Article Contents

Industry Insight: Cob Leds

Introduction & Market Demand

The Evolution of COB LED Technology in Commercial Lighting

Chip-on-Board (COB) LED technology has become the industry standard for high-performance commercial and industrial lighting applications. Unlike conventional SMD configurations, COB designs integrate multiple LED chips into a single, compact module, delivering superior lumen density, uniform light distribution, and enhanced thermal management. This architecture eliminates hotspots and glare while maintaining consistent color output across large surfaces—critical for applications such as high-bay warehouses, LED panel fixtures, floodlighting, and architectural accent lighting. As facility managers prioritize energy efficiency, longevity, and visual comfort, COB solutions have emerged as the preferred choice for projects demanding reliability and optical precision.

Why Certification Matters for Global Importers

In international lighting procurement, compliance with regional safety and performance standards is non-negotiable. Importers sourcing from China must verify that products carry certifications such as ETL (USA/Canada) and TUV CE (Europe), which confirm adherence to rigorous electrical safety, electromagnetic compatibility (EMC), and performance testing protocols. Uncertified components risk costly delays at customs, project rejections due to failed inspections, and potential liability for safety incidents. Reputable manufacturers invest in third-party certifications to ensure their products meet the stringent requirements of Western markets, providing distributors with confidence in product reliability, regulatory compliance, and long-term operational safety.

Beauty STC Lighting: 25+ Years of Industrial-Grade Solutions

Established in 1998, Beauty STC Lighting has delivered certified, industrial-grade LED solutions to over 50 countries worldwide. Our 25+ years of manufacturing expertise ensures every COB LED product undergoes stringent quality control processes, from raw material selection to final testing. As a factory-direct supplier, we specialize in OEM/ODM customization for commercial and industrial applications, with all products validated to meet ETL and TUV CE standards.

| Specification | Details |

|---|---|

| Certifications | ETL (USA/Canada), TUV CE (Europe) |

| Manufacturing Experience | 25+ years (since 1998) |

| Optical Performance | >90 CRI, MacAdam 3-step ellipse for color consistency |

| Thermal Management | Advanced heat dissipation design for 50,000+ hour lifespan |

| OEM/ODM Capabilities | Full customization: optical design, PCB layout, packaging, branding |

Our commitment to technical excellence and regulatory compliance ensures seamless integration into global projects—from warehouse high-bay systems to precision architectural installations—while eliminating the risks associated with uncertified or inconsistent components.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

COB LED Arrays for Professional Lighting Projects

At Beauty (STC) Manufacturing Co., Ltd we treat Chip-on-Board (COB) LEDs as precision opto-electronic components rather than commodity parts. Every array that leaves our Jiangmen plant is engineered to deliver repeatable photometric values, thermal stability and 50 000 h L70 lifetime under Western-market safety rules.

1. Key Performance Metrics – What We Specify & How We Test

| Parameter | Industry Symbol | Beauty STC Test Condition | Guaranteed Lot-to-Lot Tolerance |

|---|---|---|---|

| Luminous Efficacy | ηv | Tj = 85 °C, 300 mA/mm² | ±3 % (3-step SDCM) |

| Colour Rendering | CRI | 90 min. (target 93) | ±1.5 point |

| Correlated Colour Temp. | CCT | 2700 – 6500 K | ±150 K |

| Thermal Resistance | Rth j-sp | JEDEC JESD 51-14 | ≤1.2 K/W |

| Lumen Maintenance | L70 | TM-21, 55 °C Ta | >50 000 h |

| Ingress Protection | IP | IEC 60529 | IP20 (std) / IP65 / IP67 / IP68 |

| PCB Copper Weight | — | IPC-6012D | 2 oz (70 µm) base, 3 oz optional |

All measurements are performed on an integrated 2 m sphere system calibrated to NIST traceable standards and cross-verified by TÜV SÜD during annual CE surveillance audits.

