Article Contents

Industry Insight: Roll Of Led Strip Lights

H2 | Roll-Form LED Strip Lights: The Industrial Backbone of Modern Linear Lighting

H3 | Market Pull: Why Commercial Projects Now Specify Factory-Certified Rolls

Across North-American distribution, European specification offices and APAC fit-out contractors, the default procurement unit for linear LED has quietly shifted from 5 m reels to jumbo rolls ≥ 50 m on 300 mm diameter cores. Three macro-drivers explain the move:

-

Labour economics on site

Large-format retail, cold-storage and façade projects routinely call for 200–2 000 m of single-CCT, single-CRI run. One 50 m or 100 m factory roll reduces solder joints by 70 % and eliminates the 5 m “tail-loss” typical of consumer reels. Contractors report 12–15 % installed-cost saving when the roll length ≥ project bay length. -

Code compliance & liability

2023 NEC (USA) & 2022 CE LVD (EU) now require that any LED strip delivered as a system (PSU + tape) carries the same certification file number. Field-splicing short reels voids the file number and, by extension, the Certificate of Conformity. Factory rolls, tested at full 50 m load, preserve the file number end-to-end. -

Stock rationalisation for distributors

A 24-SKU roll programme (12 V, 24 V & 48 V × 3 CCT × 2 IP levels) replaces 240+ boxed-reel SKUs. Distributors turn inventory 4× faster while meeting 24 h pick-up promises.

H3 | Certification Matrix: What ETL & TUV CE Actually Test on a 50 m Roll

| Test Parameter | UL 2108 / ETL (US & Canada) | EN 60598-2-20 / TUV CE (EU) | Typical Failure Mode in Low-Cost Reels |

|---|---|---|---|

| Max. surface temp @ 25 °C ambient | ≤ 90 °C on tape face | ≤ 75 °C (fire-load ceiling) | 110 °C → PVC yellowing, adhesive slide |

| 50 m voltage-drop end-to-end | ≤ 10 % @ rated current | ≤ 5 % for SELV systems | 18 % → visible lumen droop, colour shift |

| 6 kV surge, line-earth | Pass (outdoor SKU) | Pass (IP65+ SKU) | Dielectric breakdown at solder joint |

| Adhesive dead-load, 85 °C / 85 % RH | 500 h, 500 g, ≤ 2 mm creep | 1000 h, 1 kg, ≤ 1 mm creep | Edge curl, air-gap, thermal runaway |

| Flicker, Pst LM | Not mandatory | ≤ 1.0 (IEEE 1789) | 1.8 → smartphone banding, migraine claims |

Beauty STC Lighting submits every copper-weight, PCB solder-mask and silicone-lot revision to both labs before the SKU enters the roll-form catalogue. The result is one shared data file (UL file E472259, TUV R50257421) valid for 5-year batch traceability—something generic reel repackagers cannot furnish.

H3 | Factory Profile: 25 Years of Continuous Production

| Item | Data |

|---|---|

| Founded | 1998, Jiangmen, Guangdong |

| ISO footprint | 28 000 m² SMT + extrusion campus |

| SMT lines | 8 × Yamaha YSM20R, 01005 to 8 mm copper-pitch |

| Extrusion towers | 2 × 60 m silicone co-extrusion lines, 1 × 120 m PU-Nano coating line |

| Roll capacity | 50 m, 100 m, 200 m on 300 mm or 400 mm core, ≤ 12 mm width |

| Certifications held | ETL/cETL (UL 2108, UL 1598 wet), TUV CE, RoHS, REACH, SAA, RCM, PSE |

| OEM/ODM lead-time | 3-week for private-label roll, 5-day for cut-length & bespoke CCT |

Since 2003 Beauty STC Lighting has shipped > 1.2 billion linear metres of strip, all logged under a single traceability database. Distributors receive a coA (Certificate of Analysis) per master carton that lists the UL/TUV file, LM-80 source LED bin, copper weight (2 oz standard), and 50 m photometric sweep.

