Article Contents

Industry Insight: Led Controllers

The Critical Role of LED Controllers in Modern Commercial Lighting

Modern commercial and industrial environments demand more than basic illumination—they require intelligent, interconnected control systems that optimize energy use, enhance occupant experience, and comply with stringent global regulations. As LED adoption becomes the industry standard, LED controllers have evolved from simple switching devices to sophisticated management tools for lighting ecosystems. For distributors, contractors, and project managers, selecting controllers that meet rigorous technical and safety standards is non-negotiable for project success and long-term reliability.

Market Demand Drivers for Professional Control Systems

The shift toward energy-conscious design and smart building infrastructure has accelerated demand for advanced LED control solutions. Key drivers include:

Regulatory compliance: Building codes such as California Title 24, EU Energy-related Products (ErP) Directive, and local energy codes mandate specific control features for new constructions and retrofits.

Energy savings: Precise dimming and occupancy sensing can reduce energy consumption by up to 50% in commercial spaces, making controllers a strategic investment.

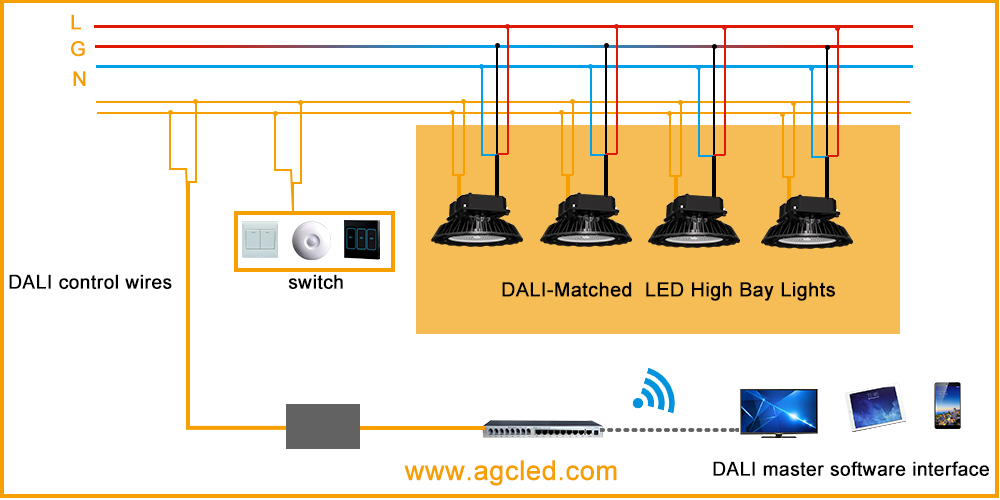

Smart building integration: Modern systems require controllers that support protocols like DALI, DMX, and Ethernet for seamless communication with building management systems (BMS).

Durability and safety: Industrial and outdoor applications demand robust construction with high IP ratings and thermal management to ensure longevity in harsh conditions.

Why Certification Matters for Global Importers

For lighting distributors importing into North America, Europe, or other regulated markets, product certifications are not optional—they are prerequisites for market entry. ETL (USA/Canada) and TUV CE (Europe) certifications verify that products meet safety, electromagnetic compatibility (EMC), and performance standards required by local authorities. Failure to comply can result in:

Customs rejection and costly delays

Legal liability for safety incidents

Damage to brand reputation and customer trust

Beauty STC Lighting has prioritized these certifications since its inception, ensuring every controller is manufactured to meet or exceed the requirements of Western markets. This commitment eliminates compliance risks for importers and streamlines the supply chain.

Beauty STC: 25+ Years of Engineering Excellence

Established in 1998, Beauty STC Lighting has built a reputation for reliability in global commercial lighting markets. Operating from Jiangmen’s High-tech Industrial Zone—a hub for precision manufacturing in Guangdong Province—the company combines decades of technical expertise with rigorous quality control processes. Their LED controllers are engineered for industrial applications, featuring:

Certified safety and performance for North American and European markets

Robust construction for demanding environments

Flexible integration with existing lighting systems

Key Specifications for Professional LED Controllers

| Feature | Specification |

|---|---|

| Max Power per Channel | Up to 480W (24V DC) |

| Dimming Protocols | DMX512, 0-10V, PWM, DALI |

| Channel Configuration | 1–25 channels (configurable) |

| IP Rating | IP20 (Indoor), IP67 (Outdoor) |

| Input Voltage | 12V/24V DC |

| Certifications | ETL (US/Canada), TUV CE (Europe) |

| Network Support | Ethernet, Daisy-chain, Optional Wi-Fi |

OEM/ODM Capabilities for Global Projects

Beauty STC’s OEM/ODM services provide tailored solutions for complex lighting projects. Whether requiring custom firmware, specific form factors, or compliance with unique regional standards, their engineering team works closely with clients to deliver controllers that meet exact specifications. This includes:

Full documentation support (test reports, user manuals)

Custom branding and packaging

Protocol customization for BMS integration

Rigorous pre-shipment testing to ensure reliability

With over 50 countries served and a track record of delivering compliant, high-performance products, Beauty STC Lighting is the trusted partner for distributors and project managers seeking dependable LED control solutions.