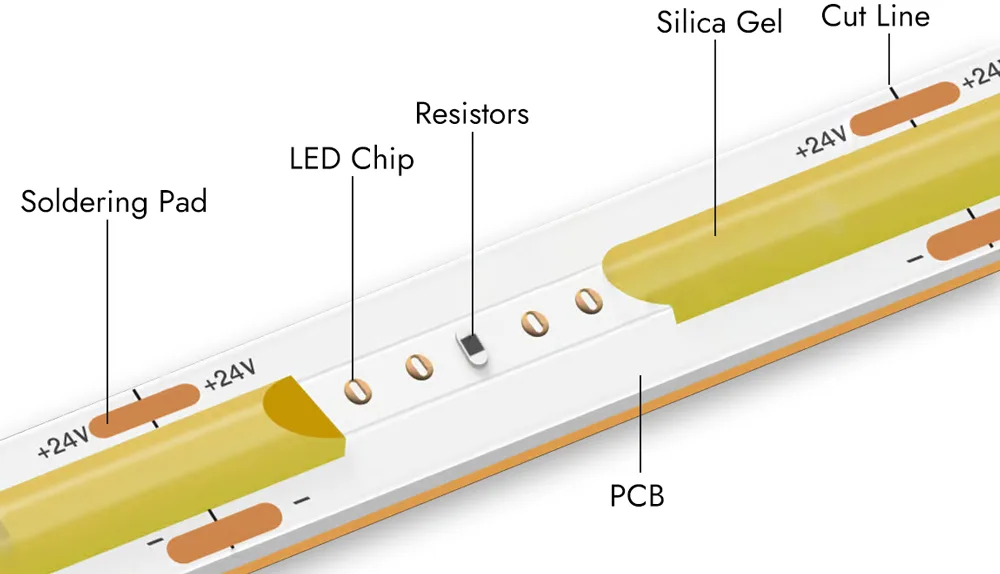

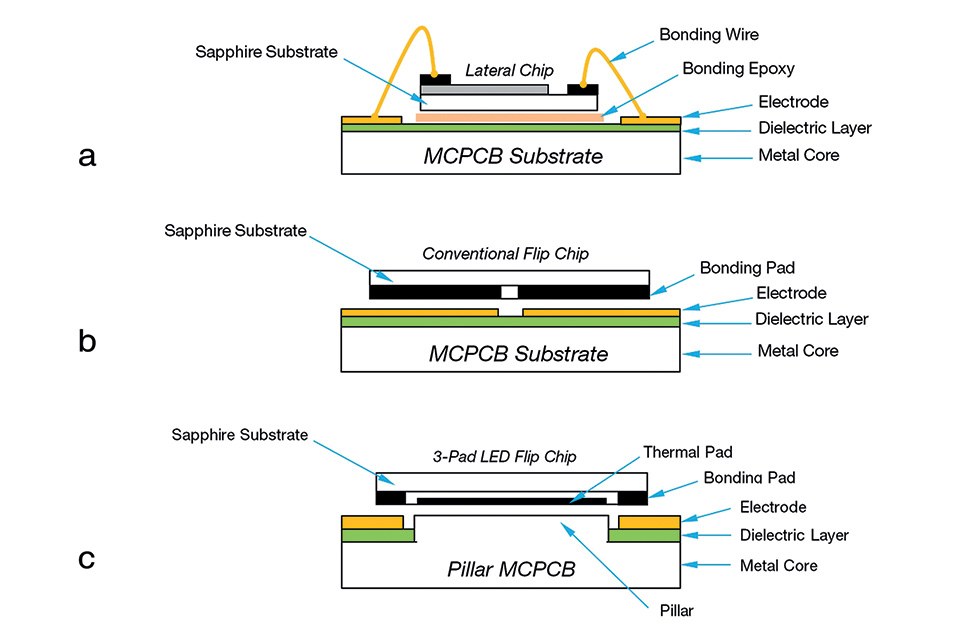

2. PCB & Packaging – Thermal Path Determines Reliability

Substrate: High-Tg 150 °C FR4 or 1 mm Al-MCPCB, both with 35 µm dielectric breakdown ≥4 kV.

Circuit: Electrolytic copper 2 oz minimum to keep current density <15 A/mm²; plated vias under each COB pad cut lateral thermal resistance by 18 %.

Consistency: Every 0.5 m reel is 100 % hi-pot tested at 1.5 kV; random 5 % sample undergoes 1000 h 85 °C/85 % RH accelerated ageing—failure rate target <0.2 %.