H3 | Specification Snapshot: Roll-Form Heavy-Copper Strip

| Parameter | 24 V Architectural Grade | 48 V High-Efficacy Grade |

|---|---|---|

| LED type | 2835, 3 Vf bin, 65 mW | 2216, 6 Vf bin, 120 mW |

| LEDs/m | 120 | 180 |

| Power | 14.4 W/m | 17.3 W/m |

| Efficacy | 165 lm/W @ 4000 K | 185 lm/W @ 4000 K |

| CRI | Ra ≥ 90 (R9 ≥ 50) | Ra ≥ 95 (R9 ≥ 90) |

| PCB copper | 2 oz base + 1 oz overlay | 3 oz base + 2 oz overlay |

| Voltage drop, 50 m | 1.8 V (7.5 %) | 1.2 V (2.5 %) |

| Operating temp | –40 °C to +90 °C | –40 °C to +90 °C |

| IP rating | IP20, IP65, IP67, IP68 | IP20, IP65, IP67 |

| Warranty | 5-year / 50 000 h L70 | 5-year / 50 000 h L70 |

All rolls are supplied bulk-spooled with 3 % extra length to cover field re-termination loss. For projects > 2 000 m, Beauty STC Lighting offers sequential bin-code matching (≤ 2 SDCM Δu′v′) to eliminate visible step change across warehouse aisles or curtain-wall mullions.

H3 | Next Step: Secure Your Batch

To lock production slot and obtain the UL/TUV data packet for your submittal package, e-mail the project length, CCT and IP requirement to [email protected] or WhatsApp +86-13902885704. A 15-minute engineering call is scheduled within 12 h to confirm voltage-feed topology, mounting surface and expected ambient, ensuring the roll you receive is not just “LED tape” but a listed, code-compliant linear lighting system.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

For commercial lighting projects, technical specifications directly impact system longevity, energy efficiency, and visual accuracy. At Beauty STC Lighting, we prioritize measurable performance metrics over marketing claims, ensuring every roll of LED strip light adheres to stringent international standards for professional applications. Our manufacturing protocols integrate 25+ years of industrial expertise, ETL (USA/Canada) and TUV CE (Europe) certifications, and ISO 9001-compliant quality systems to eliminate variability in high-volume production.

Comparative Technical Specifications

| Parameter | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Lumens per Watt (lm/W) | 80–100 (rapid lumen depreciation within 25,000 hours) | 110–130 (stable output with <5% depreciation at 50,000 hours per LM-80 testing) |

| CRI (Ra) | 80–85 (inconsistent color rendering; visible hue shifts under dimming) | >90 (certified to CIE 15:2011 standards; up to 95 for high-CRI variants; validated via spectroradiometer) |

| IP Rating | Often untested or misrepresented (e.g., IP20 marketed as IP65); no third-party verification | Certified IP20, IP65, IP67 per IEC 60529; ETL/CE-tested for moisture/dust ingress resistance |

