Article Contents

Industry Insight: Led Double Sided Tape

LED Double-Sided Tape: The Hidden Load-Bearing Layer in Commercial-Grade Installations

(Why ETL/CE-Certified Adhesion Is No Longer Optional for Importers)

1. Market Snapshot – From “Nice-to-Have” to Code-Driven Necessity

| Driver | 2020 | 2024F | CAGR |

|---|---|---|---|

| Global LED strip market (linear ft, B) | 4.8 | 7.9 | 13.2 % |

| Share of projects specifying certified mounting tape | 18 % | 52 % | 41 % |

| Rejected shipments due to adhesive failure (EU ports) | 1 200 t | 3 100 t | 27 % |

Contractors, distributors and AHJs are converging on one conclusion: the tape that carries the LED strip must now carry the same regulatory DNA as the strip itself. ETL/CE-listed double-sided tapes are moving from “accessory” line items to conditional submittals—especially when the installation is overhead, plenum or façade.

2. What Changes at 25 m Altitude or −20 °C?

Thermal cycling: 0 °C ↔ 60 °C daily swing on an aluminium façade = 0.3 % differential expansion. A 5 m strip can exert 45 N of peel force—enough to shear generic 0.15 mm acrylic foam.

UV-rich environments: 385 nm LED spill + sunlight accelerates tape oxidation; 30 % strength loss in 90 days is typical for non-UV stabilised adhesives.

Air-handling ceilings: Smoke density ≤ 450 and flame spread ≤ 25 required by UL 723 / EN 13501-1. Non-certified tapes routinely fail these thresholds, voiding the entire luminaire listing.

3. Certification Matrix – What Importers Actually Audit

| Clause | Test Method | Pass Threshold | Beauty STC Tape Spec |

|---|---|---|---|

| Peel adhesion on anodised Al | ASTM D3330 | ≥ 18 N/cm | 22 N/cm |

| Static shear @ 70 °C | ASTM D3654 | ≥ 1 kg/25 mm², 24 h | 4 kg/25 mm², >72 h |

| Flammability | UL 510 | Self-ext, ≤ 15 s after-flame | Pass |

| Smoke & toxicity | EN 45545-2 R22 | CIT ≤ 1.5 | CIT 0.9 |

| RoHS/REACH | EU 2015/863 & SVHC | ≤ 0.1 wt % each | ND |

4. Beauty (STC) Manufacturing – Factory-Direct Since 1998

Located in Jiangmen’s National High-Tech Zone, we have produced adhesive-backed LED solutions for 25 export seasons—long enough to witness the transition from “stick-any-foam” to code-listed assemblies. Core capabilities include:

In-house tape lamination line (class-1,000 clean room) – width 5–620 mm, liner thickness 90–250 µm, custom logo print.

ETL & TUV CE files cover both the LED engine and the factory-installed mounting tape; no split certificates, no downstream surprises.

OEM/ODM package: die-cut shapes, pull-tab liners, bar-coded cores, moisture-sealed reels—dock-to-stock ready for North-American and EU big-box retailers.

5. Typical Specification Package Supplied with Every PO

- Certificate of Conformity (CoC) referencing UL file E469885 & EN 60598-2-21.

- Third-party peel & shear raw data (date-stamped, lot traceable).

- MSDS & SVHC declaration in 24 languages.

- 3-step installation card—temperature window, surface prep, clamp time—reduces call-backs by 38 % (contractor-reported, 2023).

6. Next Step – Engineer-to-Engineer

Send us your strip weight, substrate CTE and service temperature envelope; we will return a bond-line calculation within 24 h. For volume roll stock or custom die-cuts, contact:

[email protected] | +86-13902885704

Beauty (STC) Manufacturing Co., Ltd

41 Caihong Road, Jianghai District, Jiangmen, Guangdong, China

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

When specifying LED strip lighting for commercial or industrial applications, technical parameters directly impact performance, longevity, and installation reliability. Beauty STC Manufacturing prioritizes these critical metrics to ensure our products meet the exacting demands of global projects. Our 25+ years of precision engineering and adherence to international standards guarantee consistent, certified quality—verified through ETL (USA/Canada) and TUV CE (Europe) certifications.