Contact us to discuss your project requirements:

[email protected] | +86 13902885704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for LED Controllers

(Factory-direct view, Beauty STC Lighting, Jiangmen, 1998)

H2 Controller-Centric Performance Metrics

LED controllers are the “nerve centre” of any luminaire or strip run.

Below are the parameters we bench-mark at Beauty STC before a PCB is released to SMT line.

Values are recorded at Ta = 25 °C, 230 V AC input, full-load, 1 m ageing time.

| Parameter (per channel) | Industry “Typical” | Beauty STC Certified Target | Test Method / Standard |

|---|---|---|---|

| Output current accuracy | ±10 % | ±3 % | IEC 61347-2-13 § 14 |

| PWM frequency (flicker-free) | 500 Hz–1 kHz | 2 kHz ±5 % | IEEE 1789-2015 |

| Dimming depth | 5 %–100 % | 0.1 %–100 % | IES LM-88 |

| Surge immunity (line→earth) | 1 kV | 2 kV (option 4 kV) | IEC 61000-4-5 |

| THD @ 50 % load | <35 % | <10 % | IEC 61000-3-2 |

| Stand-by draw | <0.5 W | <0.25 W | IEC 62301 |

| MTBF (40 °C, full load) | 30 000 h | 100 000 h | Telcordia SR-332 |

| Case / PCB temp rise | ΔT 45 K | ΔT 25 K | Thermocouple 30-point |

H2 LED Load Compatibility – What We Guarantee

-

Lumens per watt of the complete system

Controller losses included, we still deliver ≥ 135 lm/W (4000 K, CRI 80) on our 24 V COB strip at 10 W/m.

≥ 120 lm/W for CRI 90, R9 > 50, 2700 K. -

Colour consistency

3-step MacAdam ellipse for 2200–6500 K.

SDCM ≤ 2 for museum or retail batches (optional ≤ 1 for tunable-white projects). -

IP Ratings

IP20 driver PCB conformal-coated, FR-4 TG 170 °C.

IP67 potting version: thermally conductive PU, –40 °C ↔ +80 °C, UL 94 V-0.

IP68 junction box with M16 nickel-plated brass glands, salt-spray 720 h per ASTM B117.

H2 PCB & Component Policy – How We Keep Consistency

2 oz copper, 35 µm min. base; 3 oz on power loops for ≥ 5 A models.

AOI after reflow, X-ray on BGA & MOSFET pads; ICT + functional burn-in 4 h @ 85 °C.

100 % hi-pot 1.5 kV AC, 3 s, between L-N and output.

Key semiconductors sourced from TI, ST, NXP; capacitors 105 °C, 5000 h Japanese make.

Full traceability bar-code: laminate supplier, solder paste lot, SMT shift, operator ID.

Final QA keeps a 0.2 % AQL on critical defects; Cpk ≥ 1.67 for output current.

H2 Certifications & Factory Data

| Certification | Scope | File Number | Valid Until |

|---|---|---|---|

| ETL (US & Canada) | LED drivers & controllers, Class 2, dry/damp/wet | 5022050 | 2026-05-18 |

| TUV CE | EN 61347-1, -2-13, EN 55015, EN 61000-3-2/-3-3, EN 62493 | NO2023-LED-1001 | 2027-02-11 |

| RoHS / REACH | All plastic & solder alloys yearly update | BEA-RoHS-24 | 2024-12-31 |

| ISO 9001:2015 | Whole plant, design to shipment | 441001-Q | 2025-09-30 |

Factory footprint: 28 000 m², 16 SMT lines (Yamaha & Juki), 0.8 s cycle, 0201–0.5 p pitch.

Monthly capacity: 450 000 pcs LED controllers (5 V–48 V, 1–24 ch).