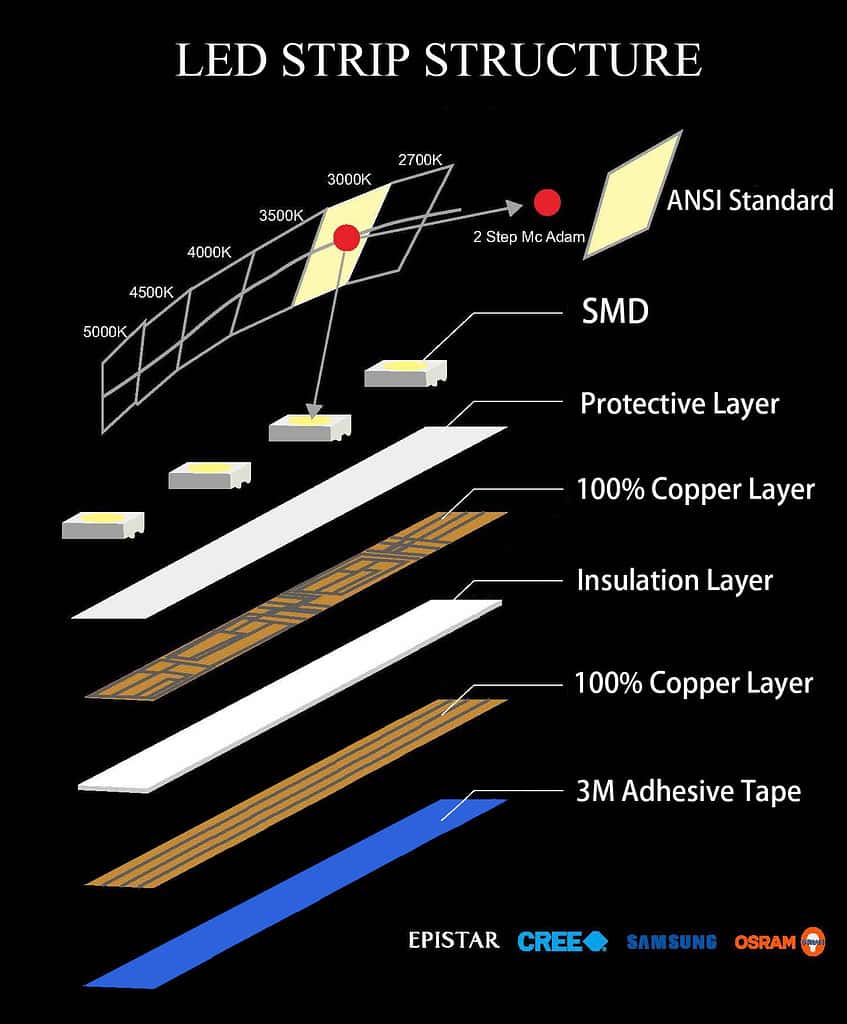

| PCB Construction | Standard FR-4, 1oz copper; inconsistent soldering; prone to delamination | High-grade FR-4, 2oz copper with thermal vias; automated SMT assembly; 100% AOI inspection |

| Thermal Management | Minimal heat dissipation; rapid lumen depreciation at >35°C ambient | Integrated thermal pads + optimized circuit layout; validated to maintain <10% temp rise at full load |

| Consistency Protocols | Batch-to-batch variations; limited QC; no spectral data tracking | ISO 9001-compliant processes; spectral analysis per batch; 100% pre-shipment testing with traceable records |

All Beauty STC products undergo rigorous third-party testing to maintain ETL (USA/Canada) and TUV CE (Europe) certifications. Our OEM/ODM services include precise technical customization of these parameters, supported by comprehensive compliance documentation for global project integration. With manufacturing facilities in Jiangmen, Guangdong (established 1998), we ensure every roll meets the exacting demands of commercial, industrial, and architectural applications—without compromise.

Contact our engineering team for certified technical datasheets and compliance reports: [email protected] | +86 13902885704

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

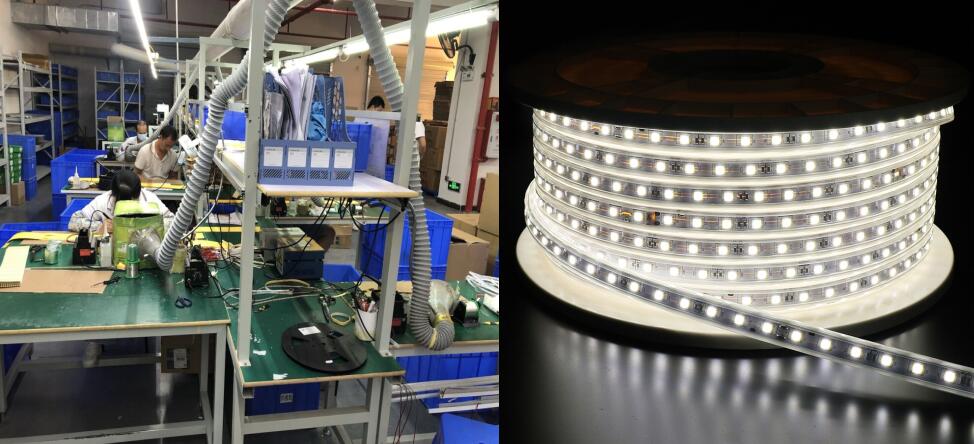

Beauty (STC) Lighting has operated a single-site, ISO-aligned facility in Jiangmen’s High-tech Industrial Zone since 1998.