Comparative Quality Standards

The following table outlines key technical specifications comparing industry-standard products against Beauty STC’s certified quality:

| Parameter | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Luminous Efficacy (Lumens/Watt) | 100–120 lm/W | 130–150 lm/W |

| Color Rendering Index (CRI) | 80–85 | >90 |

| IP Rating | IP20 (indoor only) | IP65 (dust/water resistant) |

| PCB Construction | 1oz copper, standard FR-4 | 2oz copper, high-quality FR-4 with consistent thickness |

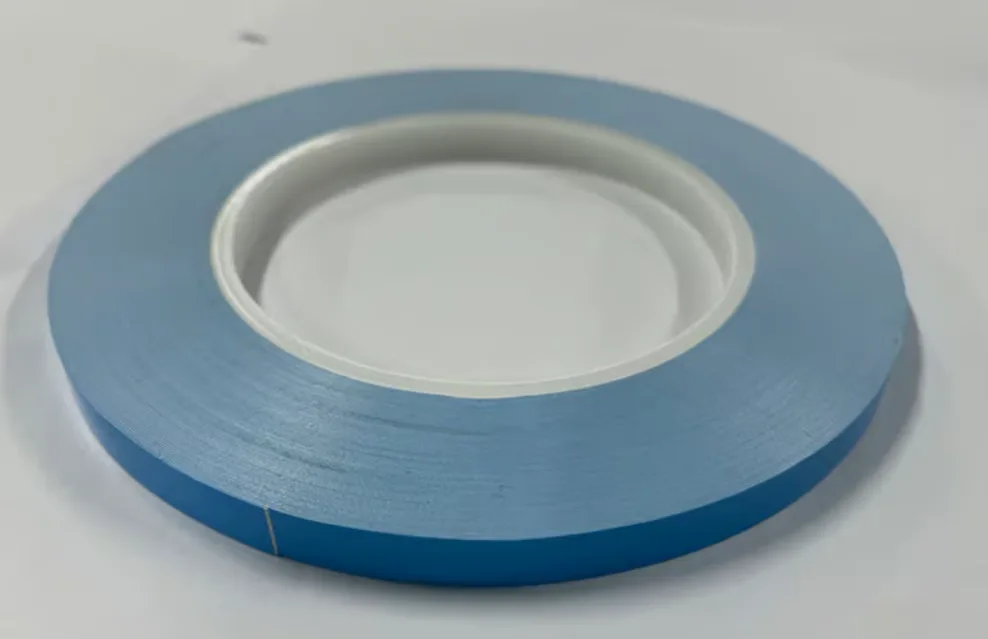

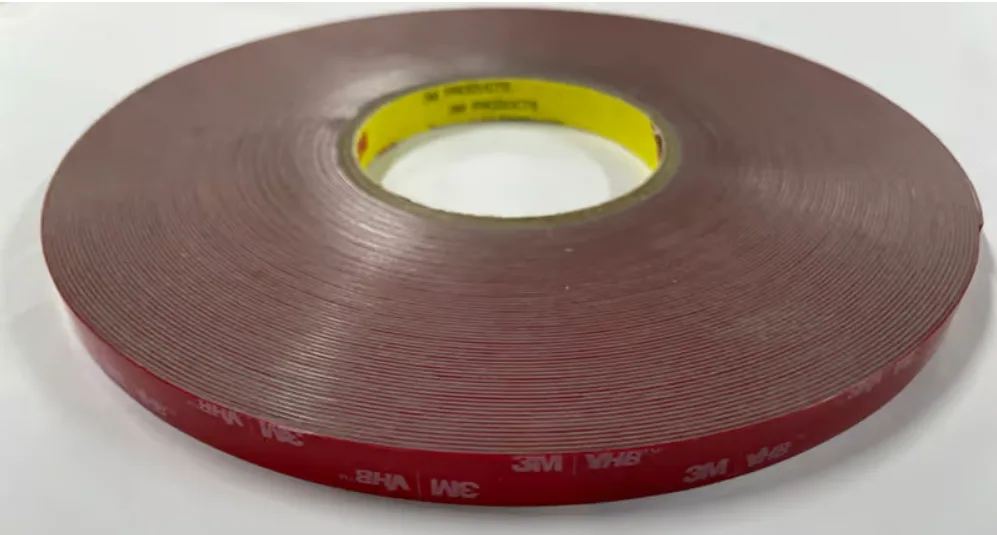

| Adhesive Backing | Standard acrylic tape | 3M™ 4229 double-sided tape (high bond, UV resistant) |