3. IP Rating Matrix – Factory-Standard Options

| Application Environment | IP Grade | Process | Test Certificate |

|---|---|---|---|

| Dry, interior coves | IP20 | Conformal coating | CE/ETL |

| Kitchens, bathrooms | IP65 | Silicone sleeve, ends potted | TÜV CE |

| façade, landscape | IP67 | Extruded silicone tube + epoxy ends | CE, RoHS, REACH |

| Under-water (≤1 m) | IP68 | PU glue fill, 1 h @ 1 m | TÜV SÜD |

4. Generic Market vs. Beauty STC Certified Quality

| Attribute | Generic Market Sample | Beauty STC Certified |

|---|---|---|

| Efficacy @ 3000 K | 110–120 lm/W | 130–140 lm/W |

| CRI (Ra) | 80 typical | ≥90 (target 93) |

| 3-step MacAdam | Optional | Standard on entire COB range |

| PCB copper | 1 oz, RA copper | 2 oz, ED+RA copper, 3 oz option |

| Binning | Single batch | Within-wafer & batch-to-batch, software matched |

| Safety mark | Self declaration | ETL cETLus, TÜV CE, RoHS, REACH, ERP |

| Lifetime claim | 30 000 h (L70) | 50 000 h (L70) with TM-21 report |

| Traceability | Batch ID | Reel ID + date code + LM-80 report link |

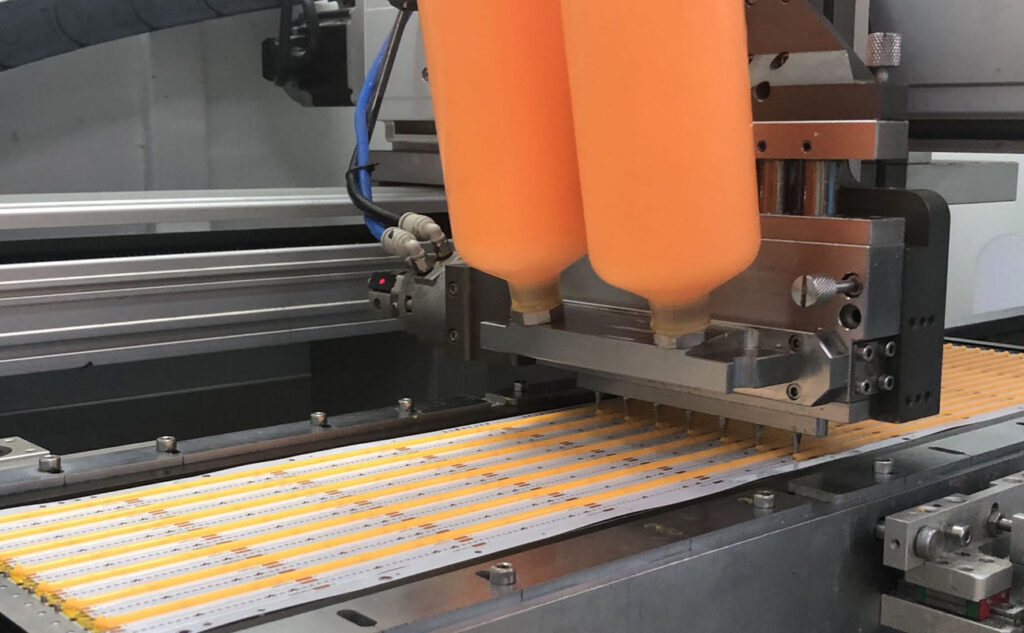

5. Process Controls that Assure Consistency

- Die attach: Silver-filled epoxy dispensed under 3 µm accuracy, void inspection by acoustic microscopy (<5 % void area).

- Wire bonding: 25 µm Au wire, 120 µm loop height, 100 % pull test ≥6 g.

- Phosphor dispensing: Automated jet valve, weight feedback to ±0.05 mg; CIE 1931 coordinates logged for every 50 mm segment.

- Final burn-in: 2 h @ 1.5× rated current, hot-cold cycle 30 °C↔85 °C; parts showing ΔCCT >75 K are rejected.

- Data retention: LM-80 & TM-21 reports stored 15 years for OEM clients’ utility rebate submissions.

6. Certification Summary (download links available on request)

North America: ETL listed to UL 1598 / UL 8750, Class 2 output, dry & damp locations.

Europe: TÜV CE, EN 62031, EN 62471 (photobiological risk group EXEMPT), ERP 2019 conformity.

Chemical: RoHS 2.0, REACH 240 SVHC, halogen-free PCB on request.