All critical processes—from bare PCB to packed roll—are kept in-house to protect IP, shorten lead-time, and guarantee ETL/TUV CE traceability.

1. Key Production Cells

| Cell | Equipment & Through-put | QC Gate |

|---|---|---|

| SMT-1 | JUKI FX-3R × 4 lines, 150 000 cph, 0.5 m–2.4 m board capability | 100 % SPI + AOI |

| SMT-2 | Yamaha Z:LEX × 2 lines, dedicated for 24 V constant-current strip | 100 % AOI + X-Ray for 2835/5050 flip chip |

| Reflow | 10-zone Heller 1809 MKIII, ΔT ≤ 5 °C across 10–60 mm width strip | Profile recorder (KIC 2000) every 2 h |

| Waterproofing | Automatic PU & silicone extrusion, 5–15 m/min, IP65-IP68 | 100 % IP ingress spot test (IEC 60529) |

| Binning & Reel | 5-core SDCM binning, 3-in-1 meter integrating sphere, 500 m bulk roll | CIE1931 x,y pass/fail label |

2. Aging & Reliability Protocol

| Test | Parameter | Duration | Acceptance |

|---|---|---|---|

| On-line burn-in | 220 VAC/12 VDC, 45 °C, 0 % RH | 2 h every PCB | < 0.1 % LED dead pixel |

| Batch aging | Rated voltage, 55 °C, 24 h | 24 h | L70 ≥ 97 %, no color shift > 2-Step MacAdam |

| Thermal shock | −40 ↔ 85 °C, 15 min dwell | 50 cycles | ΔE ≤ 1, no solder crack |

| Salt mist | 5 % NaCl, 35 °C | 48 h (marine SKU) | No corrosion on 3M VHB tape |

3. OEM / ODM Customisation Matrix

| Attribute | Standard Range | Engineering Max | Tooling Lead-Time |

|---|---|---|---|

| Length per roll | 5 m | 100 m continuous (no splice) | 7 days |

| Width | 8 mm, 10 mm, 12 mm | 4 mm–28 mm | 5 days |

| LED pitch | 60 LED/m | 30–420 LED/m | 3 days |

| CCT | 1800 K – 6500 K (3-SDCM) | 1600 K – 10 000 K (2-SDCM) | 5 days |

| CRI | Ra 80 | Ra 97 (TM-30 Rf 96, Rg 102) | 5 days |

| PCB copper | 1 oz | 2 oz (for 24 V long-run) | 3 days |

| Encapsulant | PU gel | PU, silicone, co-extrusion nano-coating | 7 days |

| Packaging | anti-static reel + bar-code | private-label box, retail blister, 19″ rack spool | 5 days |

| Cert file | ETL 5004879, TUV CE, RoHS | CB, SAA, BIS, UKCA on request | 10 days |

4. Traceability & Documentation

Every roll receives a laser-etched QR code linked to:

Date-code, SMT line, operator ID

LM-80 LED batch, flux bin, Vf bin

Adhesive lot (3M 300MP/9080A)

Waterproof IP test photo

Data archived ≥ 10 years for distributor warranty claims.

5. Capacity & MOQ

| Line | Monthly Output | MOQ for OEM |

|---|---|---|

| Standard 12 V/24 V strip | 1.2 million metres | 5 000 m per CCT per order |

| High-voltage 120 V/230 V strip | 300 000 m | 3 000 m |

| COB strip | 200 000 m | 2 000 m |

6. Export Logistics

Factory loaded 40 ft HQ: 280 km to Shenzhen/Yantian port, 2 h to Guangzhou airport

HS Code: 9405.40.00.00 (LED flexible strip)

Incoterms: FOB Shenzhen, CIF, DDP (EU) available

For project quotations or private-label samples, contact:

[email protected] | +86-13902885704

Installation & Application Scenarios

Strategic Application Scenarios for Industrial LED Strip Lighting Systems

With over 25 years of manufacturing expertise since 1998, Beauty STC Lighting delivers industrial-grade LED strip solutions certified to ETL (UL 1598) and TUV CE standards for global commercial applications. Our OEM/ODM capabilities ensure precise technical alignment with project specifications across hospitality, retail, architectural, and office environments. All products undergo rigorous testing per IEC 62471 for photobiological safety and comply with regional electrical safety requirements for seamless integration into international projects.

