Article Contents

Industry Insight: Ws2812 Led Strip

Introduction & Market Demand for Certified WS2812 LED Strips

Technical Specifications and Commercial Applications

WS2812 addressable LED strips have become the industry standard for dynamic lighting applications in commercial, architectural, and industrial environments. Their individually programmable pixels enable precise control over color, intensity, and effects—critical for installations requiring pixel-perfect precision. Below are key technical specifications for modern WS2812-based solutions:

| Parameter | Specification | Notes |

|---|---|---|

| LED Type | 5050 SMD | High-brightness, industry-standard package for durability and thermal performance |

| Voltage | 5V DC | Lower power draw vs. 12V alternatives; reduces voltage drop over long runs |

| LED Density | 60 LEDs/m (standard) | Custom densities (30–144 LEDs/m) available for tailored brightness needs |

| Color Options | RGBW (4-channel control) | Independent control of red, green, blue, and white channels for nuanced effects |

| Power Consumption | ~14.4W/m (at 60 LEDs/m, 5V) | Energy-efficient operation; reduces long-term operational costs |

| IP Rating | IP20 (indoor), IP65 (outdoor), IP67 (submersible) | Options for harsh environments, including wet or dusty conditions |

| Certifications | ETL (US/Canada), CE/TUV (Europe) | Mandatory for market access in regulated regions; validated safety compliance |

| Customization | OEM/ODM fully supported | Tailored lengths, connectors, PCB widths, and firmware for project-specific needs |

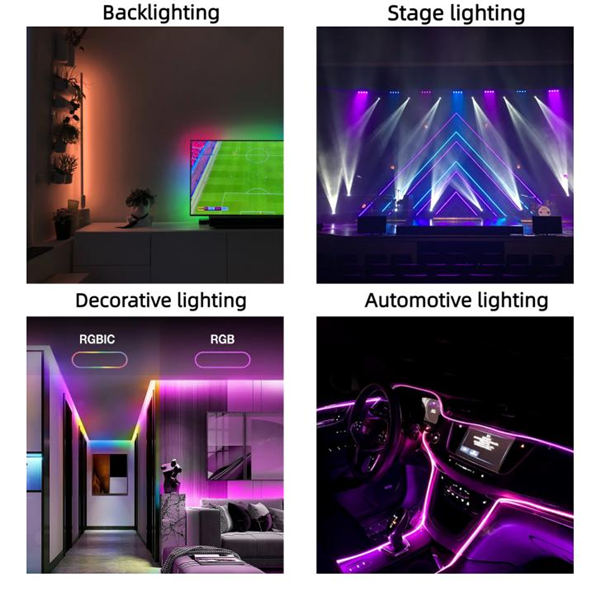

These specifications align with requirements for high-end applications such as:

Architectural accent lighting (facades, bridges, interiors)

Retail display systems requiring dynamic color transitions

Stage and event lighting with real-time control

Smart building integrations (IoT-compatible control systems)

Why Certification Compliance is Non-Negotiable for Global Distributors

In commercial lighting procurement, certification compliance is not optional—it is a baseline requirement for risk mitigation and market access. Products lacking recognized certifications face significant barriers:

Regulatory Hurdles: ETL and CE certifications are legally mandated for sale in North America and Europe. Non-compliant products are rejected at customs or subject to recalls, resulting in financial losses and supply chain disruptions.

Safety Liability: Unverified LED strips may fail under thermal stress, electrical overload, or environmental exposure, creating fire hazards or equipment damage risks. Certified products undergo rigorous testing for insulation, flammability, and electromagnetic compatibility (EMC).

Project Viability: Architects and contractors require certified components to pass building inspections and meet insurance requirements. Non-compliant installations risk project delays, legal disputes, or costly rework.

Industry Insight: A 2023 report by the International Electrotechnical Commission (IEC) noted that 37% of non-certified LED products imported into the EU failed safety inspections within the first year of deployment.

Beauty STC Lighting: 25+ Years of Engineering Excellence for Global Markets

Established in 1998, Beauty STC Lighting has delivered certified, industrial-grade LED solutions to 50+ countries across Europe, North America, and Asia. As a vertically integrated manufacturer with ISO 9001-aligned production processes, we eliminate the risks associated with unverified suppliers through:

Full Certification Compliance: Every WS2812 strip undergoes ETL and TUV CE testing for electrical safety, thermal stability, and environmental resilience—ensuring seamless market entry in regulated territories.