7. OEM / ODM Capability Snapshot

Since 1998 Beauty STC has provided private-label COB LED engines for luminaire brands in 50+ countries. Our in-house SMT line (Yamaha & Juki) places 0804–5630 packages at 40 000 CPH; conformal coating, potting and IP68 pressure-test tanks are all under one roof, enabling a 3-week lead time for custom CCT/CRI/length configurations.

For datasheets, IES files or to schedule a virtual factory tour, contact:

[email protected] | +86-13902885704

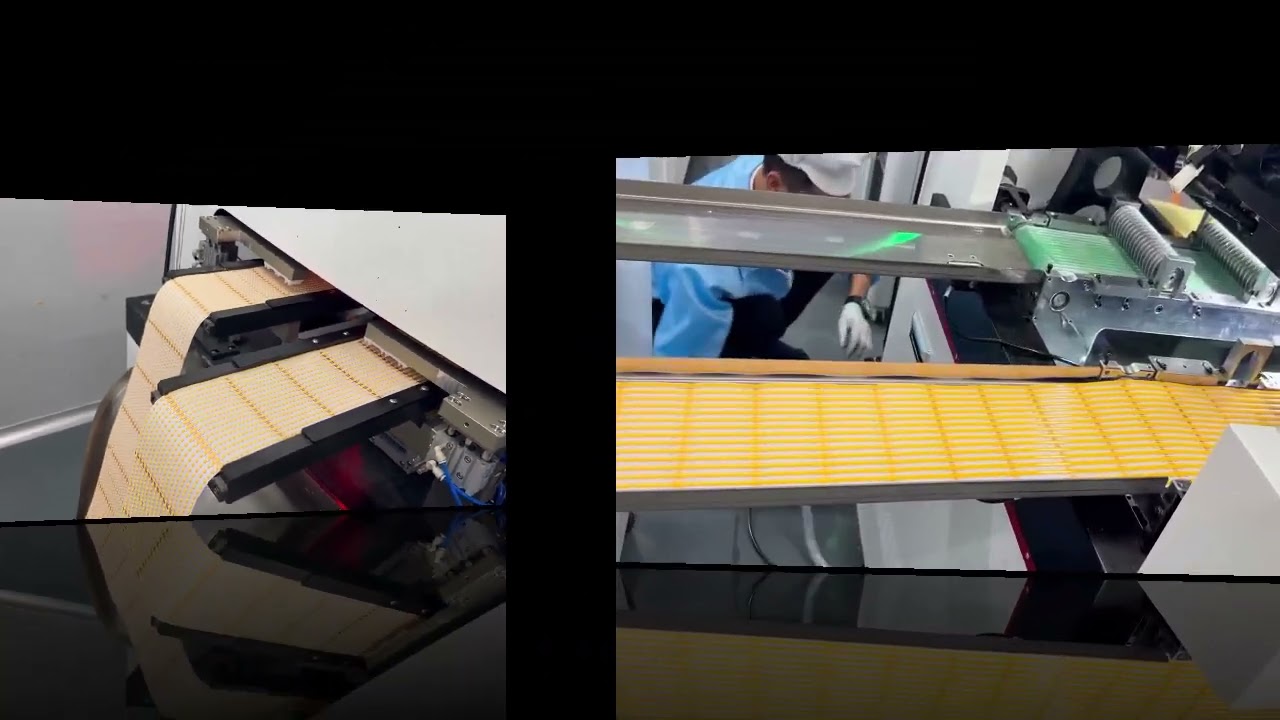

Factory Tour: Manufacturing Excellence

Manufacturing Excellence: Precision Engineering at Our Jiangmen Facility

Beauty STC Lighting’s Jiangmen facility, established in 1998, leverages 25+ years of LED manufacturing expertise with advanced production technology. Our processes comply with international quality standards, with all products certified to ETL (USA/Canada) and TUV CE (Europe).

Fully Automated SMT Production Line

Our COB LED strip manufacturing begins with a fully automated Surface Mount Technology (SMT) line featuring high-precision pick-and-place systems and controlled reflow soldering. Components are mounted with ±0.05mm accuracy, ensuring optimal thermal performance and electrical reliability. The line supports multi-layer PCBs and fine-pitch components critical for high-density COB configurations.