Hospitality & Hotel Applications

In hospitality settings, LED strip lighting must balance ambient aesthetics with functional performance. Key applications include cove lighting in lobbies, under-cabinet task lighting in bars and restaurants, and accent lighting in guest room headboards. High color rendering is critical for accurate skin tone representation in guest rooms, while moisture resistance is required in wet areas like bathrooms.

| Parameter | Requirement | Beauty STC Solution |

|---|---|---|

| Color Rendering Index (CRI) | >90 for guest rooms | 95+ CRI standard, 98+ for premium applications |

| Ingress Protection (IP) Rating | IP65 for wet areas | IP65-rated strips with silicone encapsulation |

| Continuous Roll Length | 100+ ft for seamless cove lighting | Standard 500ft rolls, custom lengths up to 1000ft |

| CCT Range | 2700K-3000K for warm ambiance | Tunable white options from 2200K-6500K |

Commercial Retail & Shopping Malls

Retail environments demand precise lighting for product visualization and brand consistency. LED strips are used for display case illumination, perimeter cove lighting, and signage backlighting. High CRI and consistent color temperature are essential for accurate color representation of merchandise, while dimmable options enable dynamic scene control for promotional events.

| Parameter | Requirement | Beauty STC Solution |

|---|---|---|

| Color Rendering Index (CRI) | 95+ for jewelry and apparel | 95-98 CRI with ±3ΔE binning consistency |

| Luminous Efficacy | 120-150 lm/W for energy efficiency | 140 lm/W standard, 160 lm/W premium options |

| Dimming Compatibility | 0-10V or DALI for scene control | Fully dimmable with certified drivers |

| IP Rating | IP20 for indoor use | IP20 strips with anti-oxidation coating |

Architectural Facades & Exterior Lighting

Exterior architectural applications require robust performance against environmental stressors. LED strips for facades must withstand UV exposure, temperature extremes, and moisture ingress. Continuous roll lengths minimize splice points for seamless visual effects, while high IP ratings ensure long-term reliability in harsh conditions.

| Parameter | Requirement | Beauty STC Solution |

|---|---|---|

| Ingress Protection (IP) Rating | IP67 minimum for outdoor exposure | IP68-rated strips with marine-grade silicone |

| UV Resistance | ASTM G154 compliant | UV-stabilized materials, 50,000+ hours lifespan |

| Thermal Management | 40°C ambient operation | Aluminum channel compatibility for heat dissipation |

| Roll Length | 500ft+ continuous runs | Custom lengths up to 1000ft with voltage drop optimization |

Office & Corporate Spaces

Office lighting must support productivity through task illumination and circadian rhythm alignment. LED strips are commonly installed in cove lighting, under-desk task lighting, and perimeter accenting. High CRI and tunable white capabilities enable adaptive lighting scenarios that enhance occupant well-being and energy efficiency.

| Parameter | Requirement | Beauty STC Solution |

|---|---|---|

| CCT Tunability | 2700K-6500K for circadian support | 2200K-6500K range with 1% step adjustment |

| CRI | >90 for accurate document viewing | 90-95 CRI with consistent binning |

| Power Density | 4-8W/m for balanced illumination | 6W/m standard, 12W/m high-output options |

| Dimming Range | 1-100% for task flexibility | 0-10V dimming compatible with BMS systems |

Installation Best Practices for Contractors

Proper installation ensures optimal performance and longevity of LED strip systems. Beauty STC provides technical guidance for critical installation steps, including thermal management, power supply sizing, and connection sealing.

| Best Practice | Technical Rationale | Beauty STC Support |

|---|---|---|

| Use aluminum extrusions for heat dissipation | Prevents thermal degradation and maintains lumen output | Aluminum channels available in 1m/3m sections |

| Calculate power supply with 20% buffer | Avoids voltage drop in long runs | Free technical support for load calculations |

| Cut only at designated points | Maintains circuit integrity and warranty | Cut points marked every 50mm on all strips |

| Seal connections with IP67-rated silicone | Prevents moisture ingress in outdoor installations | Waterproof connectors and silicone gel included |

Beauty STC Lighting’s 25+ years of manufacturing excellence, coupled with ETL and TUV CE certifications, ensures reliable, specification-grade LED strip solutions for global projects. Our OEM capabilities allow for precise customization of electrical parameters, mechanical form factors, and environmental ratings to meet exact project requirements.

