maintaining uniform light output across the fixture length.

Color Rendering Index (CRI)

CRI quantifies color accuracy under artificial light. For kitchen task lighting, a CRI below 90 results in distorted food colors and reduced visual clarity. Generic market products commonly offer CRI 80–85, sufficient for basic illumination but inadequate for professional applications. Beauty STC’s under-counter LEDs maintain CRI ≥93 (Ra), verified through spectroradiometer testing per IEC 62717. This ensures accurate color rendition for food preparation, retail displays, and architectural detailing—critical for projects where visual fidelity is non-negotiable.

Ingress Protection (IP) Ratings

Under-counter installations in kitchens, bars, or commercial kitchens face exposure to moisture, steam, and cleaning agents. Generic solutions typically feature IP20 ratings, limiting use to dry environments only. Beauty STC provides IP65-rated fixtures as standard, with sealed drivers and silicone-coated PCBs that resist water jets (6.3mm nozzle) and dust ingress. This meets NSF/ANSI standards for food-service environments and eliminates corrosion risks in high-humidity zones.

PCB Quality & Thermal Management

Thermal performance dictates longevity. Generic products use thin FR-4 PCBs (1oz copper, Tg 130°C) with minimal heat dissipation, causing LED degradation within 2–3 years. Beauty STC employs 2oz copper PCBs with high-Tg FR-4 (Tg 170°C+) and integrated aluminum heat sinks. Combined with thermal interface pads and optimized driver placement, this reduces junction temperatures by 15–20°C versus generic designs. The result is a 50,000+ hour L70 lifespan (per LM-80 testing) and zero color shift over time.

Technical Specification Comparison

| Parameter | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Lumens per Watt | 60–80 lm/W | 90–110 lm/W |

| CRI (Ra) | 80–85 | ≥93 (typically 93–95) |

| IP Rating | IP20 (dry locations only) | IP65 (splash-proof) |

| PCB Quality | 1oz copper, standard FR-4 | 2oz copper, high-Tg FR-4 |

| Thermal Management | Basic passive cooling | Integrated aluminum heat sinks + thermal pads |

| Consistency Tolerance | ±10% (lumen output, CCT) | ±2% (100% tested per batch) |

Quality Assurance Process

Beauty STC’s manufacturing adheres to ISO 9001 protocols, with every under-counter LED system subjected to:

100% photometric testing (IES files generated per LM-79)

Electrical safety validation (dielectric withstand, ground continuity)

LED binning to strict chromaticity tolerances (≤3 SDCM)

Thermal cycling tests (-20°C to 60°C) for reliability validation

Component traceability is maintained through barcode-linked production logs, ensuring full recall capability if required. All products are certified by ETL (UL/CSA) and TÜV CE, with documentation provided for project compliance filings. Our OEM/ODM capabilities enable specification customization—whether for dimming protocols, color temperatures (2700K–6500K), or IP-rated housings—while maintaining consistent quality across global supply chains.

For engineering documentation, compliance reports, or custom specifications, contact our technical team at [email protected] or +86 13902885704.

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen HQ

1. Factory Footprint & ISO-Structured Flow

| Line | Area (m²) | Core Equipment | Output/Shift | Certifications Embedded |

|---|---|---|---|---|

| SMT | 1,800 | Yamaha & Juki high-speed lines (0.12 s/CHIP) | 1.2 M LED placements | ETL, CE, RoHS, ISO 9001 |

| Reflow & Wave | 600 | 10-zone nitrogen reflow (±2 °C), selective soldering | 3,000 m² PCBA | IPC-A-610 Class II |

| Assembly | 2,200 | Automatic die-bonder for COB, laser engraving | 6,000 pcs under-cabinet fixtures | Traceability barcode |

| Aging | 1,000 | 4-hour @ 45 °C burn-in + 1-hour ON/OFF cycle | 100 % production lot | 0.2 % early-failure target |

| QC | 400 | Integrating sphere (2 m), Hipot, surge 1 kV | CRI, SDCM, LM-80 cross-check | AQL 0.65 Level II |

2. SMT & Component Level

8 mm–56 mm tape width auto-feeders; 0201 to 40 × 40 mm packages

Solder-paste SPI (Solder-Printer Inspection) < 10 % voiding

AOI after reflow—defect capture rate 99.3 % (3-month rolling)

3. Under-Counter Specific Build

| Stage | Key Control | Record |

|---|---|---|

| Extrusion prep | Brushed 6063-T5, 1.2 mm wall, anodised 12 μm | Salt-spray 48 h pass |