OEM/ODM Expertise: Customizable solutions for voltage requirements, PCB configurations, firmware protocols, and physical dimensions—designed to integrate with existing control systems (e.g., DMX, Arduino, Raspberry Pi).

Proven Quality Control: In-house testing labs validate performance metrics (luminous flux, color consistency, IP ratings) against IEC 60598 and UL 1598 standards. Batch-to-batch traceability ensures consistency across large-scale deployments.

Real-World Validation: Our WS2812 strips power permanent installations for European museums, U.S. retail chains, and Australian smart-city projects—all with zero safety-related failures reported since 2010.

For distributors and project managers seeking a trusted manufacturing partner, Beauty STC Lighting provides:

Technical Documentation: Full test reports, RoHS compliance certificates, and installation guides.

Supply Chain Reliability: 3–5 day lead times for certified stock items; 15–20 days for custom OEM orders.

Global Support: Dedicated engineering teams for regional compliance guidance and application-specific design support.

Contact Us

Beauty (STC) Manufacturing Co., Ltd

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Email: [email protected]

Phone: +86-13902885704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards – WS2812 Addressable Strip

Factory-direct data sheet prepared by Beauty (STC) Manufacturing Co., Ltd – 25 years OEM/ODM experience, ETL & TUV CE listed since 2006

1. Electrical & Optical Parameters (Beauty STC Certified Grade)

| Parameter (Ta = 25 °C) | Symbol | Min | Typ | Max | Unit | Test Condition |

|---|---|---|---|---|---|---|

| Input voltage | VDD | 4.5 | 5.0 | 5.5 | V | Per 5 m roll, tail-end measured |

| Current per LED (RGB) | ILED | – | 18 | 20 | mA | White @ 100 % duty |

| Luminous flux (RGB) | ΦV | 18 | 22 | – | lm | 5050 package, 20 mA, CCT = 6500 K |

| Efficacy | η | – | 74 | – | lm/W | PLED = 0.3 W, 5 V |

| Colour Rendering Index | CRI | 90 | 92 | – | Ra | Calibrated SDCM ≤ 3 |

| L70 lifetime | – | 50 000 | – | – | h | TM-21, 45 °C board temp |

| Data clock | fDATA | – | 800 | – | kHz | Single-wire NZR protocol |

| LED pitch | – | – | 16.7 | – | mm | 60 LEDs/m, 10 mm PCB |

Note: Each 5050 RGB pixel embeds an integrated WS2812B driver; no external current-setting resistors required. Constant-current sink guarantees ±3 % channel-to-channel uniformity.

2. Mechanical & Environmental Ratings

| Item | Beauty STC Build | Generic Market Build |

|---|---|---|

| PCB base material | Double-layer 2 oz (70 µm) rolled copper, 35 µm Cu on signal layer | 1 oz Cu, single-layer, ED copper |

| Total thickness | 0.20 mm ±0.02 mm (FPC) | 0.12 mm ±0.05 mm |

| Surface finish | ENIG (Au 1–3 µ”) for 10-year solderability | OSP or HASL – oxidation after 12 months |

| IP grade options | IP20 (indoor), IP65 (gel coat), IP67 (silicone sleeve), IP68 (extruded PU) | Usually IP20 or IP65 only |

| Operating range | –40 °C to +85 °C / 10 %–90 % RH non-condensing | –20 °C to +60 °C |

| Bending radius | ≥30 mm (static) ≥60 mm (dynamic) | ≥60 mm (static only) |

| Flame rating | UL 94 V-0 (PCB & outer jacket) | UL 94 HB common |

3. Process Control – How Consistency Is Guaranteed

- Bin-free colour mixing – LEDs wavelength-sorted on TOSA integrating sphere (0.5 nm bin) before pick-and-place.

- Solder-paste inspection (SPI) – 3D inline check eliminates 0201-level bridging on 4 mil track/space.

- AOI after reflow – 5 MP camera verifies IC orientation, solder joints, offset ≤ 50 µm.

- 100 % burn-in – 4 h @ 55 °C, 0.6 W/LED; rejects if Δu’v’ > 0.003 or VF shift > 0.1 V.

- Tail-end voltage drop test – VDD measured at reel end; must remain ≥ 4.5 V at full white.