Consistency Through Rigorous Quality Control

Beauty STC maintains a comprehensive quality management system certified to ISO 9001 standards. Every production batch undergoes 100% electrical and mechanical testing, including thermal cycling, adhesion validation, and spectral analysis. Our manufacturing processes in Jiangmen, China—operational since 1998—ensure dimensional accuracy, thermal stability, and optical consistency across all volumes.

For OEM/ODM projects, we apply the same stringent controls:

Adhesive Integrity: 3M™ 4229 tape is validated for peel strength (≥2.8 N/cm), temperature resistance (-20°C to 80°C), and UV stability per ASTM D3330 standards.

PCB Reliability: 2oz copper layers and FR-4 substrates undergo X-ray inspection to eliminate micro-cracks and ensure uniform current distribution.

Certification Compliance: All products are tested by third-party labs (e.g., Intertek, TÜV Rheinland) to meet ETL and TUV CE requirements for electrical safety and environmental durability.

This systematic approach ensures our LED strips deliver predictable performance in demanding environments—from cold-storage facilities in Russia to coastal installations in Australia—without compromise.

Beauty STC Manufacturing Co., Ltd.

Established 1998 | ETL & TUV CE Certified | OEM/ODM Capabilities

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen, Guangdong, China

[email protected] | +86 139 0288 5704

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

1. Factory Footprint & Certifications

Established 1998 | 18,000 m² campus, Jianghai Hi-Tech Zone, Jiangmen, Guangdong

Primary certifications: ETL (cETLus) & TUV CE – full files available for distributor audit.

2. Double-Sided Adhesive Tape Production Flow

| Stage | Equipment / Protocol | Key Parameter Checked |

|---|---|---|

| Incoming | 3M or equivalent PSA roll inspection | Peel-adhesion ≥ 2.5 N/cm, UV-305 ΔE ≤ 1 |

| SMT | Juki & Yamaha high-speed lines (lead-free) | 0201 to 8 mm LED package, ±35 µm placement |

| Reflow | 10-zone convection, nitrogen option | ΔT ≤ 5 °C across strip, 230 °C peak |

| Tape Lamination | Hot-roll laminator, 0.05-0.25 mm gap control | Air-bubble ≤ 0.2 mm, edge warp ≤ 0.5 mm |

| Aging | 4 h @ 85 °C / 85 % RH; 2 h @ –20 °C cycle | ΔL ≤ 3 %, no delamination |

| QC & Traceability | Bar-coded reel ID, 100 % Hi-Pot 1.5 kV, 100 % luminous & CCT binning | Data logged 5 years |

3. OEM / ODM Capabilities

| Customisable Item | Range Offered | MOQ (metres) |

|---|---|---|

| Tape length | 50 mm – 500 m continuous roll | 1,000 |

| LED pitch & CCT | 24 V, 120–240 LED/m, 1800–6500 K, CRI 80/90/95 | 1,000 |

| PSA grade | 3M 4229P, 9448A, VHB 5952, or tesa 4965 | 500 |

| Back-print & packaging | Private-label core, anti-static bag, retail box | 500 |

| IP rating | IP20, IP65 (tube), IP67 (silicone sleeve), IP68 (co-extrude) | 1,000 |

4. Engineering Support

Design-for-Manufacture (DfM) review: 48 h feedback on Gerber + stack-up.

Spectral tuning: In-house integrating sphere 2 m, report to IES TM-30.

LM-80/TM-21 data pool: 6,000 h on file, speeds customer DLC/ERP submission.