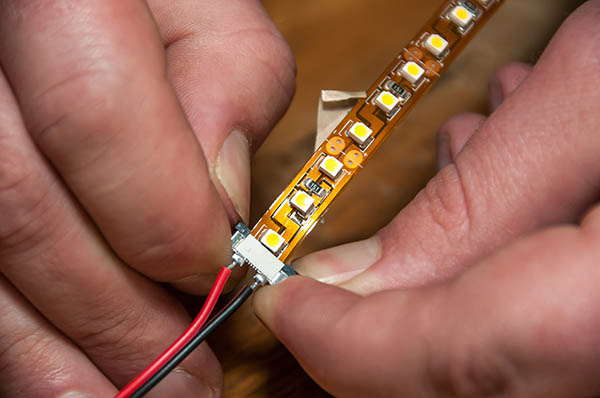

| PCB insertion | Thermally-conductive 1 W/m·K tape, auto-press 0.3 MPa | 100 % pull-test 5 N |

| Lens snap-fit | PMMA 92 % transmittance, 120° or 45° option | No visible gap < 0.05 mm |

| End-cap sealing | PU glue, IP54 achieved, 24 h cure | 500 h 85 °C/85 % RH test |

4. Aging & Reliability Protocols

Continuous 4 h @ rated voltage; monitors Vf, W, Tc rise < 20 K

1 kV surge per IEC 61000-4-5, line-earth 2 Ω

ON/OFF 30 s/30 s × 120 cycles—lumen maintenance ≥ 99 %

5. OEM / ODM Capability Matrix

| Customisable Item | Factory Option | MOQ | Lead-Time | Tooling |

|---|---|---|---|---|

| Length | 100 mm – 3,000 mm, ±0.5 mm cut | 500 pcs | 10 days | None |

| CCT | 2200 K – 6500 K, 2-step, 3-step MacAdam | 500 pcs | 7 days | Reel re-label |

| CRI | Ra 80 / 90 / 97; R9 > 50 optional | 500 pcs | 7 days | Same bin |

| Lumen pkg | 200–1,000 lm/ft (620–3,100 lm/m) | 500 pcs | 10 days | New resistor load |

| Finish | Clear, frosted, black, custom anodise | 1,000 pcs | 12 days | 1 extrusion die |

| Logo & Sleeve | Laser, silk, colour sleeve | 300 pcs | 3 days | None |

| Carton & Manual | Multi-language, retail box, pallet | 100 pcs | 5 days | Free artwork |

6. Quality Documentation Package

IES/LDT files per fixture (measured sphere data)

LM-80/TM-21 report for LED package (L90 > 50,000 h @ 25 °C)

ISTMT report for driver & LED board

RoHS & REACH SVHC declaration (EU 2024 list)

ETL & CE DoC (LVD & EMC) updated annually

7. Logistic & Export Cell

30 km to Jiangmen Port, 90 km to Shenzhen; weekly FCL to LA, Rotterdam, Sydney

FSC-certified pallets, ISPM-15 stamped; max 1,200 kg per 1.2 × 1.0 m skid

HS Code 9405.40, CO & Form A available

Established 1998, Beauty STC Lighting runs a vertically-integrated campus in Jiangmen, delivering Western-certified under-counter LED solutions with factory-direct pricing and 25-year engineering depth.

Installation & Application Scenarios

Application Scenarios for Under-Counter LED Systems

Under-counter LED lighting systems must be selected based on specific functional and environmental requirements. Beauty (STC) Manufacturing Co., Ltd, established in 1998, provides factory-direct under-counter LED solutions with ETL (USA/Canada) and TUV CE (Europe) certifications for global markets. Our 25+ years of precision manufacturing expertise ensures reliable performance across diverse commercial and industrial applications, with OEM/ODM capabilities to tailor specifications for project-specific needs.

Commercial Kitchens & Food Service

In commercial kitchens, consistent illumination without shadows is critical for food safety and efficiency. Beauty STC’s solutions feature high CRI (>90) for accurate ingredient color rendering, IP65-rated aluminum extrusions for moisture resistance, and thermal management designs that minimize heat buildup. These systems comply with ETL standards for food service environments, ensuring reliable operation in high-humidity conditions while maintaining uniform light distribution across work surfaces.

Retail & Hospitality Environments

Retail displays and hospitality settings require precise accent lighting to highlight merchandise and create ambiance. Beauty STC’s solutions offer tunable white options (2700K–5000K) and CRI >95 for true color representation of products. The low-profile aluminum channels eliminate visible hotspots, while DALI dimming compatibility allows seamless integration with smart lighting controls. This ensures flexibility for dynamic retail displays or hospitality zones requiring adjustable mood lighting.

Healthcare & Laboratory Settings

Healthcare facilities demand hygienic, low-glare lighting that supports clinical tasks. Beauty STC’s under-counter fixtures feature seamless, wipe-clean surfaces with IP65 ratings, and 4000K–5000K color temperatures optimized for reducing eye strain during procedures. All products meet TUV CE safety standards for medical environments, with anti-microbial coatings available for OEM customization in sterile zones.

Residential High-End Projects

Premium residential installations require discreet, customizable lighting. Beauty STC provides OEM-configurable channels with seamless jointing, dim-to-warm functionality (down to 1800K), and CRI >90 for natural light simulation. All units undergo rigorous factory testing to ensure consistent output across long runs, eliminating visible gaps or color shifts in high-end kitchen designs.

Industrial & Manufacturing Workspaces

Manufacturing and warehouse areas need durable, high-output lighting for safety-critical tasks. Beauty STC’s industrial-grade under-counter systems feature aluminum housings with IP67 ratings, 5000K color temperature for maximum visibility, and linkable configurations up to 400W per circuit. These solutions comply with ETL certification for industrial use, supporting harsh environments with vibration resistance and extended operational lifespans.