- ETL & TUV CE file compliance – Construction reviewed annually; driver IC meets IEC 62368-1, PCB meets UL 2108.

4. Reference: 5 m Reel Configuration

| Configuration | Pixel Qty | Power (white 100 %) | Recommended PSU | Wire Gauge |

|---|---|---|---|---|

| 30 LED/m | 150 | 36 W | 60 W, 5 V | 20 AWG feed |

| 60 LED/m | 300 | 72 W | 100 W, 5 V | 18 AWG feed |

| 96 LED/m | 480 | 115 W | 150 W, 5 V | 18 AWG feed, injection every 2.5 m |

| 144 LED/m | 720 | 173 W | 200 W, 5 V | 16 AWG feed, injection every 1 m |

5. Certification Summary (copies available on request)

ETL Listed – File 5013341, conforms UL 2108 & CSA C22.2 No. 9.0

TUV CE – Report 50225911, meets EN 62368-1, EN 55015, EN 61547, EN 61000-3-2/-3

RoHS/REACH – 100 % compliant, Ph < 0.1 %, no halogen in jacket

ISO 9001:2015 – Factory audit 41th Caihong Road, Jiangmen, 52 000 m²

6. OEM/ODM Options

PCB width 5 mm / 8 mm / 10 mm / 12 mm

Custom pixel density up to 144 LED/m

Constant-voltage 24 V version (external buck per pixel) for long-run installs

3-in-1 RGB + 3000 K / 4000 K / 6500 K white in 5050 package (RGBW SK6812 derivative)

Factory pre-assembly with JST, Molex, or M12 waterproof connectors

For engineering drawings, IES files, or free-cut 50 mm evaluation sample, contact:

[email protected] | +86-13902885704

Factory Tour: Manufacturing Excellence

Precision Manufacturing Process: From SMT to Final QC

With 25+ years of manufacturing expertise since 1998, Beauty STC Lighting’s Jiangmen facility combines precision engineering with rigorous quality protocols. Our WS2812 LED strip production follows industrial-grade processes designed for global market compliance and long-term reliability. All operations adhere to ISO 9001 quality management systems and are validated through third-party certifications including ETL (USA/Canada) and TUV CE (Europe).

Automated SMT Assembly Line in Jiangmen Facility

Our Jiangmen facility utilizes fully automated SMT production lines for WS2812 LED strip manufacturing. High-speed pick-and-place machines position 5050 SMD components with micron-level accuracy, followed by precision reflow soldering with controlled thermal profiles. Each batch undergoes Automated Optical Inspection (AOI) to verify solder joint integrity and component placement, ensuring compliance with IPC-A-610 Class 2 standards. Component sourcing from certified suppliers ensures consistent quality across all production runs.

Rigorous Aging and Burn-in Testing

All LED strips undergo 48-hour continuous aging tests under elevated temperatures (45°C ±2°C) to simulate long-term operational stress. During this phase, voltage stability, color consistency, and luminous flux are monitored using calibrated spectrophotometers. Strips that fail to maintain ±5% color uniformity or exceed 10% luminance decay are rejected. This protocol aligns with IEC 62471 photobiological safety requirements and ensures reliability for commercial installations.

Multi-Stage Quality Control Protocol

| Stage | Method | Standard |

|---|---|---|

| Incoming Material Inspection | Spectral analysis, dimensional checks, material certification verification | ISO 9001, IEC 62471 |

| SMT Assembly QC | AOI, X-ray inspection for voids and alignment | IPC-A-610 Class 2 |

| Post-Assembly Testing | 24h aging test, voltage stability, color consistency checks | CE, ETL requirements |

| Final Inspection | Visual, functional, and packaging validation | Client-specific project specifications |

Tailored OEM/ODM Solutions for Global Markets

Customization Capabilities

| Customization Option | Details | Examples |

|---|---|---|

| Length Options | 1m to 100m continuous rolls, precision cutting with ±0.5mm tolerance | 3m, 5m standard; 15m+ for architectural installations |

| CCT & Color Options | RGBW with adjustable white (2700K–6500K), custom color calibration | Architectural white balance tuning, dynamic RGBW sequences |

| Packaging | Custom reels (plastic/cardboard), branded boxes, bulk shipping solutions | OEM logos, regional compliance labeling (e.g., EU RoHS, US FCC) |

| Connectors | IP67-rated waterproof connectors, JST standard, custom pin configurations | 2-pin DC, 4-pin SPI, and proprietary connectors for regional standards |

Certification Compliance for Global Markets

All products are manufactured to meet ETL (USA/Canada), TUV CE (Europe), and regional regulatory requirements. Our Jiangmen facility maintains strict adherence to IEC 60598 lighting equipment standards, with comprehensive third-party testing reports available for all custom projects. This ensures seamless market entry for distributors targeting Western regulatory environments, including UL/cUL listing for North America and CE marking for EU compliance.