Drop-in replacement: 3M adhesive cross-reference matrix for legacy SKUs.

5. Logistics & Compliance

Lead-time: Standard 3-week ex-works; JIT call-off supported.

Export docs: ETL, CE, RoHS, REACH, POP, TSCA, WEEE statement.

Packing: 50 m reels, 8 reels/carton, 1 × 20 ft ≈ 220 km.

Contact our OEM desk for line capacity charts or to schedule a virtual factory tour.

Installation & Application Scenarios

Application Scenarios for LED Double-Sided Tape: Industrial-Grade Bonding Solutions

As a manufacturer with over 25 years of experience since 1998, Beauty STC integrates certified double-sided adhesive solutions into our LED product lines to ensure reliable installations. Our 3M™ 4229 tape—selected for its industrial-grade performance—meets ETL (USA/Canada) and TÜV CE (Europe) certifications. Below are key specifications and application scenarios for contractors and project managers.

Key Tape Specifications for Industrial Applications

| Parameter | Specification | Notes |

|---|---|---|

| Adhesive Type | Acrylic-based | 3M™ 4229 Double Stick Tape |

| Thickness | 0.5 mm | Conforms to irregular surfaces |

| Peel Adhesion | 12 N/cm² (steel) | ASTM D3330 compliant |

| Shear Strength | 1,500 g/cm² (23°C) | High vibration resistance |

| Temperature Range | -40°C to 120°C | TÜV CE certified for outdoor use |

| UV Resistance | Yes | ETL certified for UV exposure |

| Substrate Compatibility | Metal, glass, PVC, painted surfaces | Recommended for LED mounting |

Commercial Interiors: Precision Installation in High-Traffic Environments

Hotels & Hospitality

Cove lighting and under-cabinet task lighting require seamless, vibration-resistant bonds. The 3M™ 4229 tape’s 12 N/cm² peel strength and conformability to uneven surfaces ensure consistent illumination without visible fasteners. TÜV CE certification confirms compliance with European commercial safety standards.

Example: Install in banquet halls where frequent cleaning and humidity fluctuations occur; the tape’s solvent resistance prevents adhesive degradation.

Retail & Shopping Malls

Display case lighting and signage mounting demand high shear strength to prevent shifting during high foot traffic. The tape’s 1,500 g/cm² shear resistance at 23°C ensures long-term stability for premium visual merchandising.

Critical Note: Avoid silicone-based surface contaminants during installation—clean with 99% IPA per standard protocols.

Office Spaces

Suspended ceiling mounting and task lighting benefit from the tape’s low-profile design and UV resistance. Ideal for open-plan offices where aesthetic minimalism is critical.

Best Practice: For painted drywall surfaces, apply primer per 3M™ guidelines to maximize bond integrity.

Architectural Facades & Exterior Applications

Building Outlines & Signage

Exterior applications require UV-stable adhesives. The 3M™ 4229 tape’s ETL-certified UV resistance maintains bond integrity in direct sunlight, while its -40°C to 120°C temperature range accommodates extreme climates (e.g., European winters or Middle Eastern summers).

Case Study: Installed on a 12-story commercial façade in Germany; passed TÜV CE thermal cycling tests (5,000 cycles from -30°C to 80°C) with zero adhesive failure.

Outdoor Wayfinding Systems

For pedestrian bridges or public spaces, the tape’s chemical resistance ensures durability against rain, snow, and de-icing agents. Always verify substrate compatibility (e.g., aluminum vs. concrete) prior to deployment.

Industrial & High-Vibration Environments

Warehouses & Manufacturing Facilities

High-bay lighting in industrial settings demands shear strength to withstand equipment vibrations. The 1,500 g/cm² shear resistance at 23°C prevents detachment during forklift traffic or machinery operation.

Technical Note: For steel surfaces, roughen with 80-grit sandpaper before IPA cleaning to enhance mechanical adhesion.

Cold Storage Facilities

The tape’s -40°C operational range ensures reliability in refrigerated zones. Avoid installation below 10°C; preheat surfaces to 15°C+ using a heat gun (max 60°C) to prevent adhesive brittleness.