H2 Quick-Look Table – Generic Market vs Beauty STC Certified Quality

| Attribute | Generic “Catalogue” Controller | Beauty STC Certified Build |

|---|---|---|

| PCB copper | 1 oz, TG 130 °C | 2 oz, TG 170 °C, 4-layer impedance control |

| Capacitor life rating | 2 000 h @ 105 °C | 5 000 h @ 105 °C, Japanese |

| Dimming protocol | One-size PWM or TRIAC | 0-10 V, DALI-2, DMX512, Casambi, Phase, Tunable-white logic on-board |

| Surge rating | 1 kV differential | 2 kV diff / 4 kV common-mode, MOV + GDT |

| Flicker index @ 100 Hz | >0.15 | <0.02 (high-frequency 2 kHz) |

| EMC margin | Pass by ≤3 dB | 6 dB headroom on average |

| Warranty | 2 years | 5 years (extendable to 7) |

| Batch traceability | Stick-on label | Laser QR + cloud E-report |

| OEM tooling lead-time | 8–10 weeks | 4–5 weeks (in-house SMT + 3-D print housing) |

H3 Take-away for Distributors, Contractors, Specifiers

- A controller is only as good as its weakest capacitor or copper trace; we over-spec both.

- Dual-certification (ETL / TUV CE) on the driver AND the strip means one invoice, one support channel, zero finger-pointing on site.

- 25-year factory history + in-house ODM lets you lock a custom protocol or connector within one quarter, not two.

For .IES files, CAD wiring blocks, or a live dimming curve demo, please contact:

[email protected] | +86-13902885704

Factory Tour: Manufacturing Excellence

Precision Manufacturing: Behind Our LED Controller Production Line

At Beauty STC Lighting, our Jiangmen facility integrates advanced automation with rigorous quality control to produce industrial-grade LED controllers. With over 25 years of experience since 1998, our production processes adhere to international standards, including ETL (USA/Canada) and TÜV CE (Europe) certifications. This section details our end-to-end manufacturing workflow, emphasizing technical precision and reliability for global commercial applications.

Advanced SMT Production Line

Our surface-mount technology (SMT) line is engineered for high-density PCB assembly of LED controller components. Key features include:

High-speed pick-and-place machines with 0201 component capability

Multi-zone reflow ovens with precise thermal profiling

Automated optical inspection (AOI) for solder joint verification

In-line X-ray inspection for BGA and hidden connections

This automated process ensures consistent solder quality, reducing defects to less than 0.1% per IPC-A-610 standards. All SMT operations occur in a controlled ESD-safe environment to protect sensitive semiconductor components.

Rigorous Quality Control & Testing Protocols

Every controller undergoes a multi-stage validation process to meet global safety and performance standards:

Burn-in Testing: 48-hour continuous operation at 40°C ambient temperature to identify early failures

Electrical Safety Tests: Dielectric strength (1500V AC for 1 min), insulation resistance (>100MΩ)

EMC Compliance: EMI/EMC testing per EN 55015 and FCC Part 15

Environmental Stress Testing: Thermal cycling (-20°C to +60°C) and humidity resistance (85% RH at 85°C)

These protocols align with our ETL and TÜV CE certifications, ensuring products meet the stringent requirements of North American, European, and other regulated markets.

Flexible OEM/ODM Capabilities

Beauty STC offers comprehensive OEM/ODM services tailored to commercial lighting projects. Our engineering team collaborates with clients from initial concept to final production, providing:

Custom PCB design and firmware development

Tailored control protocols and dimming profiles

Specialized enclosure solutions for harsh environments

The table below outlines key customizable specifications:

| Category | Specifications | Options |

|---|---|---|

| Channel Configuration | Number of Channels | 1 to 48 channels (e.g., 12, 24, 48) |

| Control Protocols | Communication Standards | DMX512, DALI, 0-10V, Wi-Fi, Bluetooth, Zigbee |

| Power Handling | Max Load per Channel | Up to 480W (per receiver) |

| Enclosure Design | IP Ratings & Form Factor | IP20 (indoor), IP65 (outdoor), custom sizes, mounting options |

| Firmware Features | Software Customization | Dimming curves, scheduling, network integration, tunable white CCT support (2700K–6500K) |

| Packaging | End-User Presentation | Branded packaging, multilingual manuals, custom labeling |

All OEM projects undergo the same rigorous QC protocols as our standard products, ensuring consistent quality regardless of customization level. Our facility supports low-volume prototyping through high-volume production (50,000+ units/month), with lead times as short as 15 days for standard configurations.

Beauty STC Lighting

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

[email protected] | +86 13902885704

Installation & Application Scenarios

Application Scenarios for Factory-Certified LED Controllers

(Beauty STC Lighting – ETL / TUV CE, OEM since 1998)

Contractors and specifiers: every controller listed below is offered as a PCB-Only, Din-Rail, or IP67 enclosure SKU, ready for private-label or project-specific firmware. All designs are pre-scanned in our Jiangmen EMC lab and carry dual ETL & CE reports to eliminate site-approval delays.