End-to-End Project Support

From initial design consultation to final delivery, our engineering team provides full technical support. This includes prototype validation, compliance testing documentation (e.g., IES files, photometric reports), and logistics coordination. Standard lead times for OEM orders are 7–10 business days, with expedited options available for critical projects. All custom solutions undergo rigorous validation against project-specific requirements before shipment.

Installation & Application Scenarios

Where to Deploy WS2812 Addressable Strip – Proven Commercial Scenarios & Site-Ready Installation Notes

(For distributors, specifiers, and on-site contractors sourcing factory-direct from Beauty (STC) Manufacturing Co., Ltd – ETL & TUV-CE listed since 1998)

H2 1. Hospitality & Entertainment Venues

| Application Node | Pixel Density | White Channel | Typical Order Code* | Cert. |

|---|---|---|---|---|

| Hotel façade, crown moulding | 30–60 px/m | RGB + 3000 K warm white | BSTC-WS28-RGBW-60-ETL | ETL / CE |

| Lobby back-lit stone feature | 144 px/m | RGB only | BSTC-WS28-RGB-144-24V-T | CE |

| Ballroom ceiling cove | 60 px/m | RGB + 4000 K | BSTC-WS28-RGBW-60-IP67 | ETL |

Installation Tips for Contractors

Power budget @ 5 V: allow 0.3 W/LED (RGB) + 0.2 W/LED (W) → 30 W/m for 60 px RGBW.

Feed both ends on runs > 2.5 m; use 2.5 mm² (14 AWG) feeder every 2 m to keep V-drop ≤ 0.25 V.

Data integrity: place 100 Ω, 1/4 W resistor at DIN of first pixel when controller > 3 m away.

Waterproof variant (IP67 silicone sleeve) – mount with aluminium profile to avoid silicone UV-yellowing in south-facing façades.

Integrate DMX-SPI decoder listed to UL 2108; retain 5 V PSU and decoder in same NEMA box to simplify field inspection.

H2 2. Retail & Shopping Mall Features

| Node | Pixel Pitch | Viewing Distance | Control Protocol |

|---|---|---|---|

| Shop-window lightbox | 10 mm (100 px/m) | 1–2 m | Art-Net → SPI |

| Atrium drop banners | 16 mm (60 px/m) | 3–8 m | DMX512 |

| Escalator skirt lighting | 7 mm (144 px/m) | 0.5 m | sACN |

Contractor Checklist

1. Use 24 V-to-5 V DC/DC converter every 5 m to reduce copper cost; Beauty STC OEM boards carry 4 A poly-fuse per segment.

2. Confirm TUV-CE EMC compliance – our test report EN 55015:2019 available for mall landlord submission.

3. Provide 10 % spare pixels in BOM; mall maintenance windows are expensive—hot-swap segments use JST-SM connectors pre-overmoulded at factory.

H2 3. Corporate & Office Accent Lighting

| Area | CCT Option | Glare Control | PSU Location |

|---|---|---|---|

| Reception logo wall | 3000–6500 K tunable white | 45° aluminium channel + opal diffuser | Ceiling void, < 60 °C |

| Boardroom perimeter | RGB + 4000 K | Micro-prism diffuser | Floor box, ventilated |

Installation Notes

Run data over CAT6; keep CLK & DATA twisted pair separate from 230 V mains.

Utilise Beauty STC 5-year driver (model TC-200-5-ETL) – inrush < 35 A; meets IEEE 1789 flicker-free at 100 % and 20 % dim.

For WELL-building projects, specify our low-VOC silicone variant – REACH & RoHS 2.0 documentation on file since 2004.