Contact for technical specifications and project-specific engineering support:

[email protected] | +86 13902885704

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Factory-Direct LED Strip Rolls for Global Projects

One-Stop OEM/ODM Source for ETL & TUV-CE Certified LED Strip Lights

Since 1998 we have engineered, tooled and shipped more than 1.2 billion linear metres of flexible LED strip from our 38 000 m² plant in Jiangmen, Guangdong. Today our rolls power façade outlines in Oslo, cove lighting in California casinos and retail gondolas in Sydney—evidence that Beauty STC Lighting can meet both the technical file and the delivery window of any specification-grade project.

| Factory Credentials | North-America / Europe Ready |

|---|---|

| Year Established | 1998 (26th year) |

| Certifications | ETL/cETL (UL 2108), TUV CE / LVD+EMC, RoHS, REACH, ISO 9001:2015 |

| Export Markets | 52 countries (EU, NAFTA, CIS, APAC) |

| Output Capacity | 1.5 million metres/month on 500 m continuous rolls |

| OEM/ODM Lead-Time | 2–3 weeks standard, 7 days fast-track for existing boards |

Roll Specifications – Engineered for Distributors & Contractors

| Parameter | Standard Range | Project-Specific Option |

|---|---|---|

| Voltage | 12 V, 24 V, 36 V, 48 V | 120 V integrated-driver strip |

| Power | 4 W/m – 30 W/m | Constant-current 50 W/m |

| CCT | 1800 K – 6500 K | 3-STEP MacAdam ellipse |

| CRI | 80 / 90 / 95+ | 98 CRI (R9>90) |

| PCB Width | 5 mm – 58 mm | 2-layer or 4-layer heavy-copper |

| IP Rating | IP20 – IP68 | IP69K silicone-extrusion |

| Max. Continuous Length | 50 m @ 24 V | 500 m on 12 mm PCB, no voltage drop with 24 AWG bus |

| Cut Increment | 25 mm (12 V) / 50 mm (24 V) | Any length on request |

| Warranty | 5 years (50 000 h) | 7 years with LM-90 report |

Value-Add Services That Reduce Your On-Site Labour

| Service | Description | Benefit to Contractor |

|---|---|---|

| Bin-Code Consistency | Single BIN within 3-STEP for entire 500 m roll | Zero colour shift on long runs |

| Pre-Assembly | Solder-free JST, Wago or IP68 pigtail fitted in factory | 40 % faster install |

| 24 h Salt-Spray & Thermal-Cycle | In-house CNAS lab | Compliance folder ready for consultant sign-off |

| Laser Marking | Part number, CCT, date-code every 0.5 m | Traceability for maintenance |

Compliance Documentation Supplied With Every Shipment

UL 2108 report & ETL label (cETL for Canada)

TUV CE LVD 2014/35/EU, EMC 2014/30/EU, RoHS 2011/65/EU, REACH SVHC

LM-80-08 & TM-21-11 lumen-maintenance forecast

ISTA-3A transit-tested carton specification

Next Step – Request Your Project Datasheet or Roll Sample

- Email [email protected] with length, voltage, CCT and IP requirement.

- Receive formal quotation incl. FOB Shenzhen / CIF / DDP Incoterm within 12 h.

- 24 V 500 m master roll or 1 m evaluation sample dispatched within 3 working days.

Beauty (STC) Manufacturing Co., Ltd

38 000 m² Factory | 41 Caihong Road, Jianghai High-tech Zone, Jiangmen, Guangdong, China

Tel: +86-139 0288 5704 | Export Manager: Mr. David Liu

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).