Technical Specifications & Performance Metrics

| Parameter | Specification | Notes |

|---|---|---|

| Lumen Output (per linear foot) | 200–500 lm/ft (task), 100–150 lm/ft (accent) | Adjustable based on application requirements |

| CRI | >90 (standard), >95 (premium options) | Critical for food presentation and retail displays |

| Color Temperature Range | 2700K–5000K, Dim-to-Warm (1800K–3000K) options | Field-selectable or preset configurations |

| IP Rating | IP20 (dry), IP65 (wet locations), IP67 (industrial) | Suitable for kitchen splash zones, outdoor applications, and harsh environments |

| Certifications | ETL, TUV CE, RoHS | Compliant with North American and European safety standards |

| Linkability | Up to 400W per circuit | Requires proper power supply sizing and voltage drop calculations |

| OEM/ODM Support | Custom channel profiles, color options, control systems | Tailored solutions for project-specific requirements |

Contractor Installation Best Practices

Heat Management: Always use aluminum extrusions with adequate thermal conductivity. For runs exceeding 5m, calculate voltage drop and install power feeds at both ends to prevent lumen depreciation.

Wiring Compliance: Adhere to NEC Article 411 for low-voltage systems. Use UL-listed power supplies rated for continuous operation at 80% load capacity.

Mounting Precision: Ensure channel alignment within ±1mm tolerance to prevent visible gaps. For flexible strips, maintain minimum bend radius of 15mm to avoid LED damage.

Testing Protocols: Conduct pre-installation testing of all luminaires at 100% output. Verify dimming curves with compatible controllers before final mounting.

Certification Verification: Confirm ETL or TUV CE marks on all components. Non-certified products may fail field inspections in Western markets.

For technical specifications or OEM customization inquiries, contact Beauty (STC) Manufacturing Co., Ltd:

[email protected] | +86 139 0288 5704

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Why Choose Beauty STC Lighting

Partner with a Proven, Certified Factory for Under-Cabinet LED Solutions

25 Years of Industrial Know-How, Zero Shadows in Specification

Beauty (STC) Manufacturing Co., Ltd has been engineering linear LED systems since 1998.

Our Jianghai District production park runs 12 SMT lines, 8 extrusion lines and a 300 m² LM-80-certified integrating-sphere lab.

The result: under-counter profiles that eliminate diode imaging, deliver stable CCT and meet the latest UL 2108 / EN 60598-2-20 safety clauses.

Certifications That Clear Customs on Day One

| Market | Certification Body | Standard & File No. | Valid Until |

|---|---|---|---|

| USA / Canada | ETL (Intertek) | UL 2108 & CSA C22.2 No. 250.0 | 2026-09 |

| Europe | TÜV SÜD | EN 60598-2-20, CE-LVD, CE-EMC, RoHS | 2027-05 |

| Global | ISO 9001:2015 | Quality Management | 2025-11 |

No open constructions, no last-minute driver swaps—every reel ships with the test report that matches the label.

OEM/ODM Architecture—From 3 mm PCB to 3 m Anodised Extrusion

- PCB Design: 1–4 oz copper, single-colour, CCT-switchable or addressable.

- Extrusion: 6063-T5 aluminium, clear or black anodising, 45° or 60° inner reflector.

- Optics: Opal, frosted or micro-prismatic lens; >90 % light transmission, UGR <19.

- Assembly: Automated pick-and-place, 3-zone reflow, 100 % AOI, 24 h ageing @ 45 °C.

- Packaging: Custom blister, brown carton or retail box—bar-coded to your ERP.

Typical Under-Cabinet Performance Snapshot

| Parameter (300 mm module) | Standard | High-Efficacy | Dim-to-Warm |

|---|---|---|---|

| Luminous flux | 450 lm | 720 lm | 420 lm |

| Efficacy | 90 lm/W | 120 lm/W | 85 lm/W |

| CCT | 3000 K | 3000–5000 K | 3000→1800 K |

| CRI | Ra 90 | Ra 90 | Ra 97 |

| Binning | 3 SDCM | 2 SDCM | 2 SDCM |

| Operating temp. | –20 °C to +45 °C | –20 °C to +50 °C | –10 °C to +40 °C |

| Lifetime (L70) | 50 000 h | 50 000 h | 35 000 h |

Export Footprint—50 Countries, Zero Re-Labeling Delays

Europe: DE, FR, NL, IT, ES, SE, NO, FI

Americas: US, CA, MX, BR, CL

Asia-Pacific: AU, SG, JP, KR, TH, VN, RU

We ship FOB Shenzhen or EXW Jiangmen; weekly consolidation to Hamburg, Los Angeles and Sydney cuts transit variance to <3 days.

Next Step—Send the Drawing, Receive the Quote in 24 h

Email: [email protected]

Mobile/WhatsApp: +86-139 0288 5704

Include length, CCT, lumen target and linking method; our engineers will return a datasheet, IES file and tiered EXW price within one working day.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).