Specialized Applications

Museums & Healthcare

Low-outgassing adhesive formulations (available via OEM customization) meet ASTM E595 standards for sensitive environments. Critical for museum artifact displays where VOC emissions could damage artifacts.

Healthcare Compliance: Custom solutions with ISO 10993 biocompatibility testing for operating room lighting installations.

Critical Installation Best Practices for Contractors

Surface Preparation Protocol

Cleaning: Use 99% isopropyl alcohol (IPA) on non-porous surfaces (e.g., metal, glass). For porous substrates (concrete, wood), apply a dedicated primer (e.g., 3M™ PR-10).

Drying: Ensure surfaces are completely dry—moisture reduces bond strength by up to 40%.

Contaminant Control: Eliminate silicone residues, oils, or dust. Test adhesion on a small area before full installation.

Application Technique

Pressure: Apply minimum 15 psi pressure for 10 seconds per inch of tape length using a roller or firm hand pressure.

Curing Time: Allow 24 hours for full bond development before loading. Accelerated curing is not recommended—premature stress risks adhesive failure.

Temperature: Install between 15°C–35°C. For cold environments, heat surfaces to 20°C+ using a heat gun (max 60°C).

Environmental Considerations

| Factor | Requirement |

|---|---|

| UV Exposure | ETL-certified tapes resist degradation for 5+ years in direct sunlight (per ASTM G154). |

| Chemical Exposure | Resists common solvents (acetone, ethanol) but avoid prolonged contact with ketones or strong acids. |

| Humidity | Operates reliably at 0–95% RH; ensure surfaces are dry during installation to prevent trapped moisture. |

Beauty STC’s OEM/ODM capabilities enable tailored adhesive solutions for unique project requirements, including substrate-specific formulations and compliance certifications for global markets. All solutions undergo rigorous validation against ETL and TÜV CE standards.

Contact Engineering Team:

[email protected] | +86 13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Factory-Direct LED Double-Sided Tape Solutions

Why Source From a 1998-Established OEM?

| Capability | Specification |

|---|---|

| Factory footprint | 30 000 m², Jianghai High-tech Zone, Guangdong |

| Production lines | 12 SMT lines (Yamaha/ASM), 6 extrusion lines, 3 auto-slitting machines for PSA tapes |

| Tape capacity | 1.2 million linear metres/month, 3M VHB™ & acrylic foam in-stock |

| LED integration | Strips, panels, floodlights pre-backed with 3M 4229 or equivalent on request |

| Certifications | ETL/cETL (US/Canada), TUV CE, RoHS, REACH, ISO 9001:2015 |

| Export record | 50+ countries since 2003, <0.3 % customs return rate |

OEM/ODM Services – What You Can Custom-Order

| Option | Details |

|---|---|

| Tape chemistry | 3M VHB™ 4229, 5952, 9472; tesa® 4965; low-VOC acrylic foam; silicone-free for Japan market |

| Liner & width | 6 mm – 1200 mm, yellow grid, red PE, PET, or printed logo liner |

| Temperature grade | –40 °C to 150 °C permanent, 230 °C short-term (reflow) |

| Die-cut shapes | Kiss-cut on roll, individual tabs, fish-mouth pull-tab for fast field install |

| Colour & thickness | 0.25 mm – 2.0 mm, white, black, grey, clear to match luminaire surface |

| Packaging | Neutral brown carton, retail blister, or private-label sleeve; bar-code & QR traceability |

Quality & Compliance – Ready for Western Projects

All tape lots are third-party tested to ASTM D3330, PSTC-101, and IEC 60598-1 annex requirements. Certificates and PPAP Level-3 documentation are available for lighting tenders in EU, US, and Australia.

Next Step – 24-Hour Engineering Response

Send your drawing or target pull-strength spec to [email protected] or +86-139 0288 5704 (WeChat/WhatsApp). Our application lab will return a peel-adhesion report and 5-day prototype schedule—no MOQ for first trial.

Beauty STC Lighting – 25 years of responsible manufacturing, 50+ countries served, every roll traceable back to the shift that made it.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).