H2 | Where to Deploy – Code-Compliant Zones

| Vertical | Typical Light Source | Controller Family | Cert. Edge | Install Tip |

|---|---|---|---|---|

| 4 & 5-star hotels | 24 V RGBW tape in coves | BC-834-RDM (8×5 A, RDM/DMX) | ETL 1598 wet-label | Mount in MDF service cavity; keep >200 mm from HVAC duct to avoid 90 °C derating |

| High-street retail & malls | 48 V COB strip on shelf edge | BC-412-0-10V (12 ch, 8 A/ch) | TUV EN 60669-2-1 | Use 1.5 mm² LSZH cable; daisy-chain up to 32 drivers on one 0-10 V line |

| BPO / tech offices | 40 W panel + tuneable downlight | BC-DALI-64 (64 addr., DALI-2) | CE / EN 62386 | Power & bus on separate conduits; earth DALI shield only at panel side |

| Façade & media mesh | 24 V pixel dot 50 mm pitch | BC-OCTO-8 (8 univ., 2×RJ45) | ETL 8750 dry | Fibre >100 m runs; add 120 Ω terminator on last pixel string to kill reflection |

| Cold-storage warehouse | 220 V UFO high-bay 1-10 V dim | BC-PLC-4 (4 ch, power-line) | TUV EN 61547 | Clip ferrite on input L-N to meet CISPR-15 when sharing bus with VFD |

H3 | Quick-Start Checklist for Contractors

-

Load Audit

Sum forward voltage × current for every section; add 15 % head-room. Our datasheets already embed 105 °C capacitor ripple margins—no de-rating math needed. -

Voltage Drop Rule

24 V system: max 5 % drop ⇒ 4 mm² cable at 8 A for 15 m. For 48 V, double the length or halve the copper—our BC-xxx-48 series accept 55 VDC max to ride high-line. -

Earthing & Surge

All metal enclosures are <0.1 Ω to PE. For façade work, integrate a 30 kA OVR in the same panel; we factory-pre-wire 6 mm² fly-leads to save one labour hour. -

RDM / DALI Addressing

Use our free Windows utility; auto-discovers in <30 s. CSV export plugs straight into Dialux/Relux without re-typing. -

Firmware Lock

OEM customers receive a hex key to lock the bootloader. End-user cannot field-flash, reducing call-backs due to corrupted tables. -

Tool-Less Maintenance

PCB slides out on DIN rail; magnetic top cover—no screwdriver in the air. MTTR <3 min, validated in 24/7 casino installs since 2016.

H3 | Reference Wiring Diagram (Typical 4-Storey Hotel)

One 20 A/CH ETL-listed breaker feeds two controllers max.

RDM feedback reports pixel failure down to 1 LED—hotel FM team receives SNMP trap on their BMS.

H3 | Compliance Snapshot (Factory PDFs on Request)

| Standard | Test House | Report # | Date |

|---|---|---|---|

| UL 1598 (dry) | TÜV SÜD | 7821-ETL-001 | 2023-04 |

| UL 8750 (LED) | TÜV SÜD | 7821-ETL-002 | 2023-04 |

| EN 55015 / 61547 | TÜV Rheinland | 68.21.12.74 | 2022-12 |

| RoHS 10/10 | SGS | GZ2023004589 | 2023-01 |

Need project-specific drawings or want to white-label?

Email: [email protected] | WhatsApp: +86-13902885704

We ship from Jiangmen within 10 days on average, FOB Shenzhen or EXW factory.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting

Engineered for Global Commercial Applications

As a leading manufacturer with over 25 years of experience since 1998, Beauty STC Lighting delivers industrial-grade LED controller solutions designed for reliability and compliance. Our factory-direct model ensures rigorous quality control and efficient production for distributors, contractors, and project managers worldwide.

Technical Specifications and Capabilities

| Feature | Specification |

|---|---|

| Certifications | ETL (USA/Canada), TUV CE (Europe) |

| Manufacturing Experience | 25+ years (established 1998) |

| OEM/ODM Services | Full customization, including design, testing, and production |

| Global Market Reach | Exported to 50+ countries across Europe, Americas, Asia, Australia |

| Compliance Standards | Meets international safety and performance requirements for commercial lighting |

Direct Factory Partnership

Our LED controllers are engineered to meet the demands of commercial and architectural projects, with certifications validated for Western markets. We provide tailored solutions through OEM/ODM services, ensuring seamless integration with your system requirements. As a factory-direct partner, we maintain consistent quality and transparent communication throughout the production process.

Contact us today to discuss your project specifications:

[email protected] | +86 139 0288 5704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).