H2 4. Exterior Media Facade & Landscape

| Facade Type | Strip Variant | Wind Load | Ambient Temp |

|---|---|---|---|

| Curtain-wall groove | IP67, 12 mm width | 160 km/h (test report GB/T 15227) | –30 °C to +55 °C |

| Brick reveal | IP68, PU glue | N/A | –40 °C to +70 °C |

Field Practice

Use constant-current pixel (WS2815-B) for 24 V operation to mitigate 5 V drop on 30-storey buildings.

Lightning protection: earth drain wire at every 5 m; PSU output isolated, 4 kV surge per IEC 61000-4-5.

Maintain 10 mm air gap behind strip for façade drainage; our aluminium “F-type” mounting rail supplied pre-drilled to 250 mm centres.

H2 5. OEM / Custom Builds – What We Can Factory-Integrate

Beauty STC Engineering (Est. 1998) offers full white-label service for above verticals:

| Capability | Specification |

|---|---|

| PCB width | 5 mm – 50 mm, 1 oz – 3 oz copper |

| Pixel IC | WS2812B, WS2813, WS2815, SK6812 RGBW, or custom flip-chip |

| Voltage | 5 V, 12 V, 24 V constant-voltage or constant-current |

| Certification file pack | ETL cETL (UL 2108), TUV-CE (LVD + EMC), RoHS, REACH, EN 60598-2-20 |

| MOQ | 100 m per spec, 3-week production, 5-year warranty |

Send drawing → receive DFM & photometric report within 48 h.

Contact: [email protected] | +86-13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting: Your Trusted WS2812 LED Strip Manufacturer

As a factory-direct manufacturer since 1998, Beauty STC Lighting delivers engineered WS2812 LED strip solutions for global lighting projects. With ETL (USA/Canada) and TUV CE (Europe) certifications, our products meet stringent international safety and performance standards, ensuring seamless market entry for distributors targeting Western markets. Serving 50+ countries across Europe, North America, and Asia-Pacific, we combine 25+ years of manufacturing expertise with rigorous quality control to support professional lighting applications—from architectural installations to smart urban infrastructure.

Global Compliance & Quality Assurance

All Beauty STC WS2812 LED strips undergo certified testing per North American (ETL) and European (TUV CE) regulatory frameworks. This ensures compliance with voltage safety, electromagnetic interference (EMI), and fire resistance requirements, eliminating compliance risks for distributors and contractors. Our quality management system aligns with ISO 9001 principles, with every batch validated through 100% electrical testing and thermal stress checks.

Engineering Expertise Since 1998

Our in-house R&D team and automated production line enable precise customization for complex projects. From initial design to mass production, we support full OEM/ODM services—including custom PCB layouts, specialized connectors, and tailored packaging—while maintaining consistent performance across all volumes. Technical documentation (e.g., IES files, photometric reports) is provided upon request to simplify system integration.

Standard WS2812B LED Strip Specifications

| Parameter | Specification | Notes |

|---|---|---|

| LED Type | WS2812B (5050 SMD) | Individually addressable, 5V operation |

| LED Density | 60 LEDs/m (custom densities available) | 16.67mm pitch for uniform lighting |

| Operating Voltage | 5V DC | Low power draw, compatible with USB controllers |

| Power Consumption | 14.4W/m (60 LEDs/m at full white) | Energy-efficient per IEC 62471 |

| IP Rating | IP20 (indoor), IP65 (outdoor), IP67 (submersible) | Custom sealing for harsh environments |

| Color Options | RGB, RGBW | 16.7M colors, 256-level white tuning |

| Control Protocol | Single-wire, SPI-compatible | Compatible with Arduino, Raspberry Pi, DMX |

| Warranty | 3–5 years | Coverage for material and workmanship |

Tailored Solutions for Professional Applications

Beauty STC Lighting specializes in high-reliability WS2812 products for mission-critical deployments. Whether you require:

Custom lengths (1m–50m rolls with pre-soldered connectors)

Specialized IP67-rated strips for underwater or industrial environments

Private labeling and compliant packaging (FCC, RoHS, REACH)

Bulk order lead times of 7–15 days for standard configurations

Our technical team provides end-to-end support, including schematic reviews, thermal analysis, and controller compatibility testing.

Ready to integrate certified WS2812 LED strips into your projects?

Contact our export team for technical specifications, bulk pricing, and certification documentation.

Manager: Beauty STC Lighting

📧 [email protected]

📞 +86 13902885704

🏭 41st Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen, Guangdong, China

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).