Rigorous Quality Control Protocols

We implement a multi-stage quality control system aligned with global certification requirements. Each production batch undergoes strict testing to guarantee performance consistency and safety compliance.

| Test Phase | Standard | Method | Acceptance Criteria |

|---|---|---|---|

| Material Inspection | IEC 62612 | Spectrometer, Luminance Meter | CRI ≥80, CCT tolerance ±150K |

| In-Process SMT Verification | IPC-A-610E | Automated Optical Inspection (AOI) | Zero solder bridges, component placement ≤±0.05mm |

| Aging Test | IEC 62717 | 72h @ 60°C ±2°C, 85% RH | Lumen maintenance ≥95%, Δuv ≤0.003 |

| Final Functional Testing | ETL/CE Certification | Voltage, Current, Thermal Imaging | Compliance with safety and performance specs |

OEM/ODM Customization Capabilities

Our flexible manufacturing system supports end-to-end customization for global projects. All OEM/ODM solutions undergo the same certification testing as standard products, ensuring compliance for Western markets.

| Parameter | Range | Notes |

|---|---|---|

| Custom Lengths | 1m to 100m | Segmented at 50mm intervals |

| LED Density | 300–640 LEDs/m | Configurable per application needs |

| CCT Range | 2700K – 6500K | 3-step MacAdam ellipse for color consistency |

| CRI Options | 80, 90, 95+ | High CRI variants for critical color rendering |

| Packaging | Custom reels, boxes, labeling | ETL/CE compliant labeling for Western markets |

Our engineering team collaborates directly with clients to optimize designs for thermal management, driver compatibility, and installation requirements. All custom solutions are validated through full-spectrum testing to ensure performance consistency across batches. For technical specifications or project consultations, contact our global engineering team at [email protected] or +86 13902885704.

Installation & Application Scenarios

H2 | Where Chip-on-Board LEDs Deliver the Highest ROI

(Factory-direct data from Beauty (STC) Manufacturing Co., Ltd – ETL / TUV CE, since 1998)

H3 | 1. Hospitality & High-End Retail – “No-Dot” Linear Ceilings & Coves

Visual Target: Zero LED pixelation, ≥ 90 CRI for fabric & skin tone.

Preferred COB Format: 512–640 chips/m, 180° beam, 3-step MacAdam.

Mounting Tips for Contractors

Use 12 W/m @ 24 V for 3 m runs to stay below 5% voltage drop; feed both ends if > 5 m.

Extruded Al-profile with 8 mm diffusion insert; maintain 5 mm air gap for 50 000 h @ 80 °C Ts.

Class-II driver only; verify TP (touch-proof) rating for metal cove near HVAC ducts.

| COB Strip Spec (Hotel Grade) | Min. | Typ. | Unit | Certification |

|---|---|---|---|---|

| CRI | 90 | 93 | – | LM-80/TM-30 |

| R9 | 50 | 70 | – | – |

| L70 @ 45 °C Ts | 50 000 | 54 000 | h | IES LM-80-21 |

| Flicker % @ 100 Hz | – | < 1 | % | IEEE 1789 |

H3 | 2. Office & Task Lighting – 24 V Linear Arrays in 600 × 600 Panel Retrofits

Application: Replace edge-lit panels with direct COB bar; gain 15% efficacy, 30% thinner housing.

Installation Notes

Maintain 30 mm mixing chamber; COB pitch = 18 mm for UGR < 19.

Earth strap mandatory; COB substrate is AlN (dielectric) but solder mask voids can touch metal back-plate.

Use 1–10 V or DALI driver with 4 kV surge per IEC 61000-4-5; CE-EMC pass guaranteed by Beauty STC in-house 3 m chamber.

H3 | 3. Façade & Landscape – Sealed COB Modules, IP67, -40 °C to + 55 °C

Why COB? Single phosphor layer reduces colour shift vs. multi-SMD after 2 000 h salt-spray.

Contractor Checklist

Potting compound must be PU, not silicone; PU blocks sulphur that yellows phosphor.

Allow 3 mm lateral thermal gap between module and aluminium façade; prevents shear on -40 °C contraction.

Feed every 2 m; 24 V loop keeps Δu < 0.5 V → < 2% flux loss end-to-end.

| Outdoor COB Module | Value | Notes |

|---|---|---|

| Power | 15 W / 100 mm | 24 V |

| Lumen / module | 1 650 lm | 110 lm/W @ 3000 K |

| IP / IK | IP67 / IK08 | 5-year warranty |

| Surge | 4 kV diff, 6 kV common | CE / ETL per 61000-4-5 |

H3 | 4. Cold-Chain & Food Display – High-CRI, Meat-Fresh Red (R14 > 90)

COB Advantage: Single-point source behind 10 mm light-guide avoids multi-shadow on glossy meat film.

Certification Reminder: NSF splash-zone compliance possible with Beauty STC’s PPMA-coated COB; request OEM suffix “-NSF”.

H3 | 5. High-Bay Retrofit – 50 W COB Array Replacing 150 W MH in 2:1 Ratio

Thermal Rule: Keep case < 85 °C; use 0.8 mm-gap phase-change pad (θ < 0.3 K/W).

Wiring: 18 AWG silicone wire, 200 °C, routed away from heat-pipe to maintain ETL-conform 105 °C rating.

H3 | Universal Contractor Checklist (Beauty STC Factory QA)

- Verify driver model on ETL data sheet; mismatch voids field warranty.

- Use only supplied Wago 2060 or equivalents; IDC pierces silicone without blade contact.

- Measure Ts with K-thermocouple within first 30 min; send log to Beauty STC for 5-year warranty activation.

- For OEM runs > 5 km, request 3-step binning code; Beauty STC keeps 1 % reference units in Jiangmen lab for 7 years.

Need project-specific COB files (.IES, .LDT, .TM-30) or OEM extrusion drawings?

Email: [email protected] | WhatsApp: +86-13902885704

25 years factory, ETL/TUV CE listed, exporting to 50+ countries.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting

As a trusted manufacturer since 1998, Beauty STC Lighting delivers precision-engineered COB LED solutions for global commercial, architectural, and industrial projects. With 25+ years of technical expertise, rigorous compliance with Western market standards, and exports to 50+ countries, we provide end-to-end OEM/ODM support—from design to certification—ensuring reliability, consistency, and performance for demanding applications.

Global Compliance & Certification

All products undergo stringent testing to meet international safety and performance standards. Our certifications validate readiness for direct deployment in regulated markets:

| Certification | Regions Covered | Key Standards |

|---|---|---|

| ETL | USA, Canada | UL 1598, UL 8750, ICES-001 |

| TUV CE | Europe | EN 60598, EN 62368, IEC 62471 |

| RoHS/REACH | Global | Directive 2011/65/EU, Regulation (EC) No 1907/2006 |

Technical Specifications for COB LED Products

Our COB LED strips and arrays are engineered for uniform light output, high color consistency, and scalability. Key specifications include:

| Feature | Specification |

|---|---|

| CRI Options | 80, 90+, 95+ (customizable per application) |

| CCT Range | 2700K–6500K (tunable options available) |

| LED Density | Up to 512 LEDs/m (dotless, seamless illumination) |

| Power Density | 14–24W/m (adjustable for voltage and output) |

| Voltage | 12V or 24V DC (constant current/voltage options) |

| Beam Angle | 180° (optically uniform, no hotspots) |

| Compliance | IEC 62471 (photobiological safety), IP20–IP67 |

OEM/ODM Engineering Support

We collaborate directly with distributors, contractors, and architects to tailor solutions for unique project requirements:

| Service | Details |

|---|---|

| Custom Designs | Tailored CRI, CCT, density, form factor, and thermal management |

| Certification | Pre-shipment testing for ETL/CE, FCC, or region-specific requirements |

| Packaging | Private labeling, custom branding, and export-ready packaging |

| Lead Time | 15–20 days for standard orders; expedited options for urgent projects |

Why Partner with Us?

25+ Years of Industrial Expertise: From R&D to production, our Jiangmen-based facility integrates mature manufacturing processes with continuous innovation.

Global Supply Chain: Reliable logistics and compliance frameworks for seamless delivery to Europe, North America, Southeast Asia, and beyond.

Technical Rigor: Every batch undergoes binning verification (MacAdam 3-step ellipse) and thermal stability testing to ensure optical consistency.

“Be a responsible enterprise, Be a caring person” guides our commitment to sustainable manufacturing and long-term partnerships.

For detailed technical documentation, sample requests, or project-specific engineering support, contact our global sales team directly:

[email protected] | +86 13902885704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).